Patents

Literature

99results about How to "Easy subsequent assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

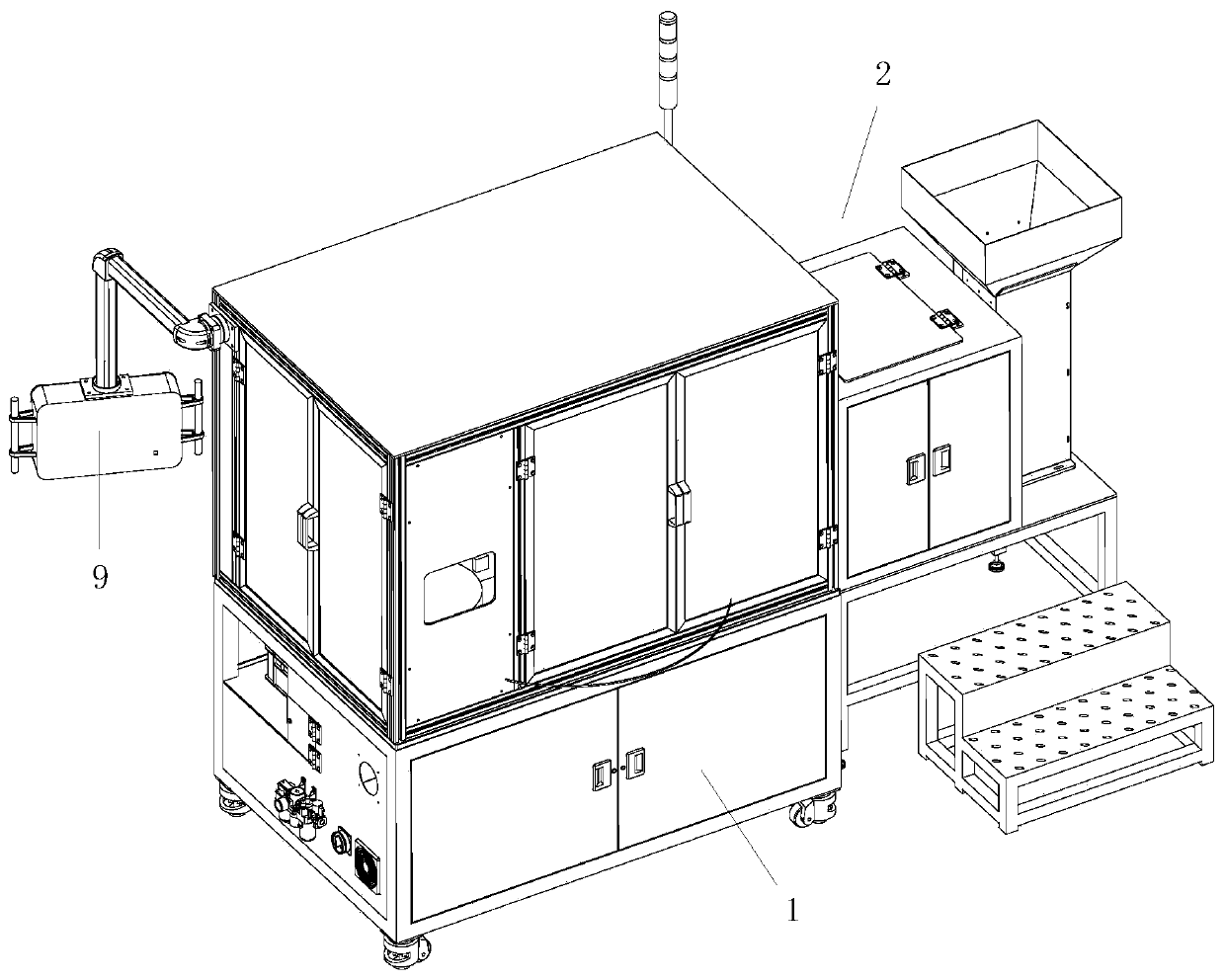

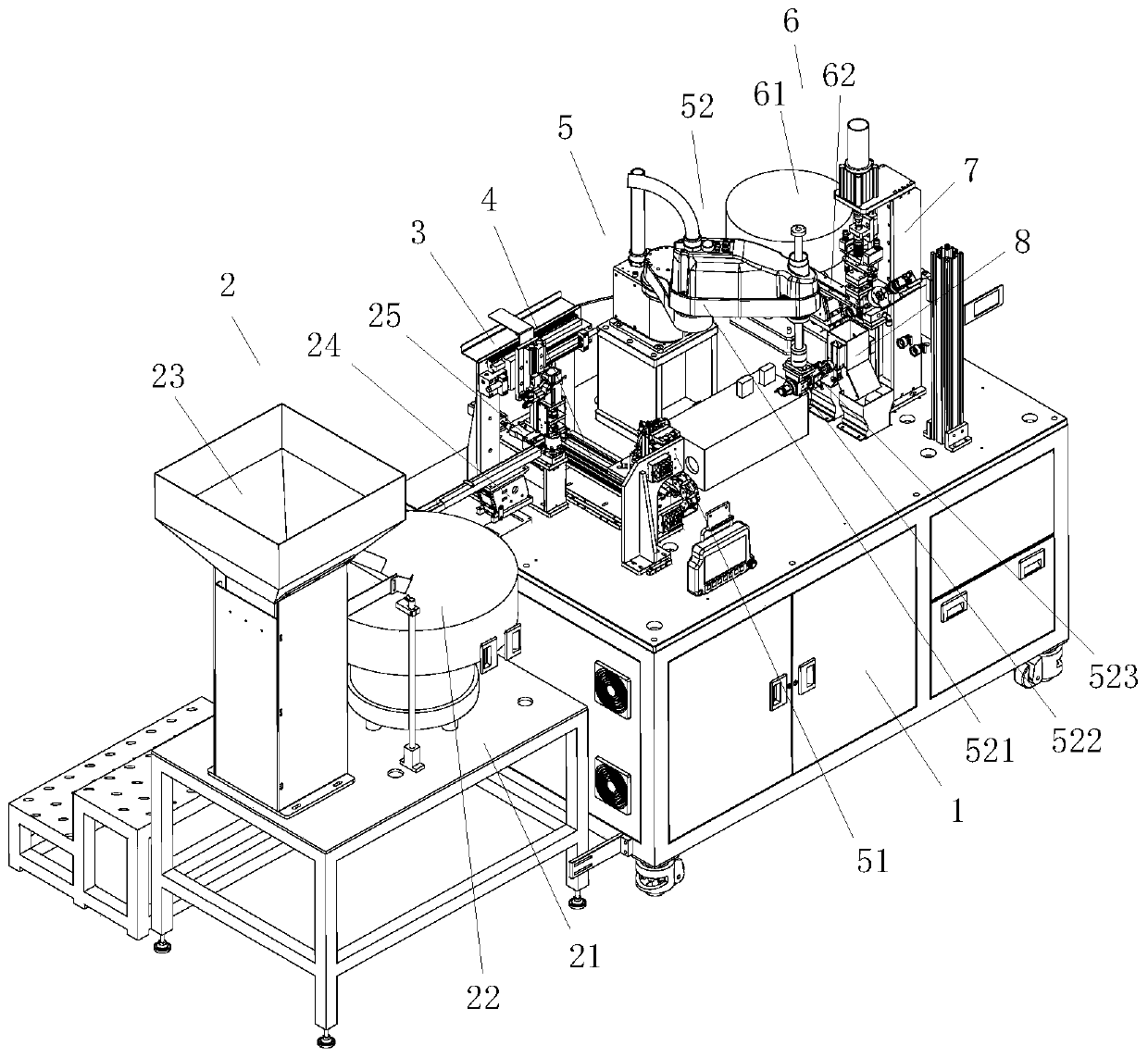

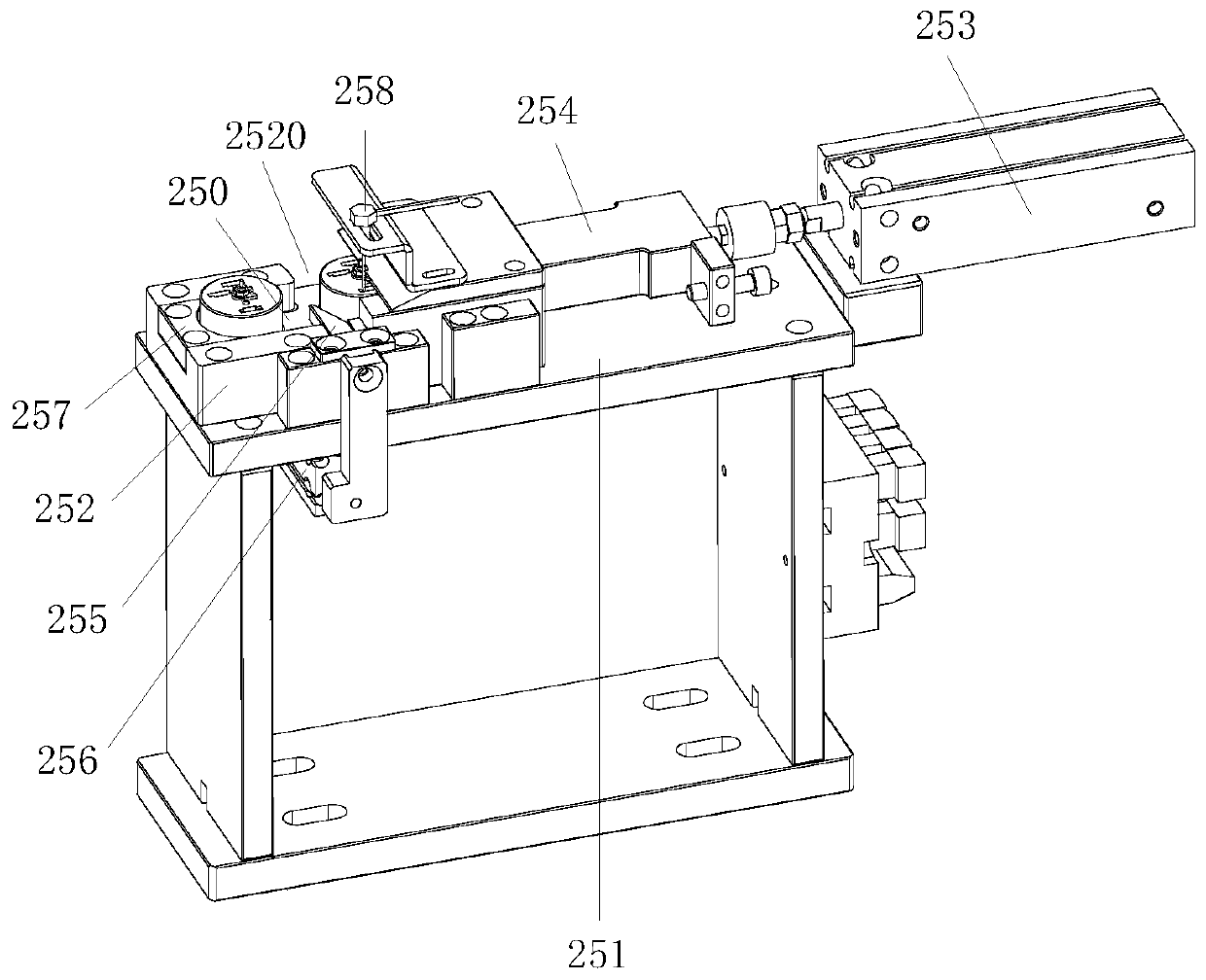

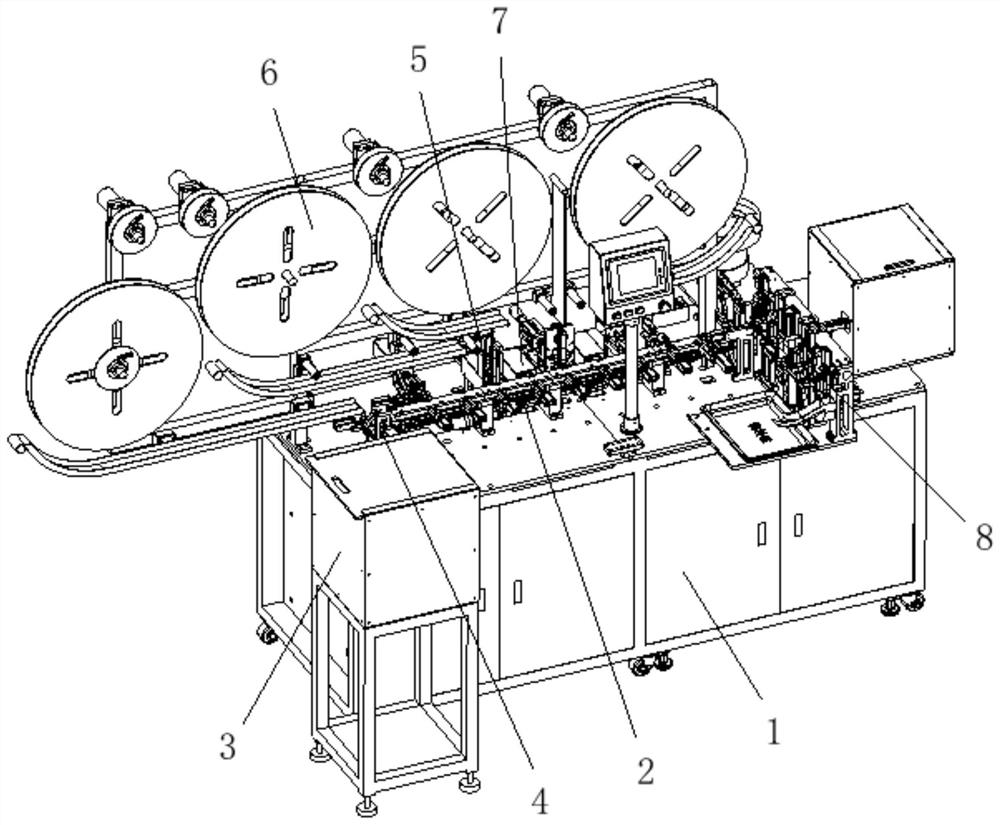

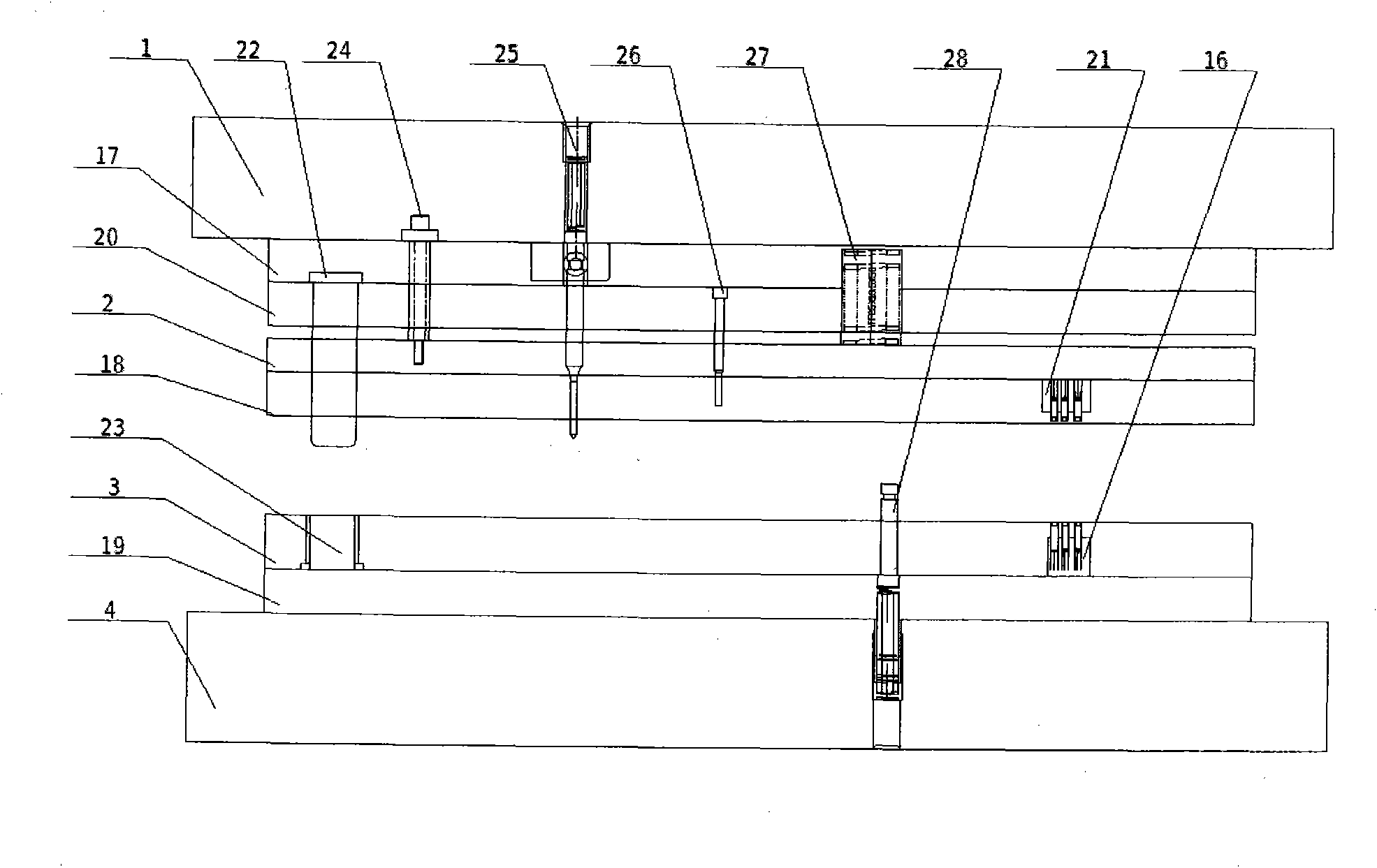

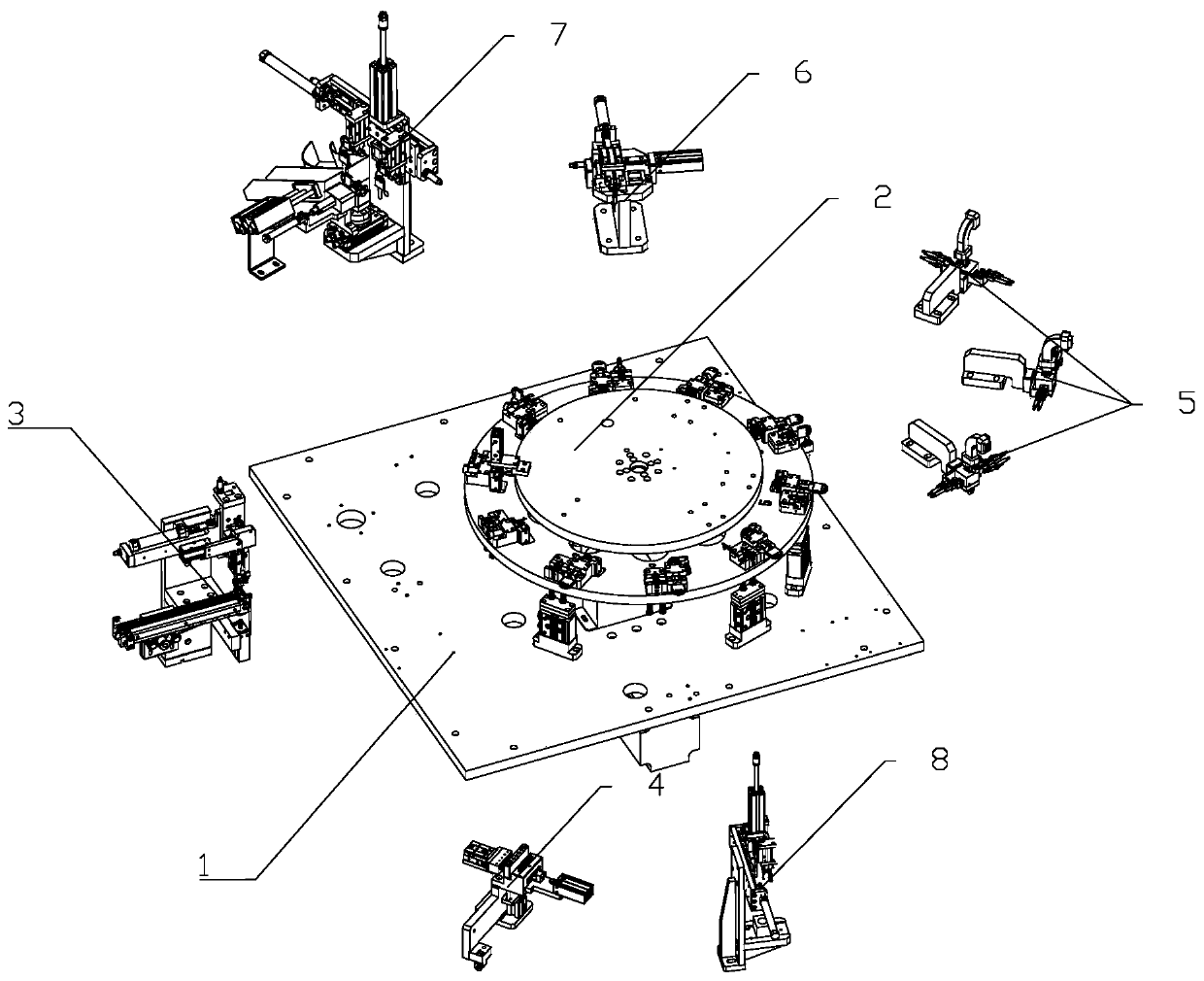

Terminal assembling welding device

PendingCN110125569ACompact structureGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectric control

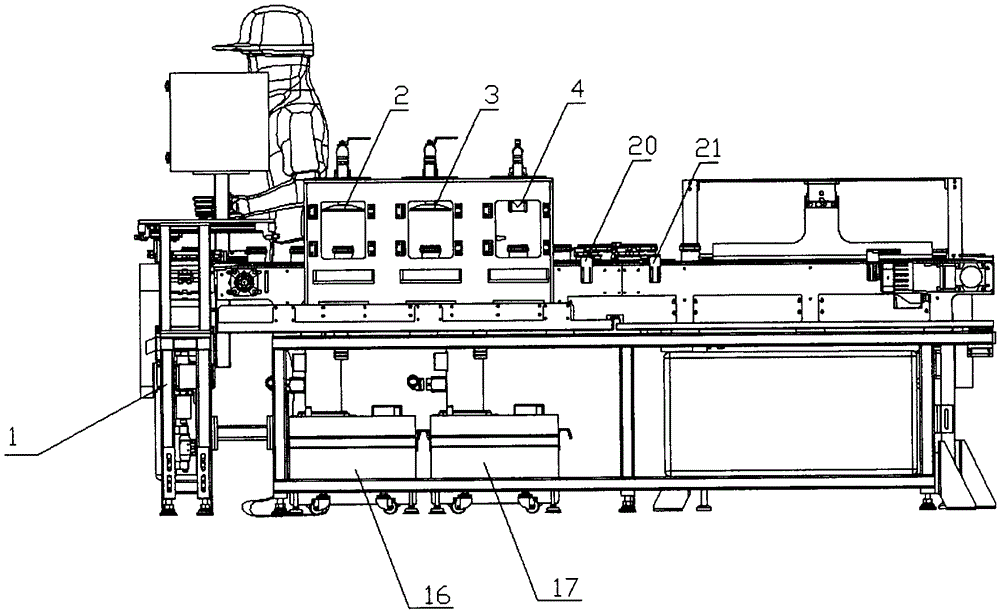

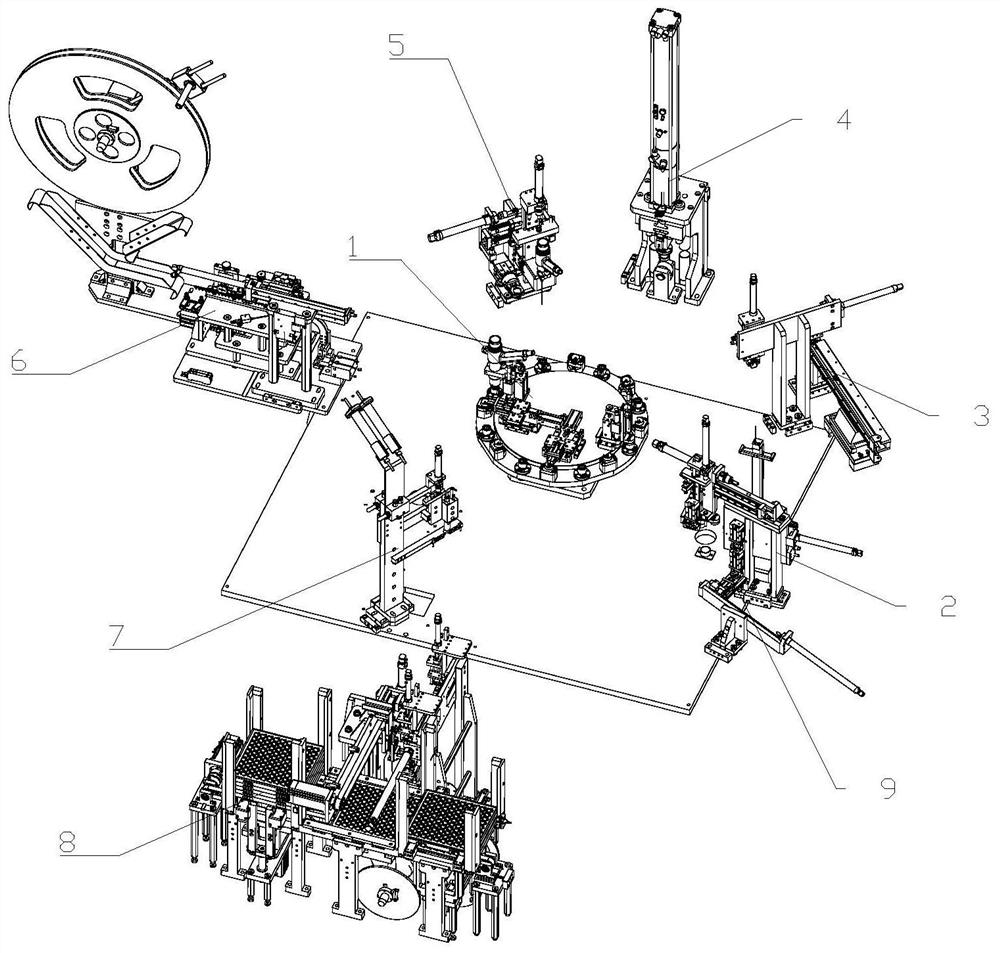

The invention discloses a terminal assembling welding device. The terminal assembling welding device comprises a terminal housing feeding mechanism arranged on a workbench of a box and located in a protection cover, a moving mechanical arm, a positioning mechanism, a flipping material transfer mechanism, a terminal feeding mechanism, a welding mechanism and a material splitting mechanism, whereinan operation interface is arranged on the protection cover of the box, an electric control cabinet is arranged in the box, the moving mechanical arm transports a terminal housing on the terminal housing feeding mechanism to the positioning mechanism for positioning, the terminal feeding mechanism comprises a terminal vibration disk and a line vibration rail, the line vibration rail is arranged ona discharging port of the terminal vibration disk, the line vibration rail points to the welding mechanism, the flipping material transfer mechanism transports the terminal housing after being positioned to the welding mechanism so as to match the terminal housing with a terminal, and the material splitting mechanism is arranged below a welding work station of the welding mechanism. By adopting the above mode, the terminal assembling welding device is compact in structure, can replace manual work for automatically performing assembling welding on the terminal product, and meanwhile performs detection sorting on the product.

