Three-jig efficient transferring device and method for assembling charging connector

A technology of charging connection and fixture circulation, applied in the field of three fixture efficient circulation devices, can solve the problems of low precision, low fixture circulation efficiency, and difficulty in clamping the material of the clamping shell, so as to improve the efficiency and precision, The effect of facilitating integrated processing and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

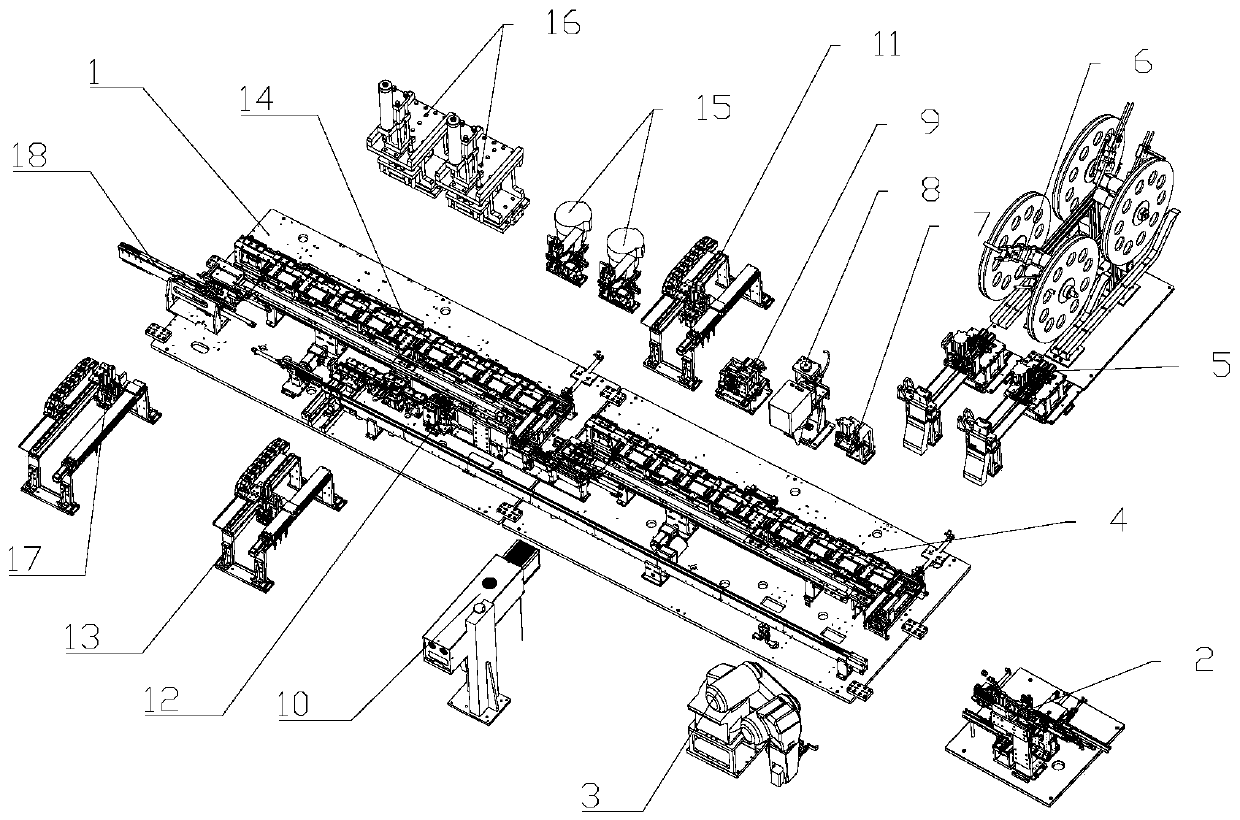

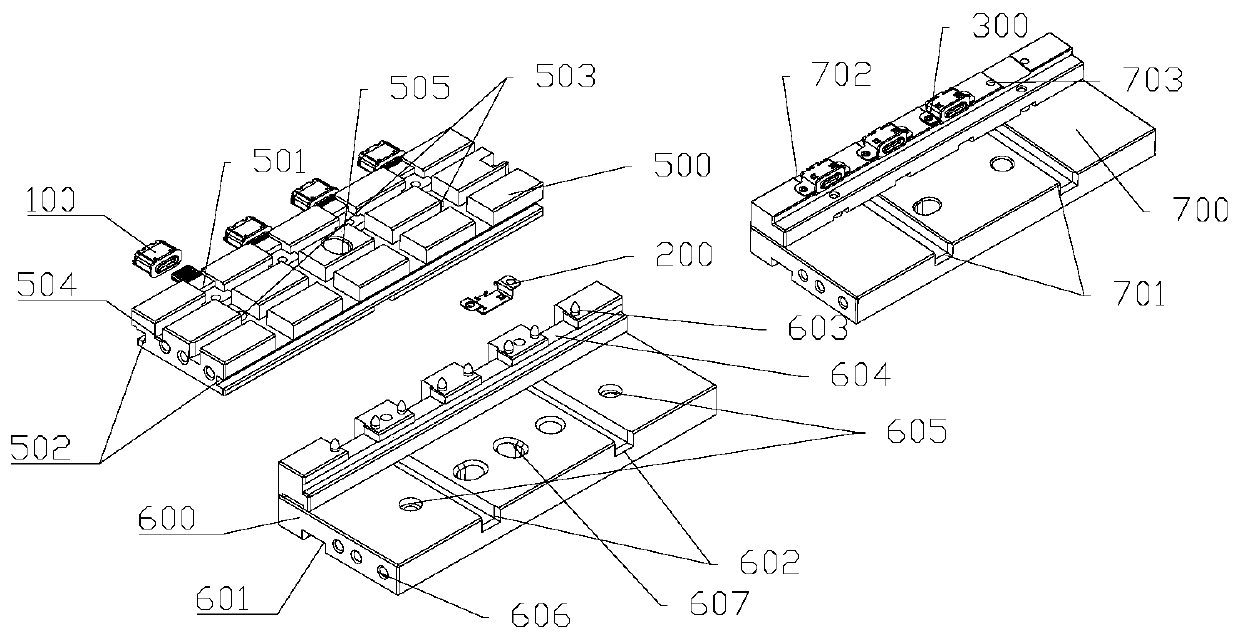

[0046] like figure 1 As shown in the figure, the automatic assembly equipment for electronic connectors includes a frame 1 and a substrate feeding device 2 installed on the frame 1, a lower clamping shell feeding device 5, an upper clamping