Patents

Literature

55results about How to "For subsequent packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

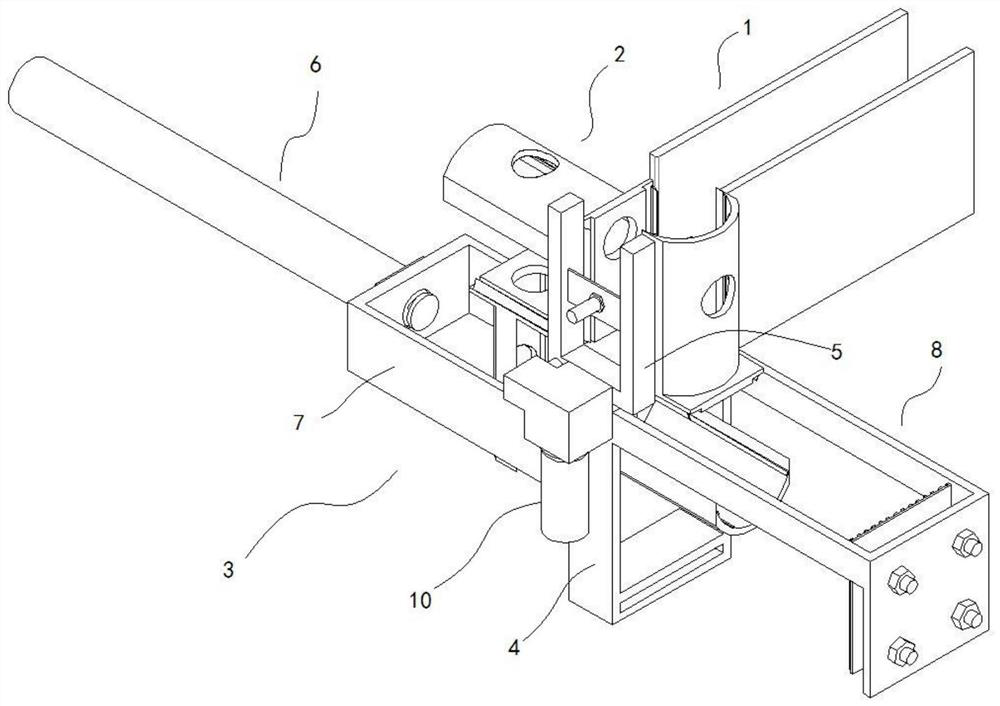

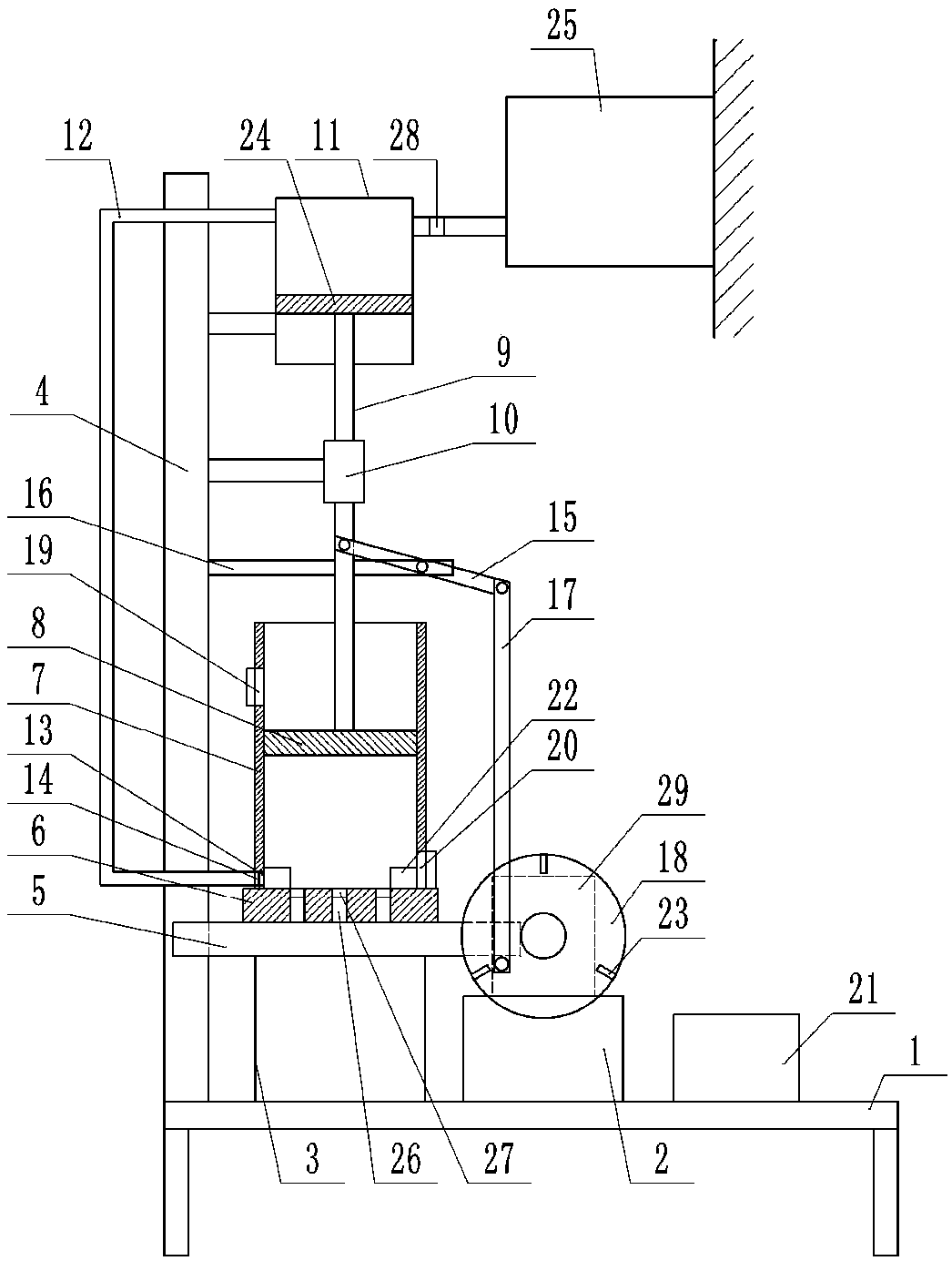

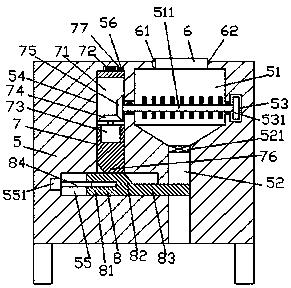

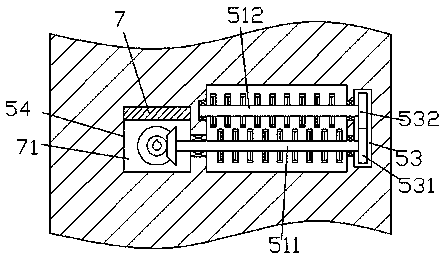

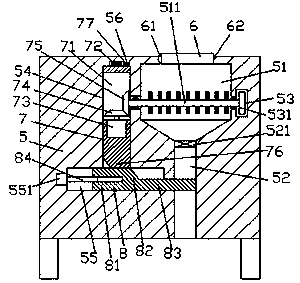

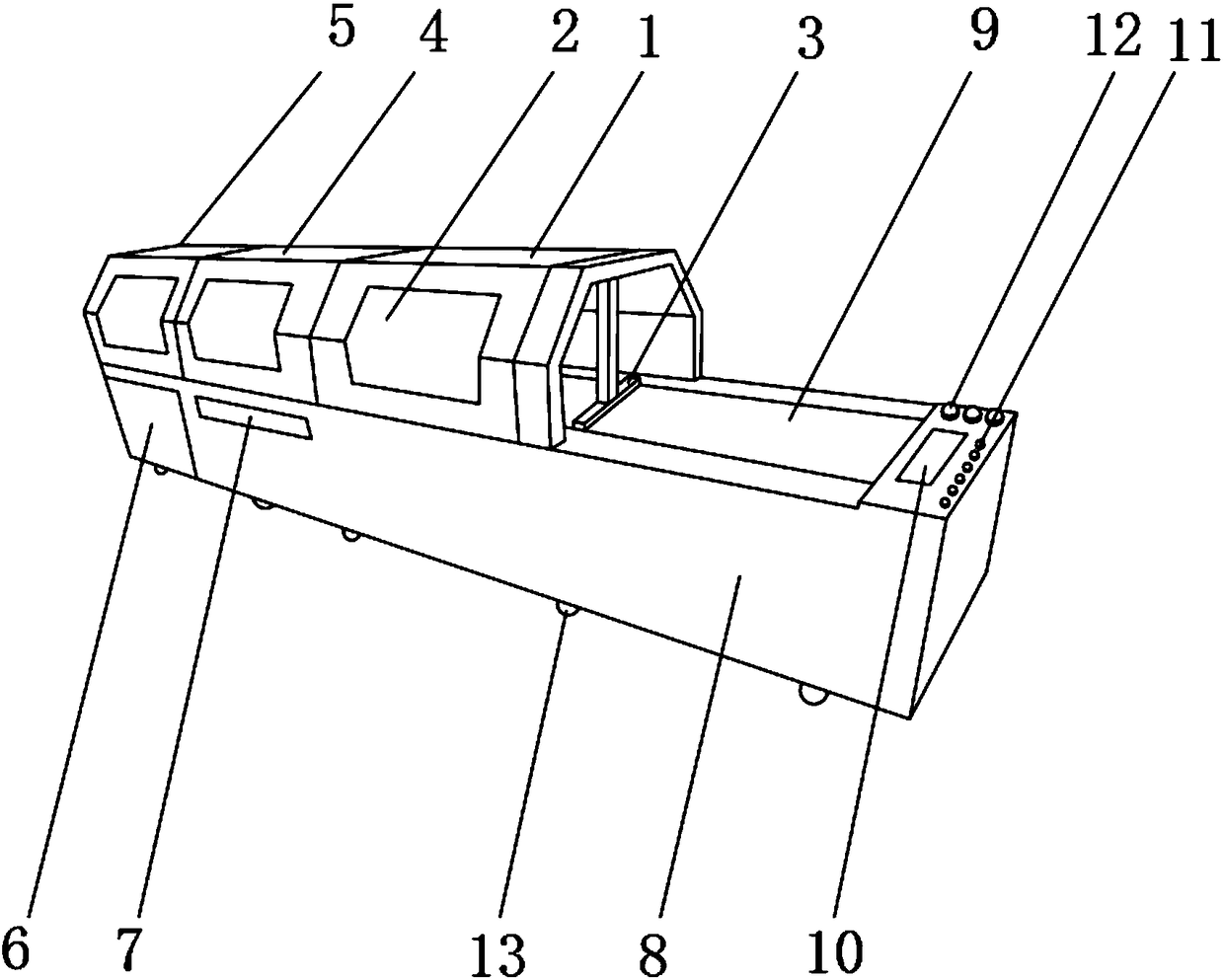