Owner:昆山美佳合自动化设备有限公司

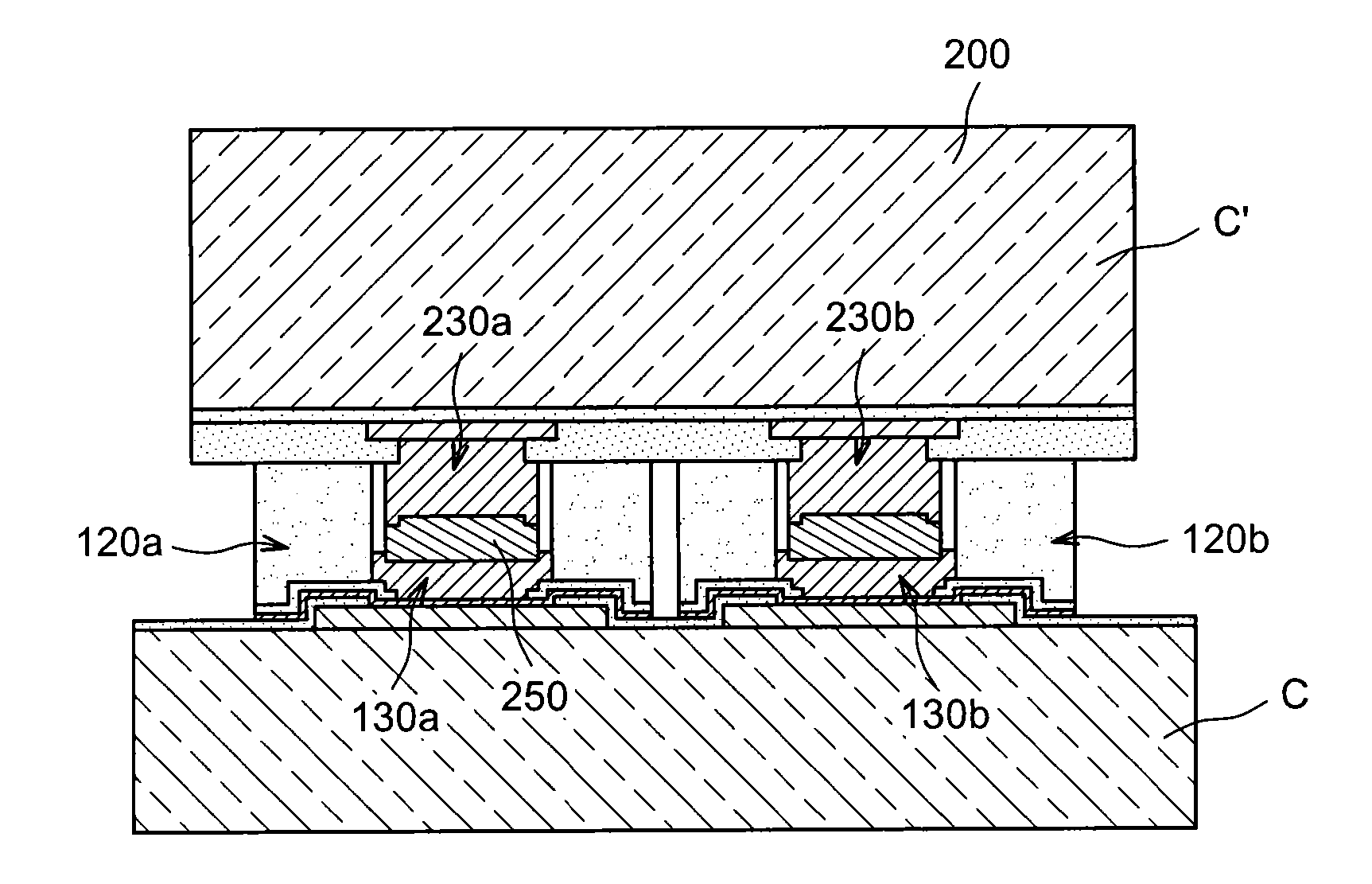

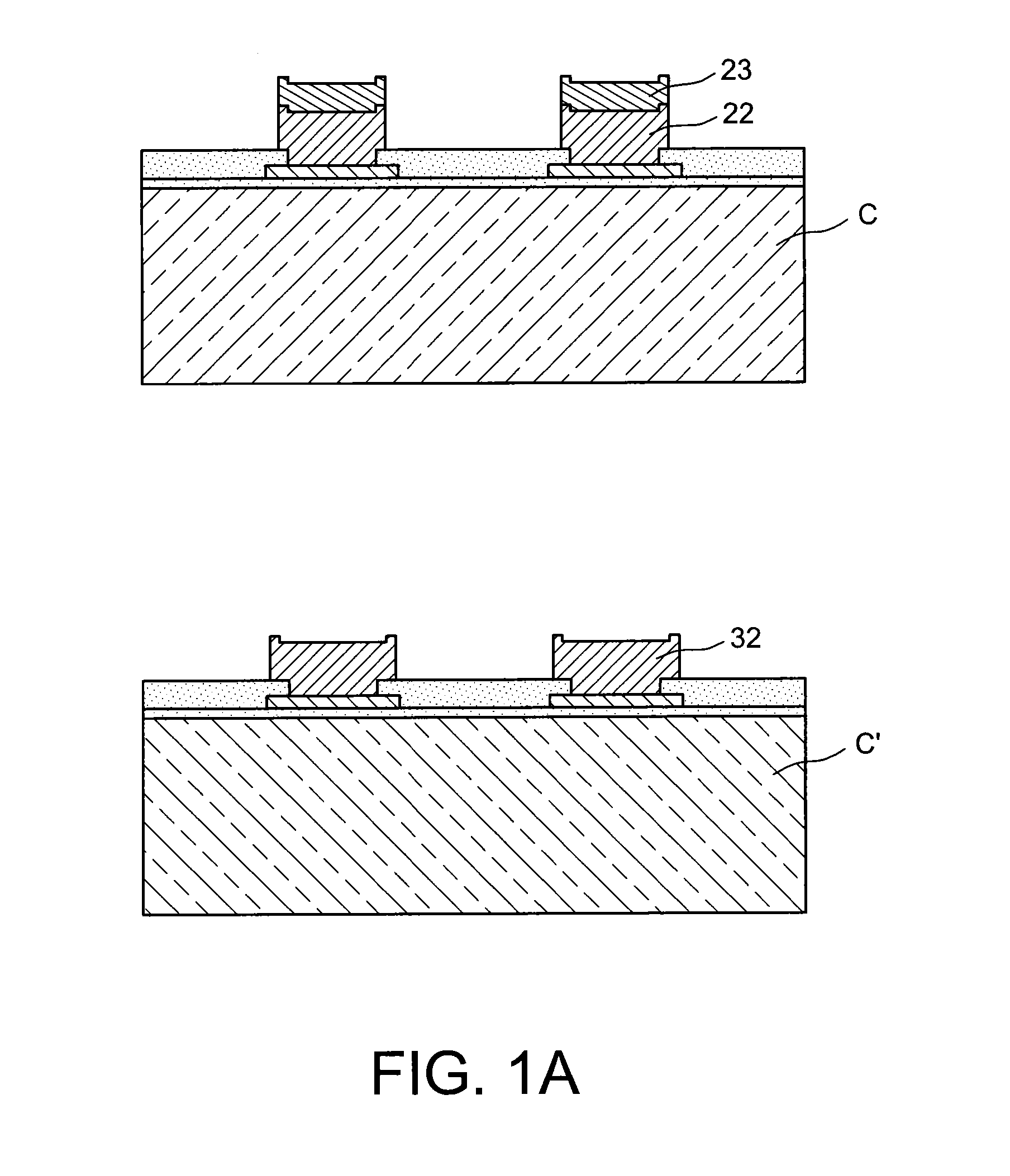

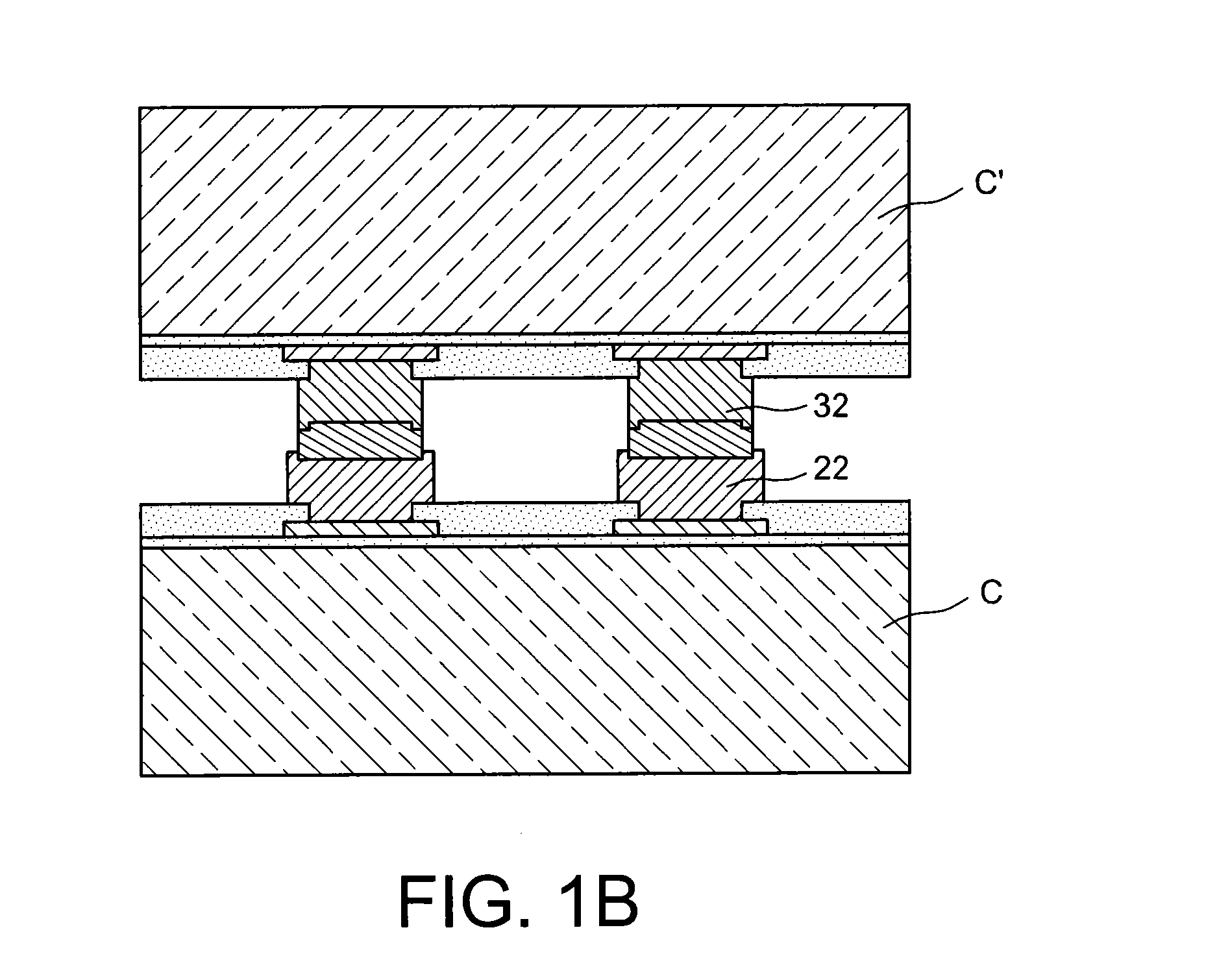

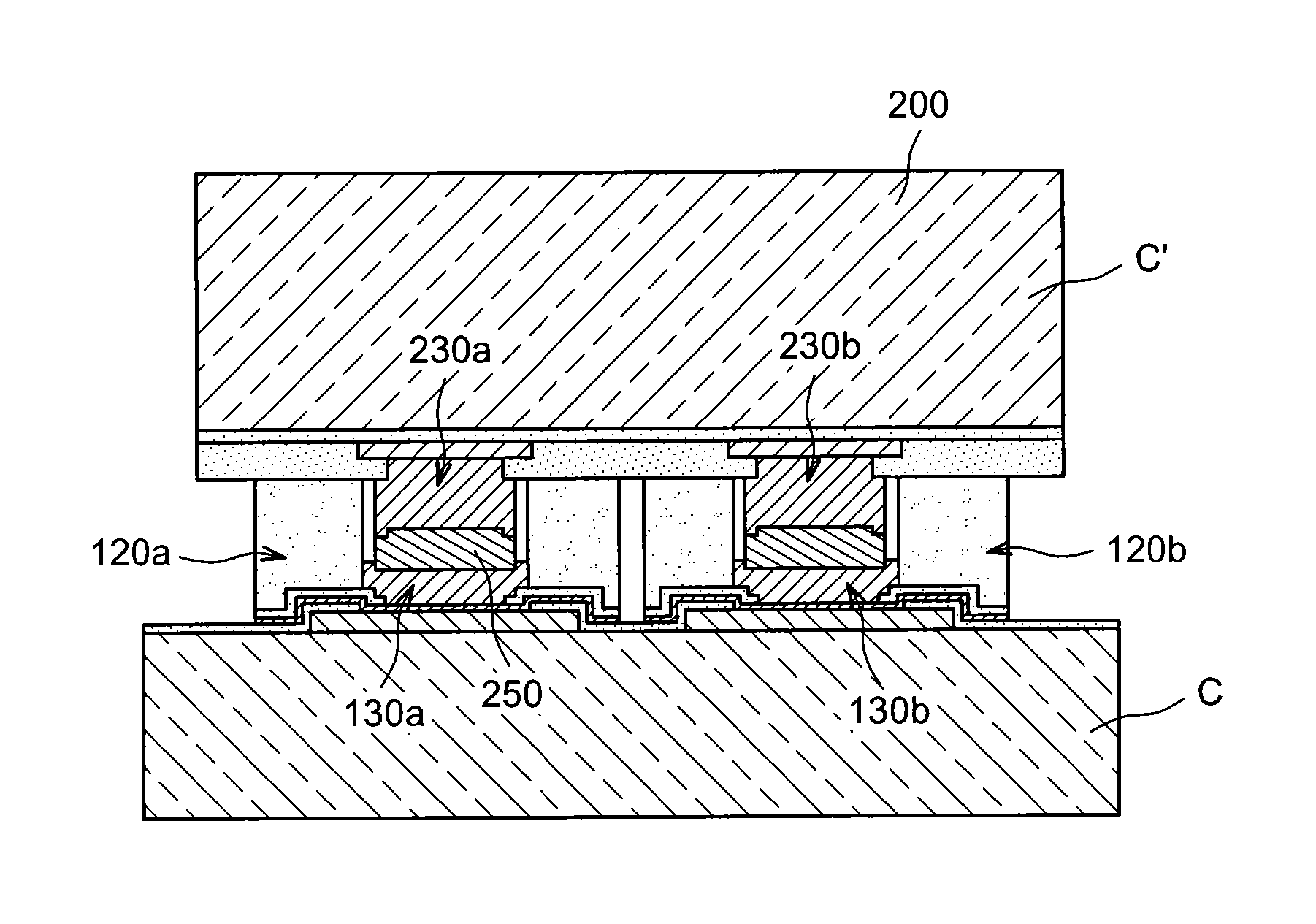

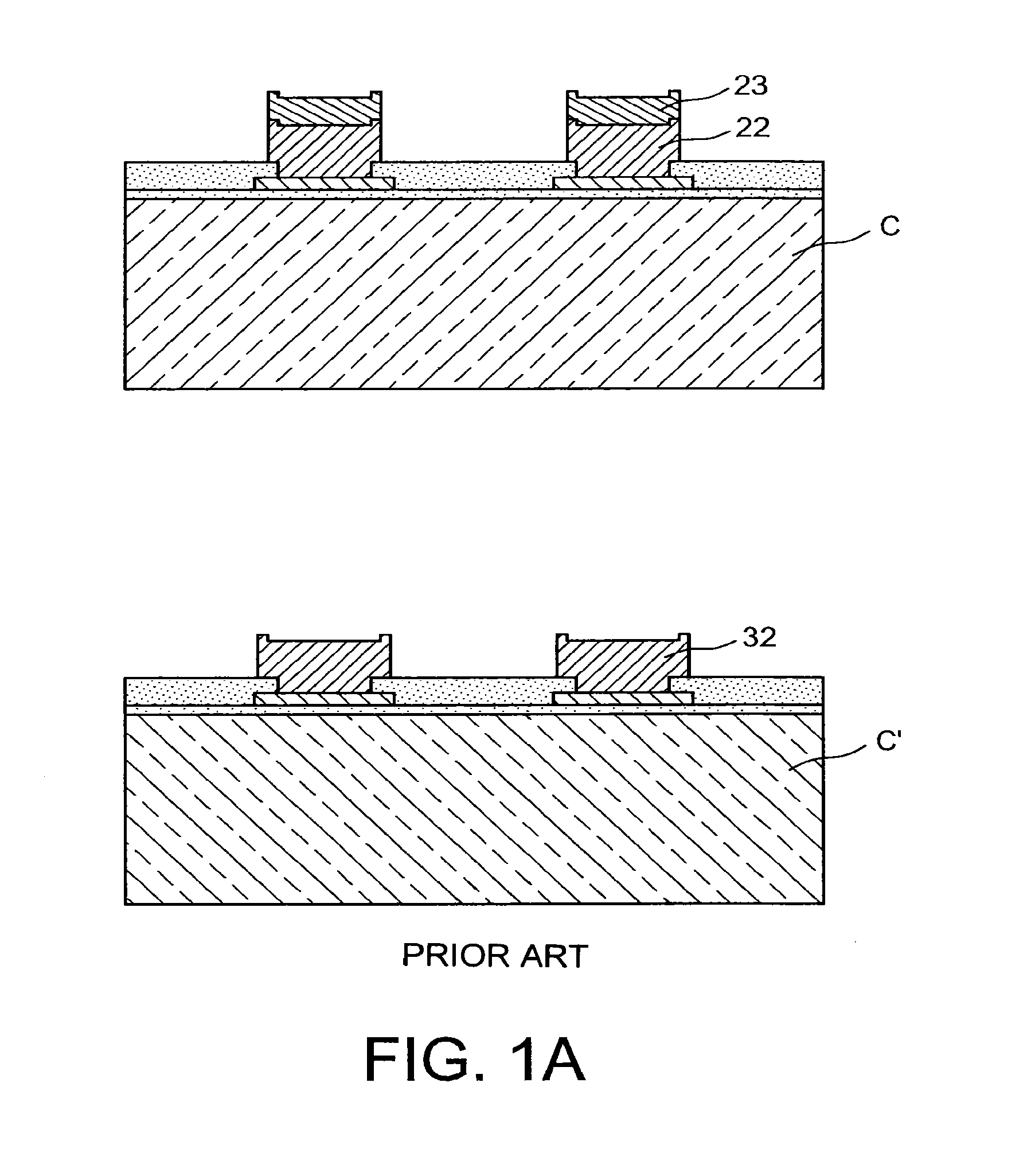

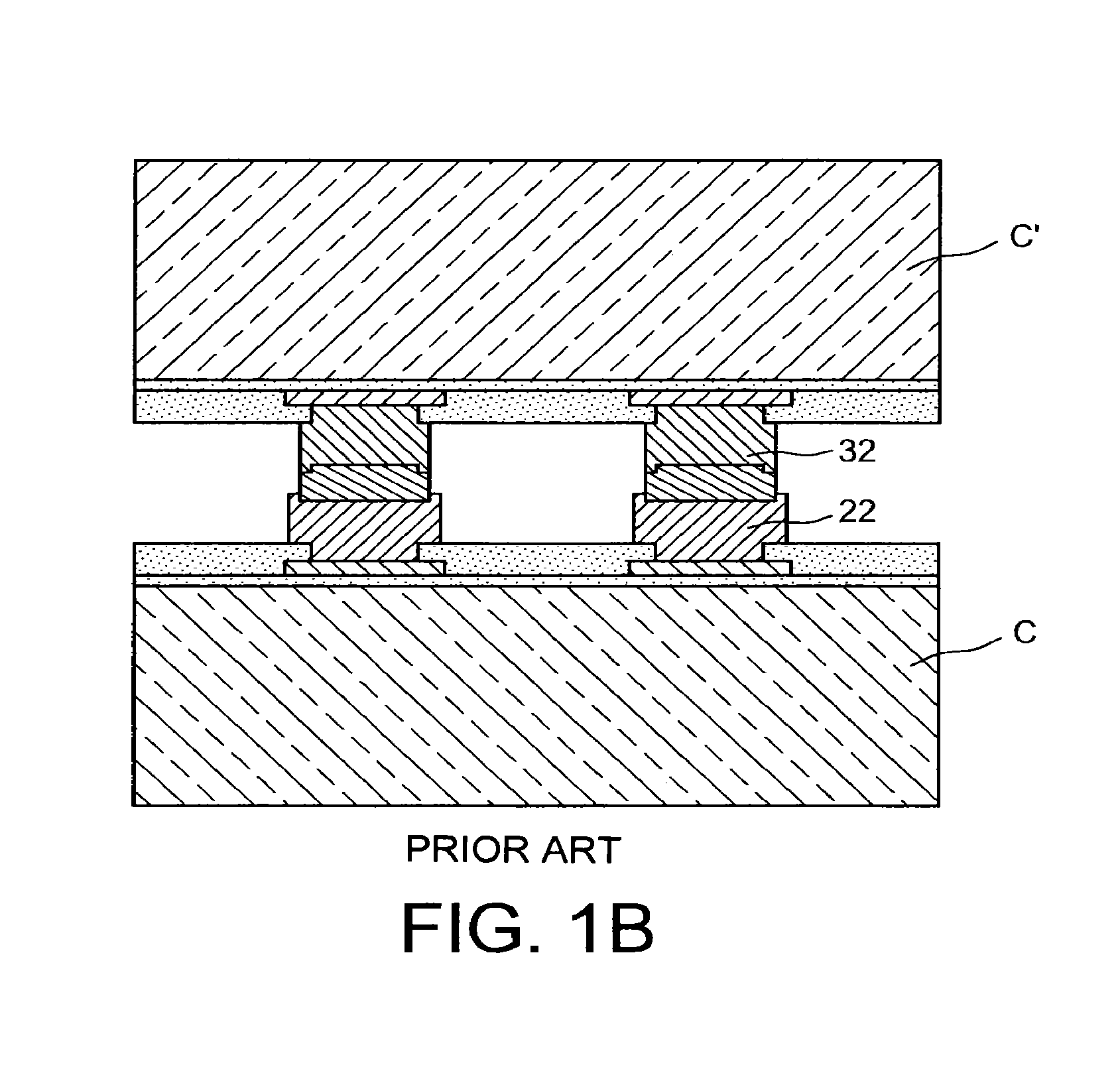

Method for producing a structure for microelectronic device assembly

ActiveUS20140144690A1Easy subsequent assemblyGood body shapeSemiconductor/solid-state device detailsSolid-state devicesDielectric layerElectrical and Electronics engineering

The invention concerns the forming of a microelectronic device comprising a substrate containing at least one conductive pad, the said pad being provided with a bottom surface resting on the substrate and an upper surface opposite said bottom surface, the said upper surface of said pad having a stack applied thereto formed of a conductive layer and a protective dielectric layer comprising an opening called first opening facing said pad and exposing the said conductive layer, at least one insulating block (120a, 120b) being arranged on a peripheral region of said upper surface of said pad, the said insulating block (120a, 120b) having a cross-section forming a closed contour and comprising an opening called second opening, a conductive pillar (130a, 130b) being located in the centre of said contour in the said second opening.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

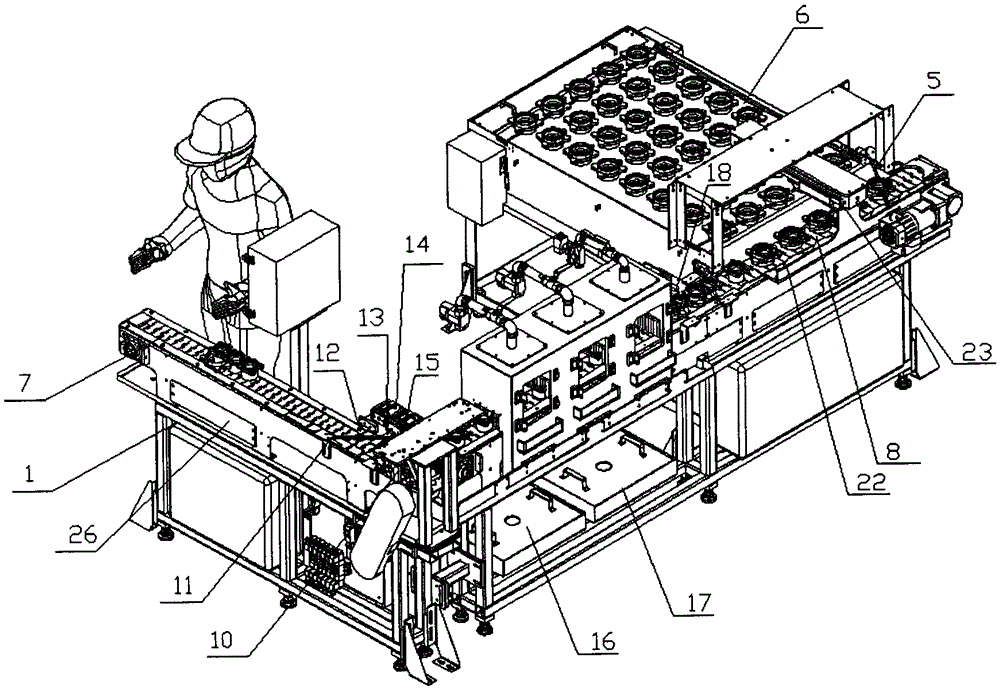

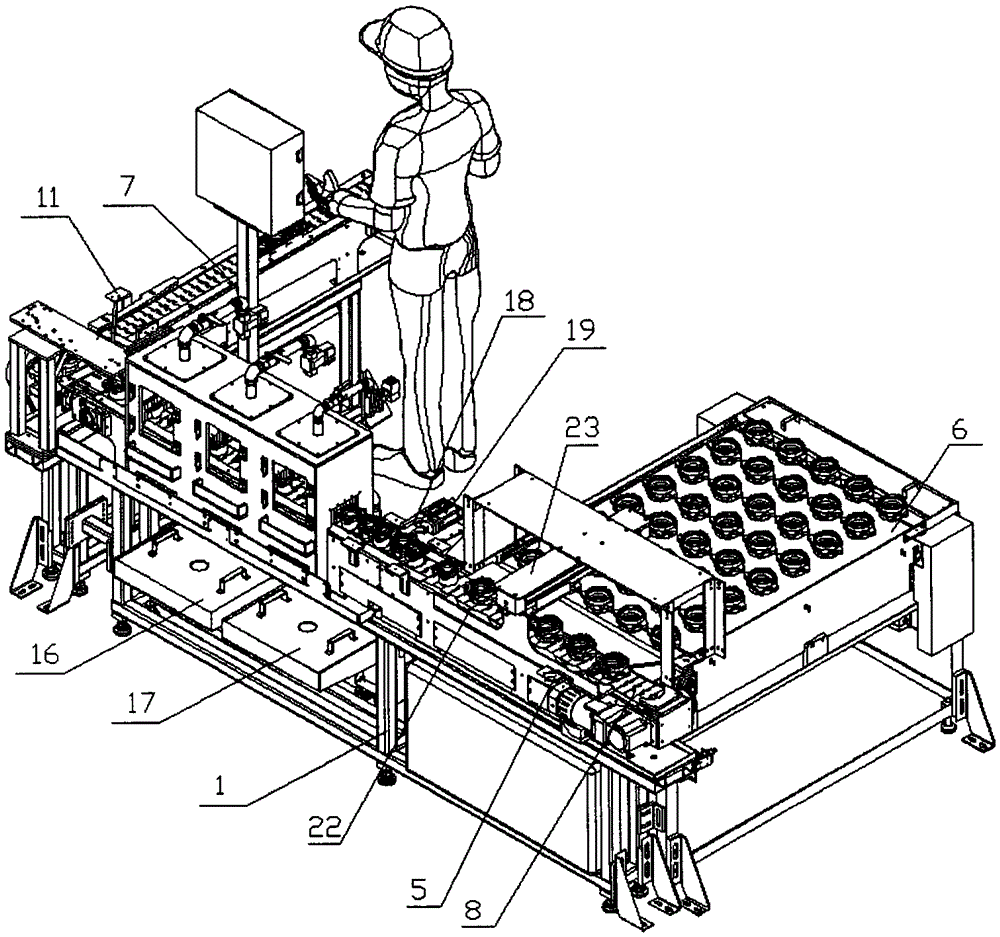

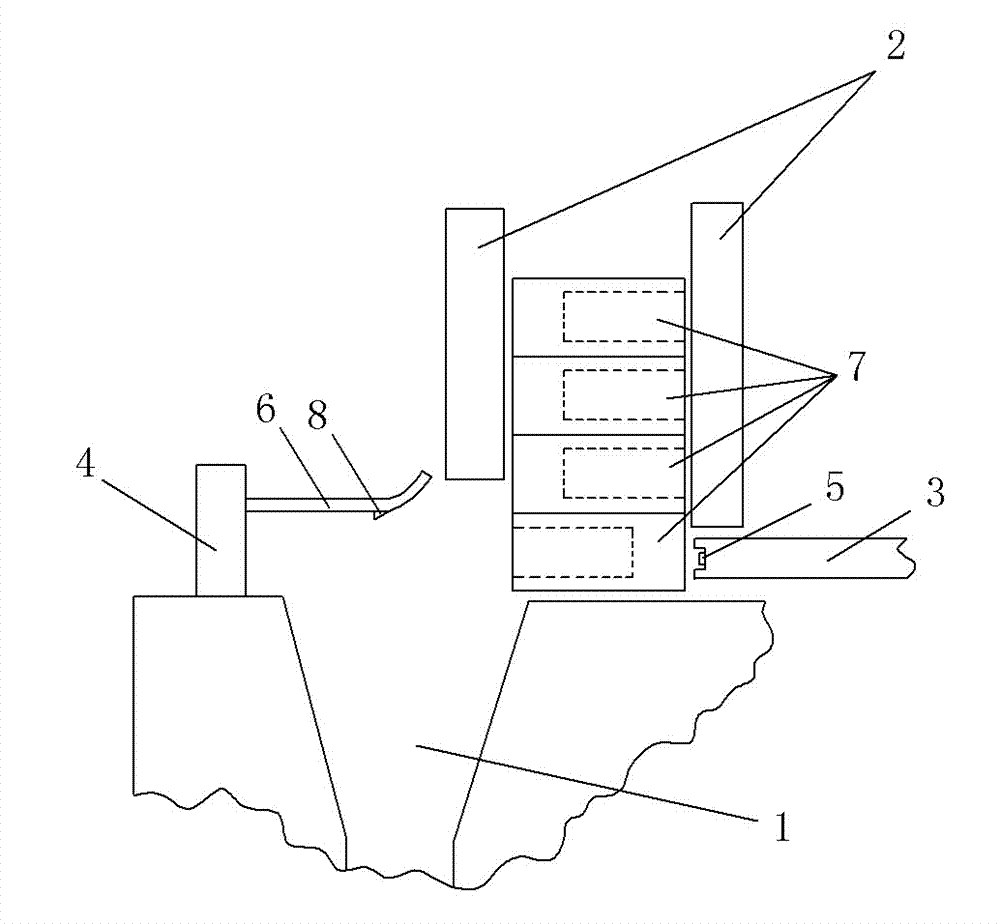

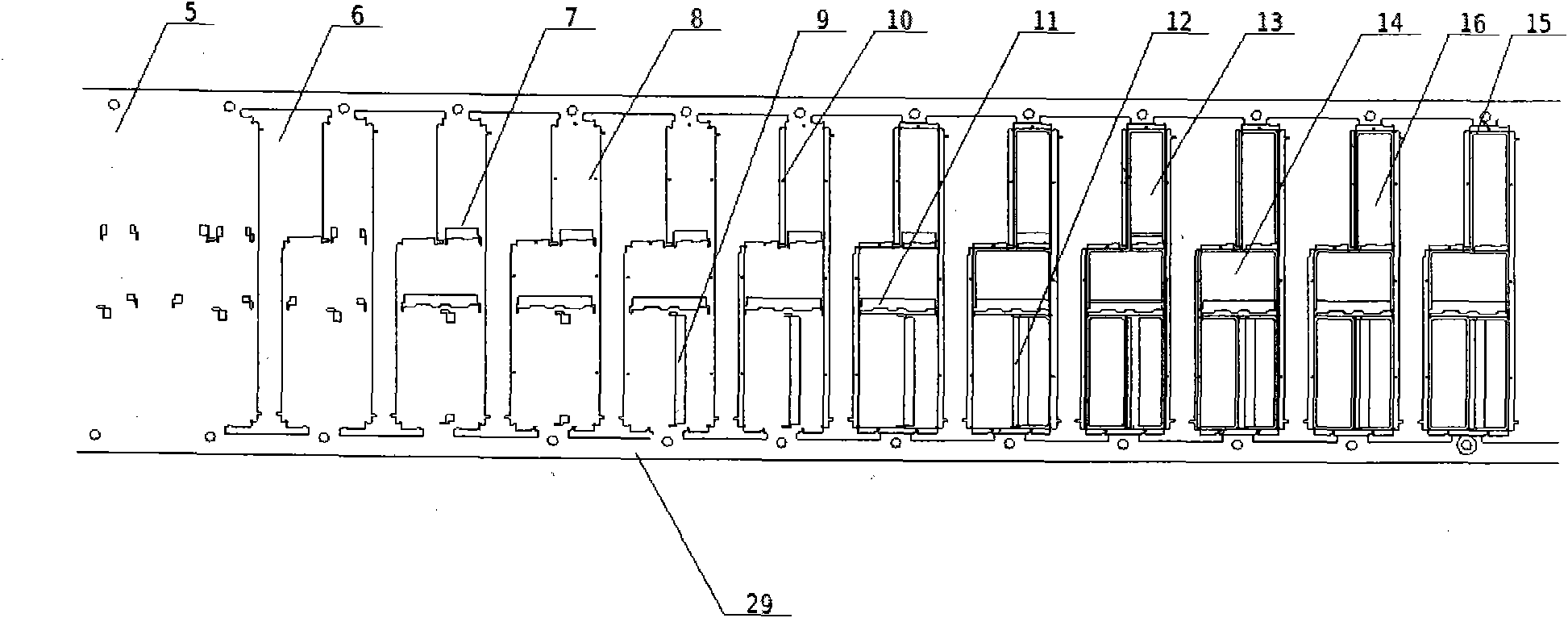

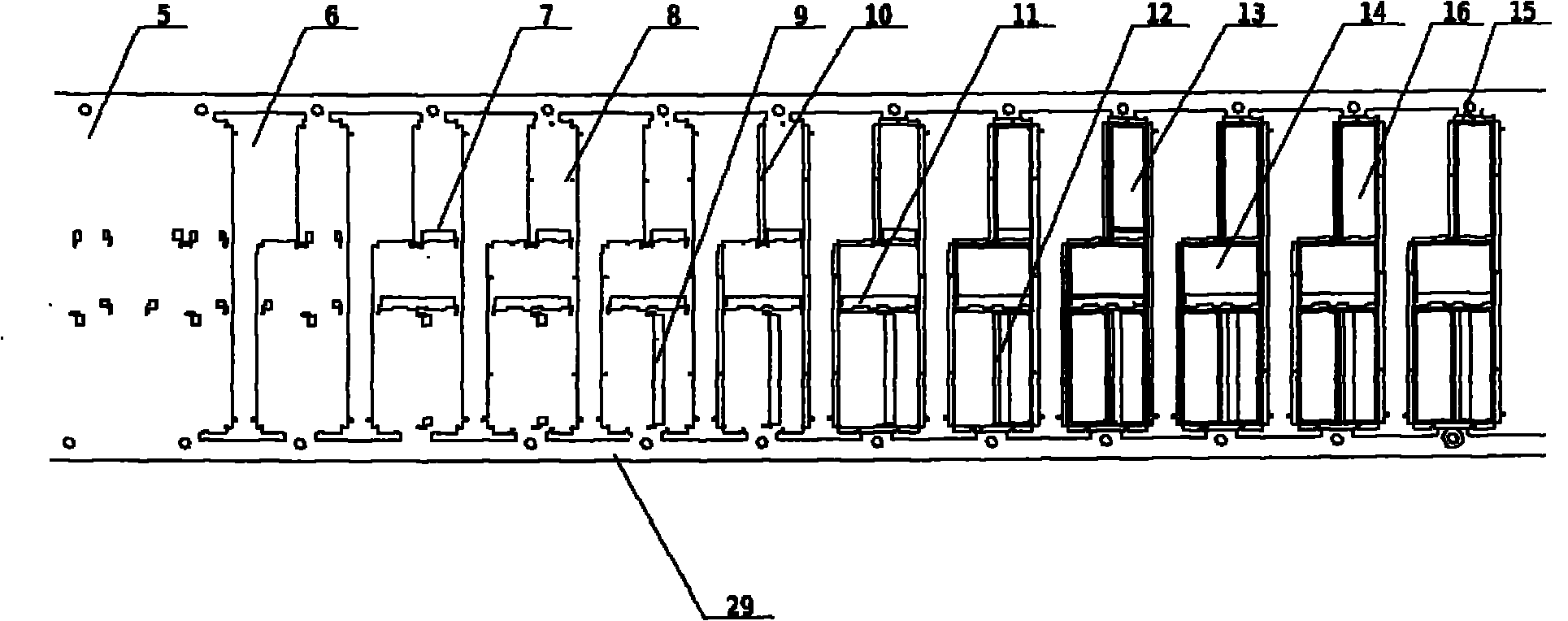

Automatic cyclic cleaning, rust preventing and arraying equipment

ActiveCN105521964APrevent rustEasy to storeCleaning using liquidsConveyor partsSprayerControl system

The invention discloses automatic cyclic cleaning, rust preventing and arraying equipment. A conveying channel is used for conveying workpieces; a cleaning oil sprayer, a rust preventing oil sprayer and an air blowing device which are sequentially fixed to a machine frame over the conveying channel can spray cleaning oil, rust preventing oil and high-pressure air to the workpieces passing under the cleaning oil sprayer, the rust preventing oil sprayer and the air blowing device respectively; a distance adjusting device on one side of the front of the conveying direction of the air blowing device can array the workpieces passing through the distance adjusting device on the conveying channel at equal intervals; a first sensing device can sense the workpieces reaching the set position of the conveying channel and transmit the information to a control system; a material pushing device can convey the workpieces at the set position of the tail end of the conveying channel to an appointed position of a material receiving and conveying platform on one side of the tail end of the conveying channel; the control system controls the conveying channel, the cleaning oil sprayer, the rust preventing oil sprayer, the air blowing device, the distance adjusting device and the material pushing device to act. Fully automatic operation of cleaning, rust preventing and arraying of inner wheels of hub bearings is achieved, the inner wheels of the hub bearings are cleaned thoroughly, and subsequent assembly and use are facilitated.

