Automatic cyclic cleaning, rust preventing and arraying equipment

A technology of automatic circulation and equipment, applied in cleaning methods and utensils, cleaning methods using liquids, conveyor objects, etc., can solve problems such as rust on the inner wheel of hub bearings, achieve a high degree of automation, save labor, and tilt cleanly and thoroughly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

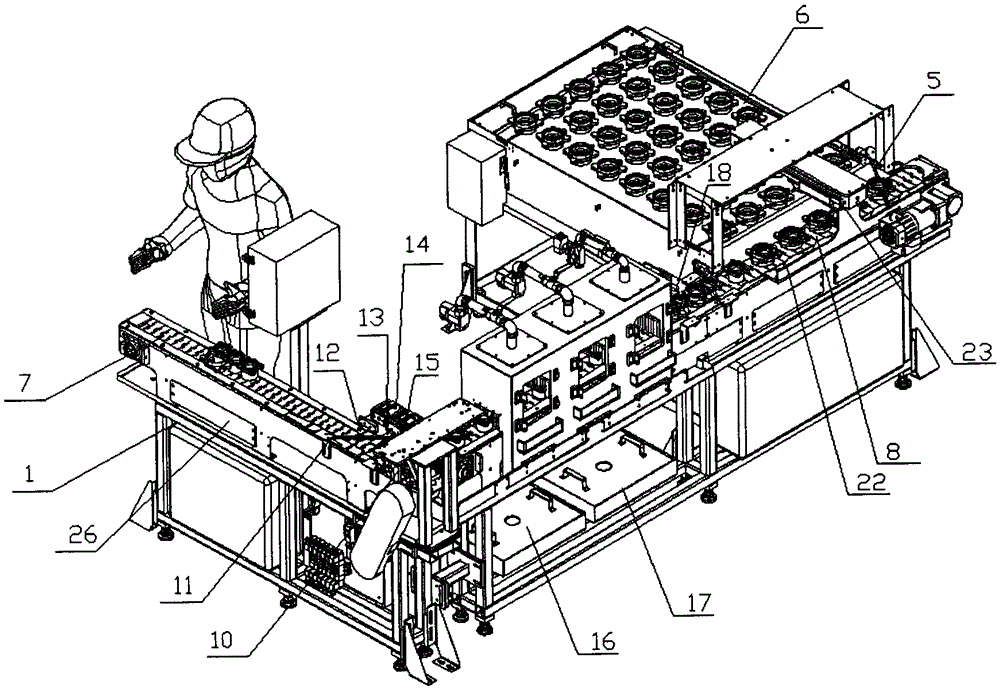

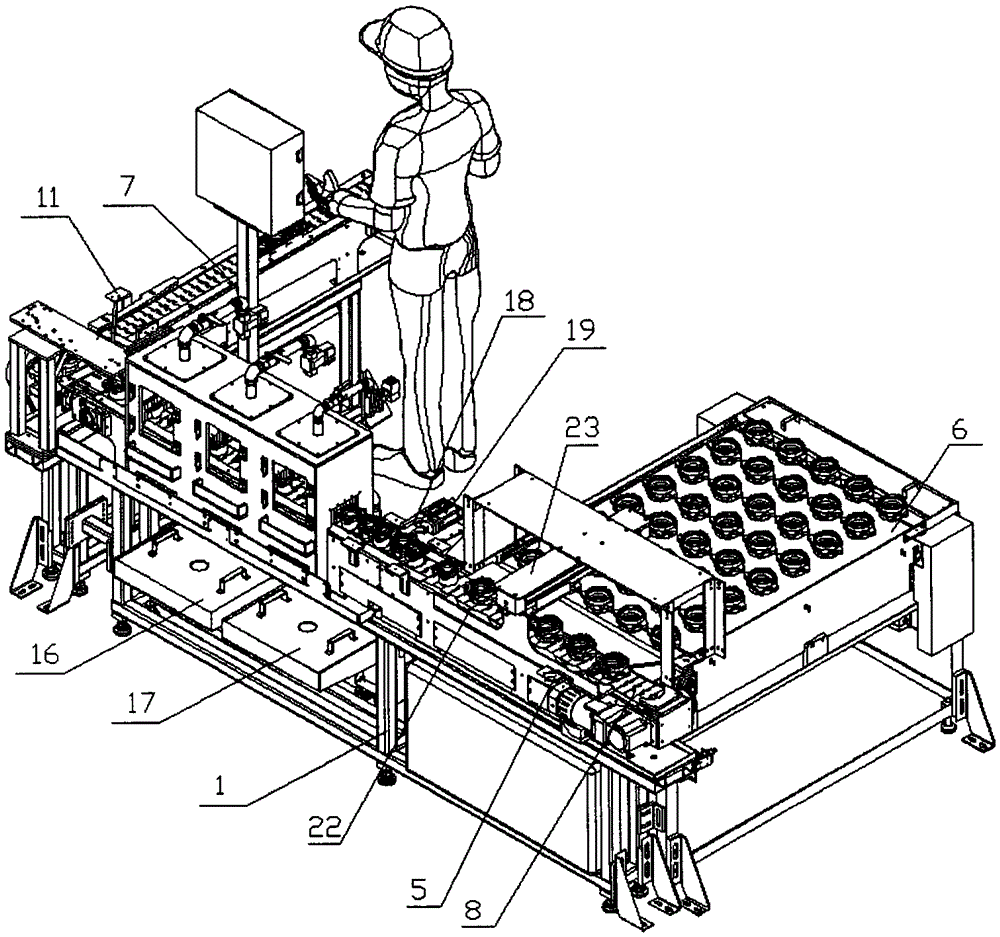

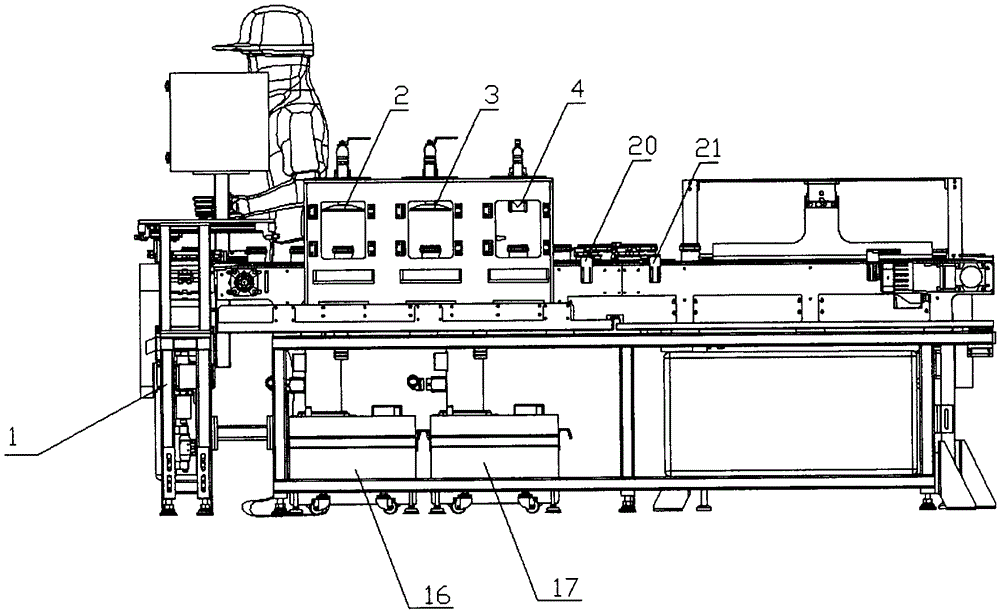

[0022] Embodiment: An automatic cycle cleaning and anti-rust alignment equipment, including a frame 1, a conveying channel, a cleaning oil nozzle 2, an anti-rust oil nozzle 3, a blowing device 4, a distance adjustment device, a first sensing device 5, a material pushing device, Receiving conveyor platform 6 and control system, wherein:

[0023] The conveying channel is positioned on the frame 1, and the conveying channel can drive the workpiece forward. The cleaning oil nozzle 2, the anti-rust oil nozzle 3 and the blowing device 4 are respectively fixed on the frame 1 directly above the conveying channel in order along the conveying direction, and the cleaning oil The nozzle 2 can spray clean oil towards the workpiece passing directly below it, the anti-rust oil nozzle 3 can spray anti-rust oil towards the workpiece passing directly below it, the blowing device 4 can blow high-pressure air on the surface of the workpiece passing directly below it, and adjust the distance The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com