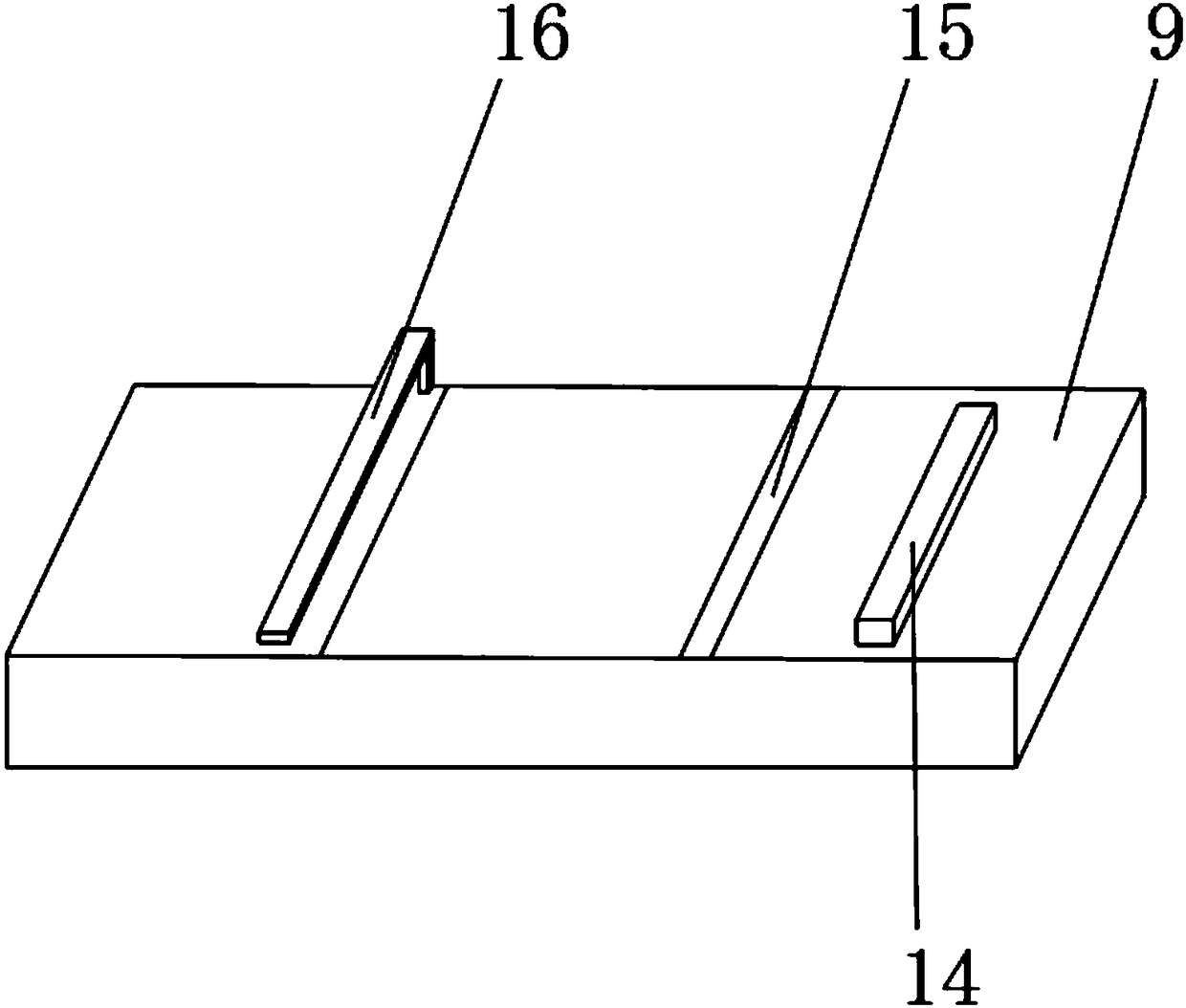

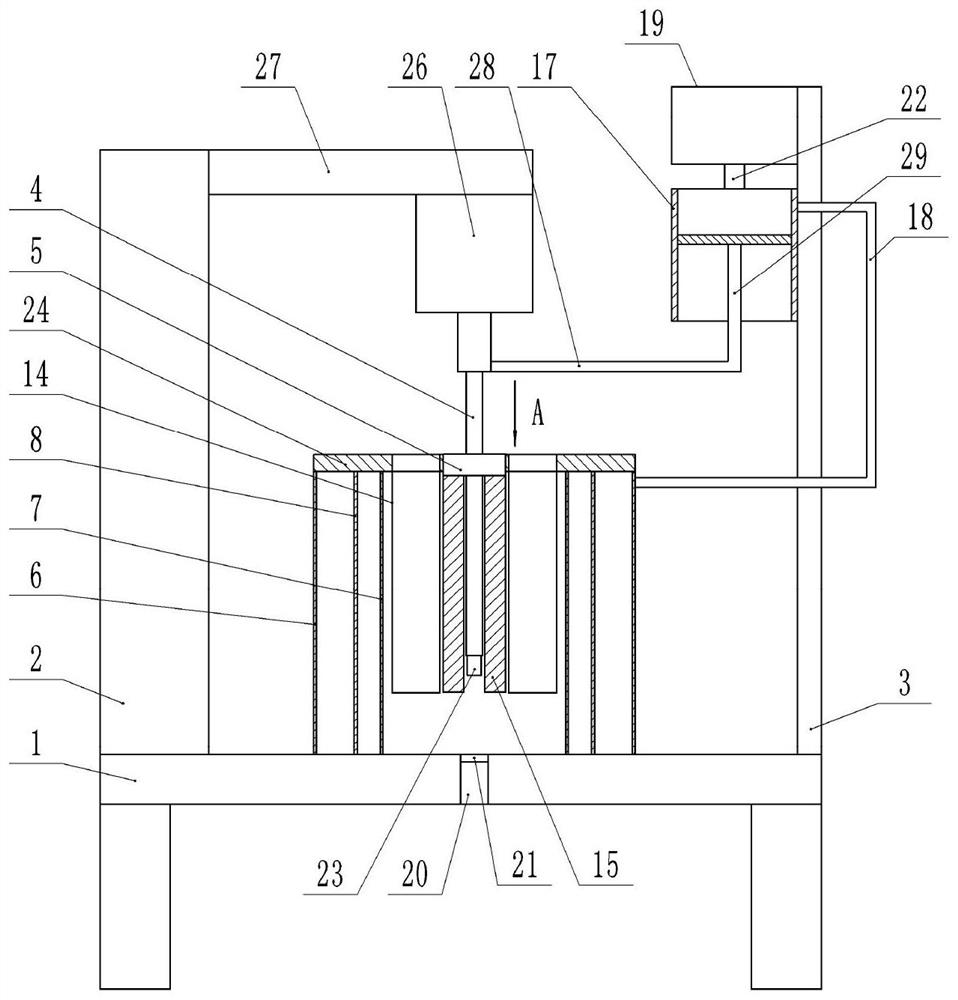

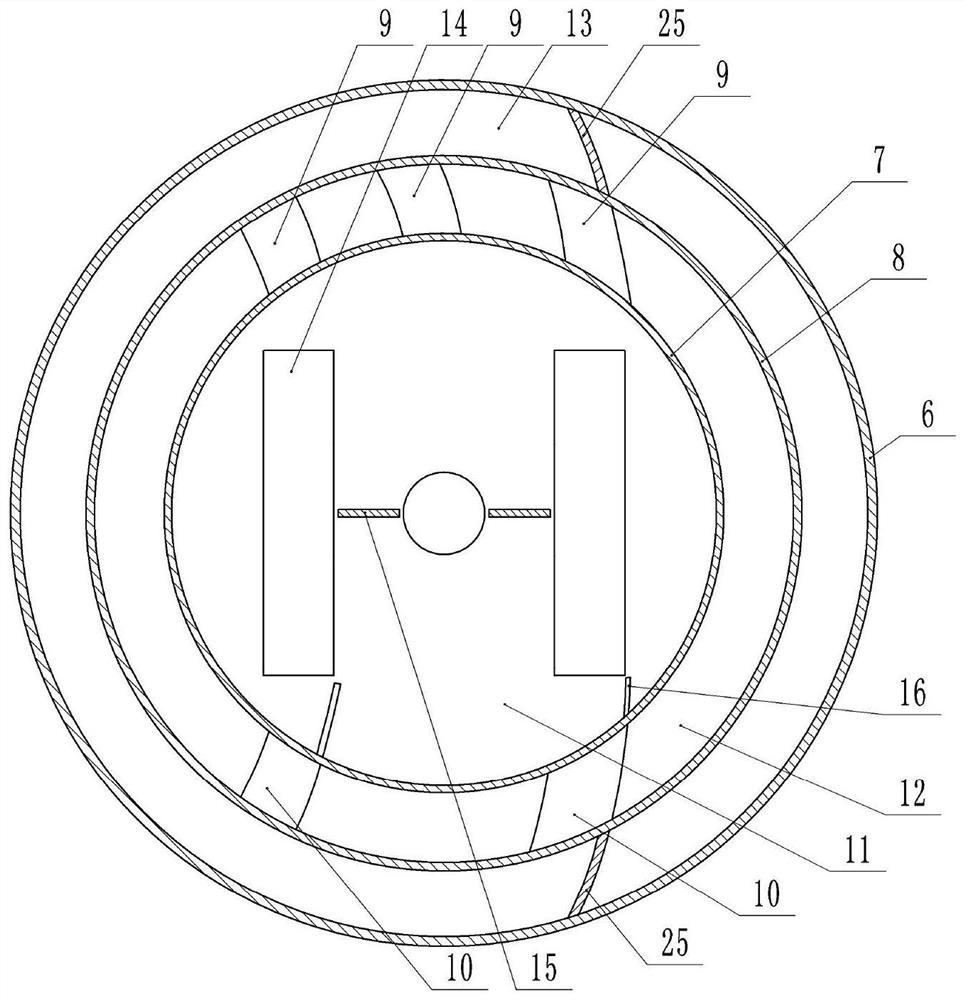

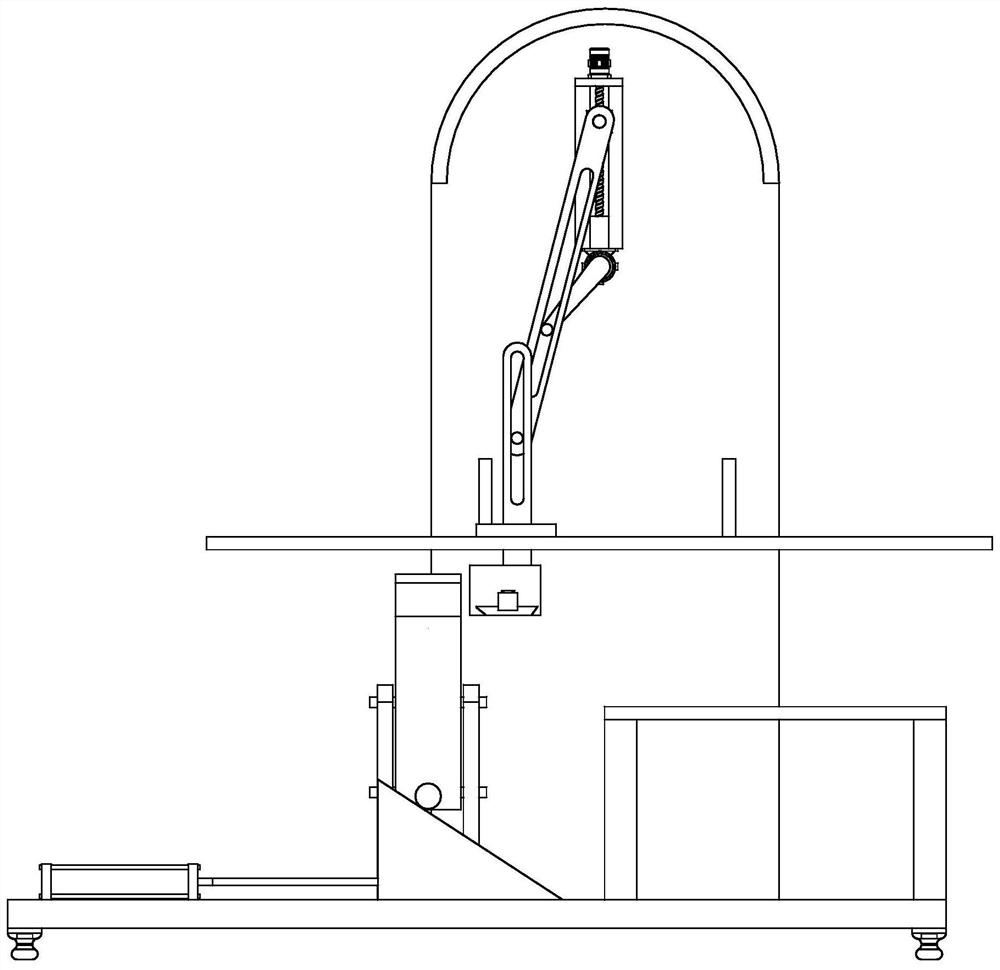

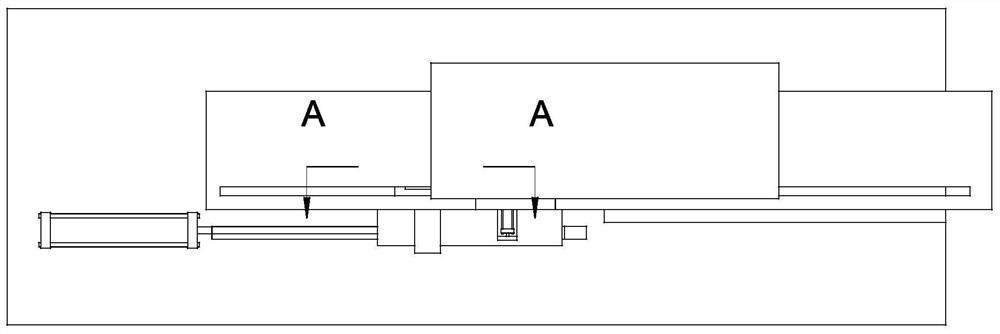

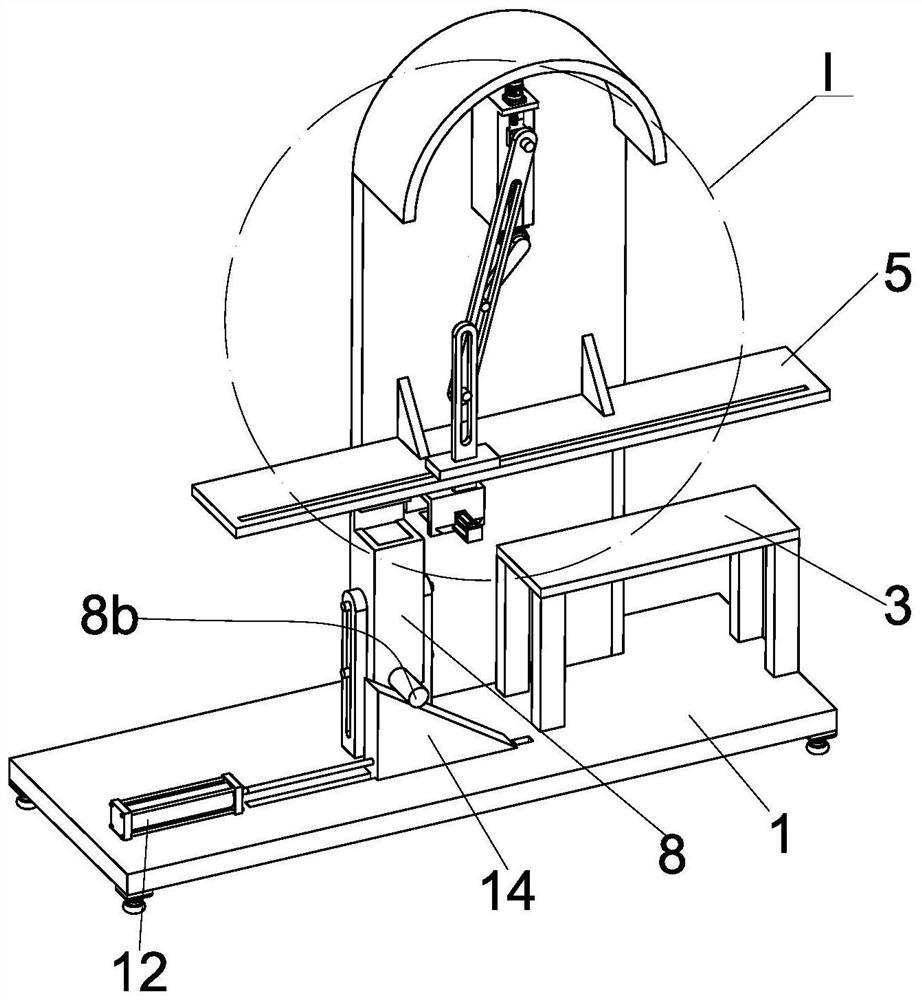

Terminal assembling welding device

PendingCN110125569ACompact structureGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectric control