Owner:昆山海新润自动化设备有限公司

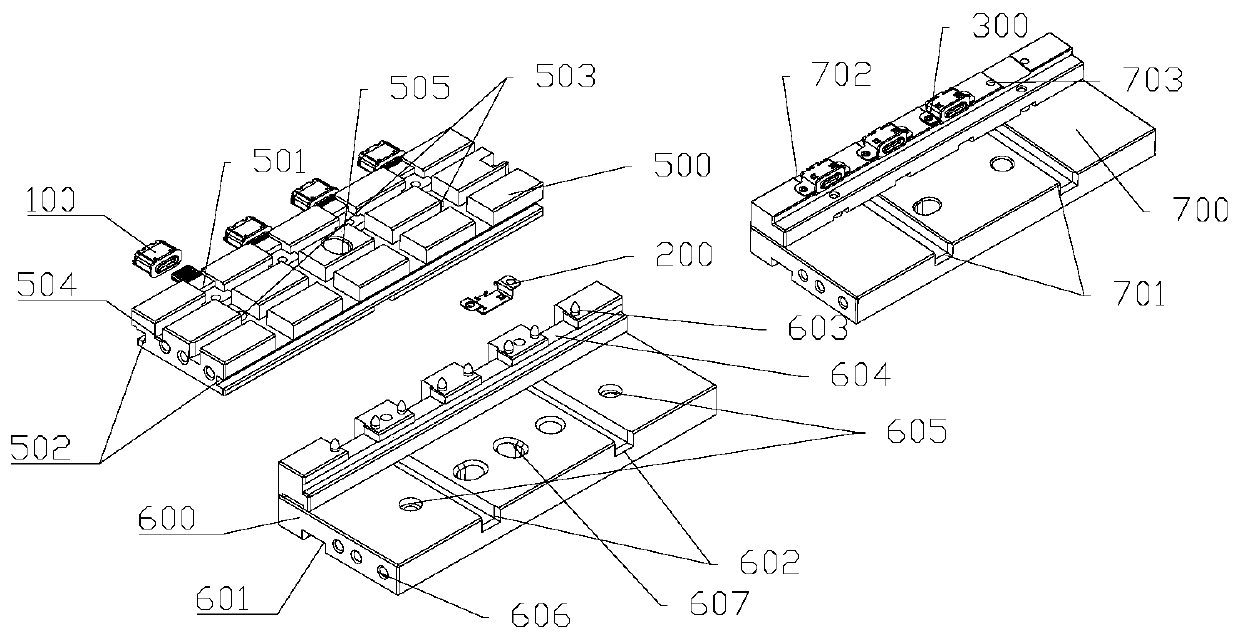

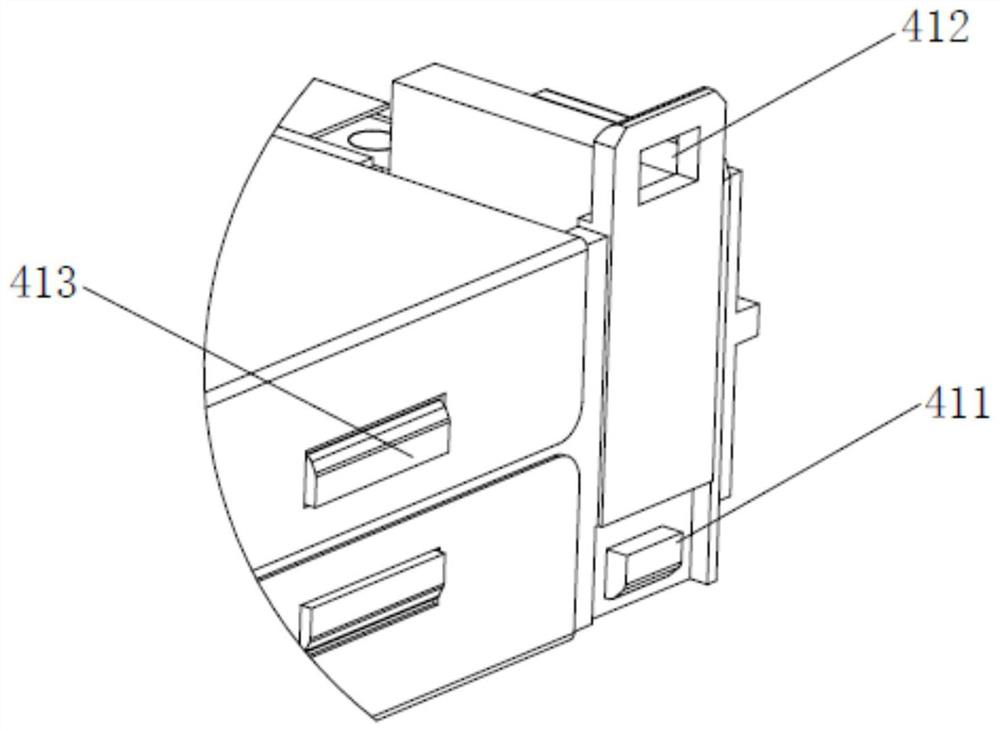

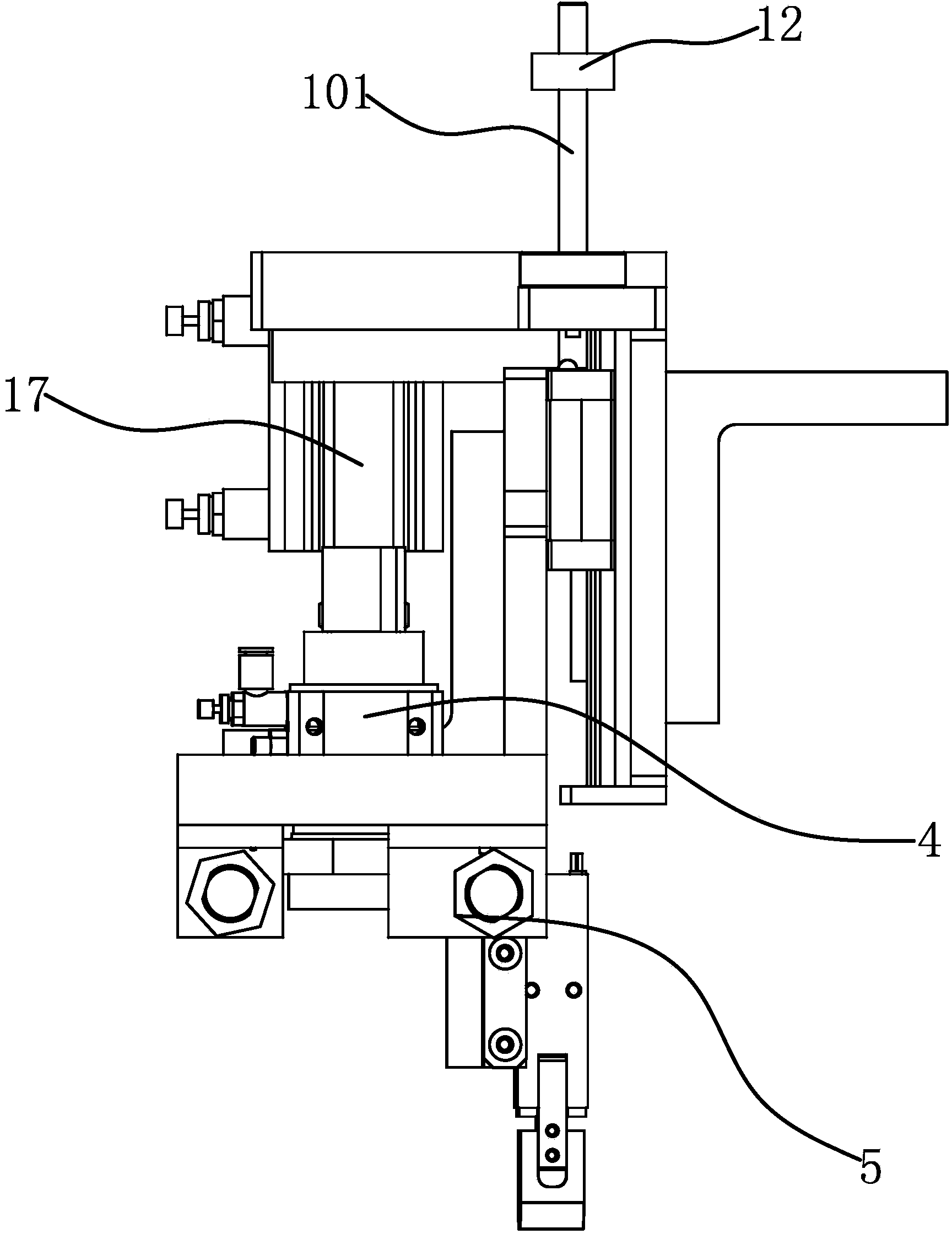

Capacitor feeding device for capacitor set assembly equipment

InactiveCN110626783ASo as not to damageUniform lengthCapacitor manufactureConveyor partsCapacitanceEngineering

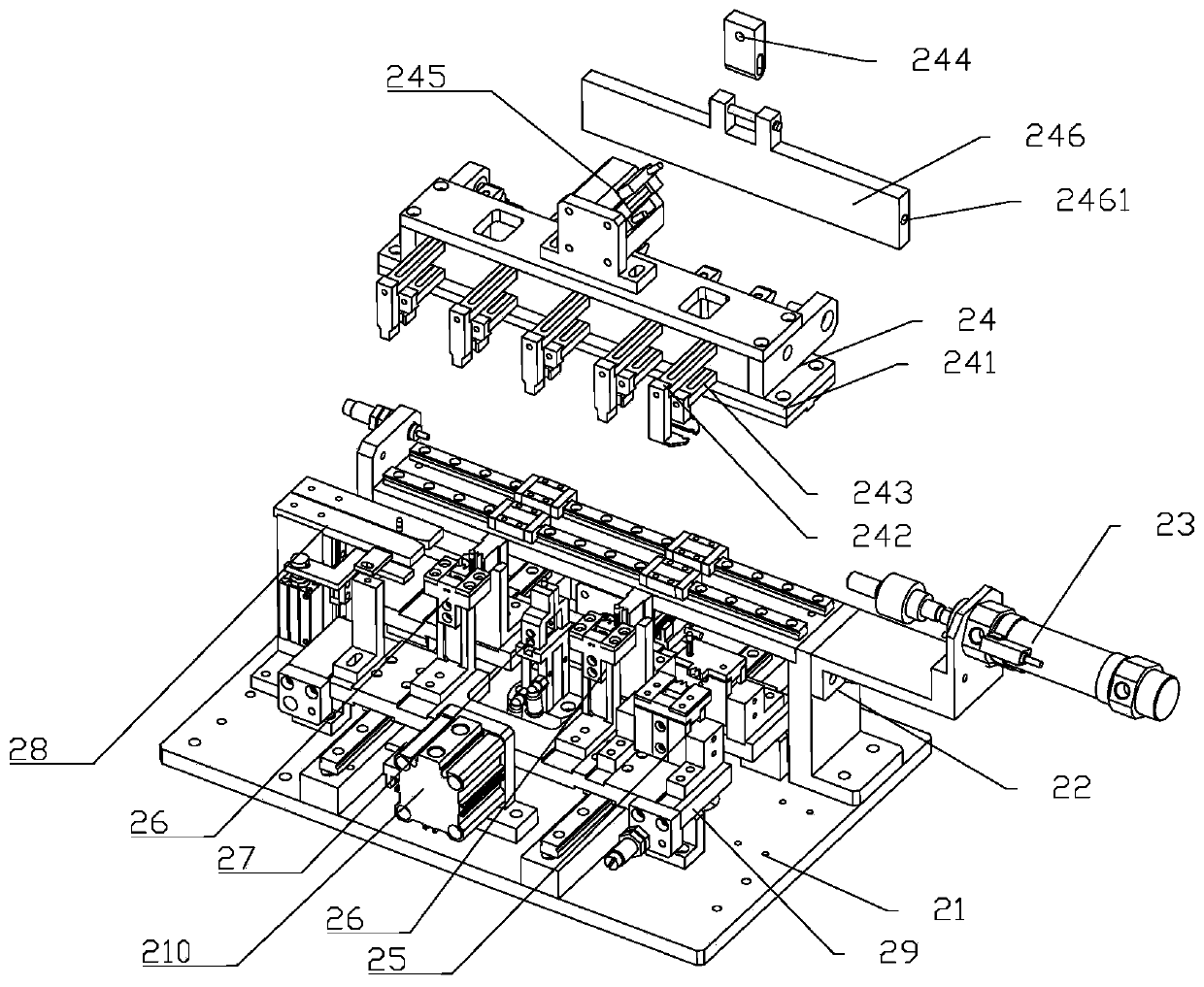

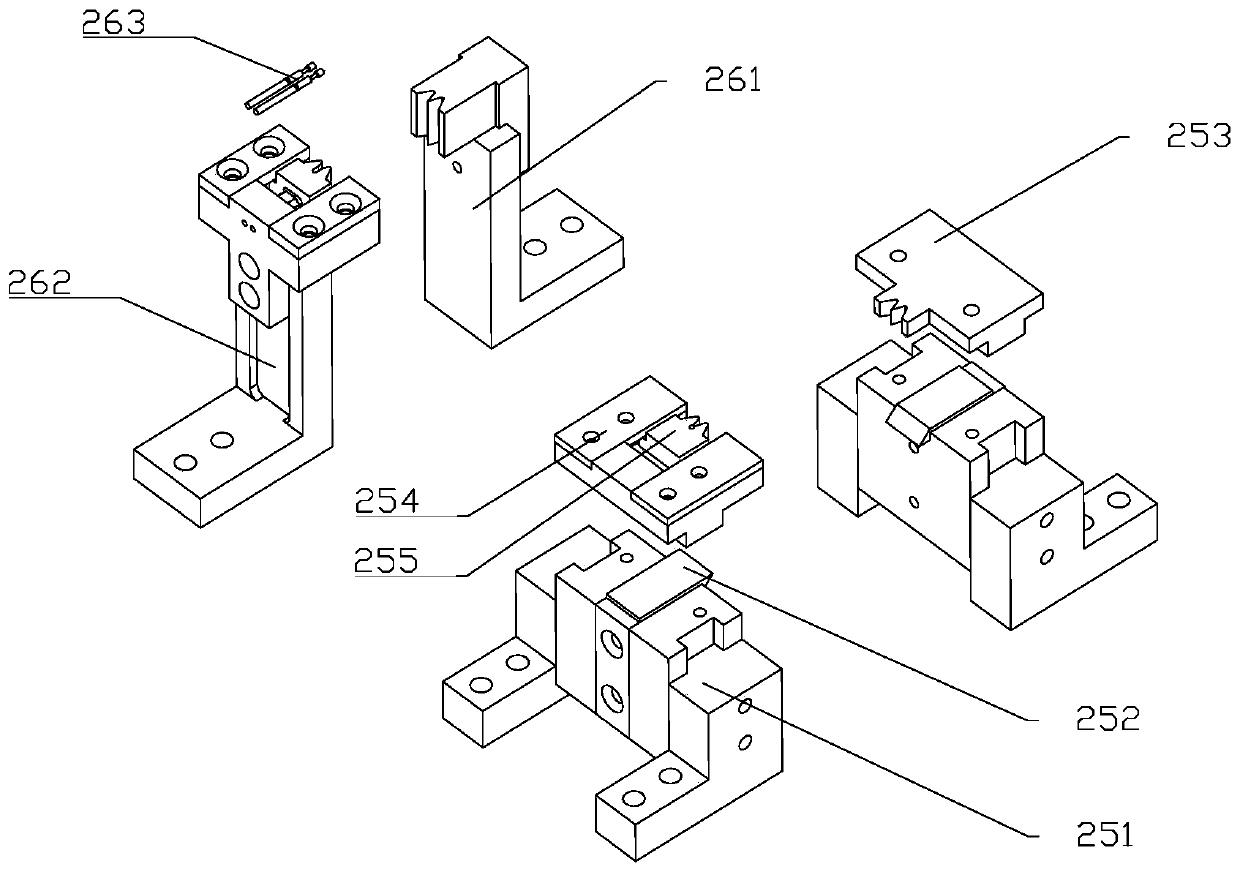

The invention relates to the technical field of circuit element production fabrication and provides a capacitor feeding device for capacitor set assembly equipment. The capacitor feeding device comprises an installation plate, a support seat, a horizontal moving air cylinder, a clamping mechanism, a cutting component, conduction detection components, an overturning component, a material receivingcomponent, sliding bottom plates and clamping air cylinders, wherein the support seat is arranged on the installation plate, the clamping mechanism is movably connected to the support seat through a sliding rail component, the horizontal moving air cylinder is horizontally arranged on the support seat, the stretching and contracting end of the horizontal moving air cylinder is connected with the clamping mechanism, the clamping air cylinders are fixedly arranged on the installation plate, the stretching and contracting ends of the clamping air cylinders are connected with the installation plate, the cutting component, the conduction detection components, the overturning component and the material receiving component are all installed on the two sliding bottom plates, in the processing direction, the sequence is the cutting component, the conduction detection component, the overturning component, the conduction detection component and the material receiving component, and the installation plate is provided with a vibrating material feeder. The capacitor feeding device for the capacitor set assembly equipment has the advantages of being capable of performing positive pole and negative pole detection, shaping capacitor wire connection poles and feeding materials efficiently and reliably.

Owner:何国标

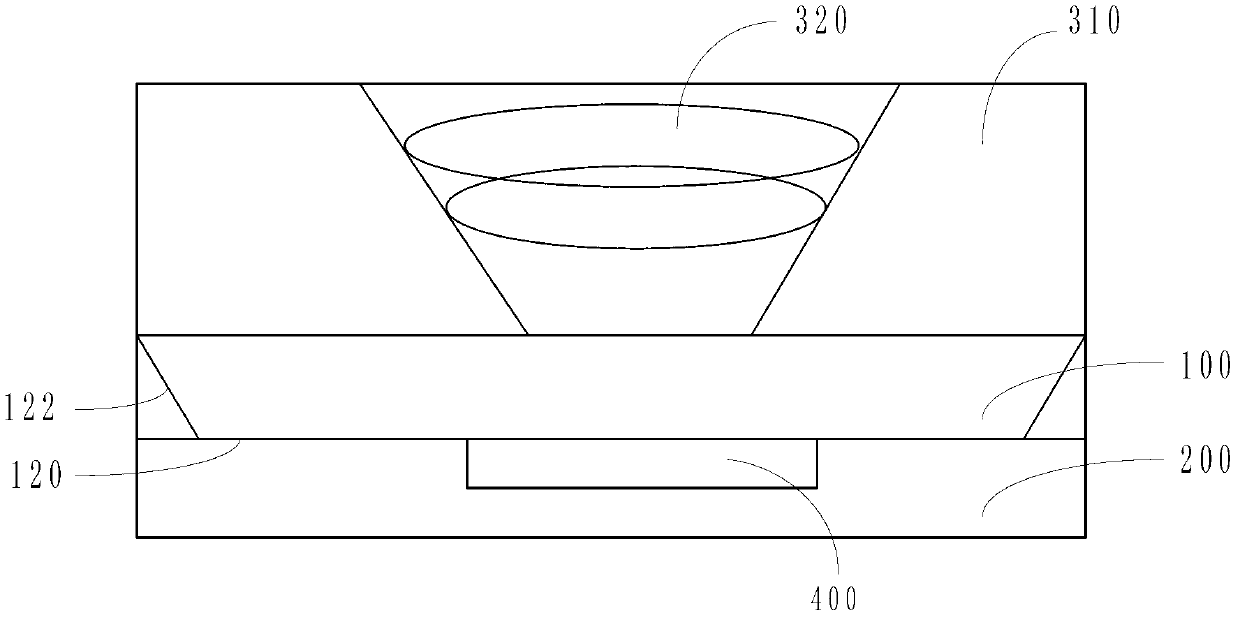

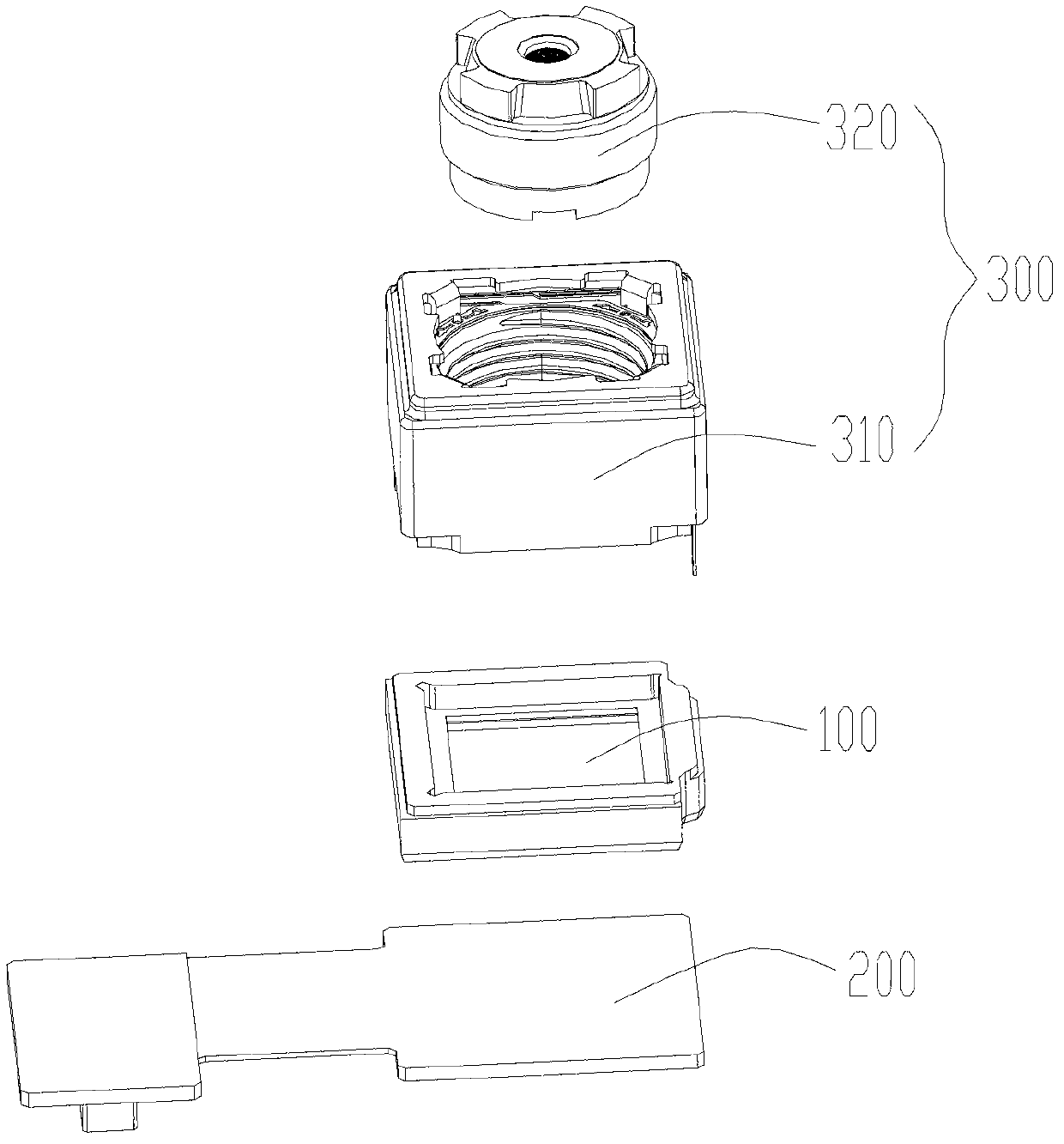

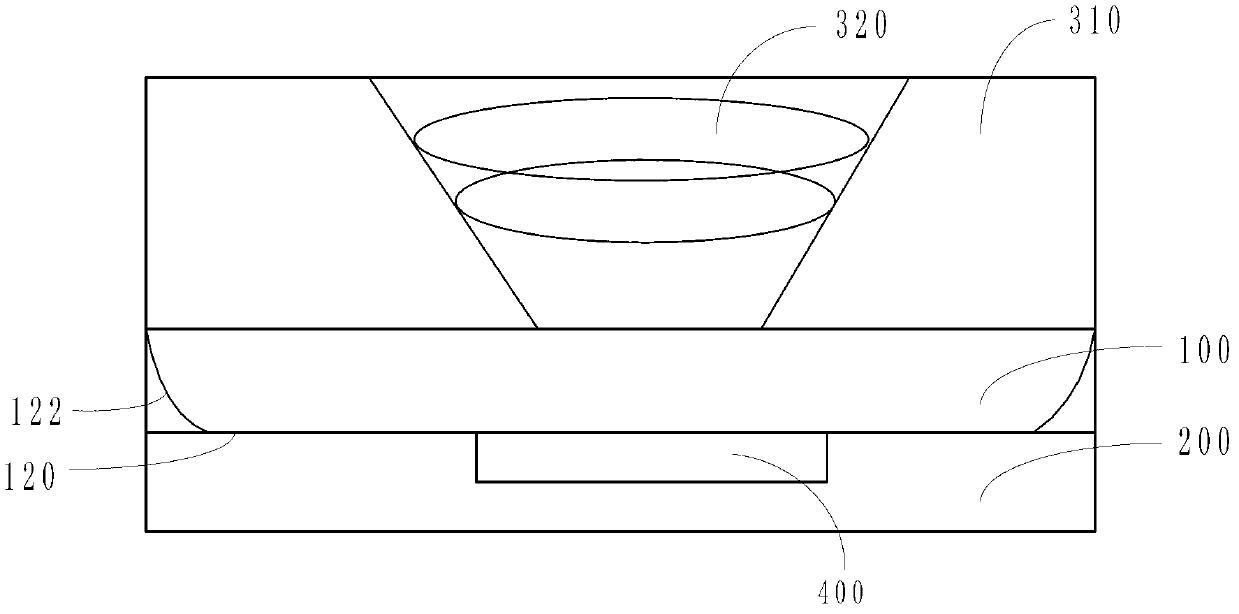

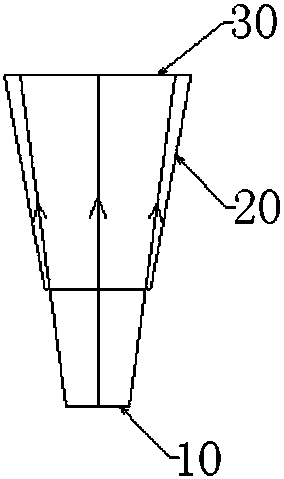

Support structure and camera shooting module with support structure

InactiveCN103279001AGuaranteed accuracyImprove yieldTelevision system detailsColor television detailsUltimate tensile strengthBiomedical engineering

The invention relates to a support structure which comprises a first surface and a second surface which is oppositely arranged with the first surface. A lens driving assembly is installed on the first surface, the second surface is attached to a base plate, a glue fixing face is formed on at least one edge of the second surface, the glue fixing face is a plane or a curved face which is slant relative to the second surface, a gluing space is defined between the glue fixing face and the base plate, therefore, when the second surface of the support structure is connected with the base plate in a flush and gluing mode through a bonding agent, the arrangement of the glue fixing face enables the bonding space to be defined between the edge area of the second surface and the base plate, the bonding agent can be spilled to the bonding space, poor size quality caused by that fact that the bonding agent is spilled to the periphery of the support structure can be avoided, the support structure is to the benefit of guaranteeing accuracy of the appearance size of a camera shooting module, follow-up assembly can be conveniently carried out, and the yield of the camera shooting module is improved. In addition, a contact area among the bonding agent, the support structure and the base plate can be expanded, and therefore adhesive strength of the support structure and the base plate can be strengthened.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