shell feeding device 6, a clamping shell Pressing device 7, jacket detection device 8, jacket bending device 9, jacket welding device 10, rivet column feeding device 15, riveting column pressing device 16, product unloading device 18 and high-efficiency flow device; high-efficiency flow The device includes a robotic arm conveying device 3, a collet jig circulating device 4, a first conveying device 11, a base jig returning device 12, a second conveying device 13, a riveting jig circulating device 14 and a third conveying device 17;

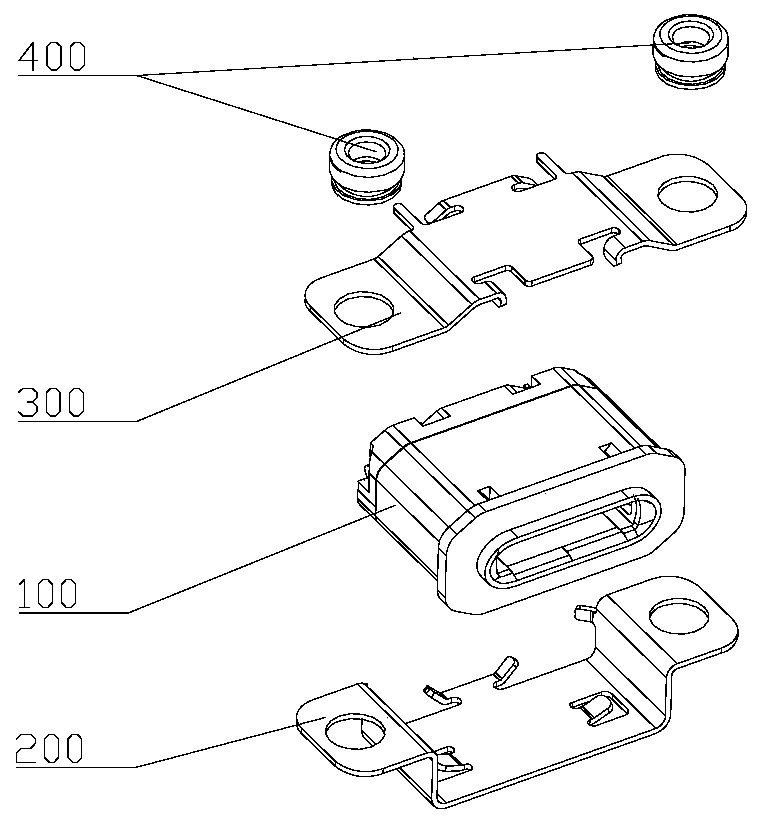

[0047] The substrate feeding device 2 is used to place the substrate into the substrate jig, and feed the substrate together with the substrate jig; the robotic arm handling device 3 is connected with the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com