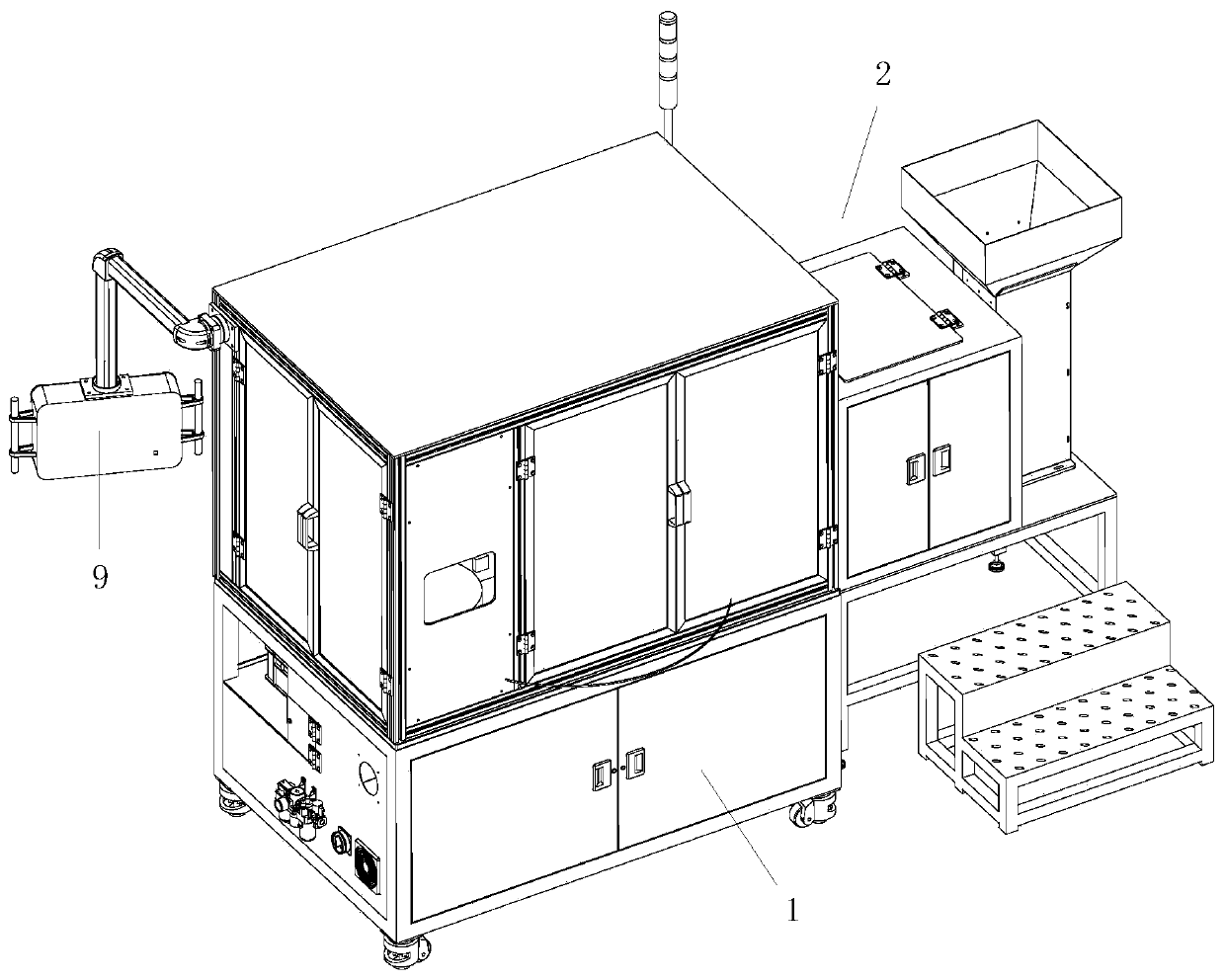

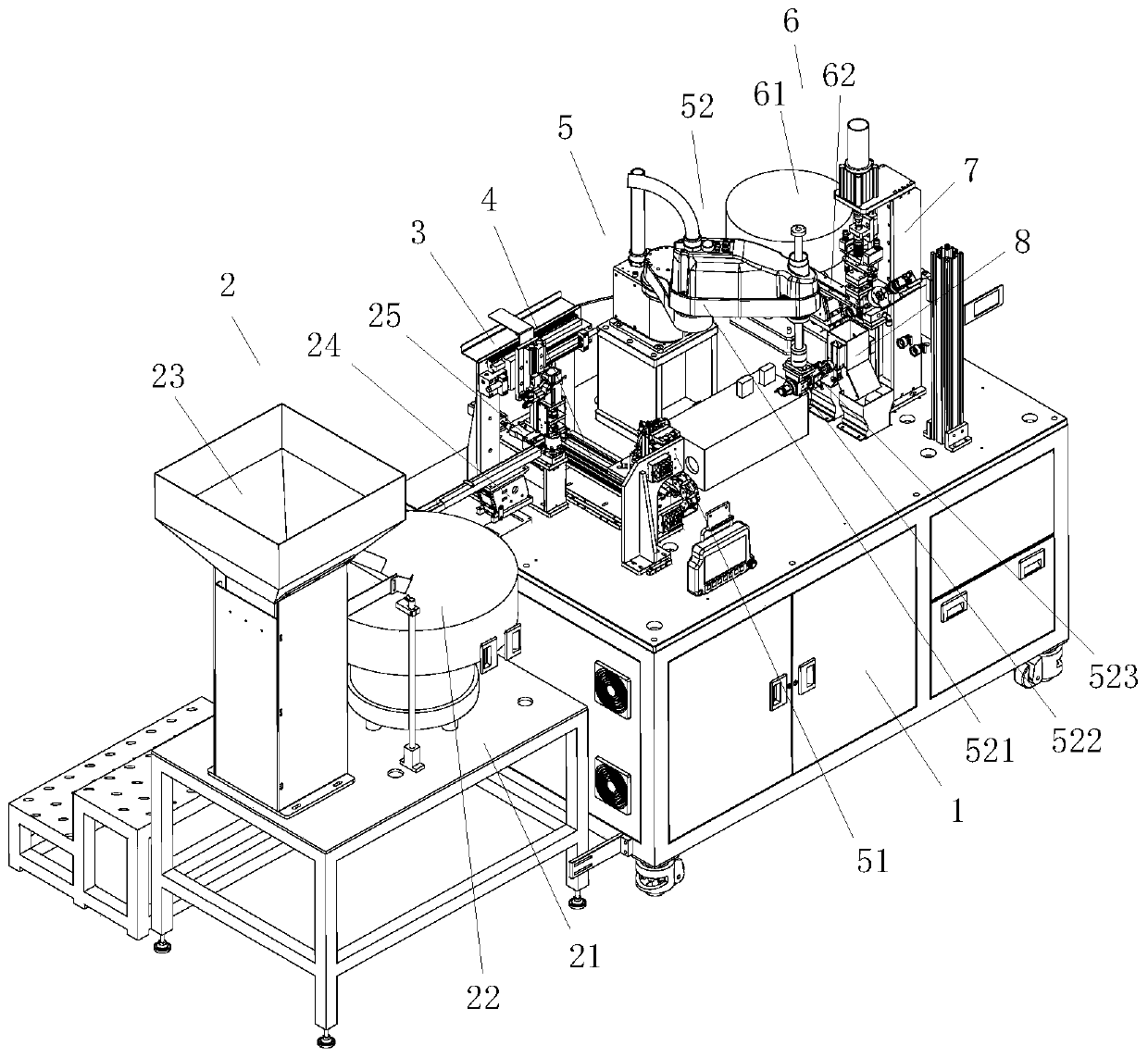

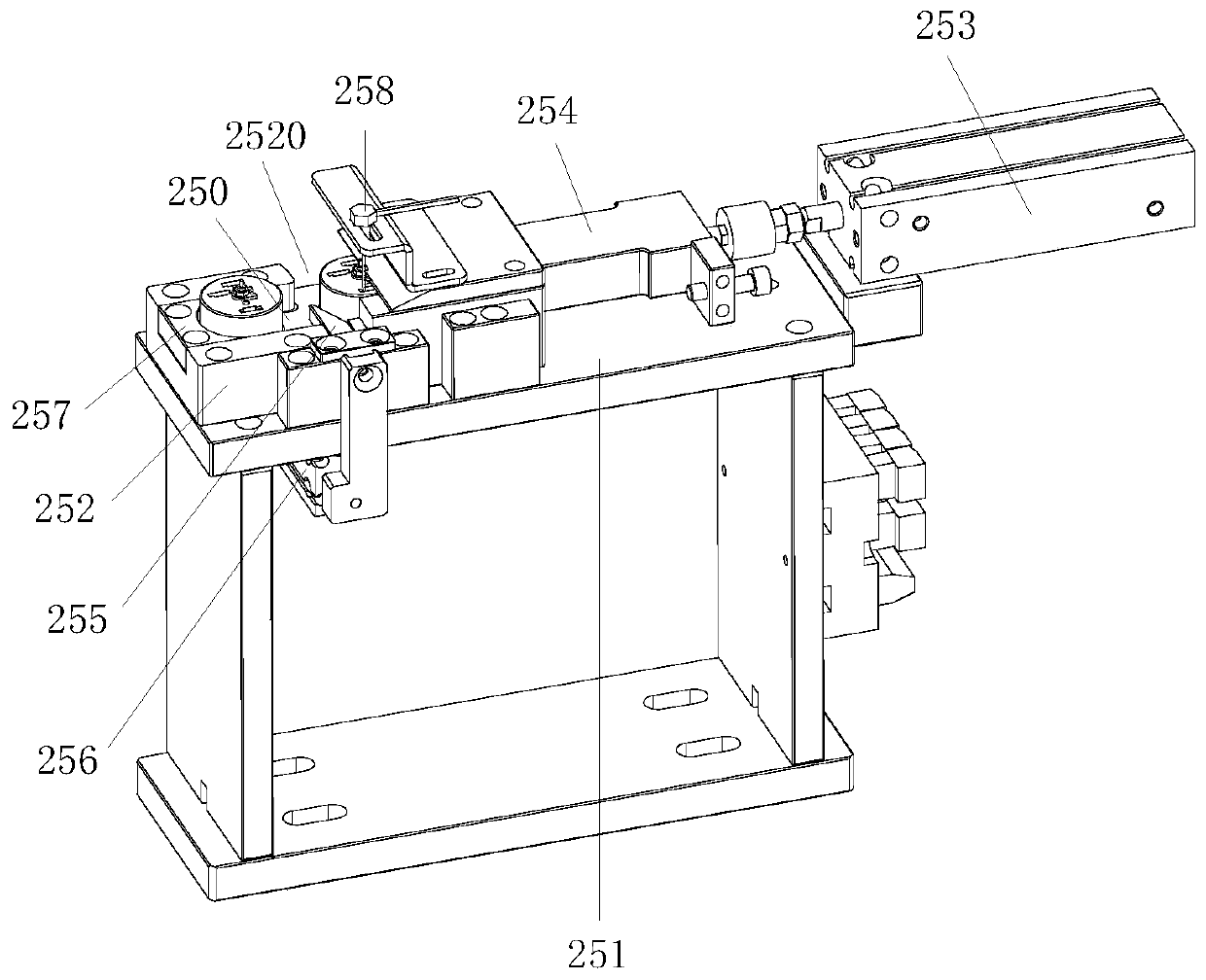

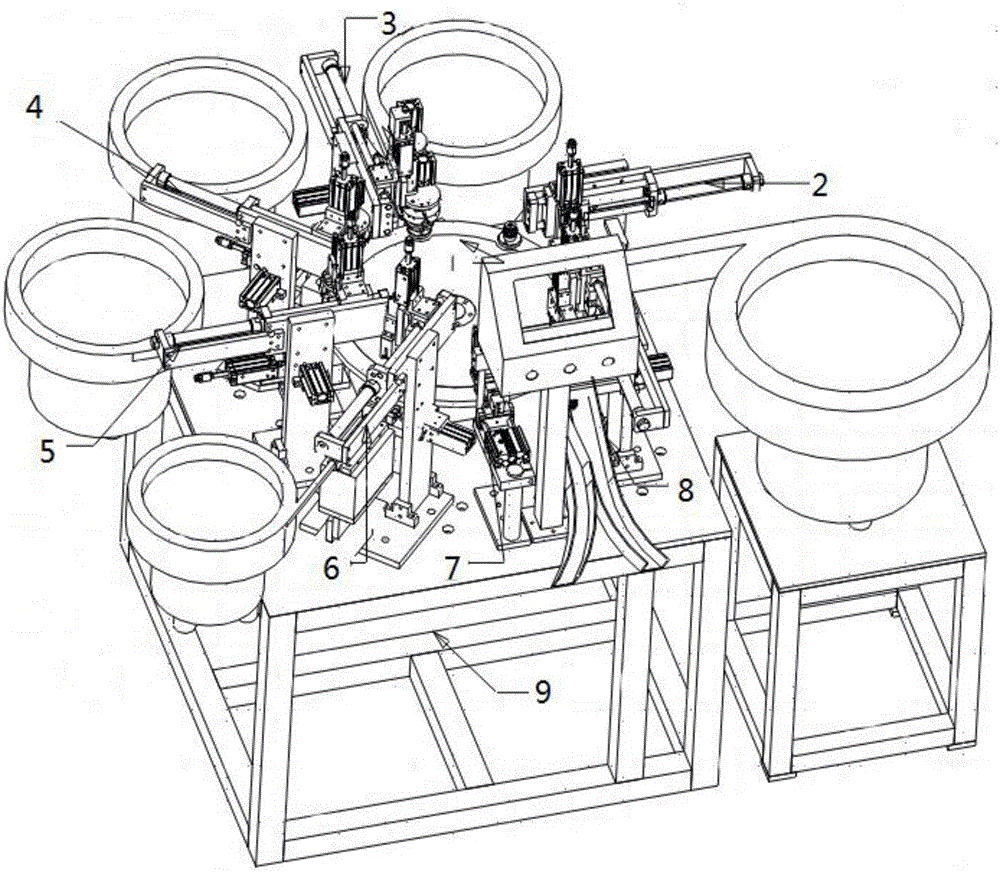

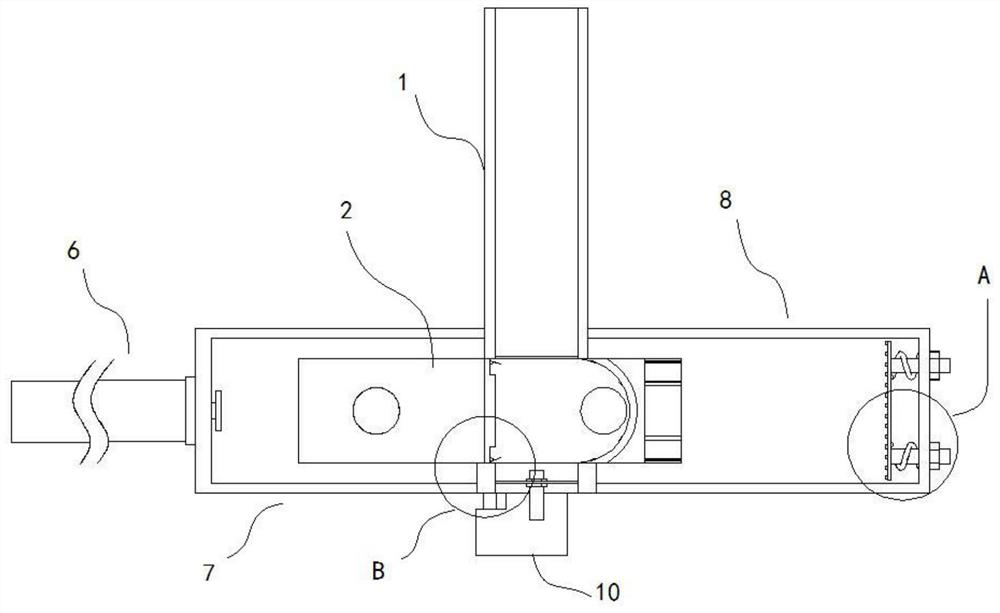

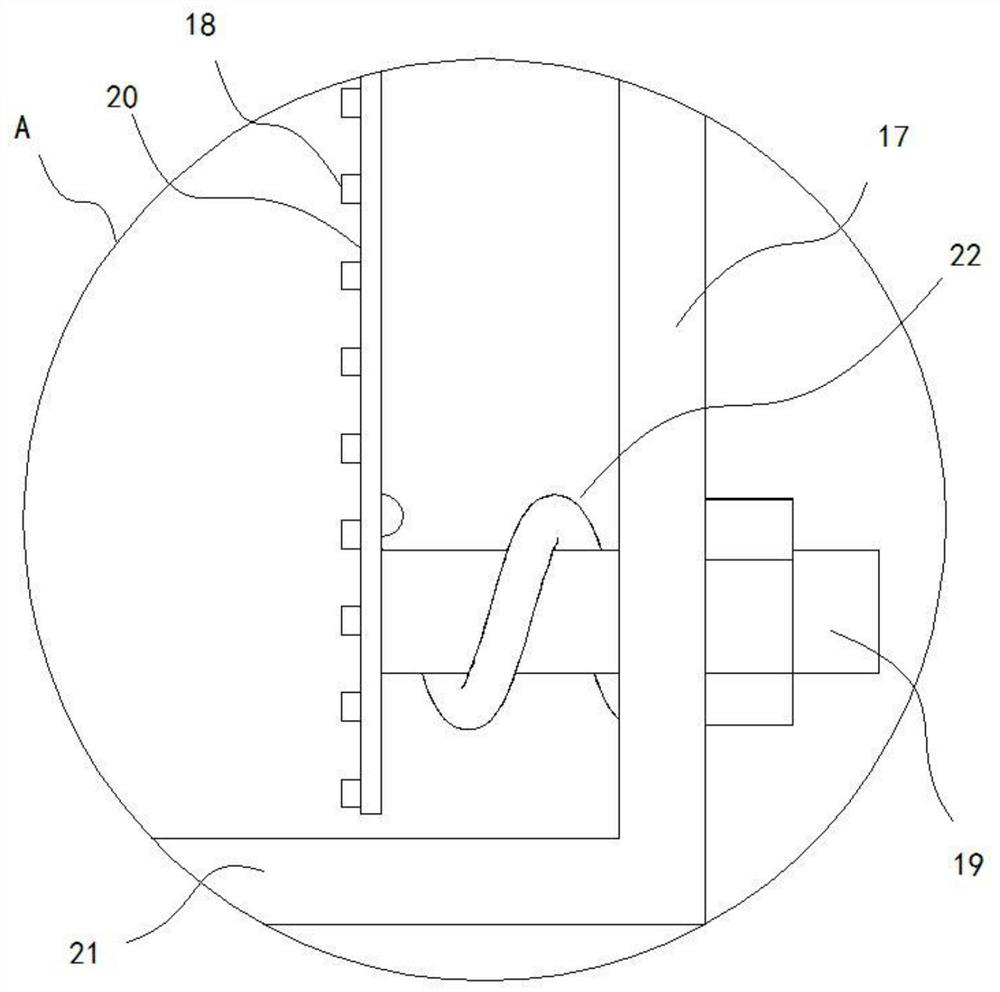

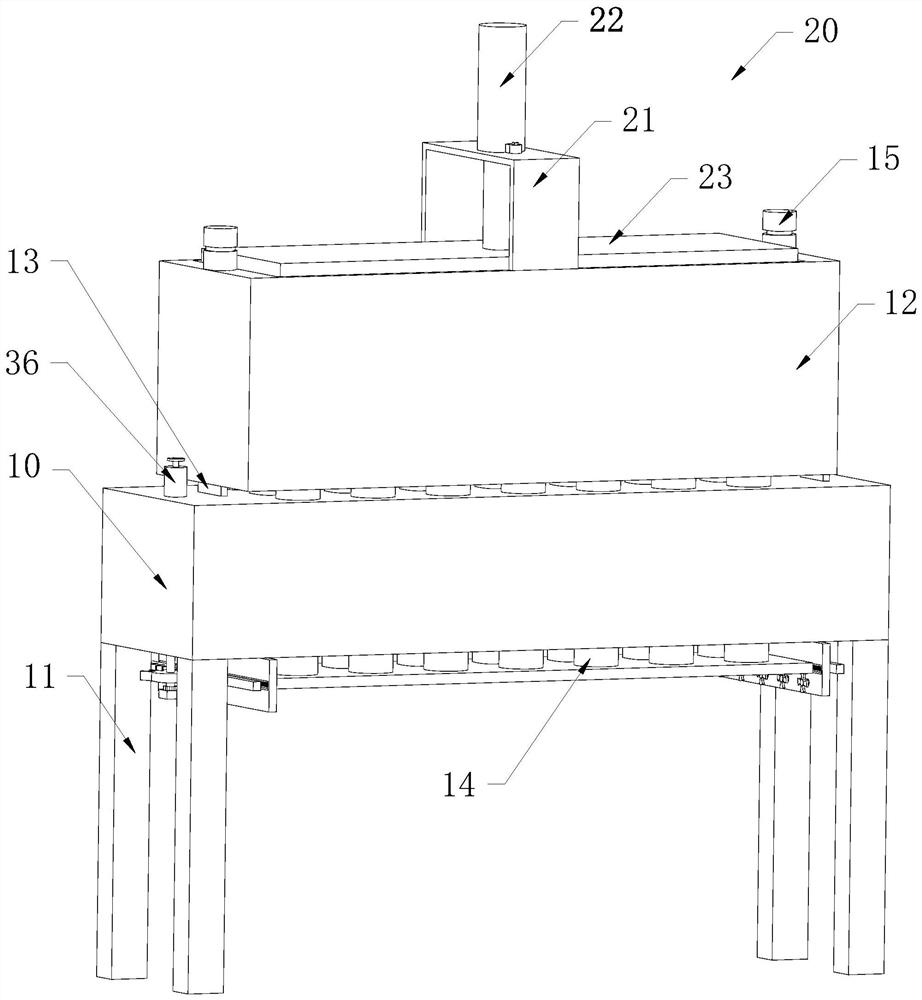

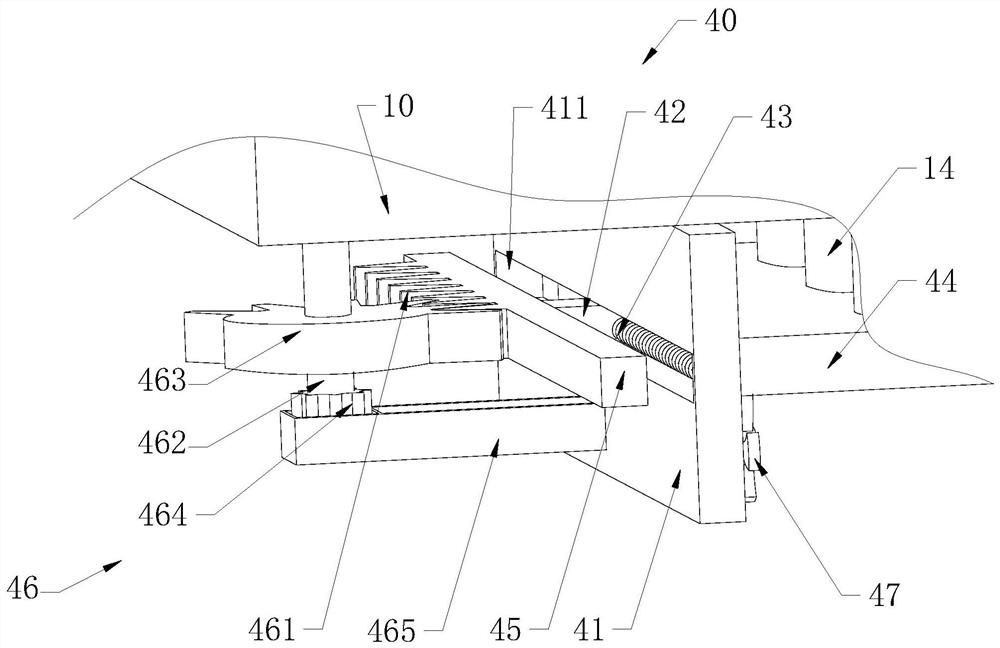

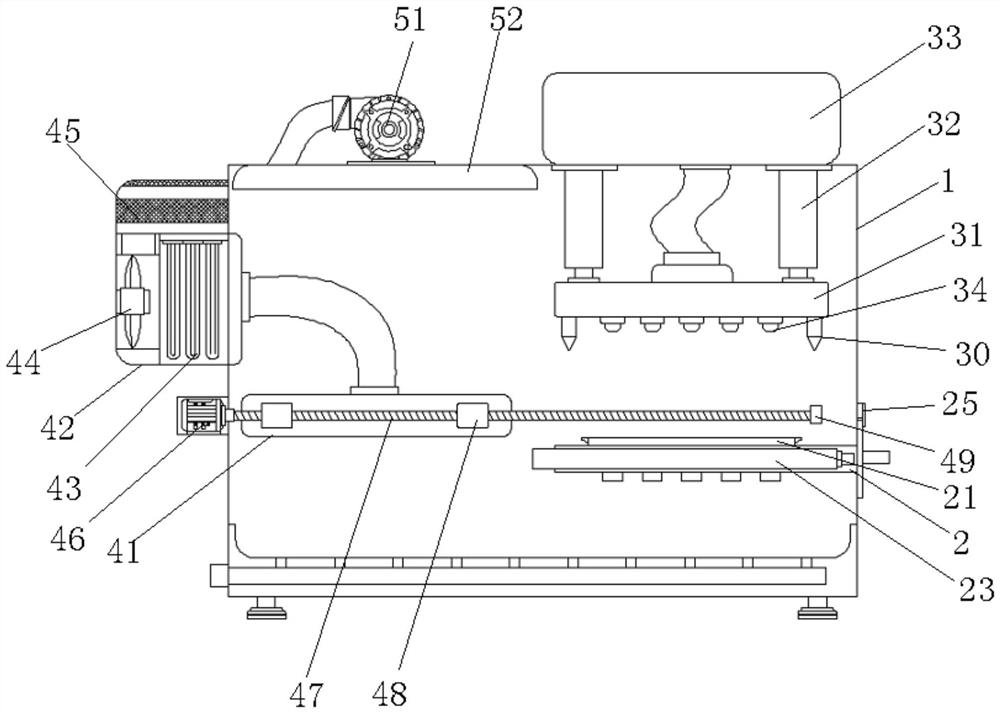

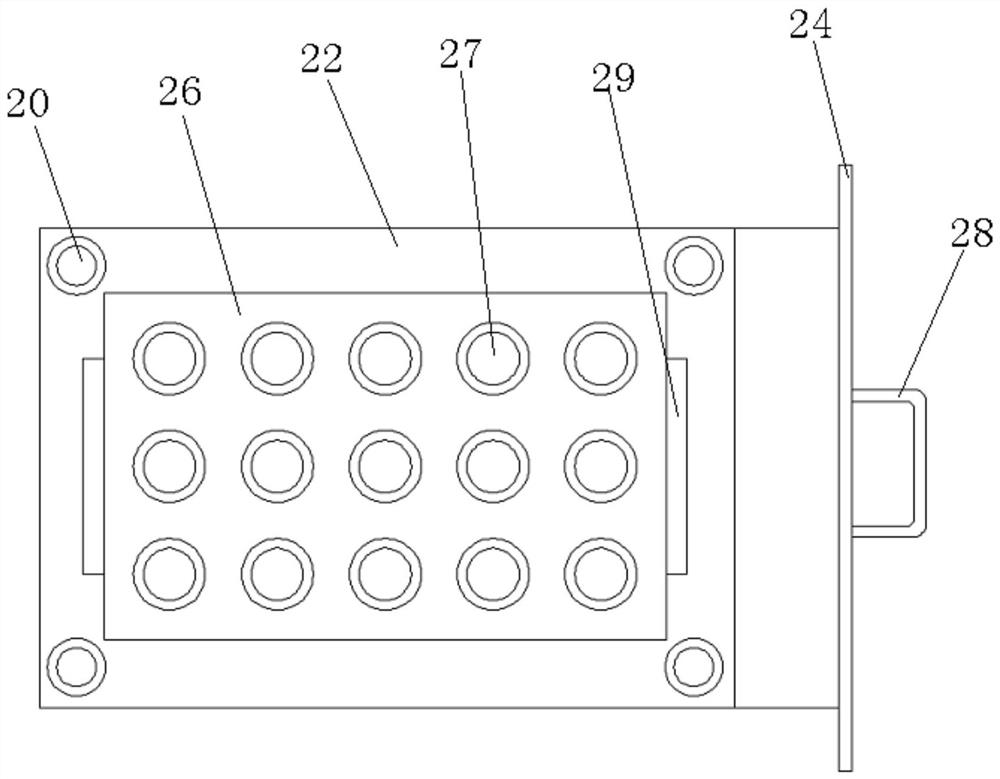

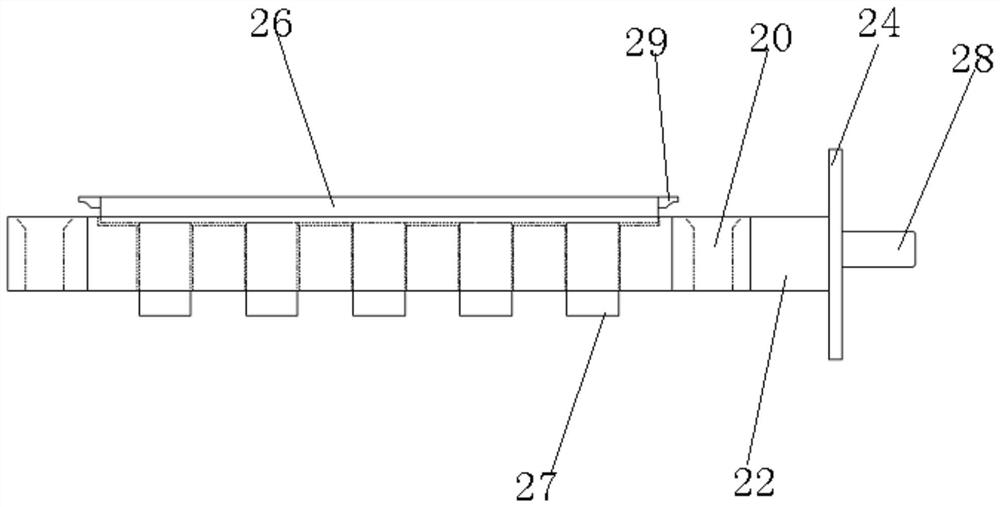

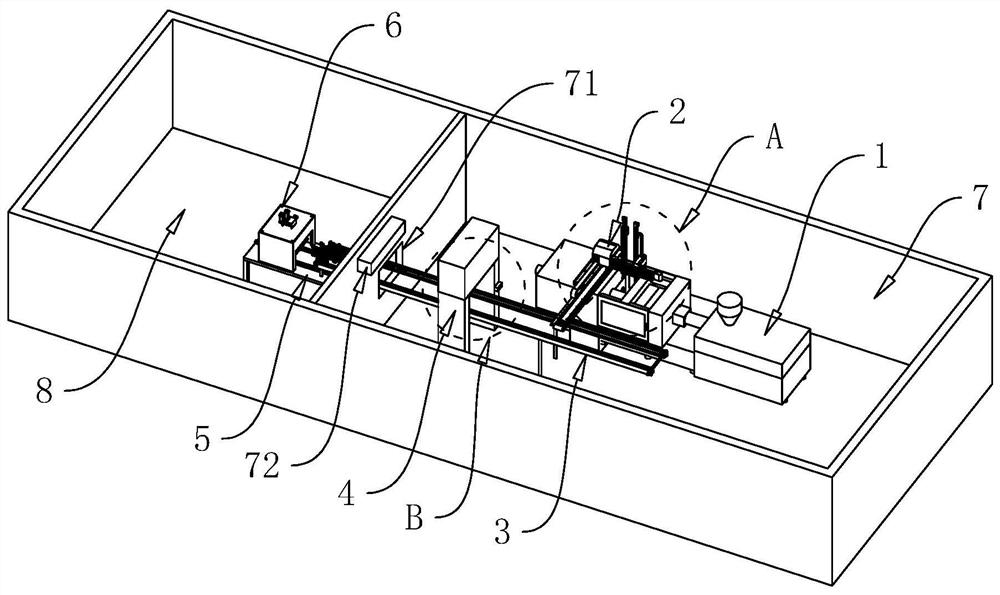

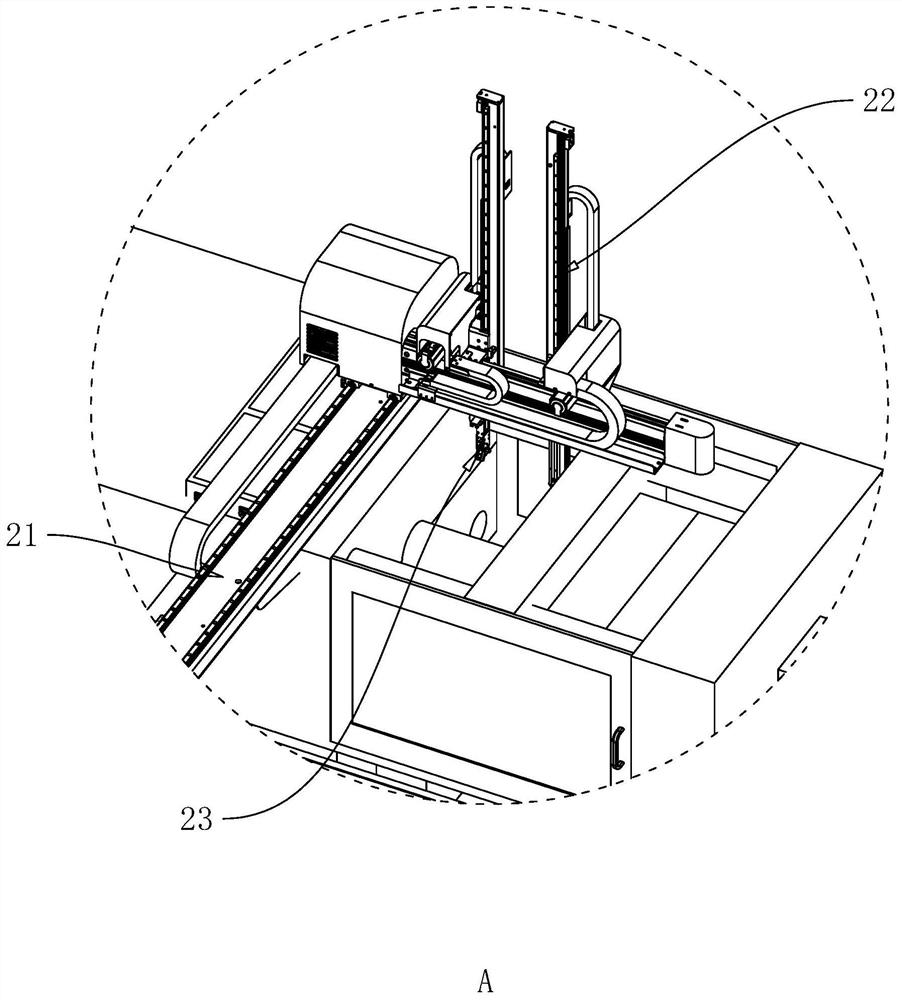

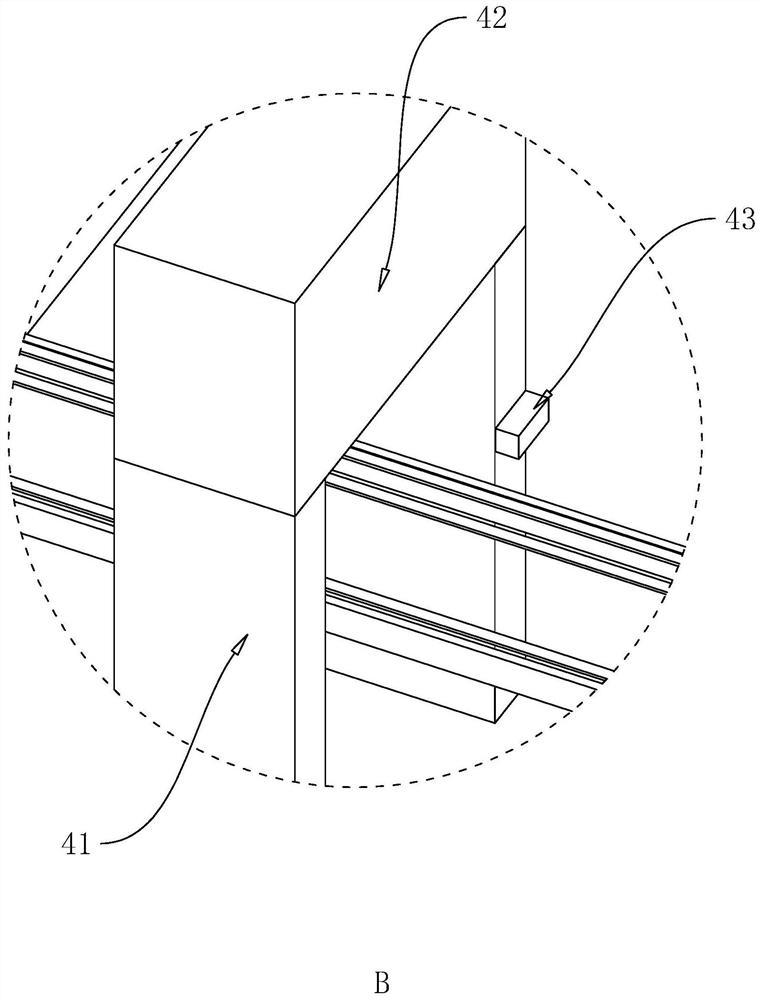

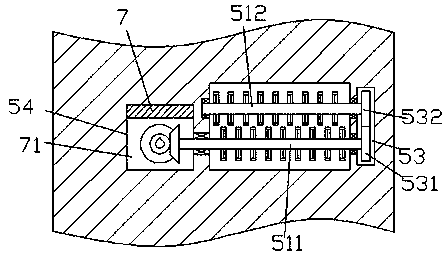

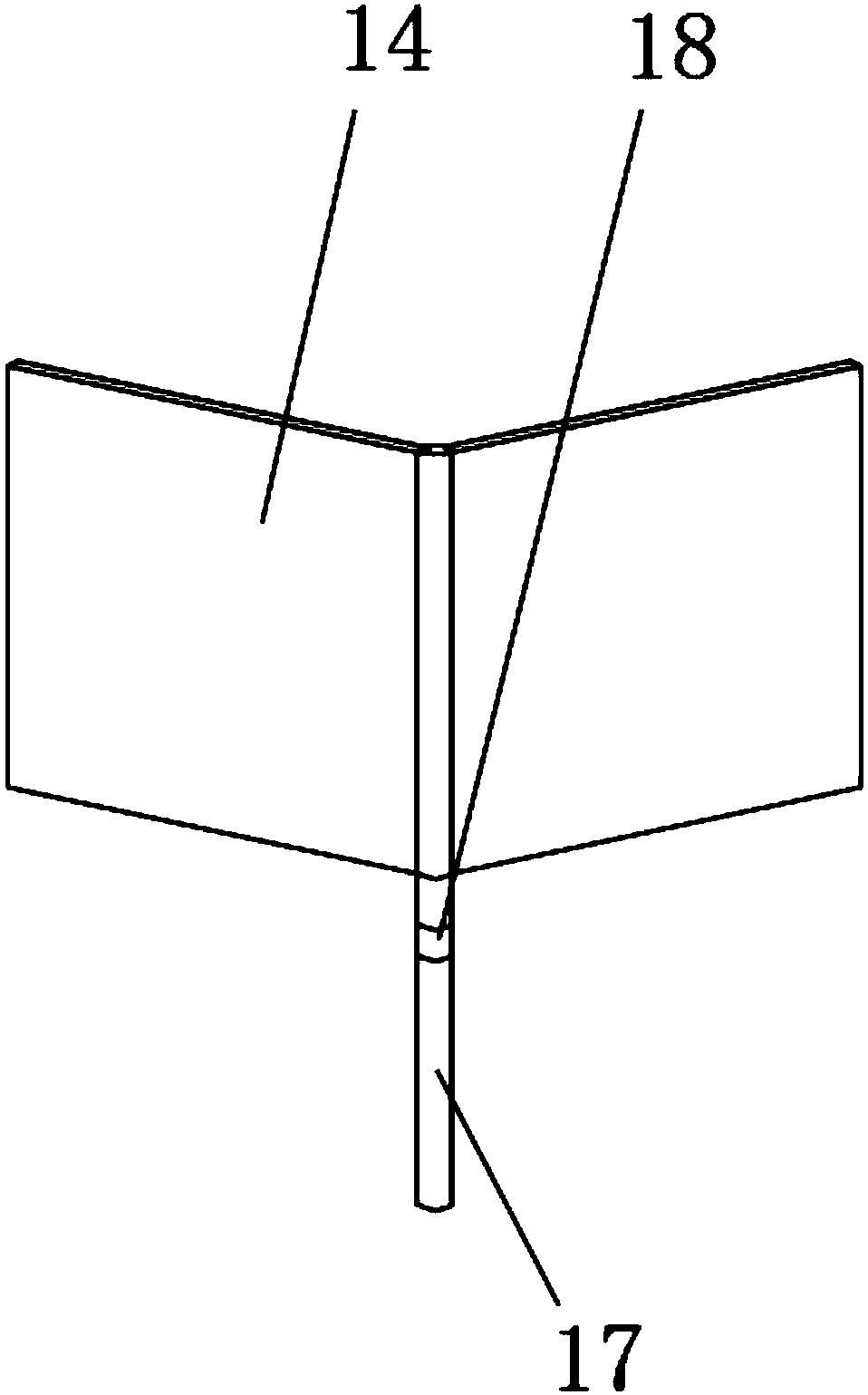