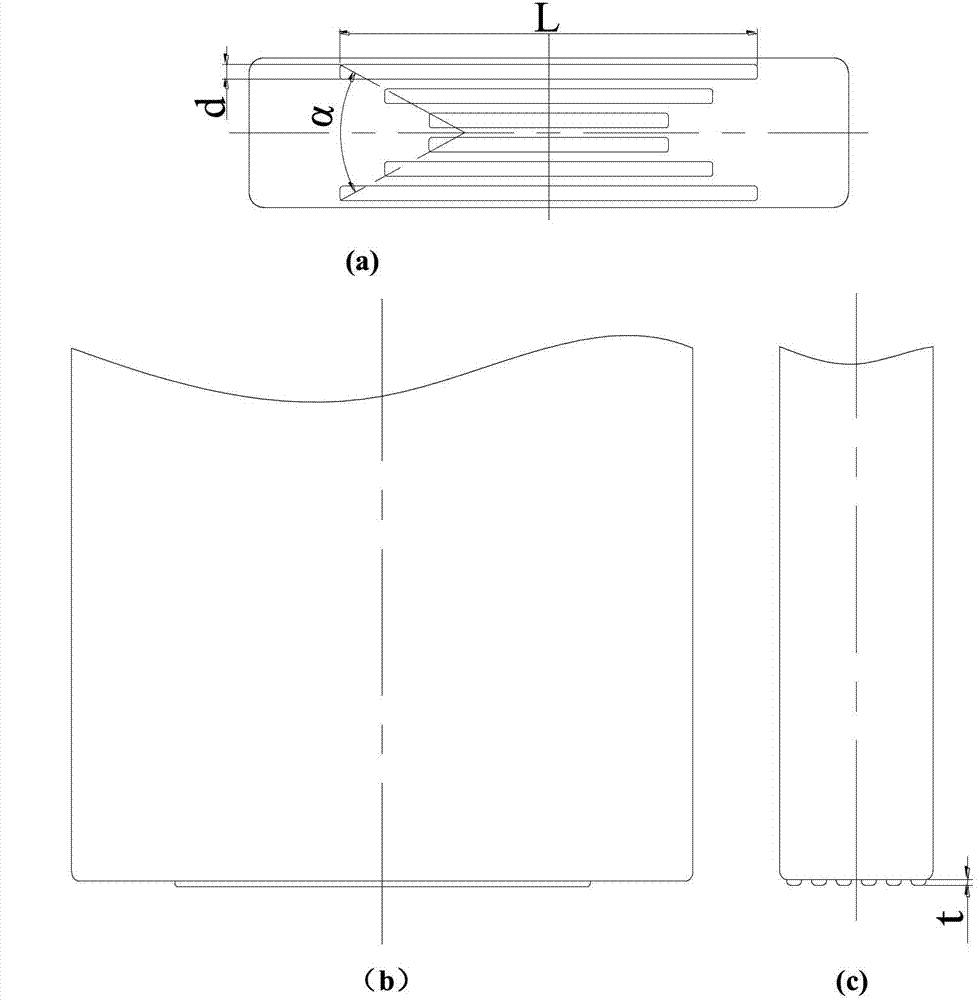

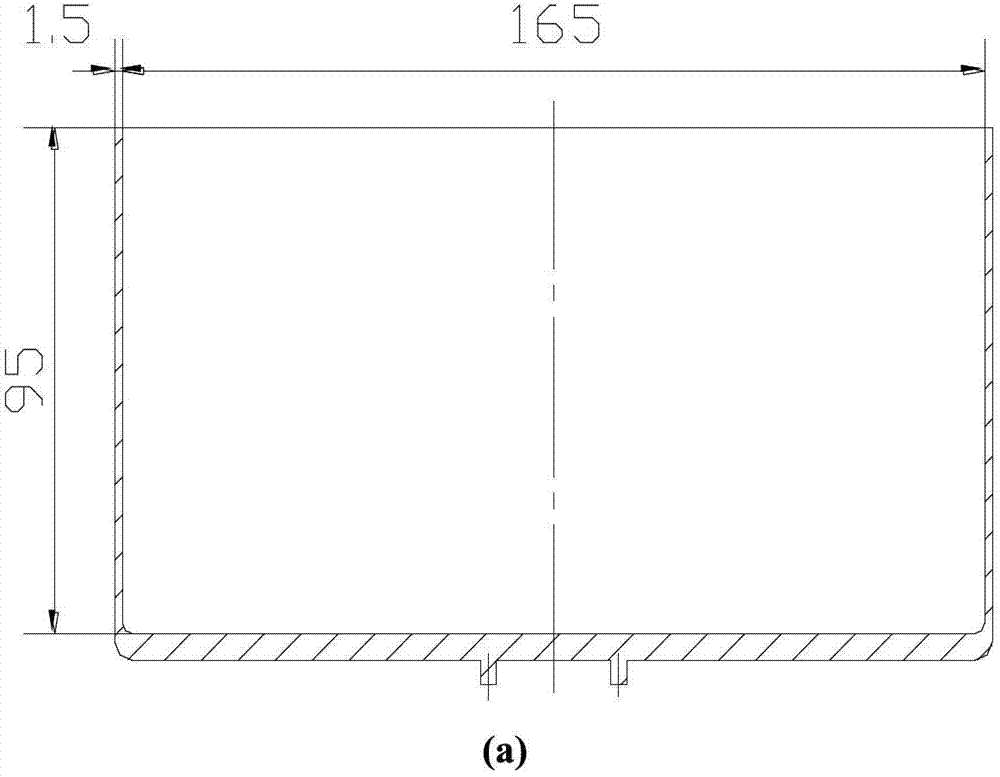

Extrusion molding mould and molding method of large-length-width-ratio aluminum alloy rectangular box-shaped piece

The invention provides an extrusion molding mould and a molding method of a large-length-width-ratio aluminum alloy rectangular box-shaped piece, and belongs to the technical field of plastic molding of metal. The method comprises the following steps of: 1. utilizing annealed-state aluminum alloy raw materials to prepare a blank; 2. corroding the blank by using an NaOH solution and corroding for 8-15 minutes; 3. uniformly coating zinc stearate powder on a corroded blank and providing lubrication for subsequent extrusion molding; 4. utilizing a convex mould with a damping rib to carry out the extrusion molding on the rectangular box-shaped piece; and 5, according to the height of the box-shaped piece, meeting the design and use requirements that the end surface of the box-shaped piece which is subjected to saw cutting and extruding. The extrusion molding mould and the molding method of the large-length-width-ratio aluminum alloy rectangular box-shaped piece avoid the defects of wrinkling, cracking, ledging and the like in a forming process of the rectangular box-shaped piece and improve the product yield; and meanwhile, the machining procedure is effectively reduced, the material utilization rate is increased, the mold cost is saved and the production cost of a single piece is reduced.

Owner:安徽金铂新材料科技有限公司

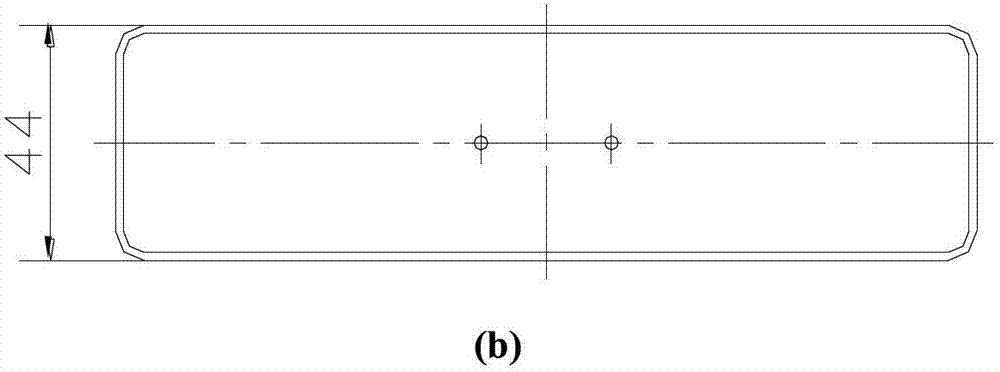

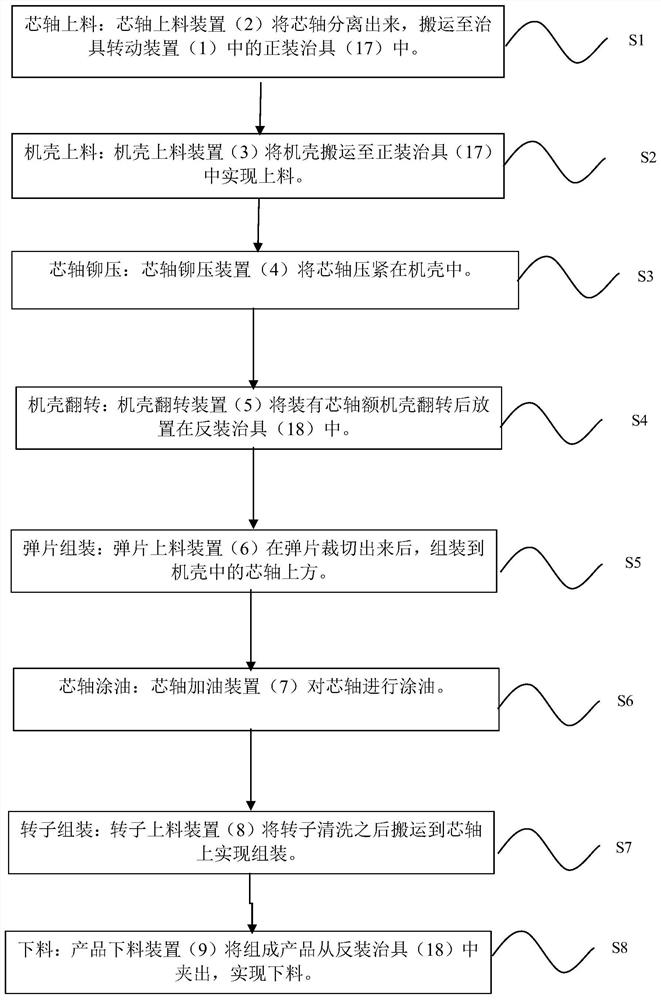

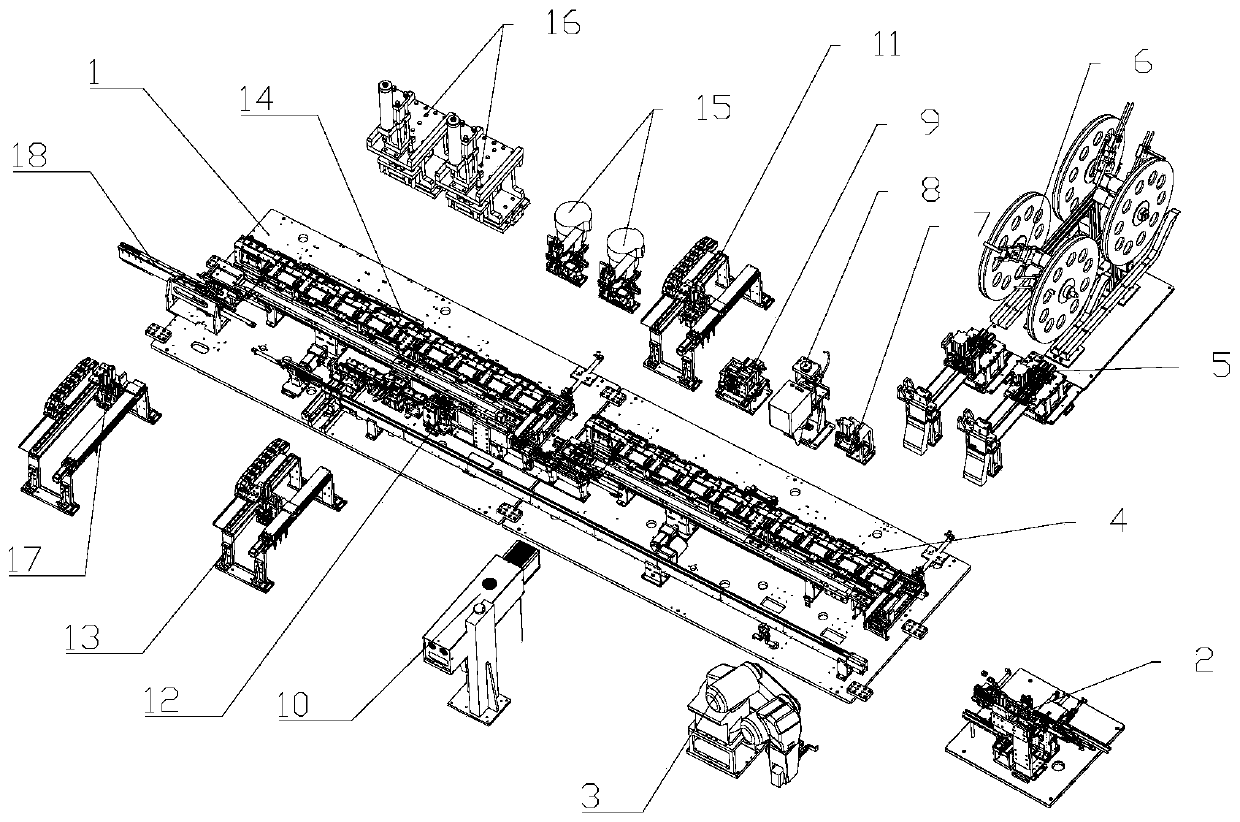

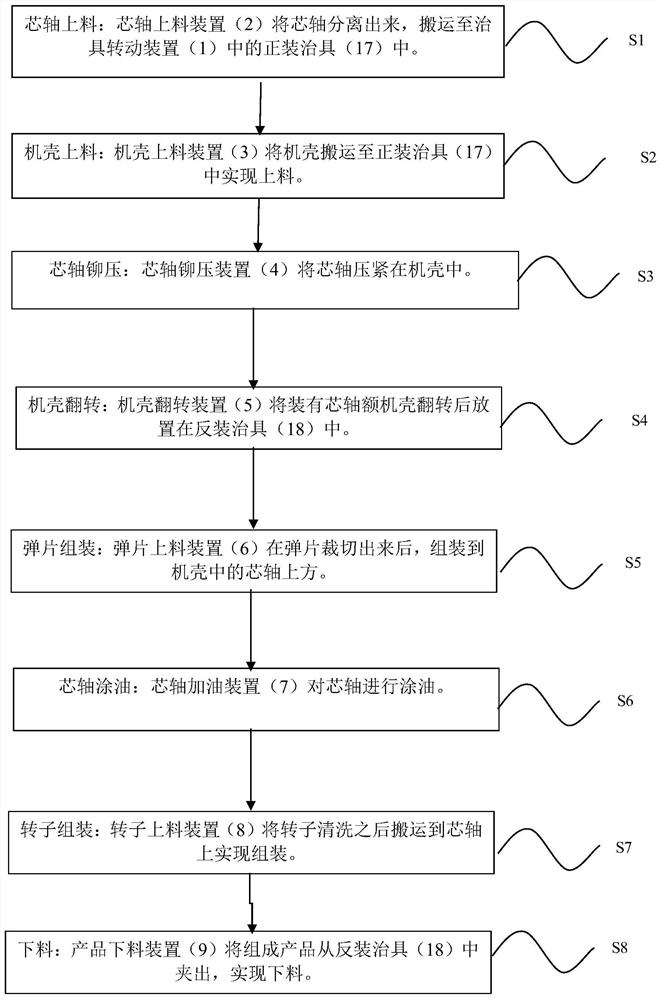

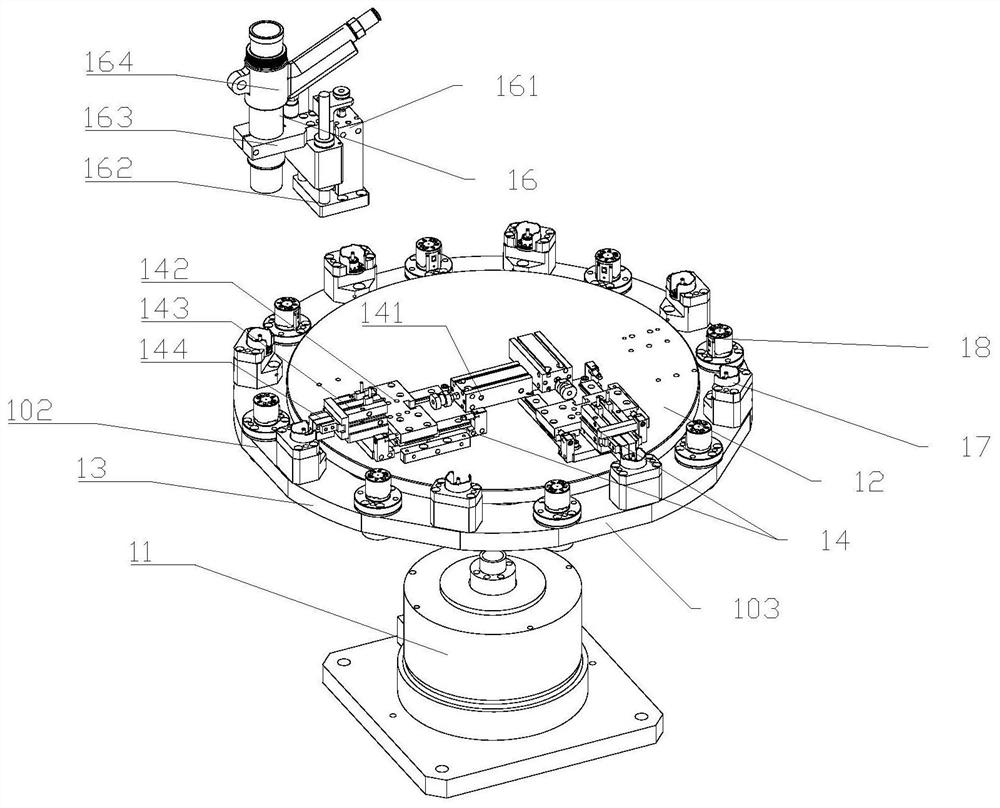

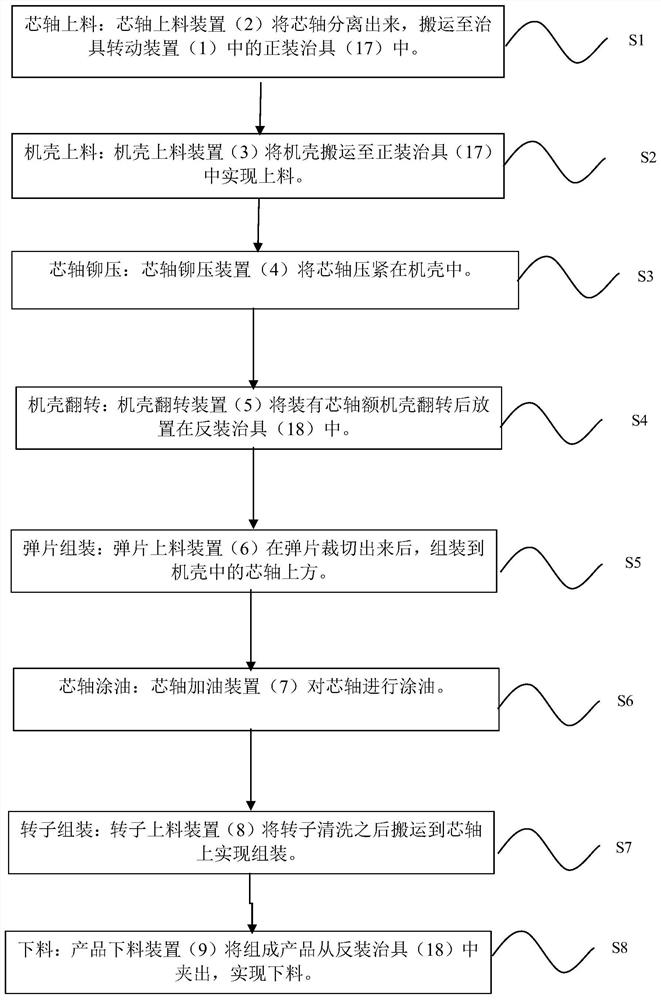

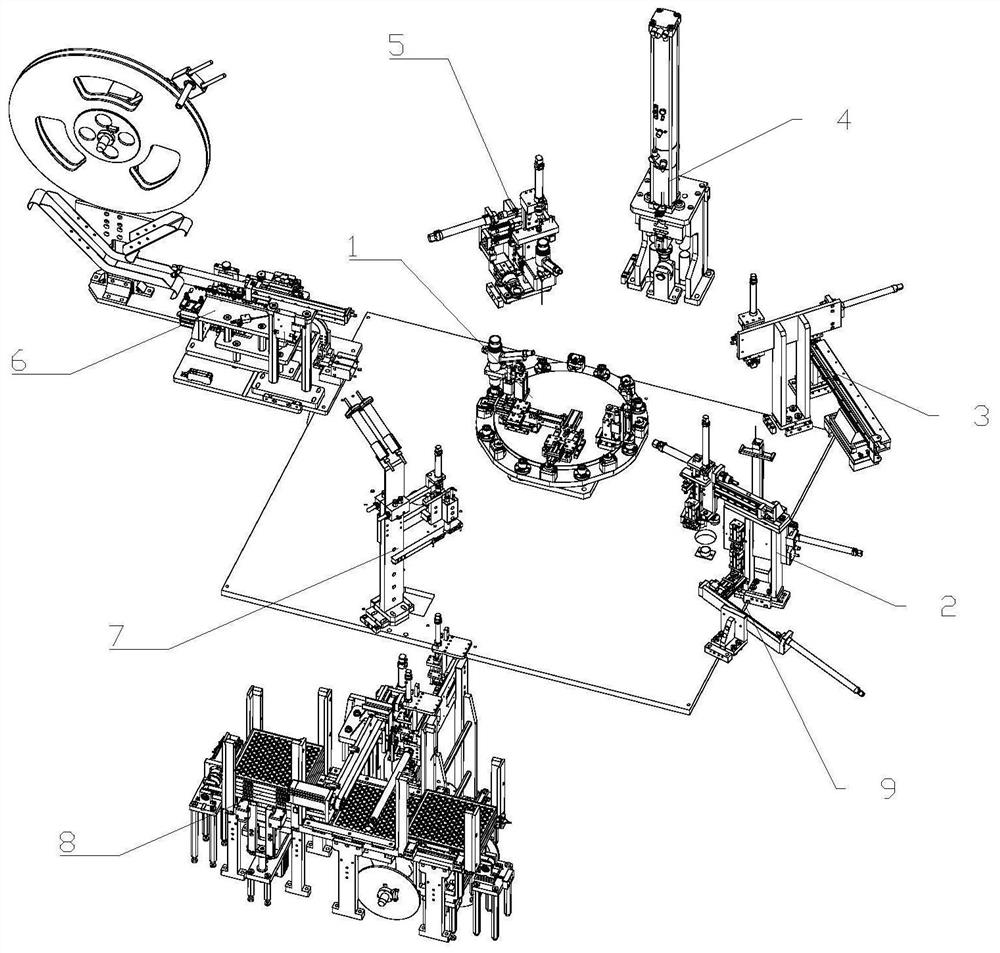

Automatic assembly production method of permanent magnet direct current motor

InactiveCN113241907AIncrease success rateImprove assembly efficiencyManufacturing stator/rotor bodiesCleaning processes and apparatusElectric machineryProcess engineering

The invention relates to the field of motor production, in particular to an automatic assembly production method of a permanent magnet direct current motor. The invention discloses an automatic assembly production method for a motor. Equipment adopted by the method comprises a rack, and a jig rotating device, a mandrel feeding device, a shell feeding device, a mandrel riveting device, a shell overturning device, an elastic piece feeding device, a mandrel oiling device, a rotor feeding device and a product discharging device which are mounted on the rack; a plurality of stations are arranged on the circumference of the jig rotating device and include a mandrel feeding station, a machine shell feeding station, a riveting station, an overturning station, an elastic piece feeding station, an oiling station, a rotor feeding station and a discharging station, and the mandrel feeding device, the machine shell feeding device, the mandrel riveting device, the machine shell overturning device, the elastic piece feeding device, the mandrel oiling device, the rotor feeding device and the product discharging device sequentially correspond to the jig rotating device by one circle in the machining direction. The equipment has the advantages that multi-station simultaneous machining is achieved, workpiece circulation is efficient, and machining efficiency is high.

Owner:陈荣乾

Workpiece orientation device with push rod

InactiveCN103754626AAchieve the effect of orientationAvoid bouncingConveyor partsBiochemical engineeringReciprocating motion

The invention discloses a transportation device, and particularly relates to a workpiece orientation device with a push rod. The workpiece orientation device comprises a frame, a positioning groove, feeding chutes, the push rod and a baffle, the positioning groove is formed in the frame, the push rod is connected with a driving device, the feeding chutes are formed in one side of the positioning groove, the reciprocating push rod is arranged at the bottoms of the feeding chutes, the baffle is arranged on the other side of the positioning groove opposite to the push rod, a groove is formed in the end of the push rod, and an infrared probe is arranged in the groove. By the aid of the technical scheme, an orientation transmission mechanism is simple in structure, and workpieces can be transmitted in an oriented manner.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

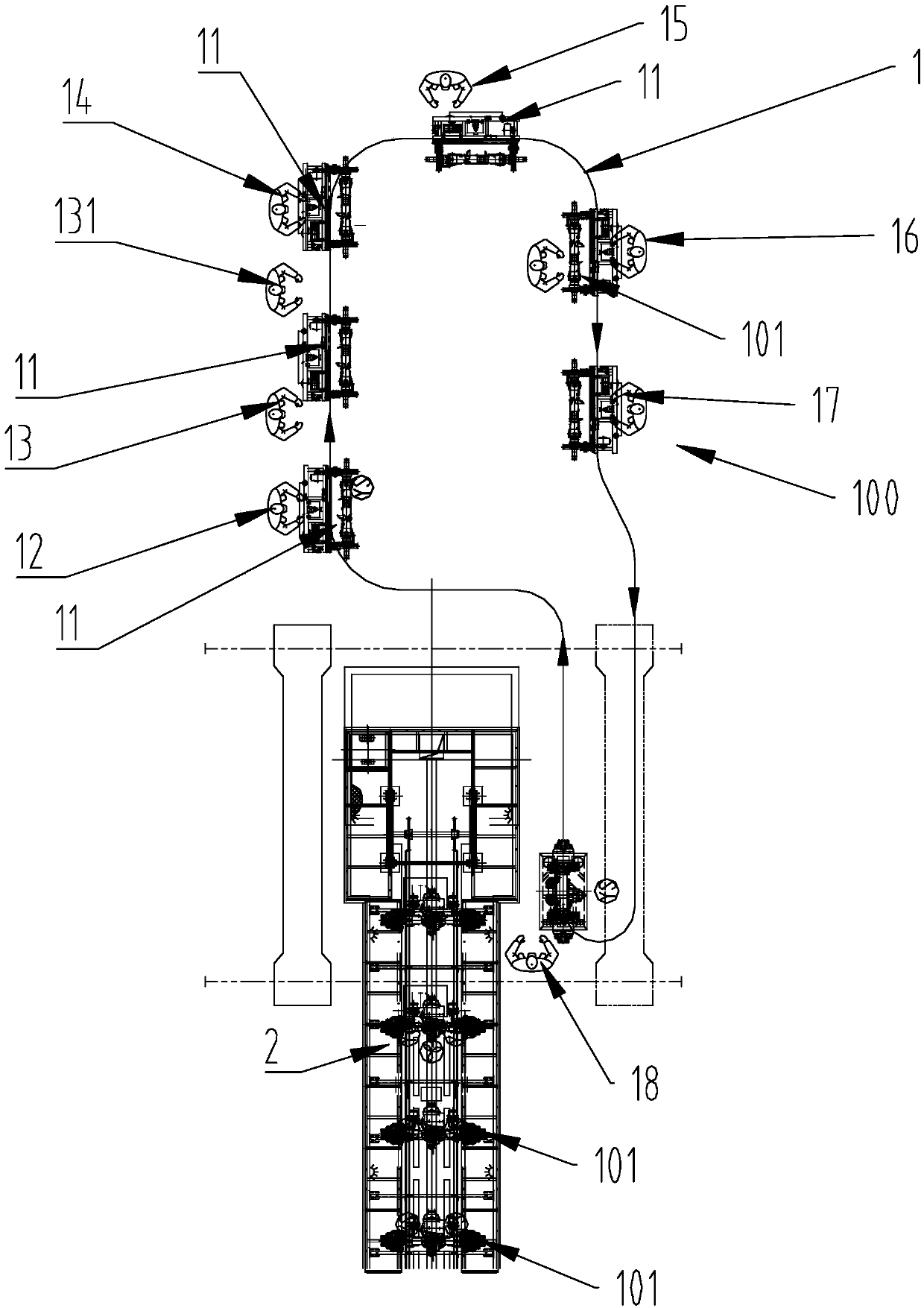

Three-jig efficient transferring device and method for assembling charging connector

InactiveCN109732344AEasy loading and unloadingImprove work efficiencyAssembly machinesWork in processEngineering

The invention relates to the field of production and manufacturing of a charging plug, and in particular to a three-jig efficient transferring device and method for assembling a charging connector. The three-jig efficient transferring device for assembling a charging connector comprises a robot arm conveying device, a clamping shell jig transferring device, a first conveying device, a base jig flow returning device, a second conveying device, a riveting jig transferring device and a third conveying device. The clamping shell jig transferring device is used for circulation transferring of a clamping shell jig, the riveting jig transferring device is used for circulation transferring of a riveting jig, and the base jig flow returning device is connected with the clamping shell jig transferring device and the riveting jig transferring device. The above three-jig efficient transferring device is convenient for loading and unloading of the jigs, improves the work efficiency, optimizes the work flow, and adapts to the processing mode of assembling into semi-finished products with workpieces and then assembling the semi-finished products into finished products.

