Conductive slip ring

A conductive slip ring and conductive ring technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve problems such as voice out of sync, unstable work, expensive prices, etc., to achieve the effect of ensuring stability and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

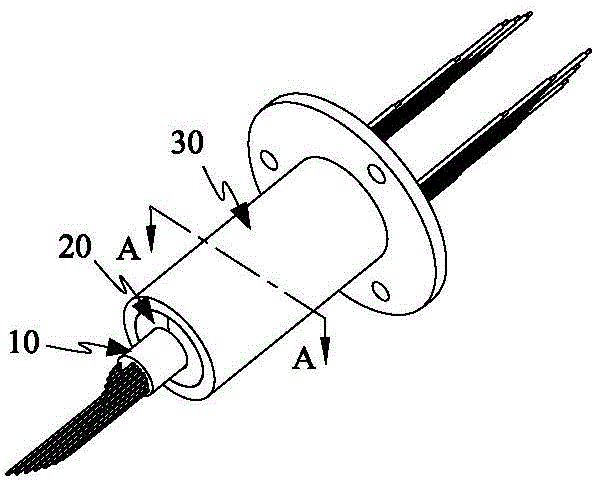

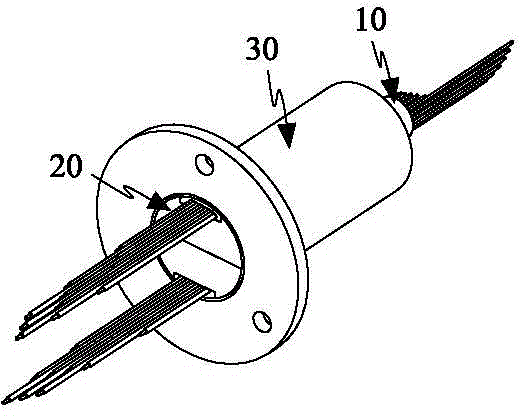

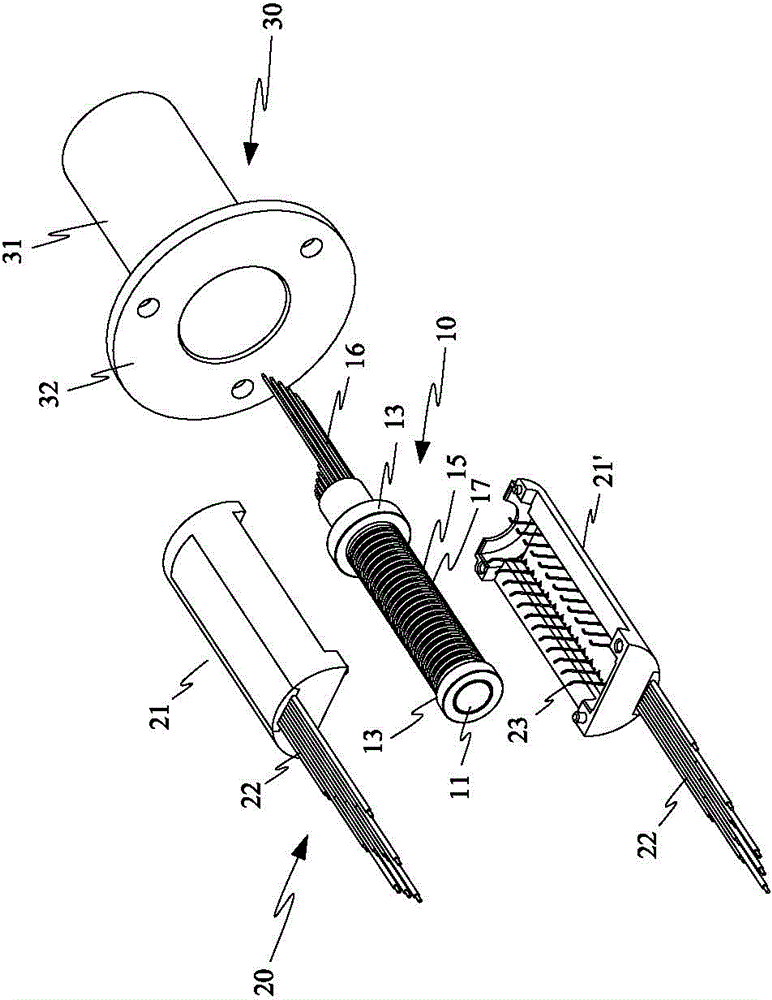

[0068] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, the conductive slip ring includes a rotor assembly 10, a stator assembly 20 and a casing 30, the stator assembly 20 wraps the rotor assembly 10, and the casing 30 It is sleeved on the outside of the stator assembly 20 . By making the rotor assembly 10 rotate relative to the stator assembly 20, signal transmission is realized, which solves the problem that the traditional straight-through cable transmission cannot rotate and twist.

[0069] Among them, such as Figure 4 to Figure 20 As shown, the rotor assembly 10 includes a shaft core 11 , a distribution disc 12 , two bearings 13 , a sealing cover 14 , several conductive rings 15 and several inner ring wires 16 .

[0070] Such as Figure 15 As shown, the shaft core 11 has a cylindrical central shaft body 111 and a blocking piece 112 integrally formed at the tail end of the central shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com