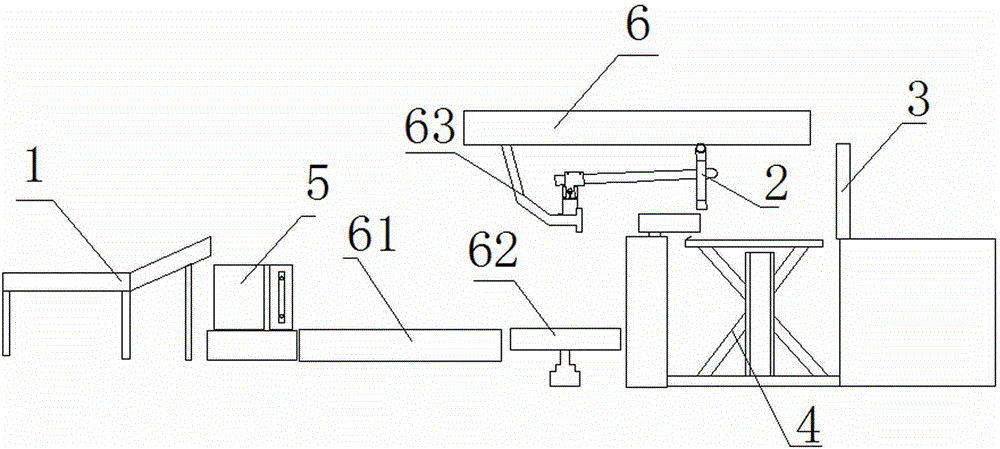

The invention discloses a terminal assembling welding device. The terminal assembling welding device comprises a terminal housing feeding mechanism arranged on a workbench of a box and located in a protection cover, a moving mechanical arm, a positioning mechanism, a flipping material transfer mechanism, a terminal feeding mechanism, a welding mechanism and a material splitting mechanism, whereinan operation interface is arranged on the protection cover of the box, an electric control cabinet is arranged in the box, the moving mechanical arm transports a terminal housing on the terminal housing