Owner:李琼

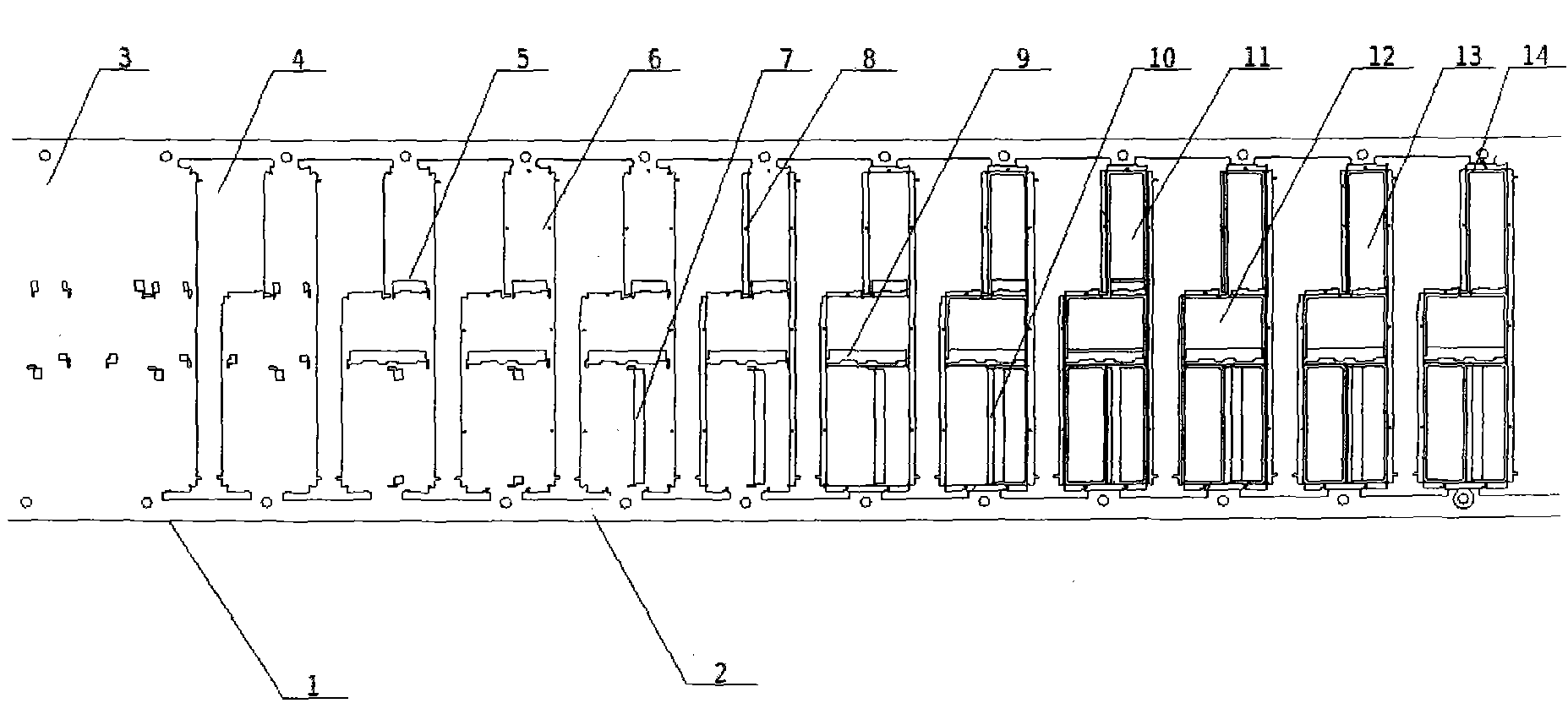

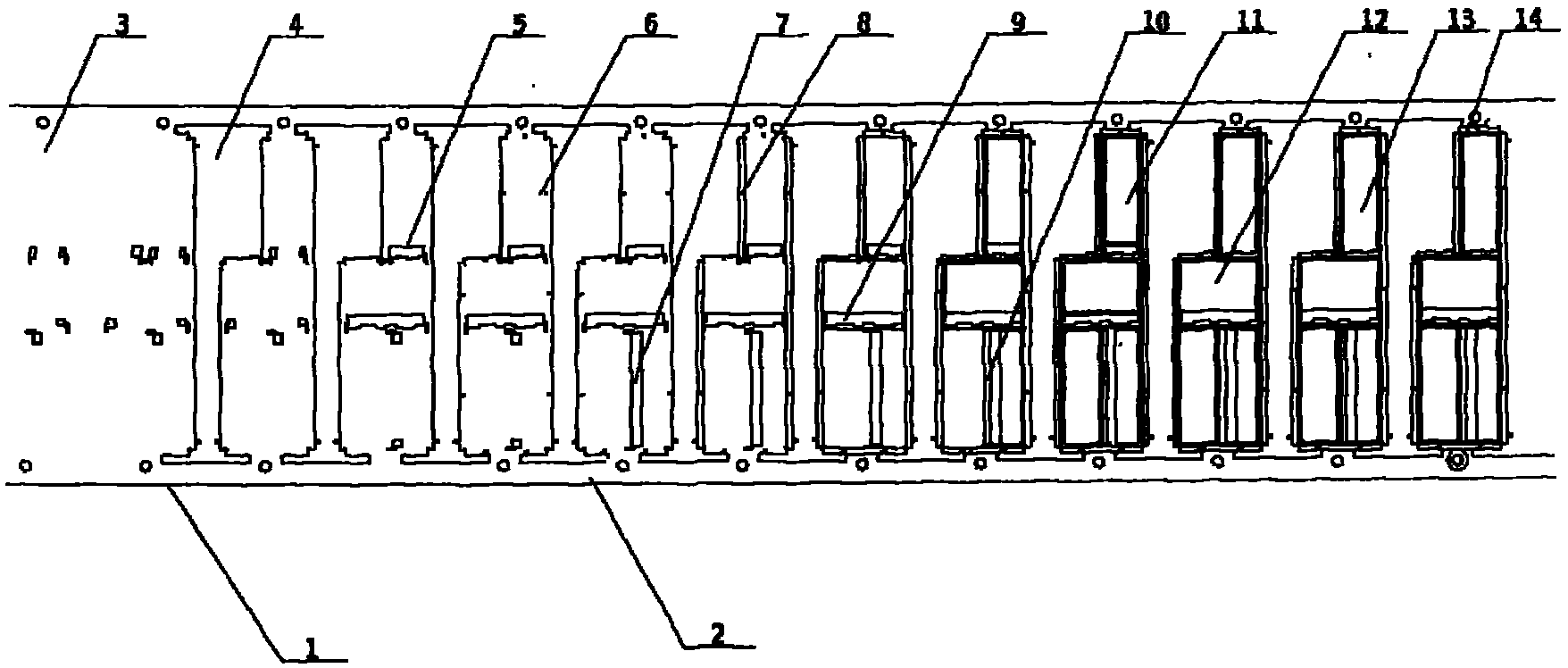

Process for producing shielding case

InactiveCN101856699APrecision structureImprove shielding effectShaping toolsMagnetic/electric field screeningPunch pressEngineering

The invention discloses a process for producing a shielding case. The process sequentially comprises the following steps of: connecting a punch press with a lower die base fixedly, and then connecting the other side of the lower die base with a lower plate fixedly; then sequentially arranging a pre-punching module, a flashing module, a middle punching module, a bump beating module, a bottom punching module, a three-edge flanging module, a one-edge flanging module, a two-edge flanging module, an upper punching hole module, a hollow module, a levelling block and a two-edge shearing and bending module on the lower plate; placing a raw material on the lower plate, and then operating the machine; and processing the raw material by the pre-punching module, the flashing module, the middle punching module, the bump beating module, the bottom punching module, the three-edge flanging module, the one-edge flanging module, the two-edge flanging module, the upper punching hole module, the hollow module, the levelling block and the two-edge shearing and bending module sequentially to obtain the shielding case finished product. The process has the advantages of high production efficiency, and high planeness and quality of the product.

Owner:KUNSHAN ZHENHE MOLD HARDWARE MACHINERY

Automatic coiling and welding integrated machine

PendingCN111975361AEasy to operateCompact structureOther manufacturing equipments/toolsButt jointMachine

The invention discloses an automatic coiling and welding integrated machine which comprises a roller conveyor line arranged on a rack, a coiling bending mechanism, a positioning welding device and a loading station, wherein the side end of the bracket of the roller conveyor line is equipped with a four-station pushing assembly; a coiling bending mechanism which is opposite to the pushing assemblyin a one-to-one mode is arranged on the rack; the rear end of the coiling bending mechanism is in butt joint to the positioning welding device; the front side of the conveying end of the roller conveyor line is equipped with a loading station; and a steel strip material box with steel strips and a loading worker are on the loading station. In this way, the automatic coiling and welding integratedmachine is compact in structure, is stable in operation, can integrate transporting, double-sided coiling bending, assembling and welding, is high in processing efficiency, is more convenient in operation by staff, is safer, and is relatively stable in quality.

Owner:江苏酉立智能装备股份有限公司

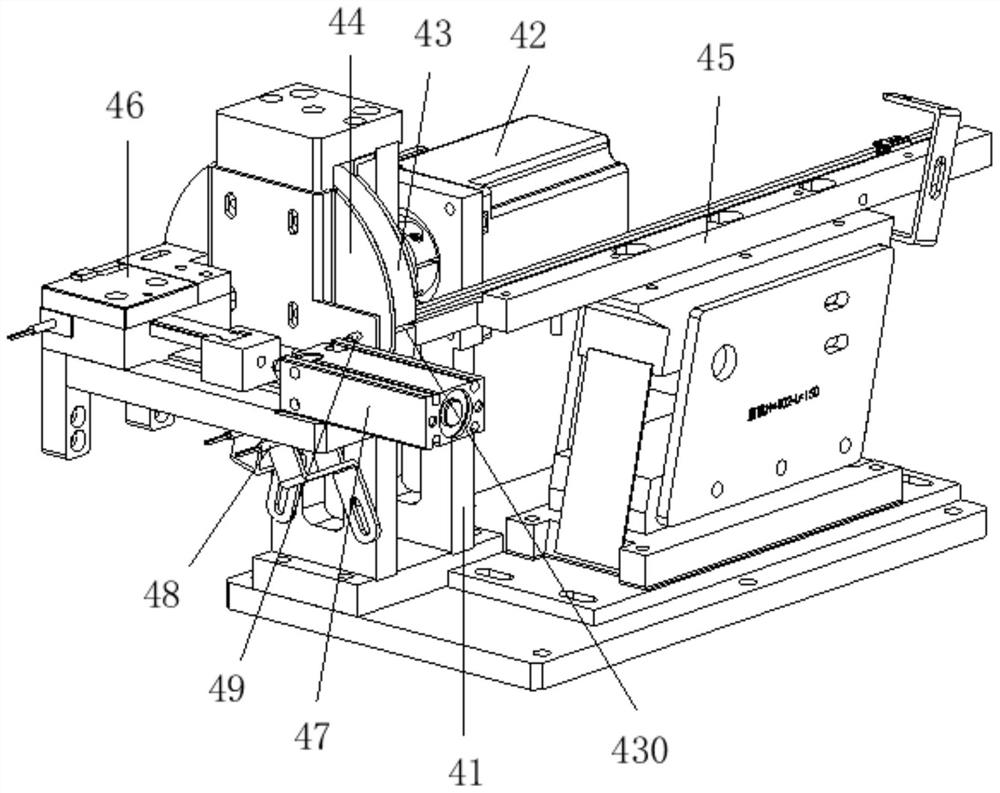

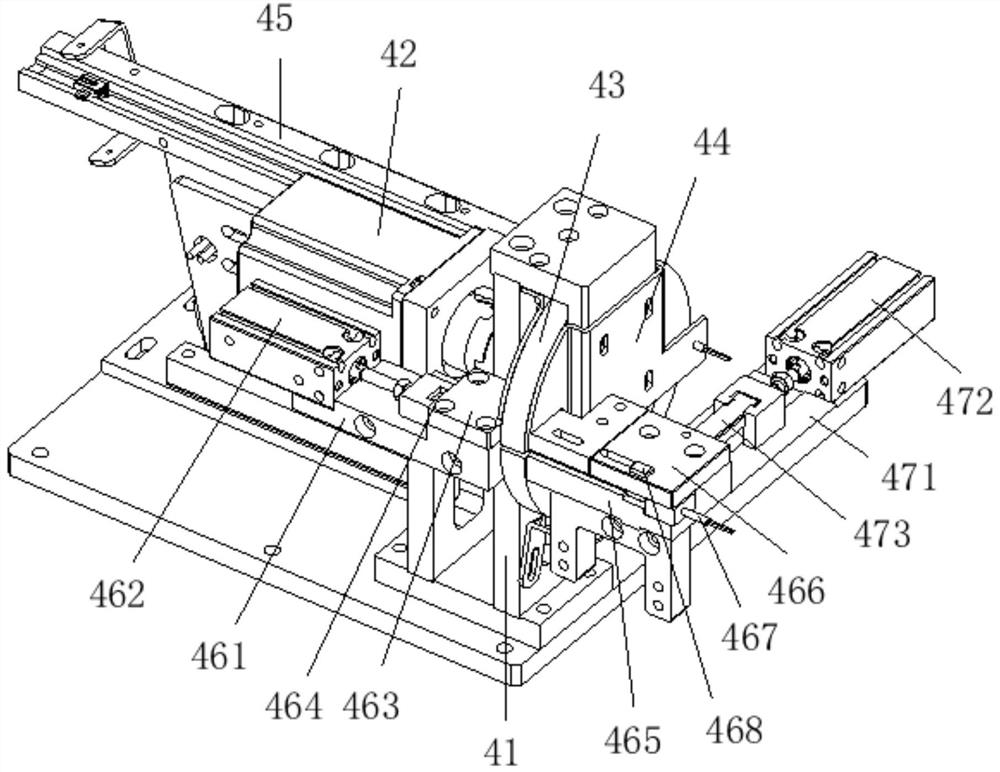

Automatic assembly equipment and method of miniature capacitor set

InactiveCN110600281AControllable clamping forceImprove quality and pass rateCapacitor manufactureCapacitanceEngineering

The invention relates to the technical field of production and manufacturing of circuit components. The automatic assembly equipment of the miniature capacitor set in the invention comprises a machineframe, a capacitor feeding device, a capacitor carrying device, a capacitor base feeding device and an elbow device; the capacitor feeding device, the capacitor carrying device, the capacitor base feeding device and the elbow device are installed on the machine frame; the capacitor base feeding device is arranged in the middle part of the machine frame, and comprises two feeding stations; the elbow device is positioned at the side part of the capacitor base feeding device; the capacitor carrying device is positioned over the capacitor carrying device; the capacitor feeding device is installedat the side part of the machine frame; and the capacitor feeding device is positioned at the side part of the elbow device. The automatic assembly equipment of the miniature capacitor set in the invention has the advantages of being automatic to assemble, effective to produce and high in success rate.

Owner:何国标

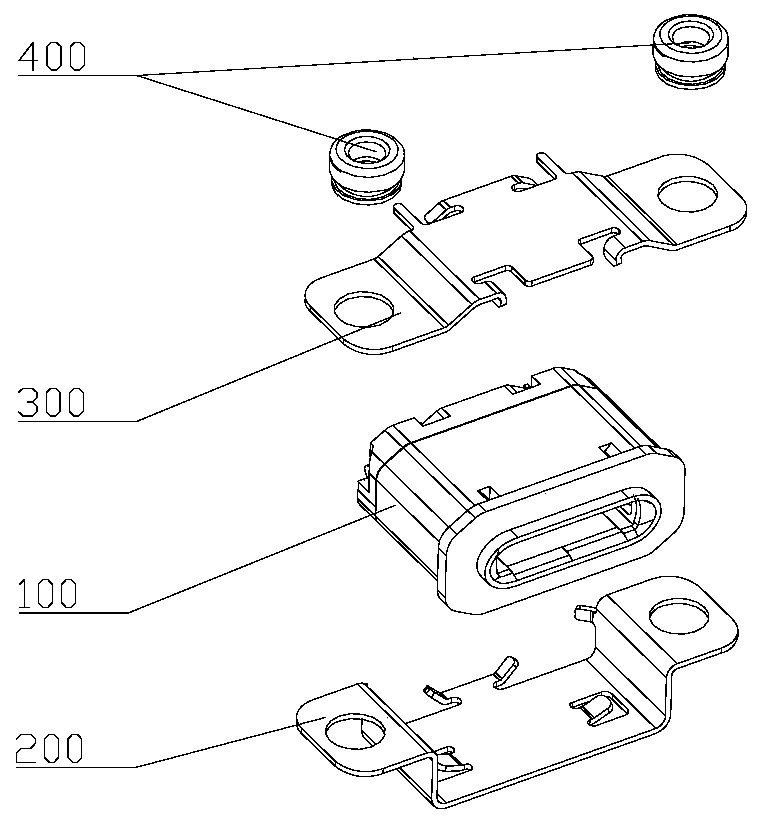

Novel automatic assembling equipment for power supply socket

PendingCN112072444ACompact structureGuaranteed uptimeContact member assembly/disassemblyStructural engineeringMachining

The invention discloses novel automatic assembling equipment for a power supply socket. The novel automatic assembling equipment comprises a rack, a linear machining flow channel, a rubber core vibration disc, a rotary overturning and staggering mechanism, a pin mechanism, a terminal discharging device, material sweeping belt structures and an assembling and testing mechanism, wherein the linear machining flow channel is arranged on the rack; the rubber core vibration disc is arranged on the left side of the linear machining flow channel and is conveyed to the linear machining flow channel through the rotary overturning and staggering mechanism; the pin mechanism is arranged on the rear side of the linear machining flow channel and comprises a positive terminal, a center pin and a negativeterminal pin; the terminal discharging device in butt joint with the rear side terminal of the pin mechanism is arranged on the rear side terminal; the next station of each terminal pin is provided with one material sweeping belt structure; and the right side of the linear processing flow channel is provided with the assembling and testing mechanism in a butt joint manner. By means of the mode, the novel automatic assembling equipment is compact in structure, stable in operation, capable of automatically assembling, detecting and classifying power sockets and high in assembling efficiency.

Owner:SUZHOU E CONN TECH

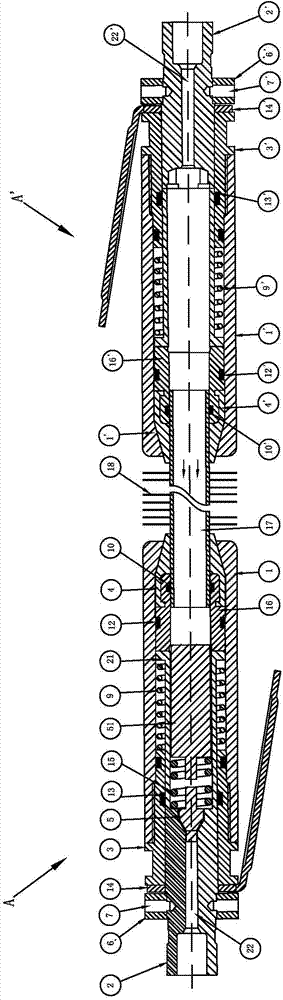

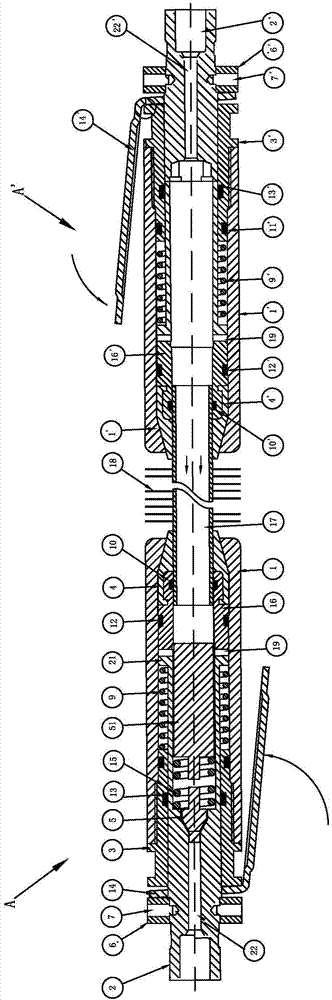

Tube expanding device of tube expander

ActiveCN104289611AUniform pressureGuaranteed stabilityHeat exchange apparatusInlet channelEngineering

The invention relates to the technology of tube expanding, in particular to a tube expanding device of a tube expander. The tube expanding device is composed of a liquid inlet part and a fixing seat, and the liquid inlet part and the fixing seat are each provided with a clamping mechanism, In the tube expanding process, the clamping mechanism of the liquid inlet part is fixedly connected with one end of an expanded metal tube in a sealed mode, and the clamping mechanism of the fixing seat is fixedly connected with the other end of the expanded metal tube in a sealed mode. The liquid inlet part and the fixing seat comprise cylindrical actuating rods respectively, an axial liquid inlet channel is arranged in the outer side part of the actuating rod of the liquid inlet part, and an axial exhaust channel is arranged in the outer side part of the actuating rod of the fixing seat. The actuating rod is sleeved with an end cover and is in sliding fit with the end cover. The outer end of the end cover is in threaded fit with the outer end of a cylindrical shell, and flangings are arranged at the inner ends of the actuating rods. The inner side part of the actuating rod of the fixing seat is made to be in a hollow shape, can contain a one-way valve structure and is communicated with the exhaust channel through a one-way valve. According to the tube expanding device, residual air in the expanded tube is exhausted from the exhaust channel, so that the pressure in the expanded tube is even; a tapered clamping head can be automatically locked, the structure is simple, and operation is convenient.

Owner:ZHEJIANG DAYANG SEWING MACHINE

Shielding case progressive die

ActiveCN101869945AFast productionPrecision structureShaping toolsMagnetic/electric field screeningProduction rateEngineering

The invention discloses a shielding case progressive die, which comprises an upper die base, an upper baffle, a lower template, and a lower die base. A pre-punching module, a flash module, a middle punching module, a projection point module, a bottom punching module, a trilateral folding module, one-side folding module, two-side folding module, an upper punching module, an idle module, a leveling block, and a two-side shearing module are arranged on the lower template in turn. An upper base plate, the upper baffle, a striper plate, and the lower template are arranged between the upper die base and the lower die base in turn; an auxiliary leveling block is arranged on the striper plate and corresponds to the leveling block on the lower template. A guide post is arranged in the upper baffle in a penetrating mode; a guide sleeve which corresponds to the guide post is arranged in the lower template; an isoheight sleeve is arranged on the upper die base; a delivery error resistant device is arranged inside the upper die base; a spring is arranged between the upper base plate and the upper baffle; and a lifter pin is arranged on the lower die base. The shielding case progressive die has the advantages of higher production rate, better product quality, better product flatness, and higher production safety.

Owner:KUNSHAN ZHENHE MOLD HARDWARE MACHINERY

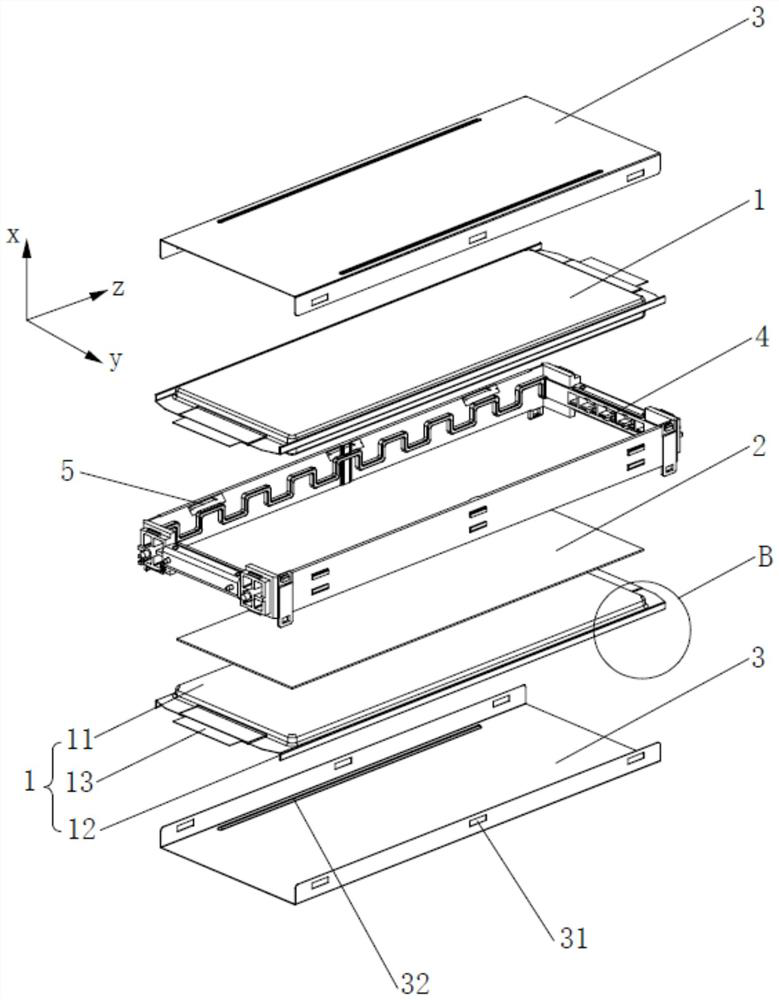

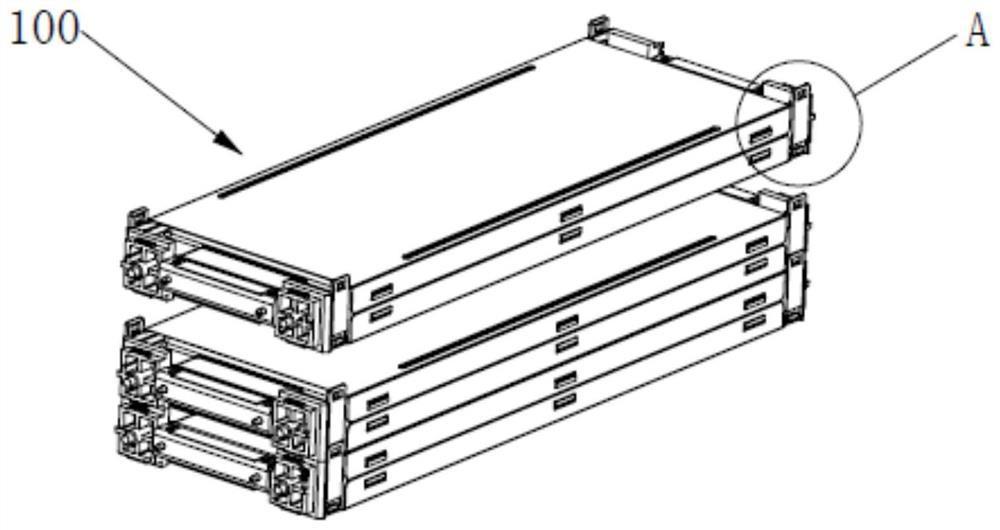

Battery core stacking module and soft package battery module

PendingCN112259868AImprove installation stabilityImprove connection reliabilitySecondary cellsCell component detailsPower batteryStructural engineering

The invention discloses a battery core stacking module and a soft package battery module, and belongs to the technical field of power batteries. The battery core stacking module comprises a pluralityof battery core stacking assemblies which are stacked in a first direction, wherein each battery core stacking assembly comprises a single battery core, a heat dissipation piece and a rubber frame assembly, the single battery cores are stacked in the first direction, the heat dissipation piece is arranged on the single battery core and is connected with the single battery core to form a combined battery core, the rubber frame assemblies are arranged around the single battery cores in a surrounding manner and are connected with the combined battery cores, and the rubber frame assembly of one battery core stacking assembly is connected with the rubber frame assembly of the other battery core stacking assembly. The battery core stacking module and the soft package battery module are good in installation stability and connection reliability, high in assembly precision and good in heat dissipation performance.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

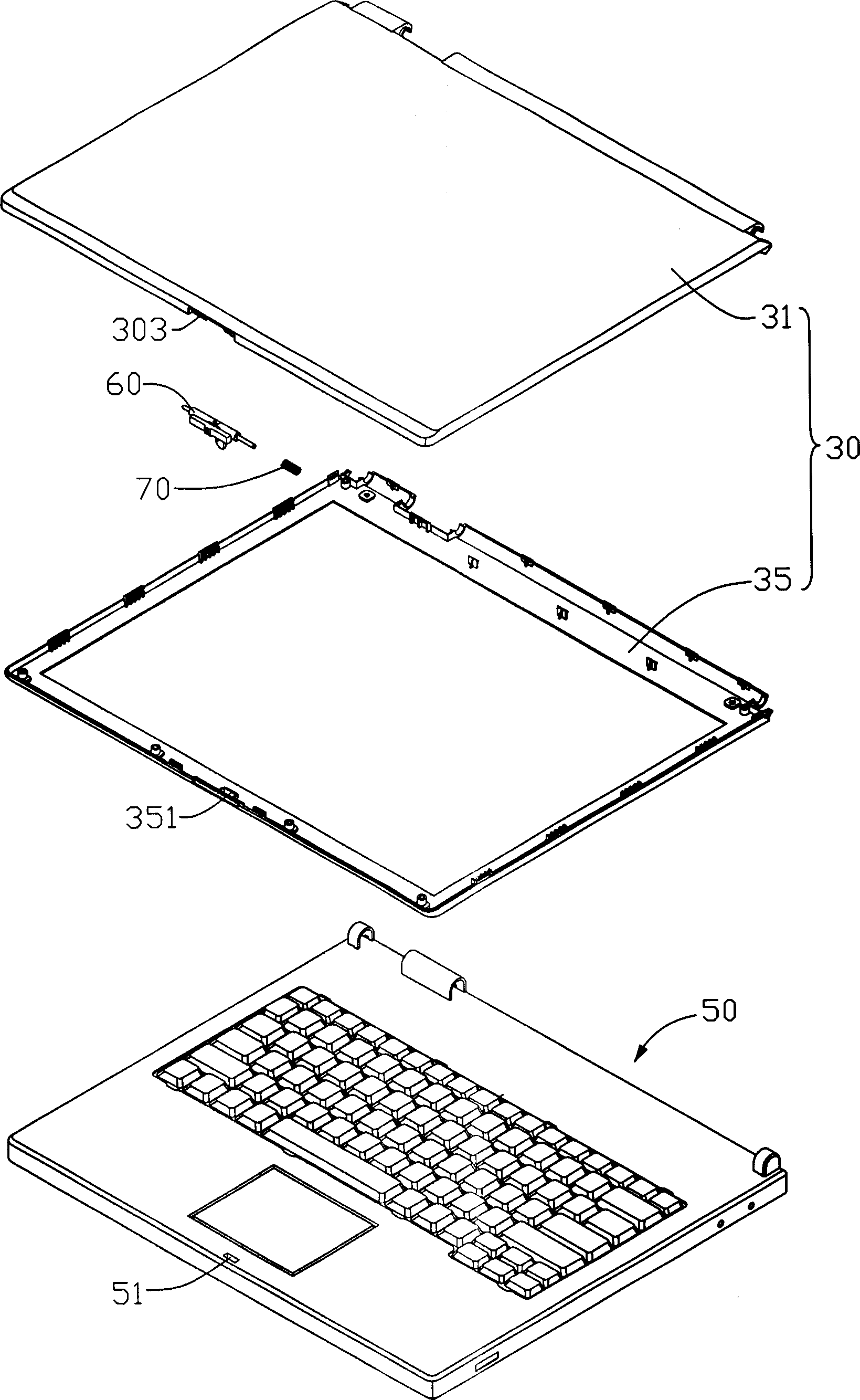

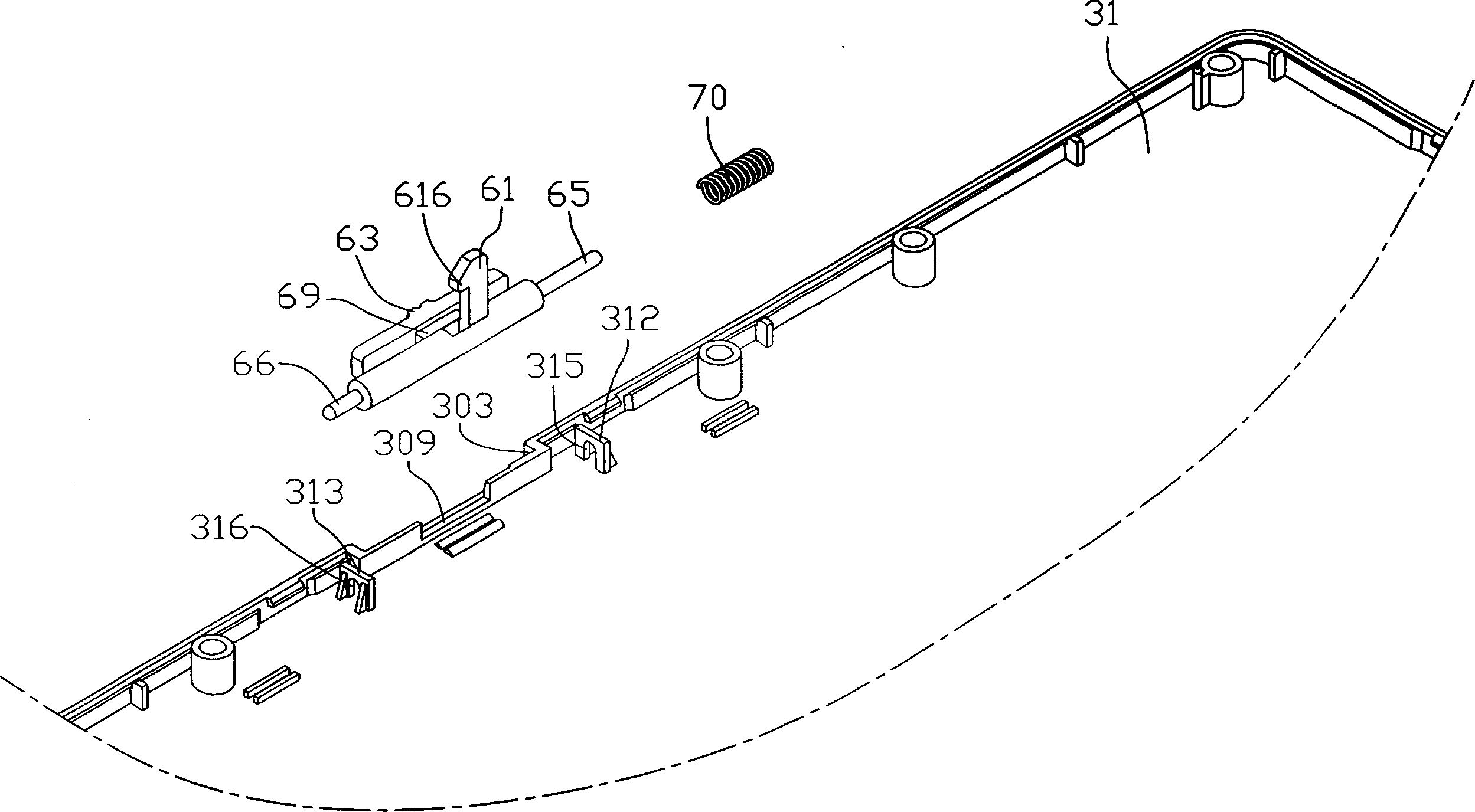

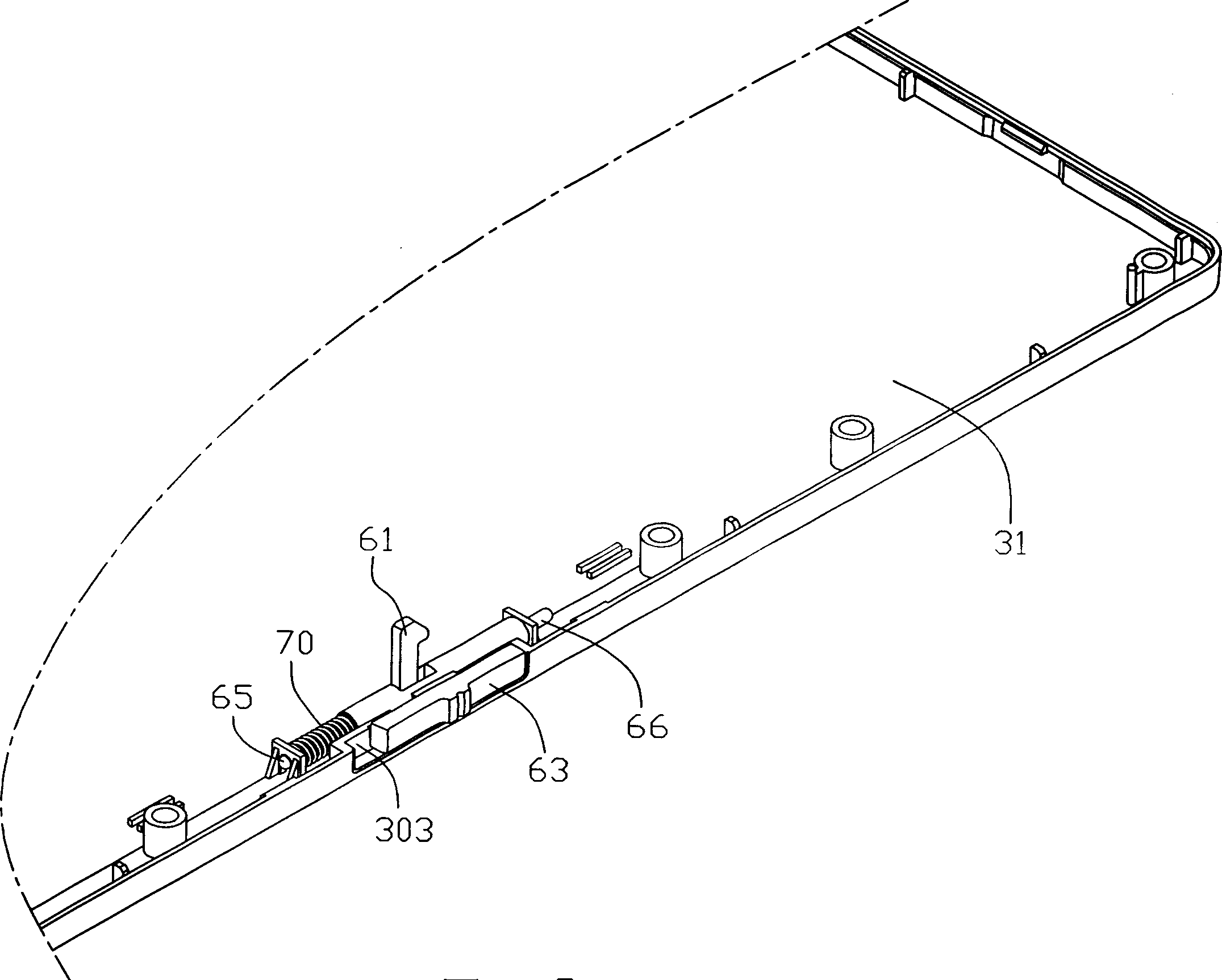

Notebook computer upper cover locking device

InactiveCN1841260ASimple structureReduce volumeDetails for portable computersEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

