Orientation transmission mechanism for workpiece with end face with hole

A transmission mechanism and workpiece technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as inability to realize workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

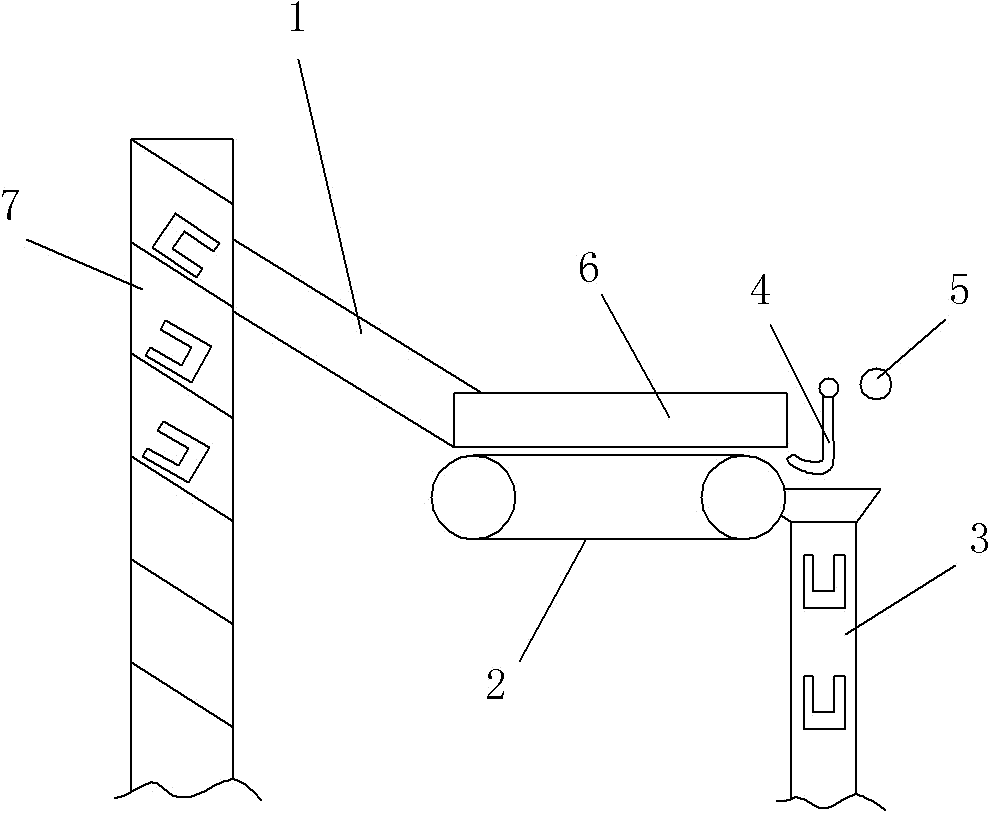

[0010] The reference signs in the drawings of the specification include: feeding chute 1, conveyor belt 2, orientation groove 3, swing hook 4, stop pin 5, baffle plate 6, elevator 7

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0012] Such as figure 1 As shown, the present invention provides a kind of directional conveying mechanism of workpiece with holes on the end face, comprising feeding chute 1, conveyor belt 2 and directional groove 3, the outlet of feeding chute 1 is close to the input end of conveyor belt 2, and directional groove 3 is arranged on The output end of the conveyor belt 2 is also provided with a swing hook 4 above the orientation groove 3, and the curved free end of the swing hook 4 faces the conveying direction of the conveyor belt 2. A stop pin 5 is arranged behind the swing hook 4, and the stop pin 5 is positioned at the side of the orientation groove 3. Ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com