feeding mechanism to the positioning mechanism for positioning, the terminal feeding mechanism comprises a terminal vibration disk and a line vibration rail, the line vibration rail is arranged ona discharging port of the terminal vibration disk, the line vibration rail points to the welding mechanism, the flipping material transfer mechanism transports the terminal housing after being positioned to the welding mechanism so as to match the terminal housing with a terminal, and the material splitting mechanism is arranged below a welding work station of the welding mechanism. By adopting the above mode, the terminal assembling welding device is compact in structure, can replace manual work for automatically performing assembling welding on the terminal product, and meanwhile performs detection sorting on the product.

Owner:昆山美佳合自动化设备有限公司

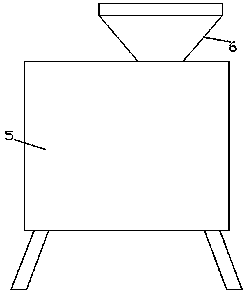

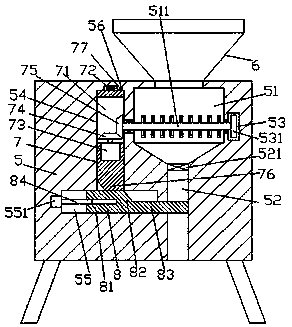

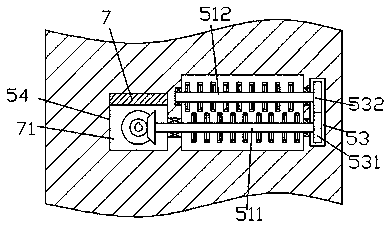

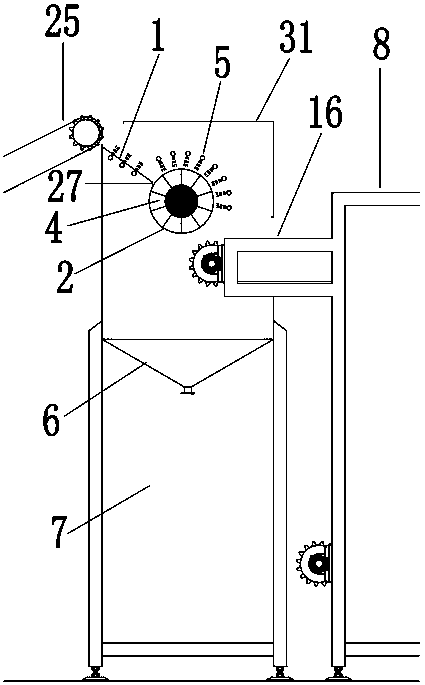

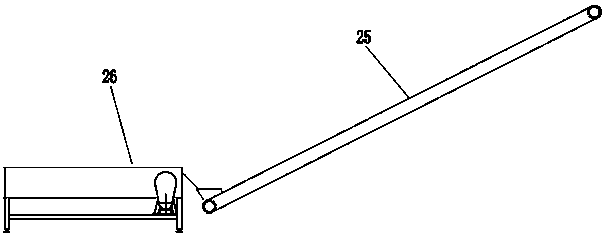

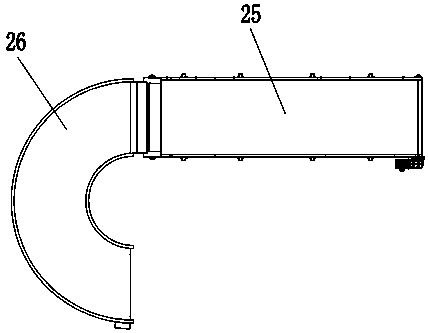

Environment-friendly smashing device with quantitative discharging function

InactiveCN106423387AGood crushing effectSpeed up the fallUsing liquid separation agentGrain treatmentsEnergy consumptionMechanical engineering