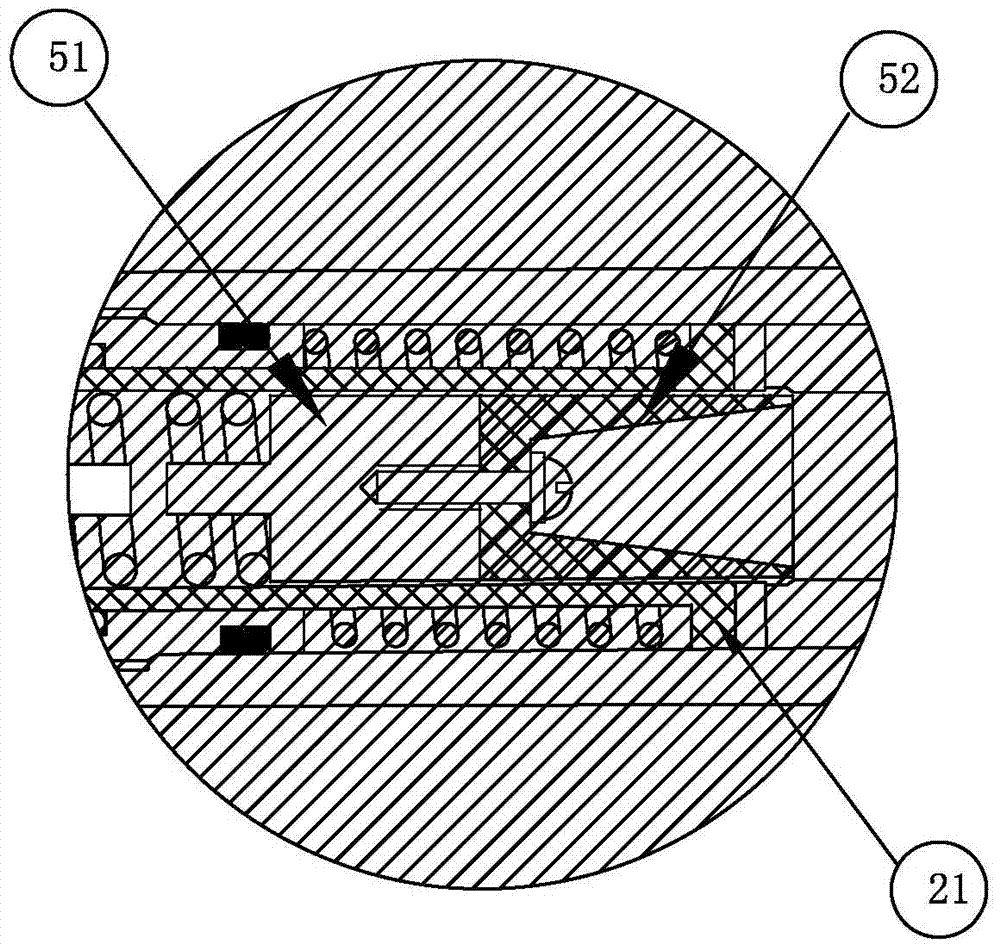

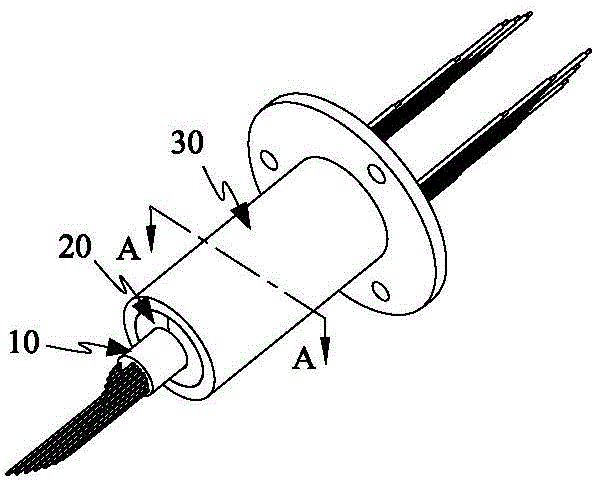

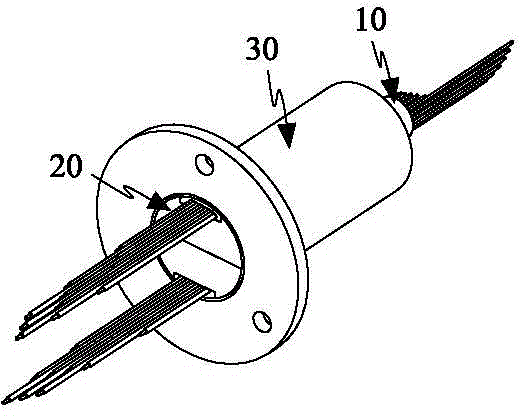

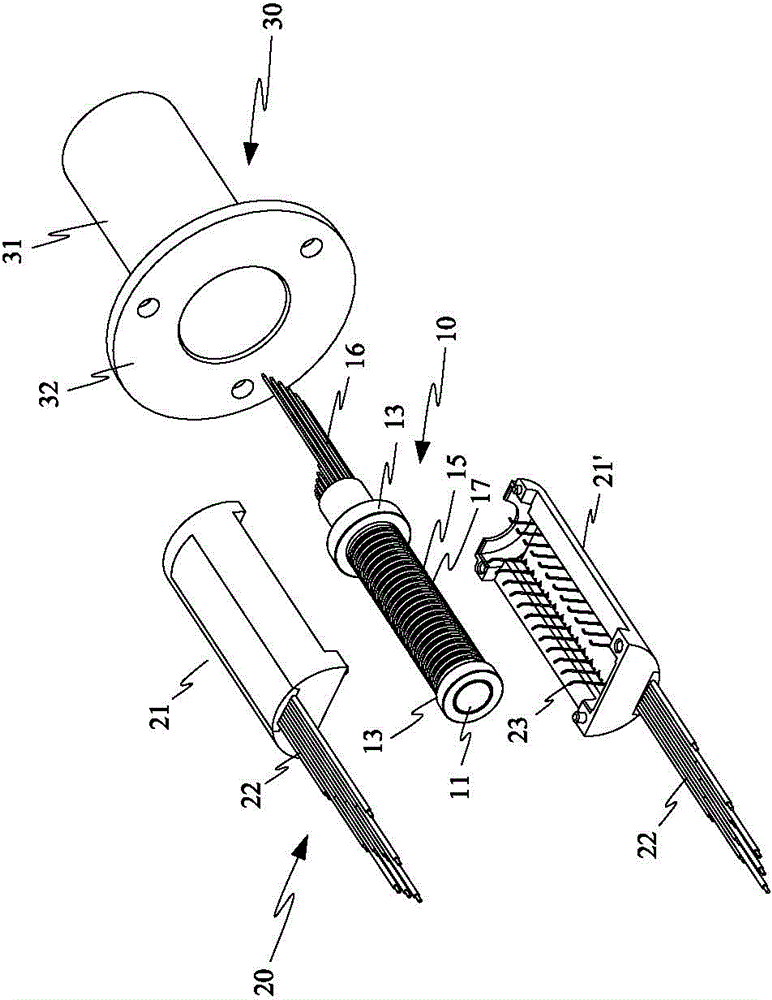

Conductive slip ring

The invention discloses a conductive slip ring which comprises a rotor assembly, a stator assembly and a housing, wherein the stator assembly covers the rotor assembly; and the housing is arranged outside the stator assembly in a sleeving manner. The rotor assembly rotates relative to the stator assembly, so that signal transmission is achieved, and the problem of incapable rotation and twisting of the traditional through-type cable during transmission is solved. The rotor assembly comprises a shaft core, a distributing board, a plurality of conductive rings and a plurality of inner ring leads, wiring grooves are uniformly formed axially at the periphery of the shaft core, and limiting grooves are uniformly formed at the periphery of the distributing board, so that the inner ring leads are distributed in the wiring grooves and the limiting grooves in a one-to-one correspondence manner. Wiring is very concise and easy; disalignment does not exist after wiring; looseness is not easy; positioning is good; stable signal transmission is ensured; next assembling and forming are facilitated; the assembling time is saved greatly; and the assembling efficiency is improved.

Owner:DONGGUAN TECONN ELECTRONICS TECH CO LTD

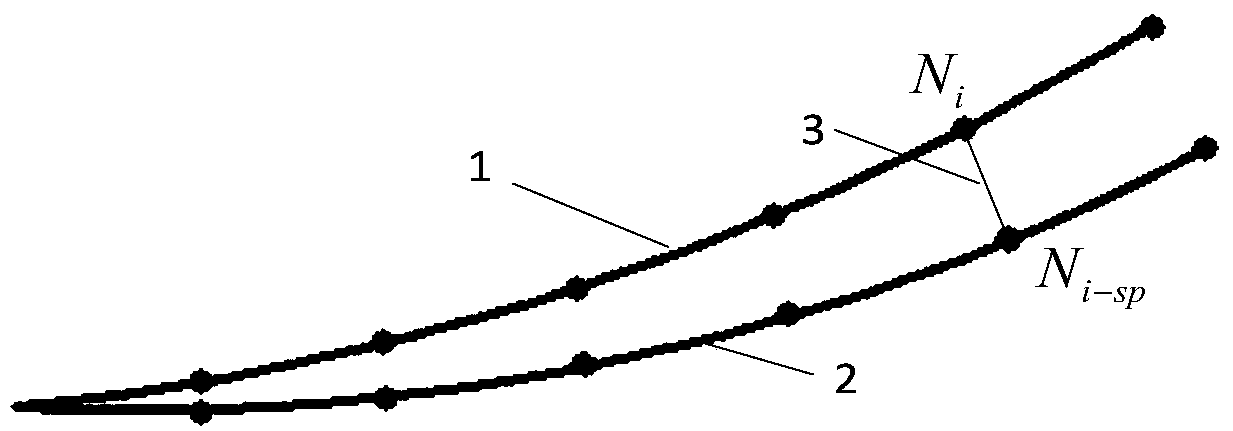

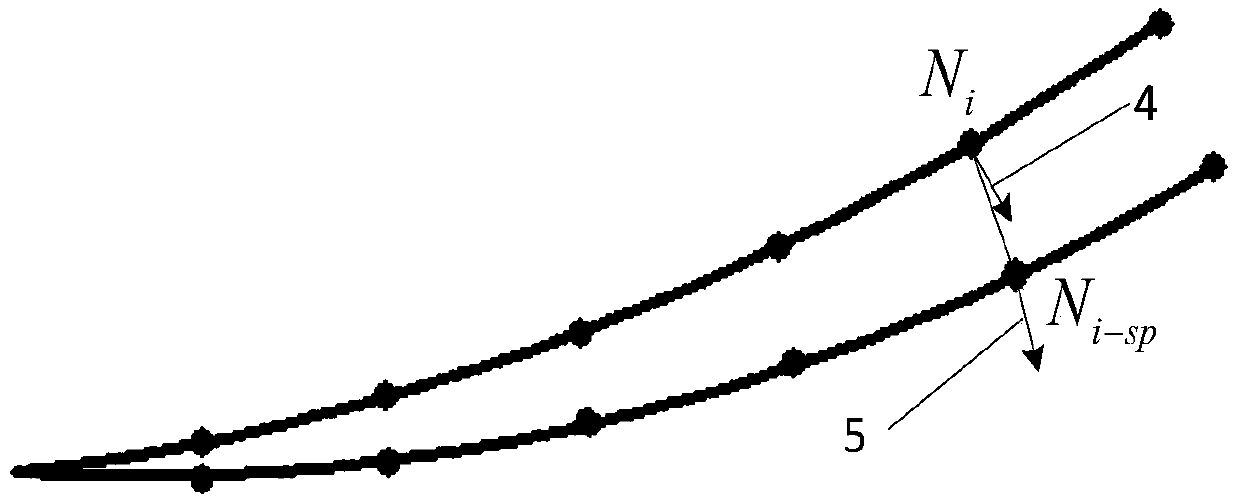

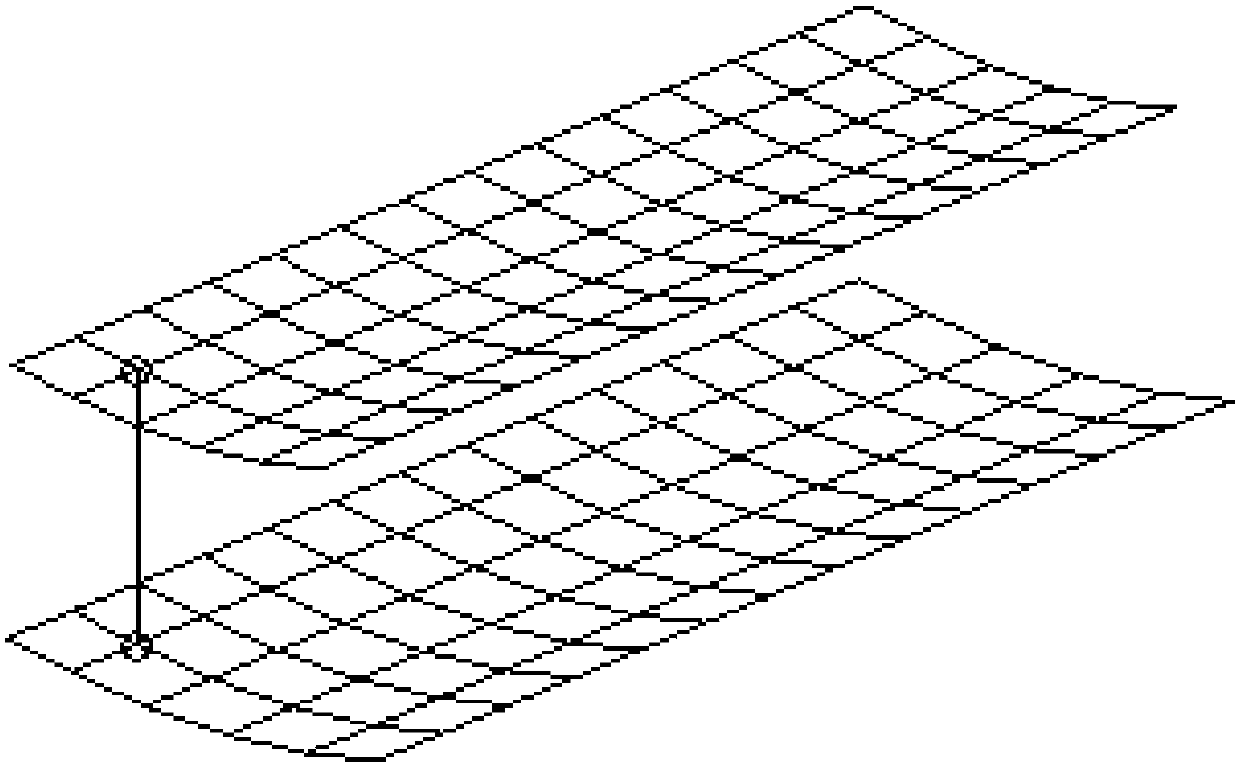

Construction method of springback compensation grid models

InactiveCN108595886AGood part shape accuracyGuaranteed position accuracyDesign optimisation/simulationSpecial data processing applicationsLine segmentElement analysis

The invention discloses a construction method of springback compensation grid models. Finite-element analysis is used as a means to obtain grid models before and after springback through springback simulation calculation, and springback path relationships of nodes are constructed through a manner of corresponding-node line connection; then normal vectors of each corresponding node on the grid models before and after springback are calculated, and normal vectors and line segments of a grid model after springback are translated onto corresponding nodes of a grid model before springback, and anincluded angle of two normal vectors and a constructed plane are calculated; and then translated the normal vectors and line segments are rotated until the same coincide with the normal vectors of thenodes on the grid model before springback, and currently endpoints of the line segments are compensation nodes of solving. According to the method, reverse compensation of the nodes is carried out by a method, of rotating springback paths according to the normal vectors of the nodes, according to the characteristics that feature forms of parts before and after springback are not changed, and only curvature of curved surfaces is changed, thus location precision of each node of springback compensation is effectively guaranteed, and precise construction of the springback compensation grid models is realized.

Owner:HUNAN UNIV

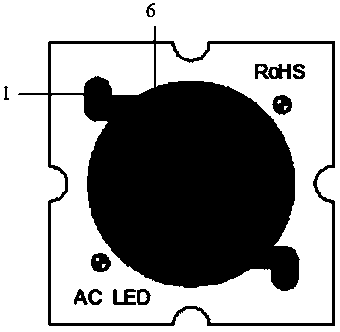

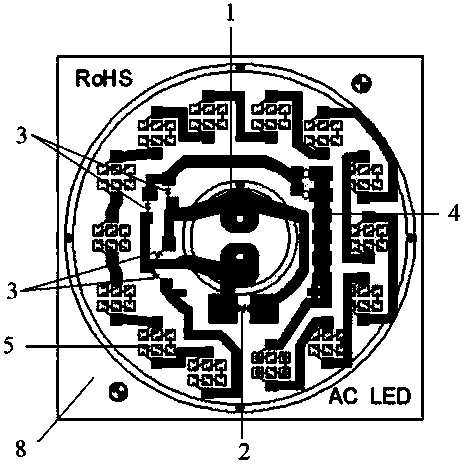

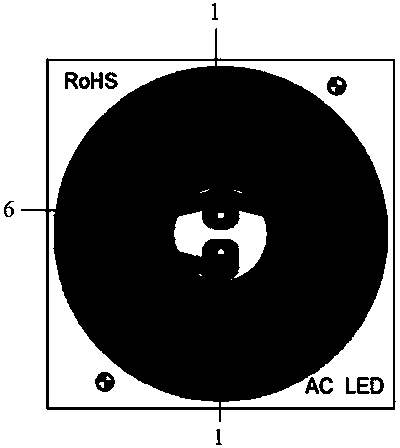

Full-chip integrated AC LED light source

InactiveCN103596339AReduce volumeImprove lighting effectsElectric light circuit arrangementElectricityEngineering

The invention relates to the illumination field, in particular to a full-chip integrated AC LED light source. The full-chip integrated AC LED light source comprises a bridge rectifier circuit, a constant current tube, multiple LED chips and a substrate. A power contract is arranged on the substrate. The input end of the bridge rectifier circuit is connected with an alternating current power supply through the power contact. The output end of the bridge rectifier circuit is electrically connected with the input end of the constant current tube. The output end of the constant current tube is electrically connected with the LED chips. The bridge rectifier circuit, the constant current tube and the LED chips are all unpacked chips and are arranged on the substrate by means of a WB technology. The substrate is an aluminum oxide ceramic substrate. According to the full-chip integrated AC LED light source, good heat dissipation performance and pressure-resistant performance can be realized, and the safety performance is more reliable.

Owner:深圳市红日光电有限公司

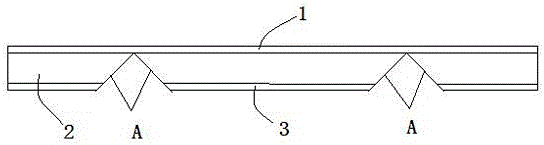

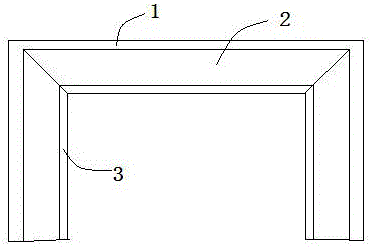

Easily assembled composite material box structure

InactiveCN106218147AWith acid and alkali corrosion resistanceScratch resistantSynthetic resin layered productsDomestic containersSurface layerEngineering

The invention relates to an easily assembled composite material box structure, and belongs to the field of box structure manufacturing. The easily assembled composite material box structure comprises a surface layer, an enhancement layer and a lining layer from the top down, wherein the surface layer is a continuous fiber reinforced thermoplastic prepreg tape, the fiber direction is vertical to the bending direction, the enhancement layer and the lining layer are arranged to be inclined planes with certain angles, and the lining layer is made of a sound and heat insulating material. The easily assembled composite material box structure disclosed by the invention has the advantages of simple and reasonable structure, light weight, high strength, good sealing property and reduced working procedure.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

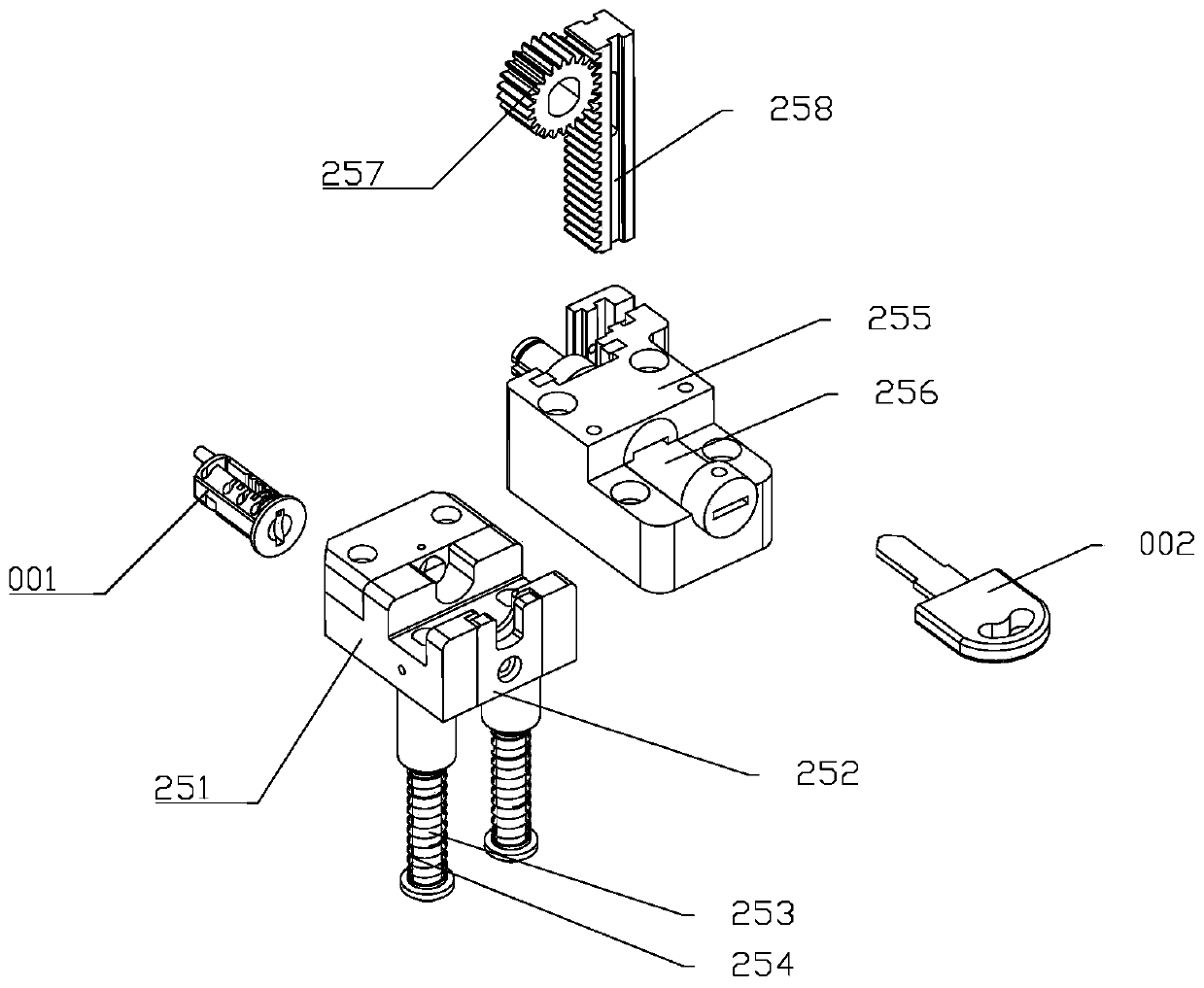

Lock plug spring and lock plate assembling machine and assembling method

InactiveCN110948198AUniqueness guaranteedEasy to adjust postureMetal working apparatusRobot handElectrical and Electronics engineering

The invention relates to the field of lock production, in particular to a lock plug spring and lock plate assembling machine. The machine comprises a rack, a rotating table jig device, a lock plug feeding device, a spring feeding device, a locking plate feeding device, a key assembling device, a detection discharging device and a key feeding manipulator, wherein the rotating table jig device is arranged in the middle of the rack, the lock plug feeding device, the key assembling device and the detection discharging device are installed on the rack, and are located on the outer side of the rotating table jig device, the spring feeding device and the locking plate feeding device are installed at a fixed part of the rotating table jig device, and the lock plug feeding device, the spring feeding device, the key feeding manipulator, the locking plate feeding device, the key assembling device and the detection discharging device are sequentially connected in the machining direction. Accordingto the machine, jig bodies for placing a lock plug and a key are arranged in a jig at the same time, so that subsequent assembly is facilitated, a specific lock plug corresponds to a specific key, one-to-one correspondence is achieved, the lock plug feeding is positioned through a positioning strip, and the correct posture of the lock plug can be ensured.

Owner:何国标

Reversing device for infusion device accessory

The invention provides a reversing device for an infusion device accessory, and belongs to the technical field of medical appliance production equipment. The reversing device solves the problem for achieving the effect of transferring the infusion device accessory from an assembling station into a clamping position. The reversing device for the infusion device accessory comprises a machine frame, wherein a first support element used for supporting the infusion device accessory is arranged on the machine frame, a first driving source used for driving the first support element to ascend and descend is also arranged on the machine frame, the reversing device also comprises a rotating driving source, a mechanical hand is respectively arranged on each rotating driving source, the mechanical hand can realize the vertical opposite position to the position of the first support element, and a driving mechanism used for driving the rotating driving source for respectively sliding in the horizontal and vertical directions is also arranged on the machine frame. The reversing device has the advantages that the infusion device accessory is supported through the first support element, a catheter is supported through a second support element, the mechanical hand can conveniently clamp the soft infusion device accessory, the steering and the moving of the infusion device accessory can be realized through a rotating air cylinder and the driving mechanism, and the subsequent assembling of an infusion device is convenient.

Owner:MAIDER MEDICAL IND EQUIP

Axle assembly assembling line

The invention discloses an axle assembly assembling line. The axle assembly assembling line includes an assembling loop line and a transport main line. A plurality of assembling stations are arrangedalong the assembling loop line, a first transport vehicle for performing the circulating movement along the assembling loop line is mounted on the assembling loop line, the first transport vehicle isused for carrying the axle assembly to sequentially transport the axle assembly to the plurality of assembling stations; a first transfer station is arranged between the transport main line and the assembling loop line, and the first transfer station is used for transferring the axle assembly assembled on the assembling loop line to the transport main line. The axle assembly assembling line can ensure that each assembling process of the axle assembly is carried out in an orderly manner, the assembling stroke of the assembling loop line is long, the spacing of each station is reasonable and does not interfere with each other, and the axle assembly can be transferred to the transport main line from the first transfer station after assembly is completed on the assembling loop line, the overall layout of the assembling line is orderly and regular, and the overall structure design is reasonable.

Owner:BEIQI FOTON MOTOR CO LTD

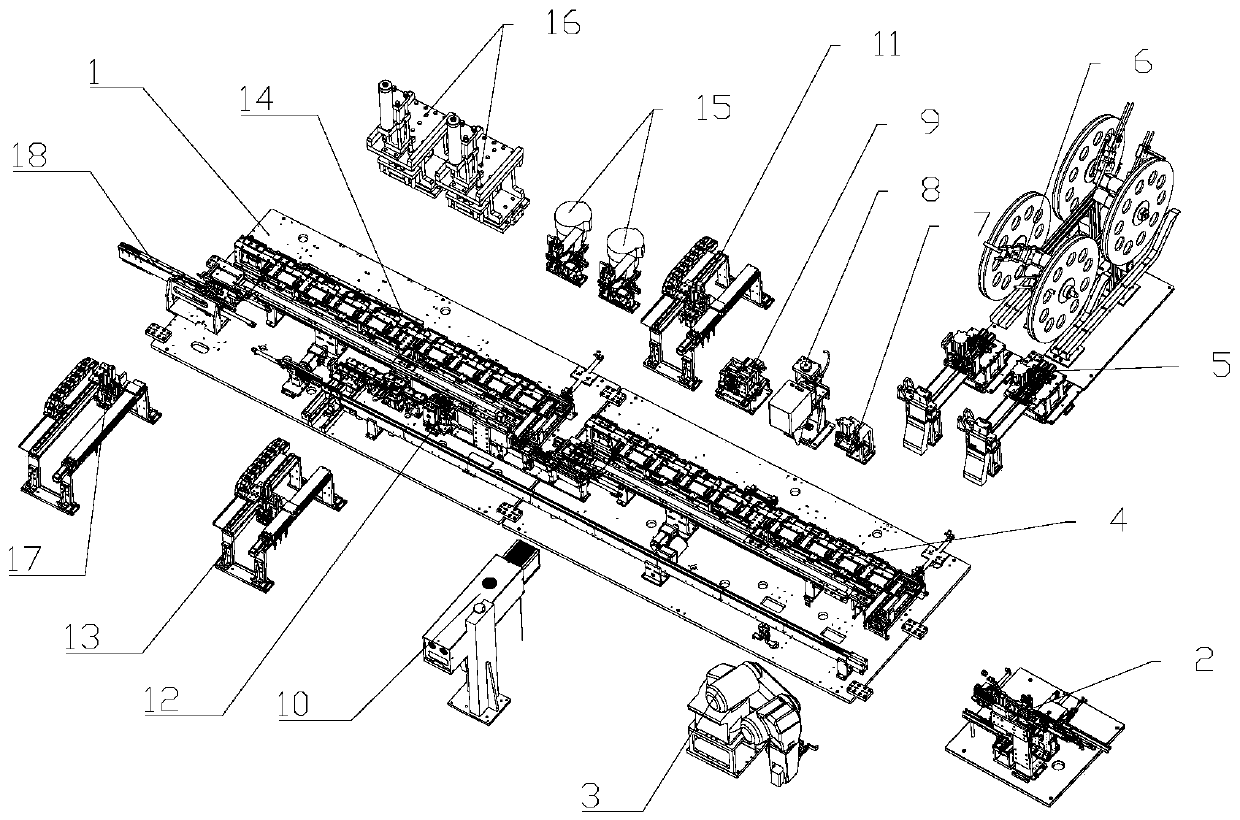

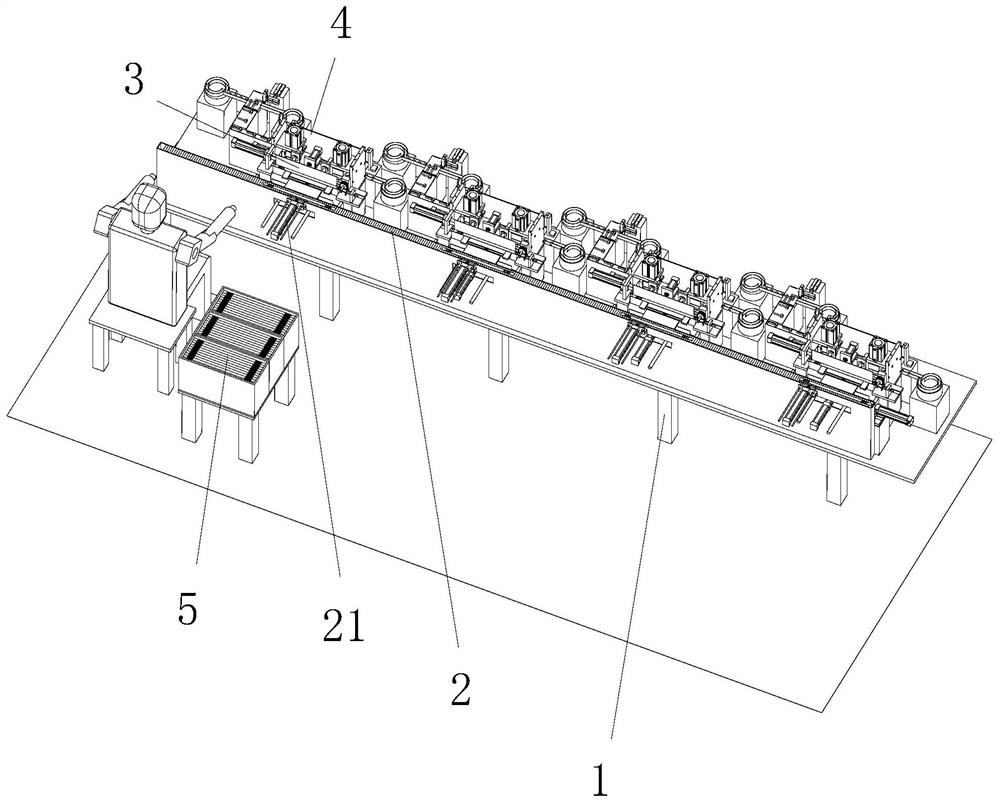

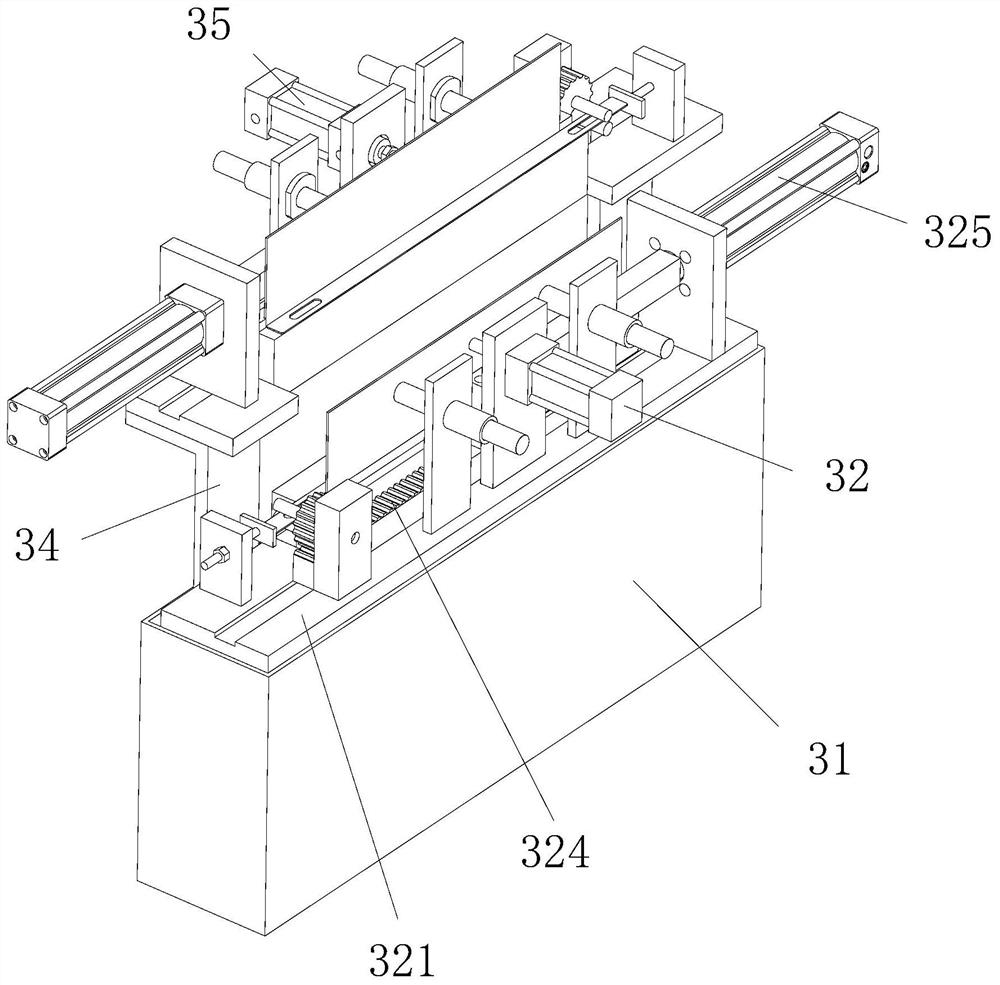

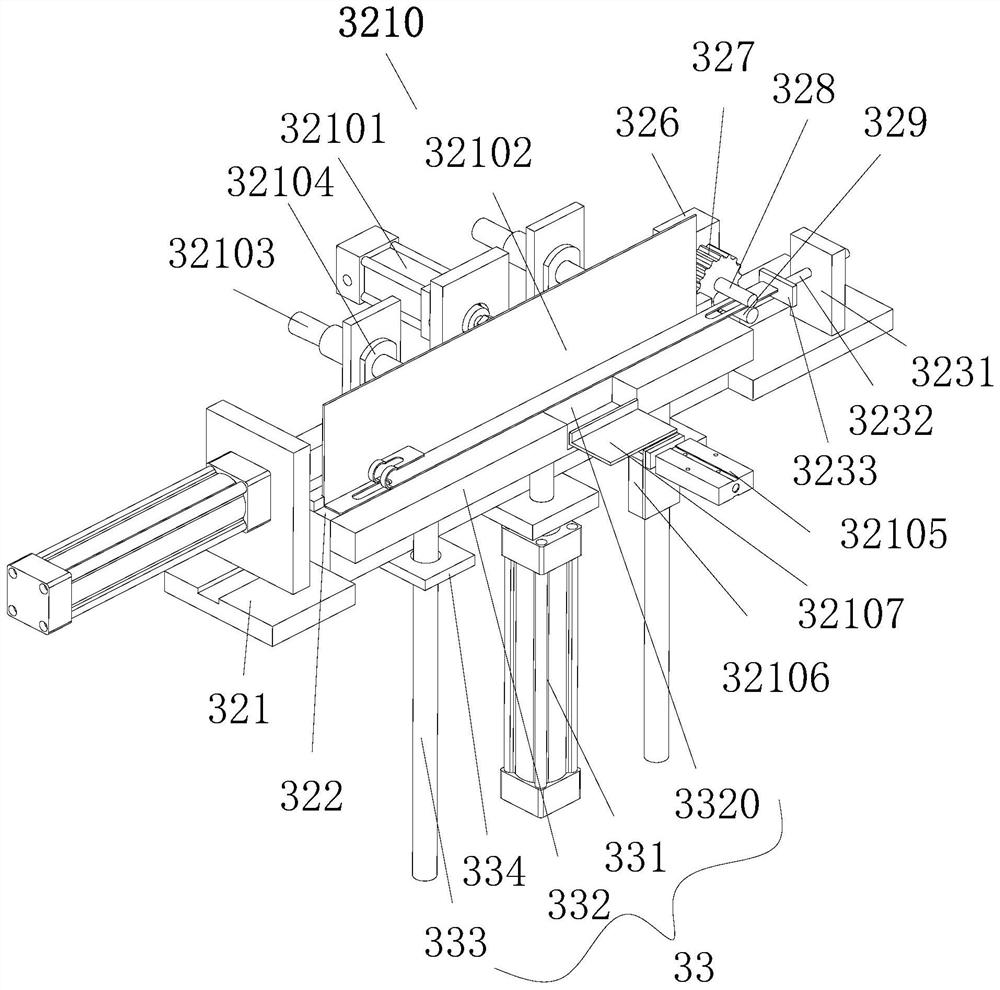

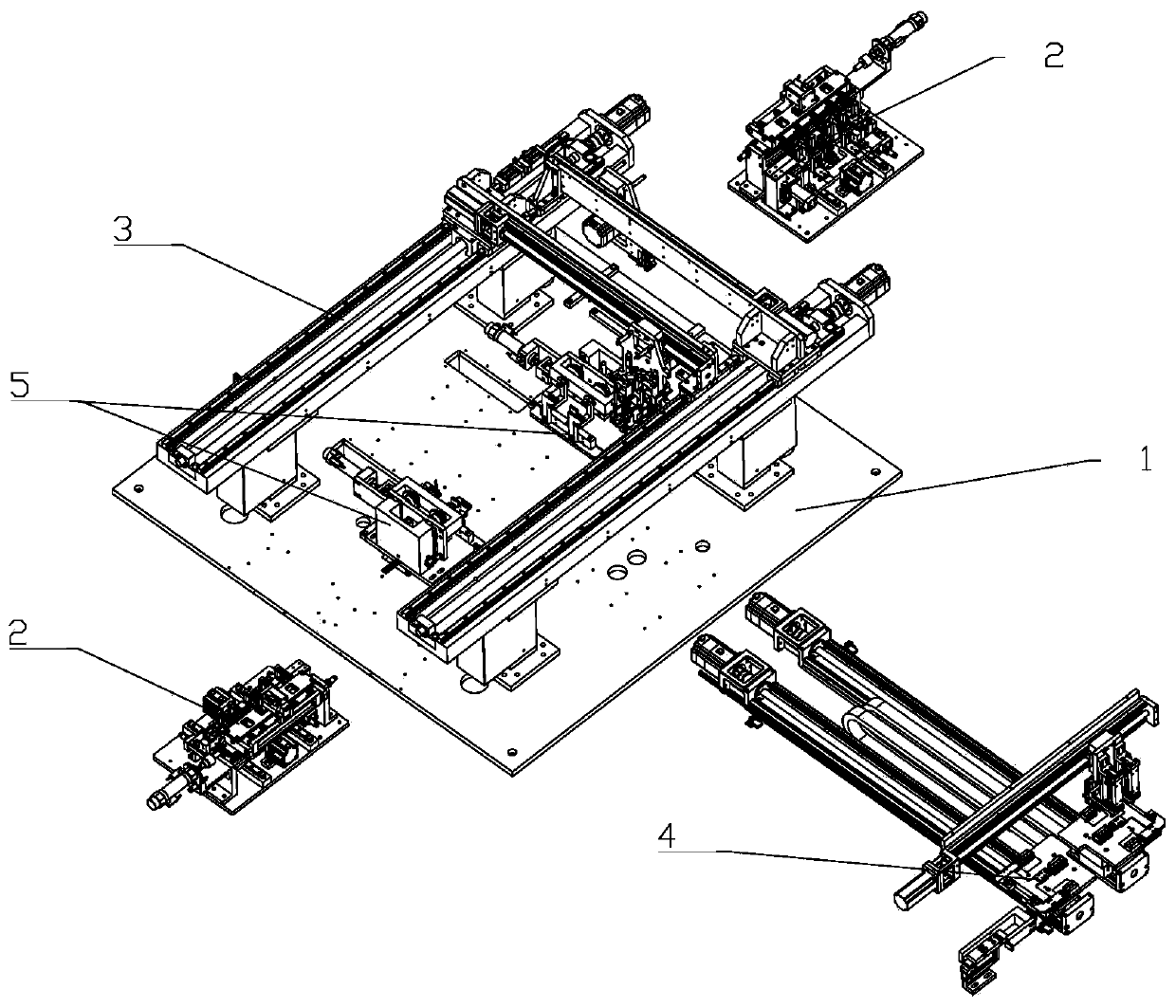

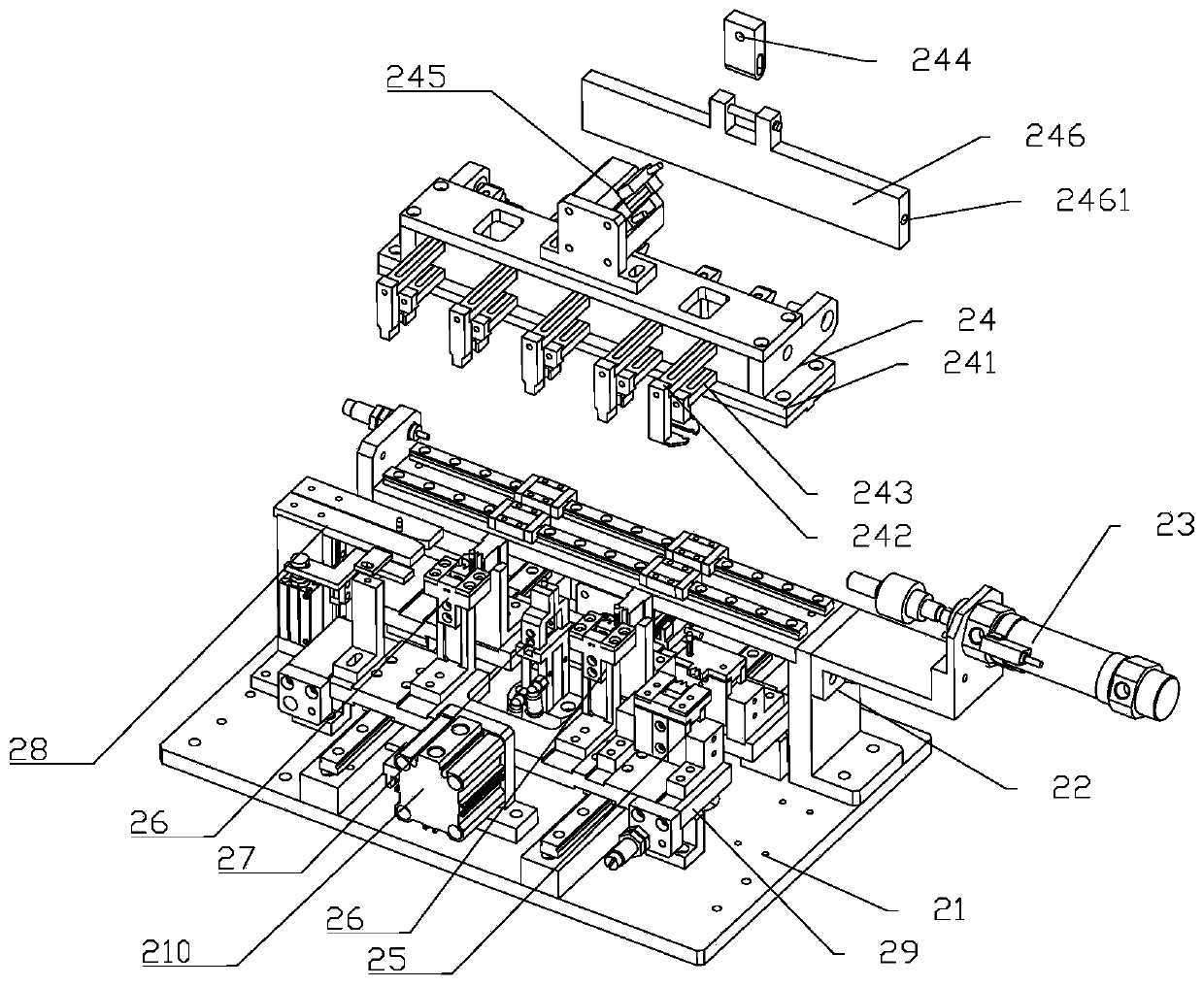

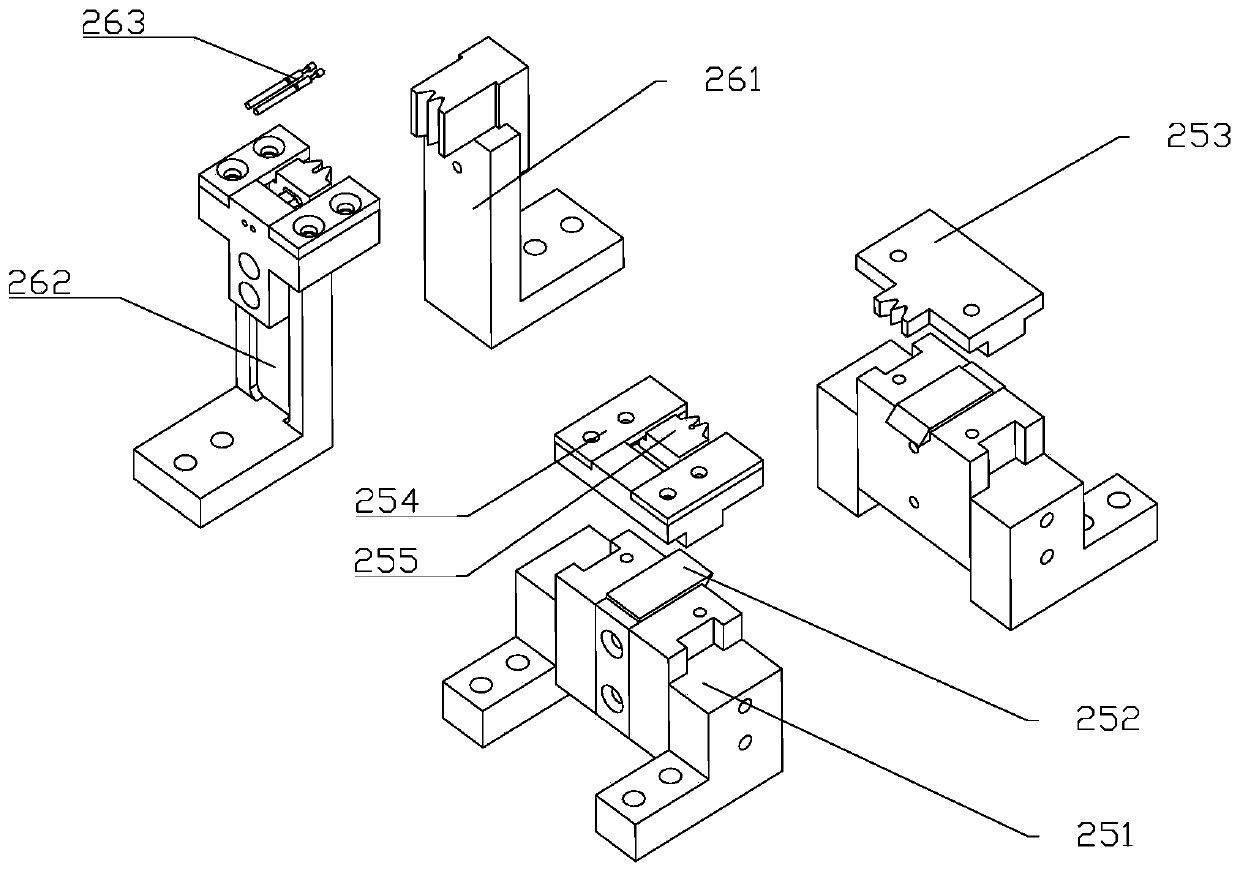

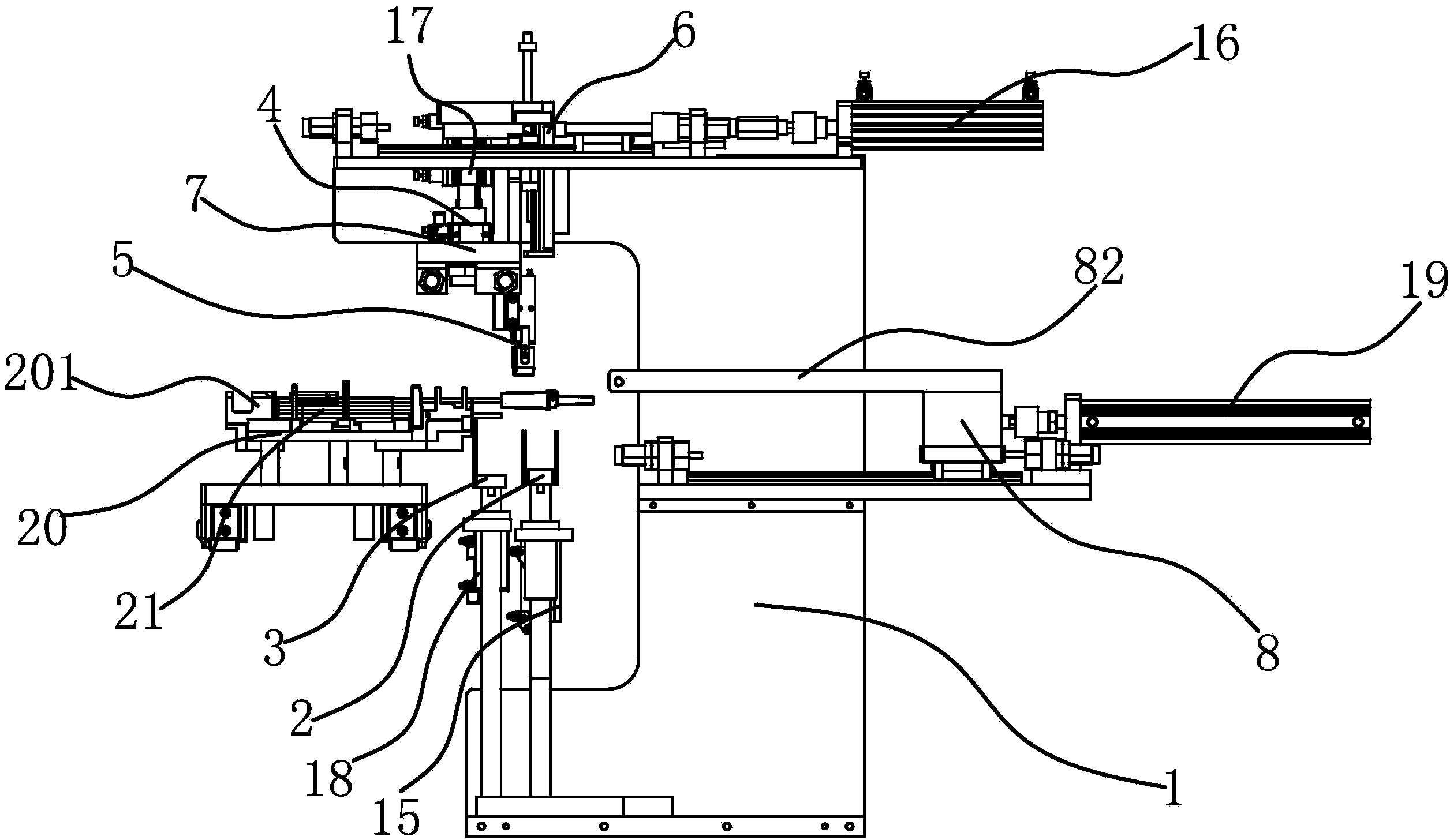

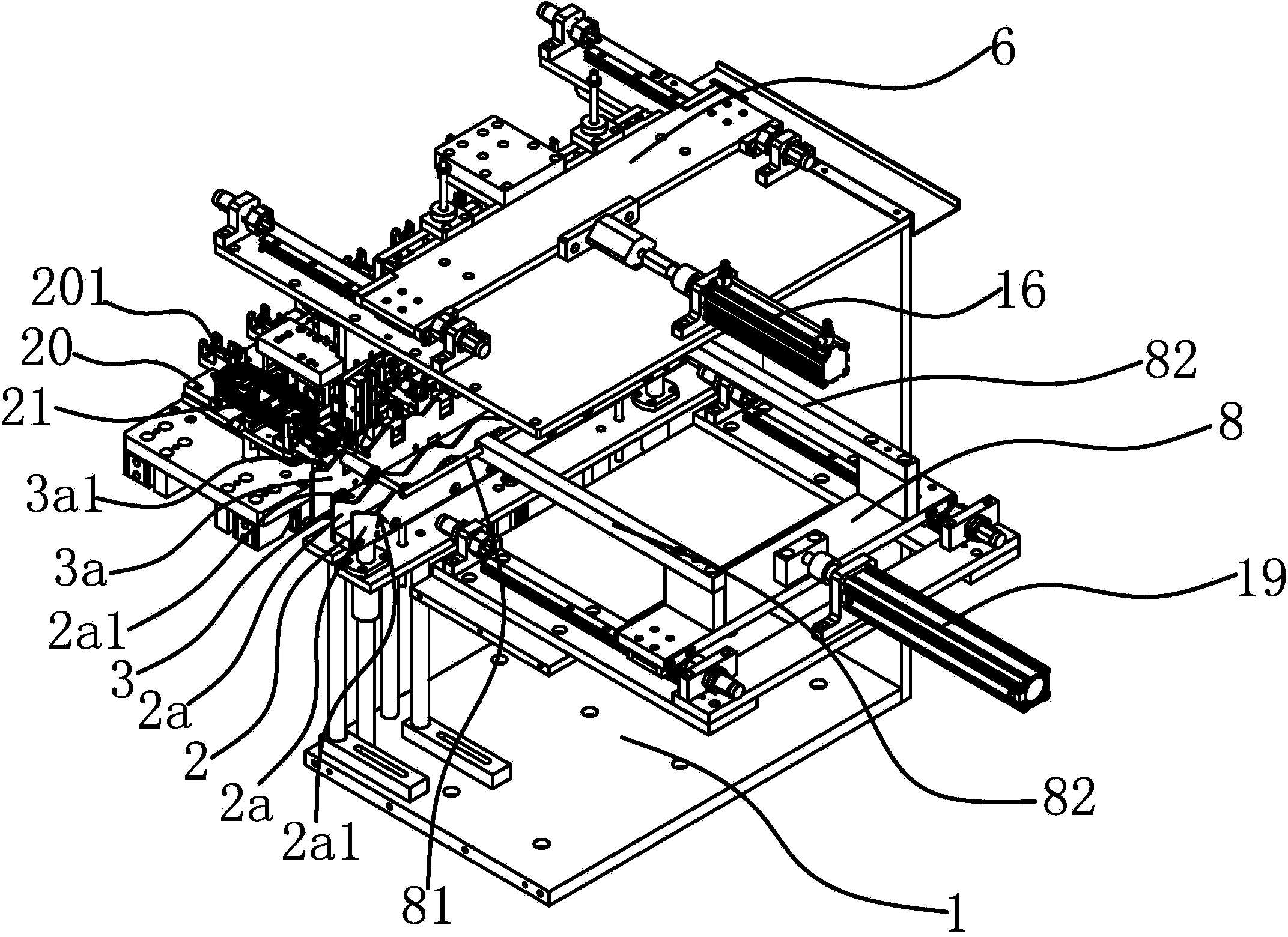

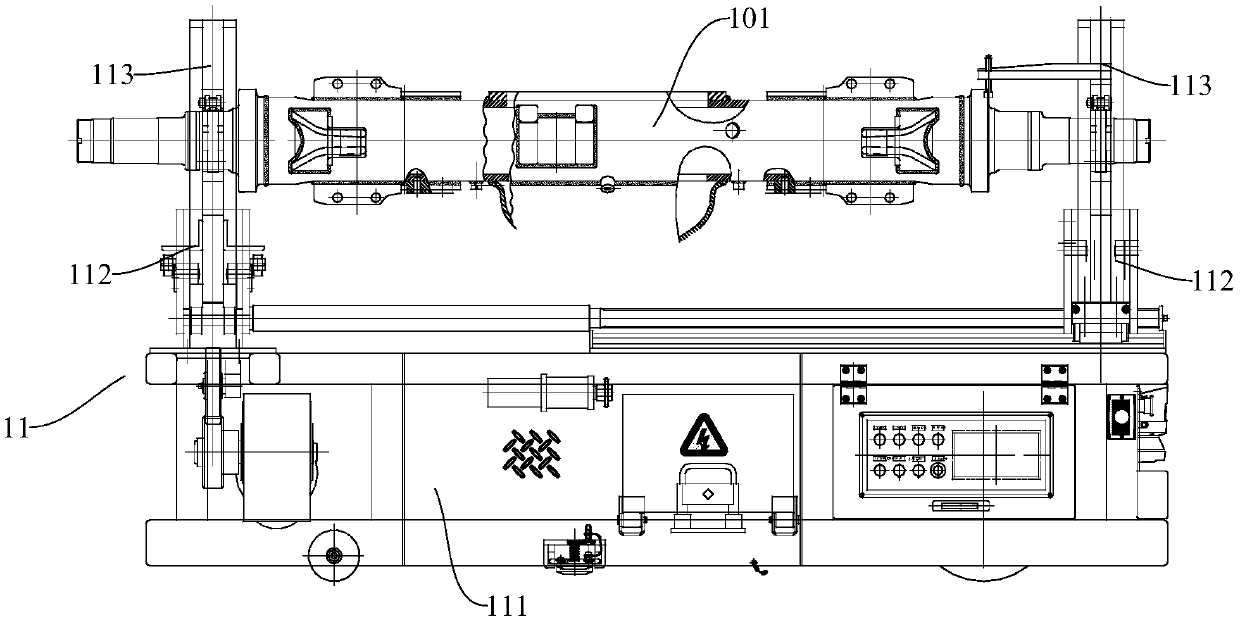

Matrix loading device and method for full-automatic assembly of charging connector