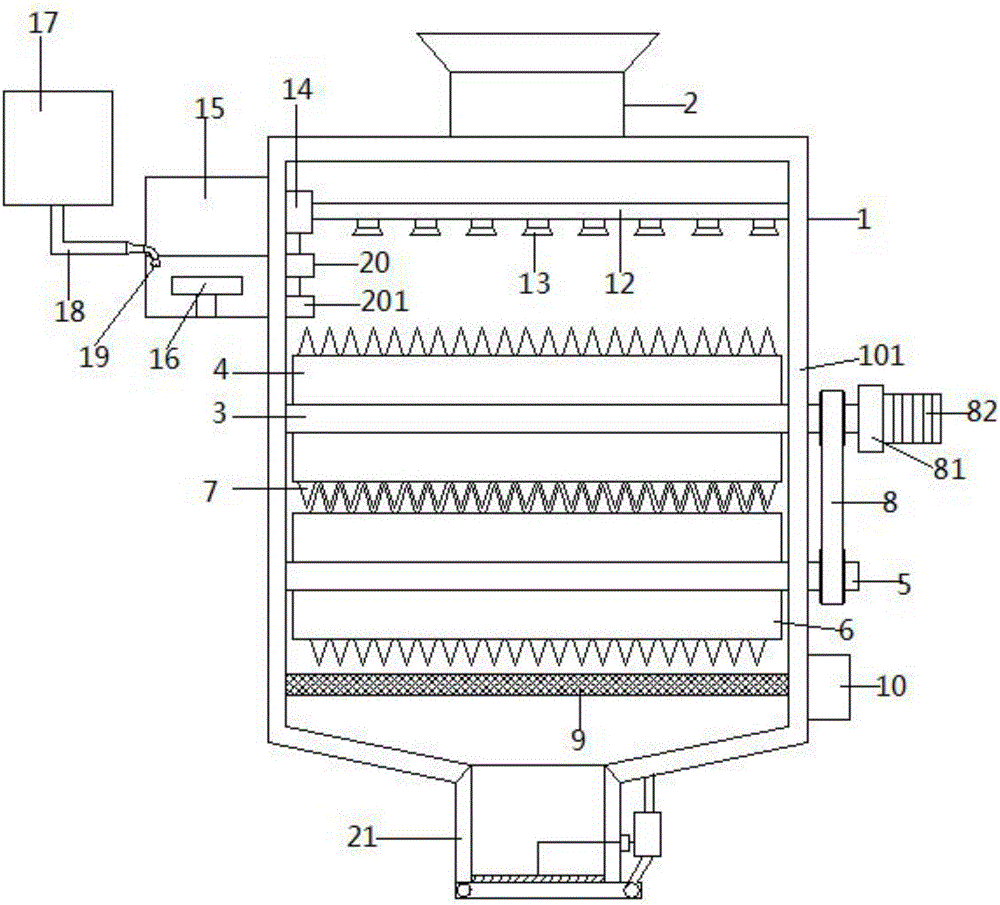

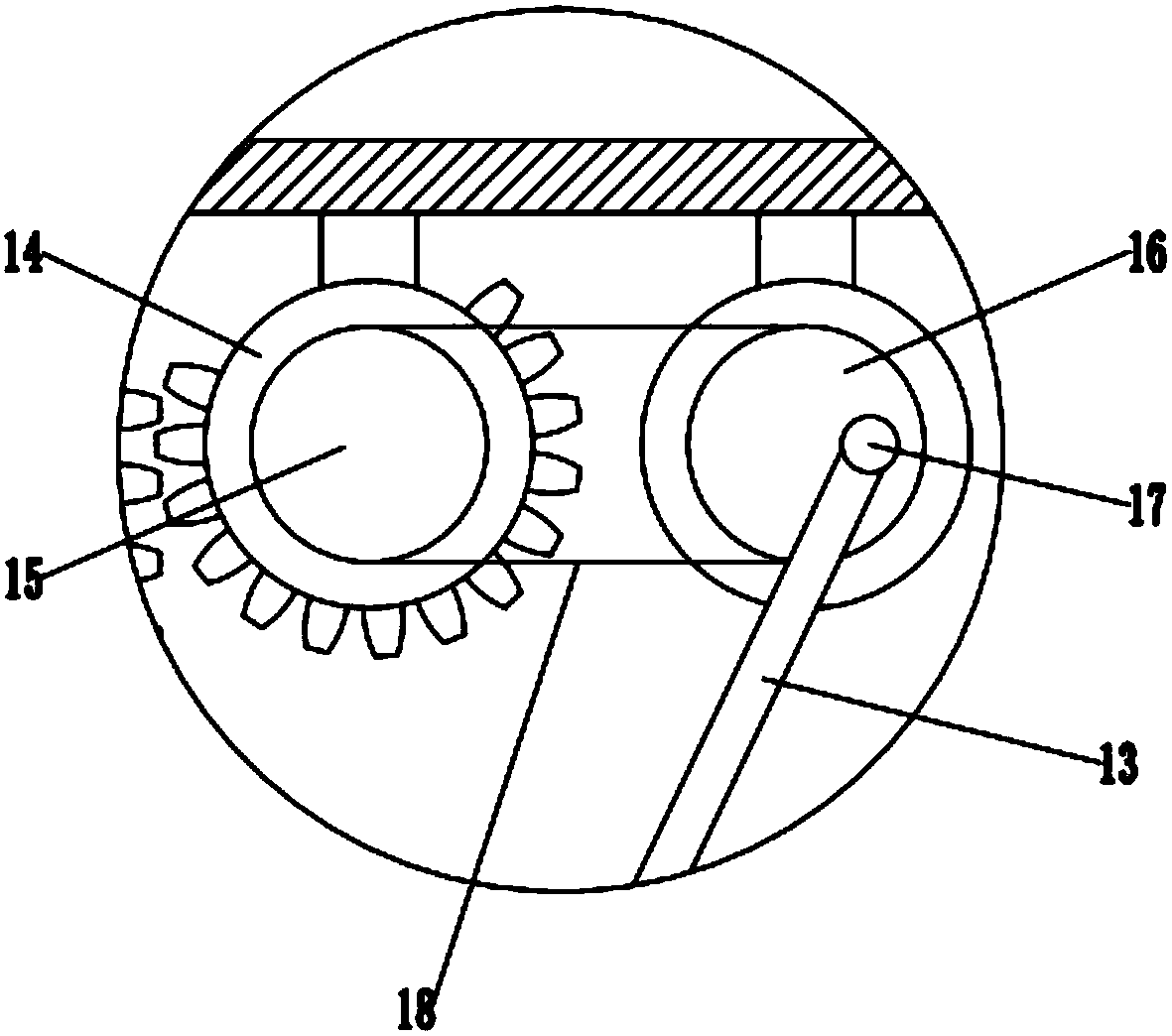

The invention discloses an environment-friendly smashing device with a quantitative discharging function. The environment-friendly smashing device comprises a device body. A silencing layer is arranged on the outer wall of the device body. A feed hopper is arranged on the upper side of the device body. A first rotary shaft is arranged on the upper side of the inside of the device body. A first squeeze roller is arranged on the outer wall of the first rotary shaft. A second rotary shaft is arranged below the first rotary shaft. A second squeeze roller is arranged on the outer wall of the second rotary shaft and arranged parallel to the first squeeze roller. Smashing teeth are arranged on the outer walls of the first squeeze roller and the second squeeze roller. According to the