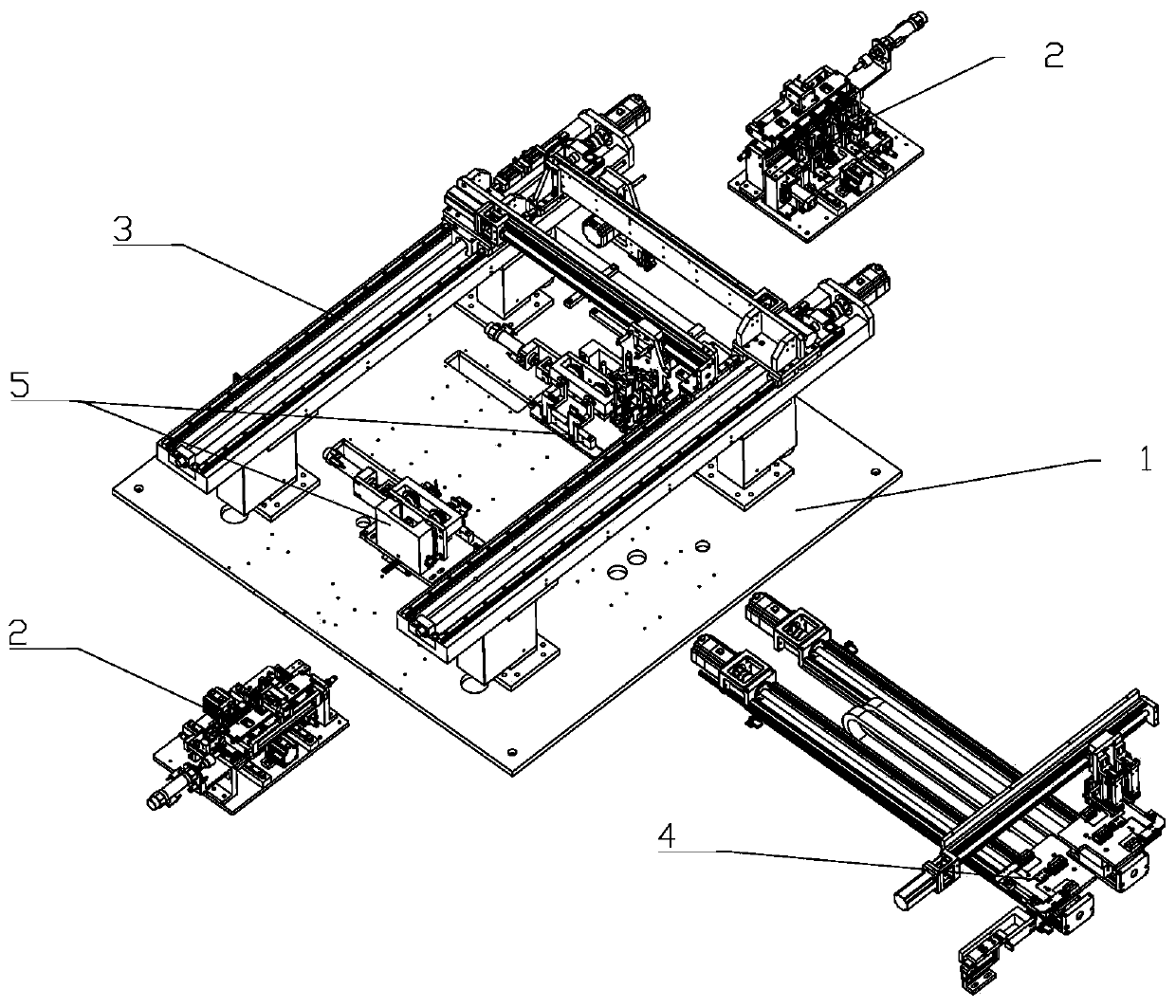

ActiveCN109888596AEasy subsequent assemblyImprove assembly accuracyContact member assembly/disassemblyMechanical engineeringStructural engineering

The invention relates to the field of electric plug production and manufacturing, in particular to a matrix loading device and method for full-automatic assembly of a charging connector. The matrix loading device for full-automatic assembly of the charging connector comprises a first base, a matrix jig loading assembly, a jig transfer assembly, a matrix loading assembly, a matrix feeding assemblyand a matrix jig discharging assembly, wherein the matrix jig loading assembly is arranged on the first base and is used for loading and transferring the whole jig, the jig transfer assembly is used for turning over the jig, the matrix loading assembly and the matrix jig loading assembly are linked, the matrix loading assembly and the matrix feeding assembly are linked, the matrix loading assemblyis used for assembling the matrix jig and the matrix, the matrix jig discharging assembly and the matrix loading assembly are linked, and the matrix jig discharging assembly is used for pressing thematrix and achieving discharging of the matrix jig. In the matrix loading device, the matrix loading device is assembled by simultaneous loading of the jig and the matrix, the matrix is arranged on the jig, subsequent assembly is facilitated, and the assembly accuracy is improved.

Owner:中海宏祥铜业江苏有限公司

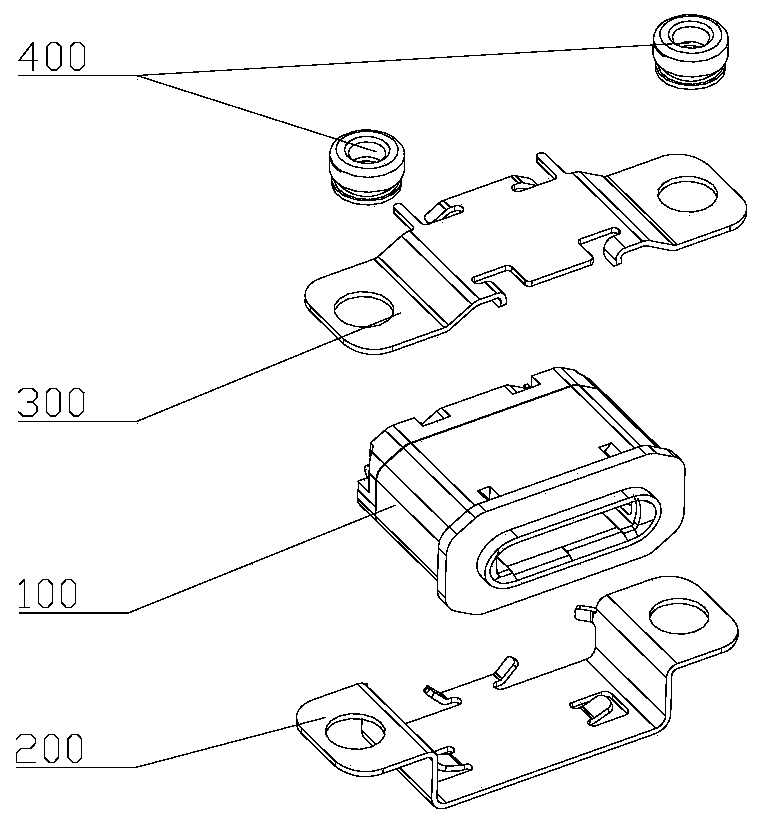

Permanent magnet direct current motor elastic piece feeding device, feeding method and motor assembling equipment

InactiveCN113231821AImprove uprightnessIncrease stiffnessMetal-working feeding devicesAssembly machinesElectric machineWaste material

The invention relates to the field of motor production, in particular to a permanent magnet direct current motor elastic piece feeding device, a feeding method and motor assembling equipment. The motor elastic piece feeding device comprises a base plate, a material belt feeding mechanism, an elastic piece cutting mechanism, an elastic piece carrying mechanism and a material belt collecting mechanism. The material belt feeding mechanism is installed on the base plate, the elastic piece cutting mechanism is located below the material belt feeding mechanism, the elastic piece carrying mechanism corresponds to the discharging end of the material belt feeding mechanism, and the material belt collecting mechanism is connected with the lower end of the material belt feeding mechanism. The material belt feeding mechanism is used for driving a material belt of an elastic piece to achieve feeding, the elastic piece cutting mechanism is used for separating the elastic piece from the material belt, the elastic piece carrying mechanism is used for carrying and feeding the elastic piece, and the material belt collecting mechanism is used for cutting and collecting waste materials of the material belt. The elastic piece carrying mechanism comprises a vertical base, a horizontal air cylinder, a vertical air cylinder, a suction block, a centering column and a limiting sensor. The permanent magnet direct current motor elastic piece feeding device, the feeding method and the motor assembling equipment have the advantages of accurate connection, high carrying efficiency and high accuracy.

Owner:陈荣乾

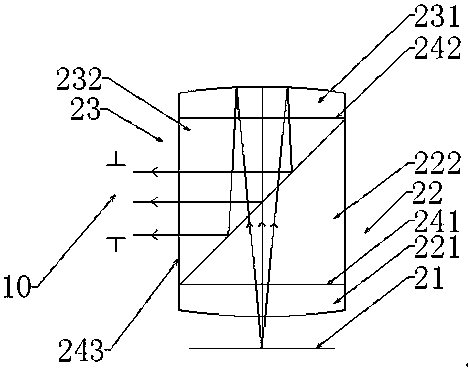

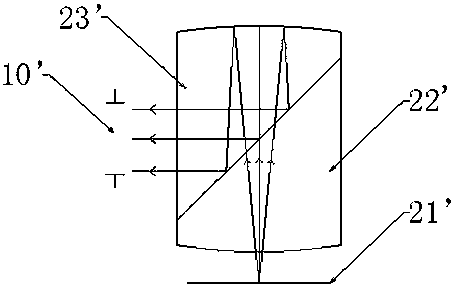

Augmented reality optical system capable of improving ghost images

The invention discloses an augmented reality optical system capable of improving ghost images, which comprises a human eye and a lens group, wherein the lens group comprises a light source module, a first curved surface prism and a second curved surface prism, the first curved surface prism and the second curved surface prism are sequentially arranged between the light source module and the humaneye, the first curved surface prism and the second curved surface prism are connected in a glued manner, and the lens group is of a trapezoidal structure. The augmented reality optical system effectively improves a ghost image phenomenon. Meanwhile, the augmented reality optical system is simple in structure and high in imaging brightness.

Owner:SHENZHEN D LIGHT TECH CORP LTD

Method for producing a structure for microelectronic device assembly

ActiveUS9241403B2Easy subsequent assemblyGood body shapeSemiconductor/solid-state device detailsSolid-state devicesDielectric layerElectrical and Electronics engineering

Forming of a microelectronic device including a substrate containing at least one conductive pad, the pad being provided with a bottom surface resting on the substrate and an upper surface opposite the bottom surface. The upper surface of the pad has a stack applied thereto formed of a conductive layer and a protective dielectric layer including an opening called first opening facing the pad and exposing the conductive layer. At least one insulating block is arranged on a peripheral region of the upper surface of the pad, the insulating block having a cross-section forming a closed contour and having an opening called second opening. A conductive pillar is located in the center of the contour in the second opening.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

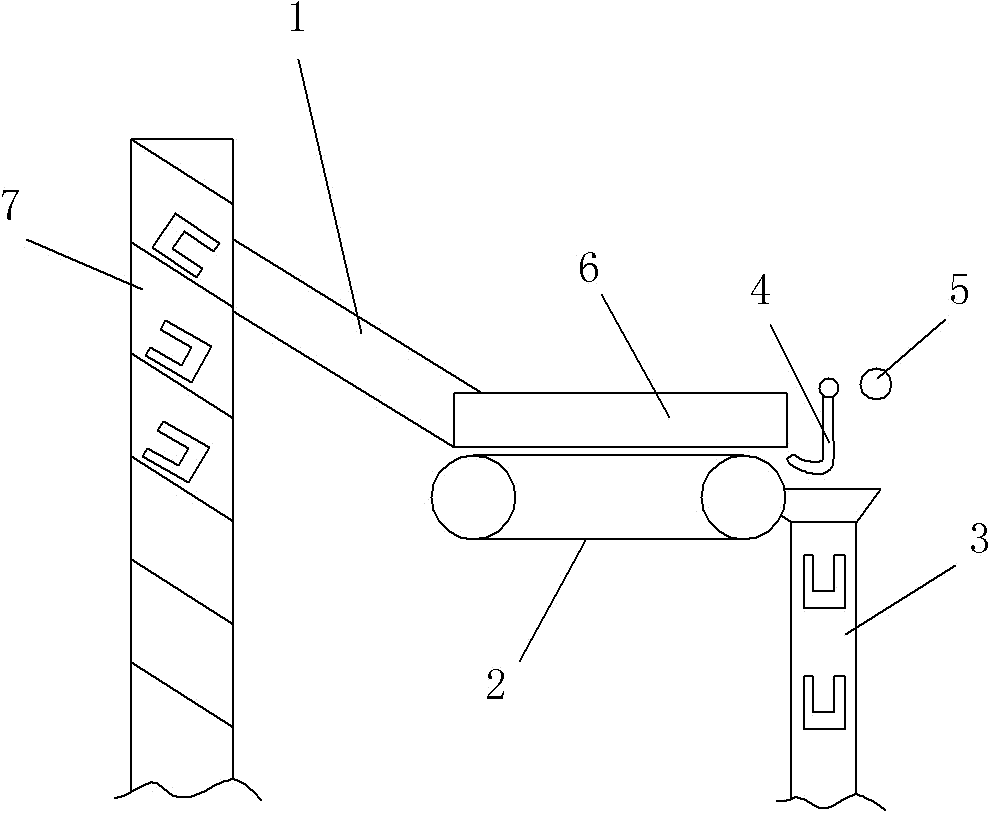

Orientation transmission mechanism for workpiece with end face with hole

InactiveCN103754614APrevent slippingWith guiding functionConveyorsConveyor partsTransmission beltEngineering

The invention discloses a transportation device, and particularly relates to an orientation transmission mechanism for a workpiece with an end face with a hole. The orientation transmission mechanism comprises a feeding chute, a transmission belt and an orientation groove, an outlet of the feeding chute is close to an input end of the transmission belt, the orientation groove is formed in an output end of the transmission belt, a swing hook is arranged above the orientation groove, a bent free end of the swing hook faces the conveying direction of the transmission belt, a stop pin is arranged behind the swing hook and positioned above an opening of the orientation groove, and the stop pin and a suspension point of the swing hook are positioned at the same height. By the aid of the technical scheme, the orientation transmission mechanism for the workpiece with the end face with the hole is simple in structure, and the workpiece can be transmitted in an oriented manner.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

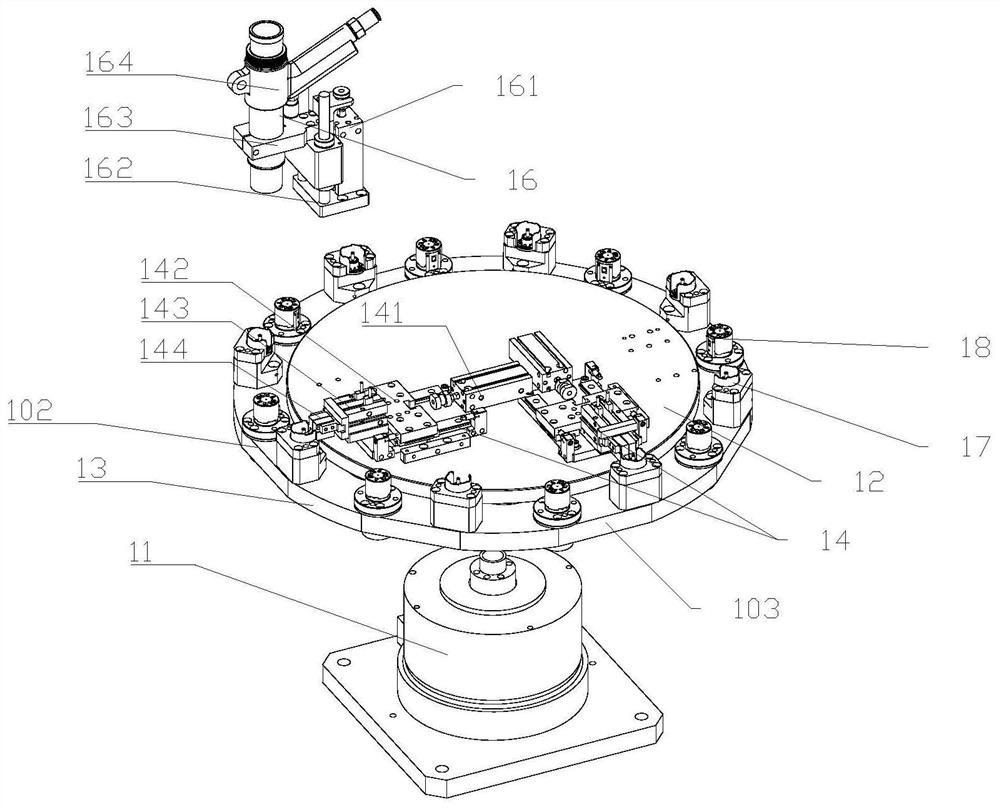

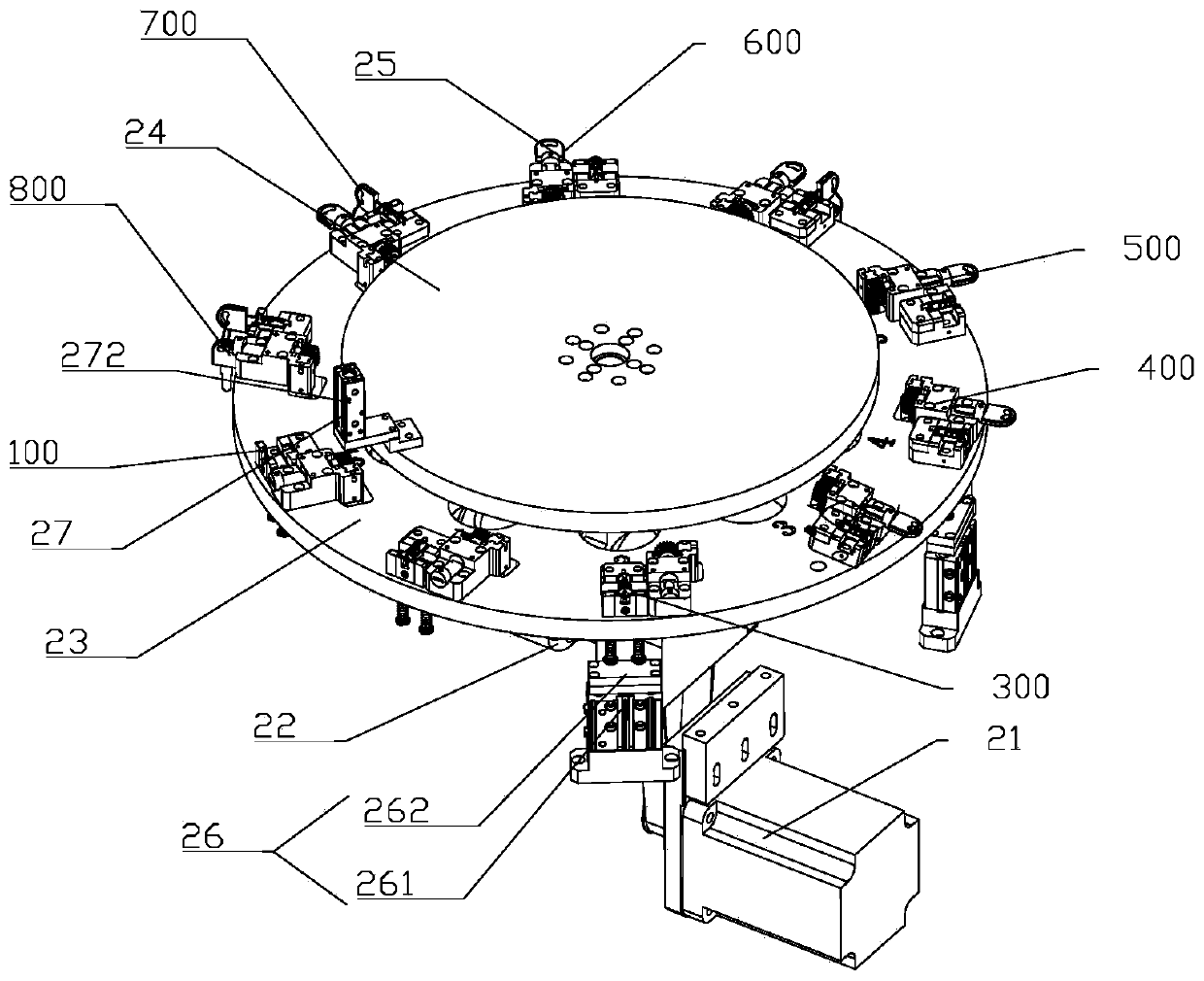

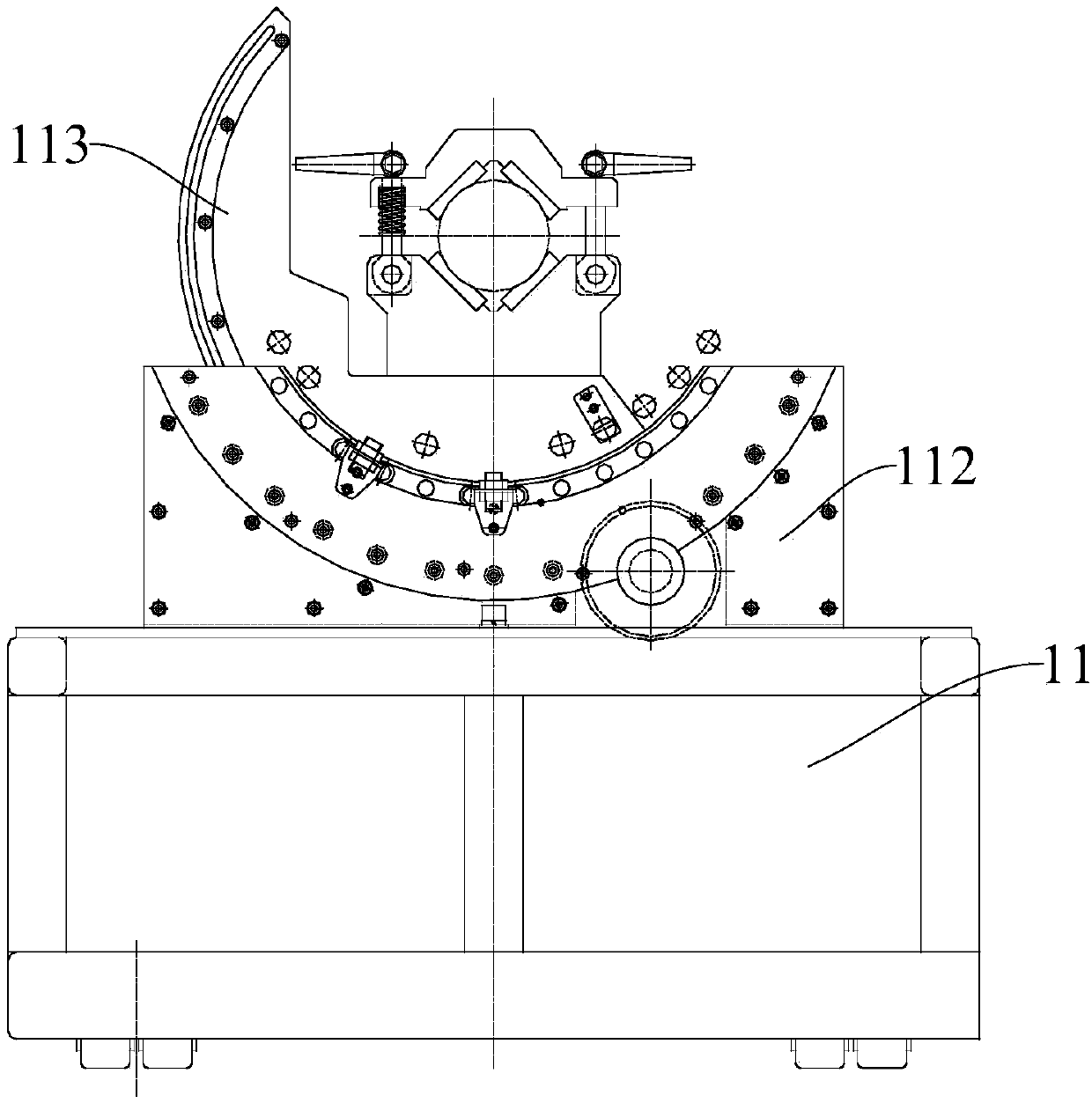

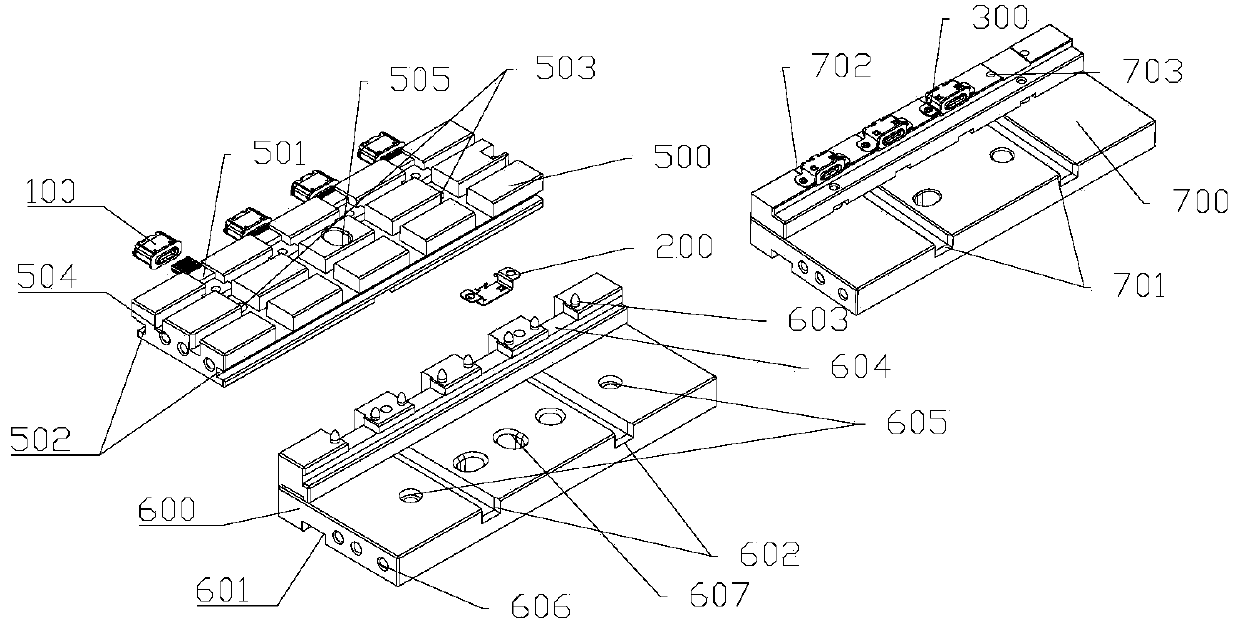

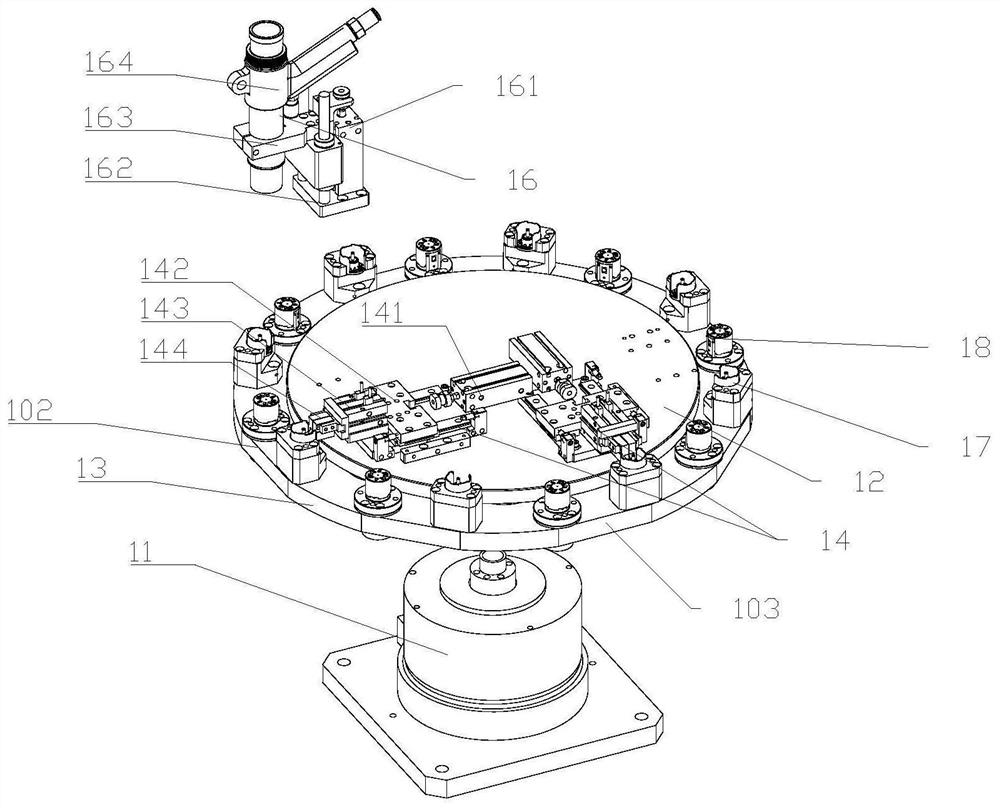

Jig rotating device and circulating method for permanent magnet direct-current motor and motor assembling equipment

InactiveCN113385932AImprove uprightnessIncrease stiffnessAssembly machinesWork holdersCircular discElectric machinery

The invention relates to the field of motor production, in particular to a Jig rotating device and circulating method for a permanent magnet direct-current motor and motor assembling equipment. The jig rotating device for motor assembly production comprises a turntable, a fixed disc, a rotating disc, a clamping assembly, an air blowing assembly, a forward mounting jig and a reverse mounting jig, wherein the turntable is arranged on the rack; a fixed shaft and a rotating shaft are arranged at the upper end of the turntable; the center of the fixed disc is fixed on the fixed shaft;the rotating disc is mounted on the rotating shaft; and the fixed disc is positioned above the rotating disc; the forward mounting jig and the reverse mounting jig are mounted on the periphery of the clamping assembly mounted on the rotating disc; the clamping assembly is fixed on the disc; and the air blowing assembly is arranged on the fixed disc and corresponds to the reverse mounting jig at an elastic sheet feeding station. Two jigs are adopted, so that the jig rotating device has the advantages of being suitable for mandrel loading and high in loading precision.

Owner:陈荣乾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com