environment-friendly smashing device with the quantitative discharging function, the smashing teeth on the two squeeze rollers arranged vertically are engaged to smash materials, and the smashing effect is good; the two squeeze rollers are driven by one motor, so that the energy consumption is lowered; water mist can be sprayed into the device body through an atomizing device, the water mist fully covers the materials, the materials are humidified while dust is reduced, and the quality of the materials is guaranteed; and in addition, automatic discharging can be achieved, the discharging quantity in the discharging process can be controlled, and quantitative discharging is achieved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

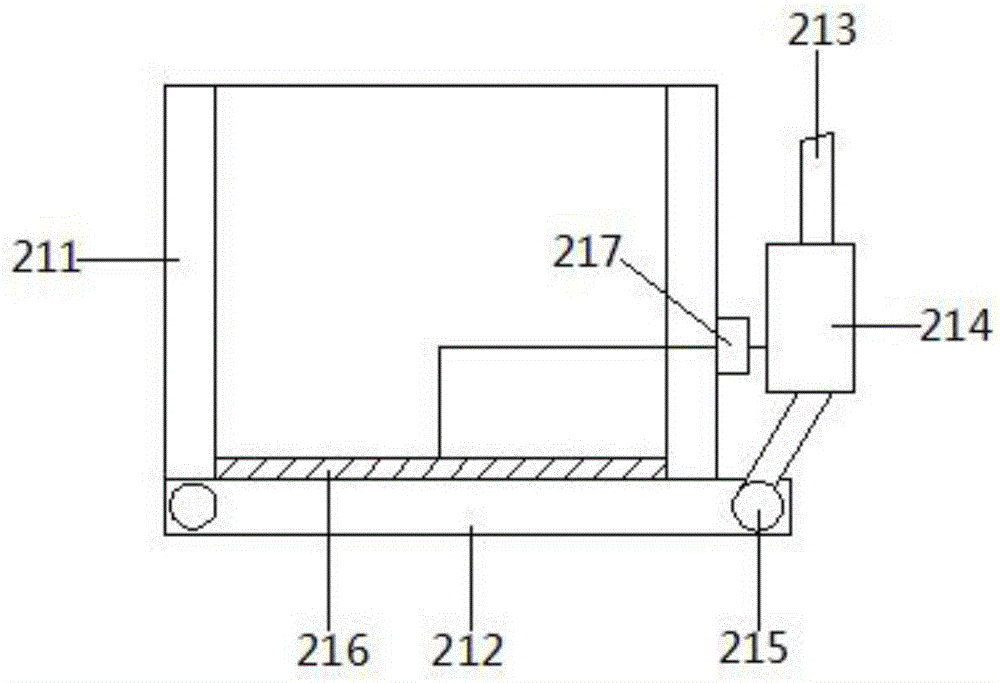

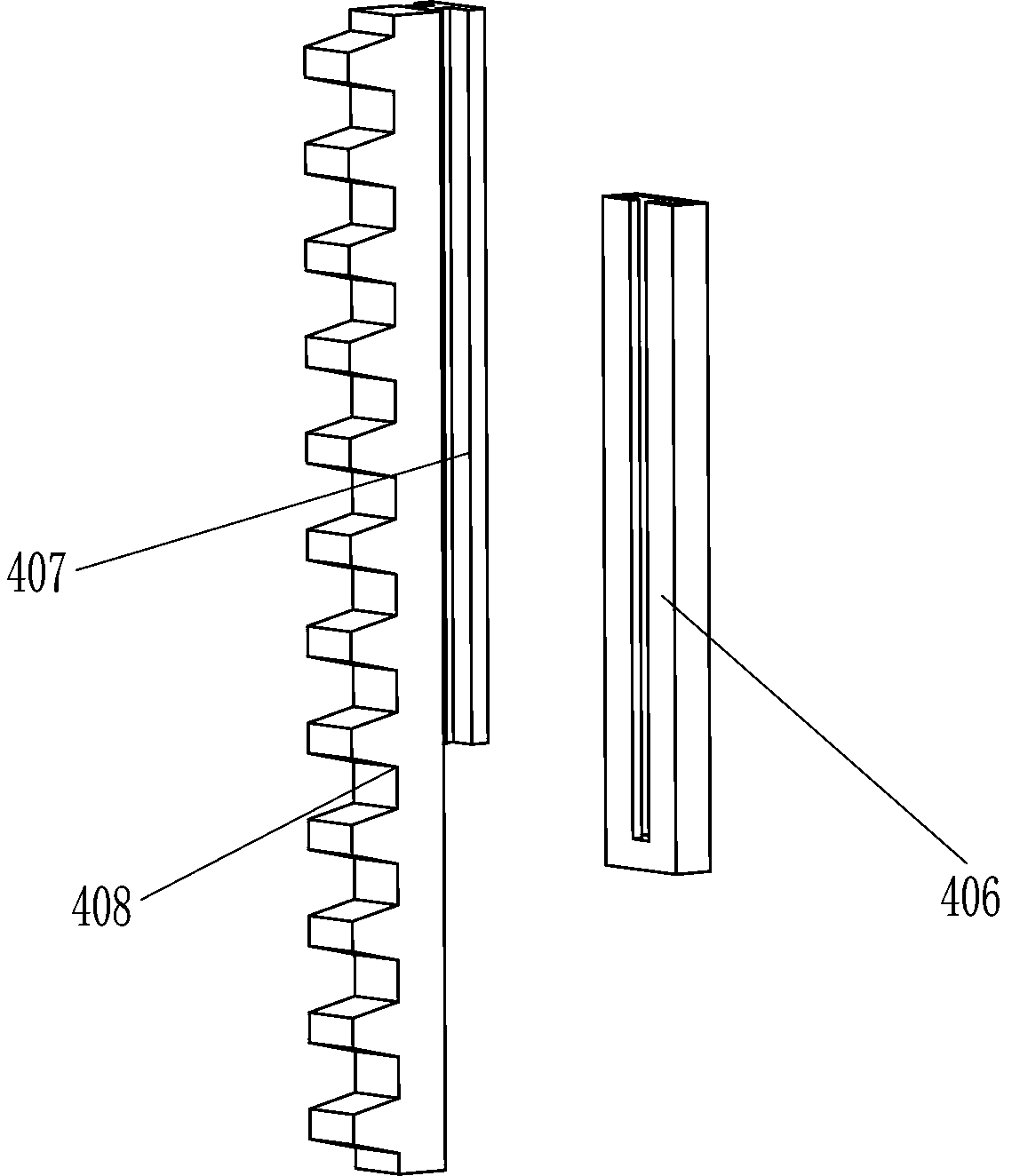

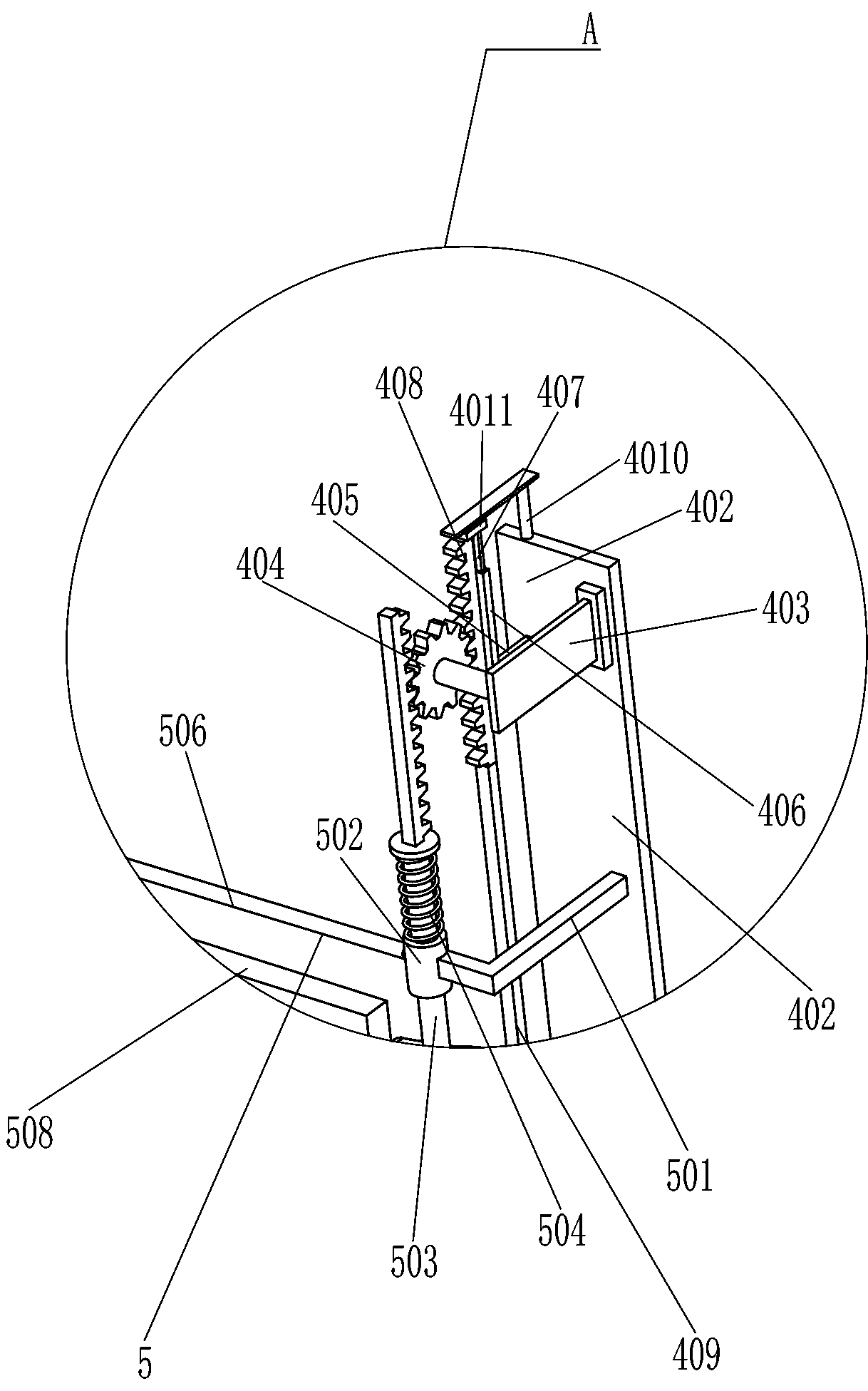

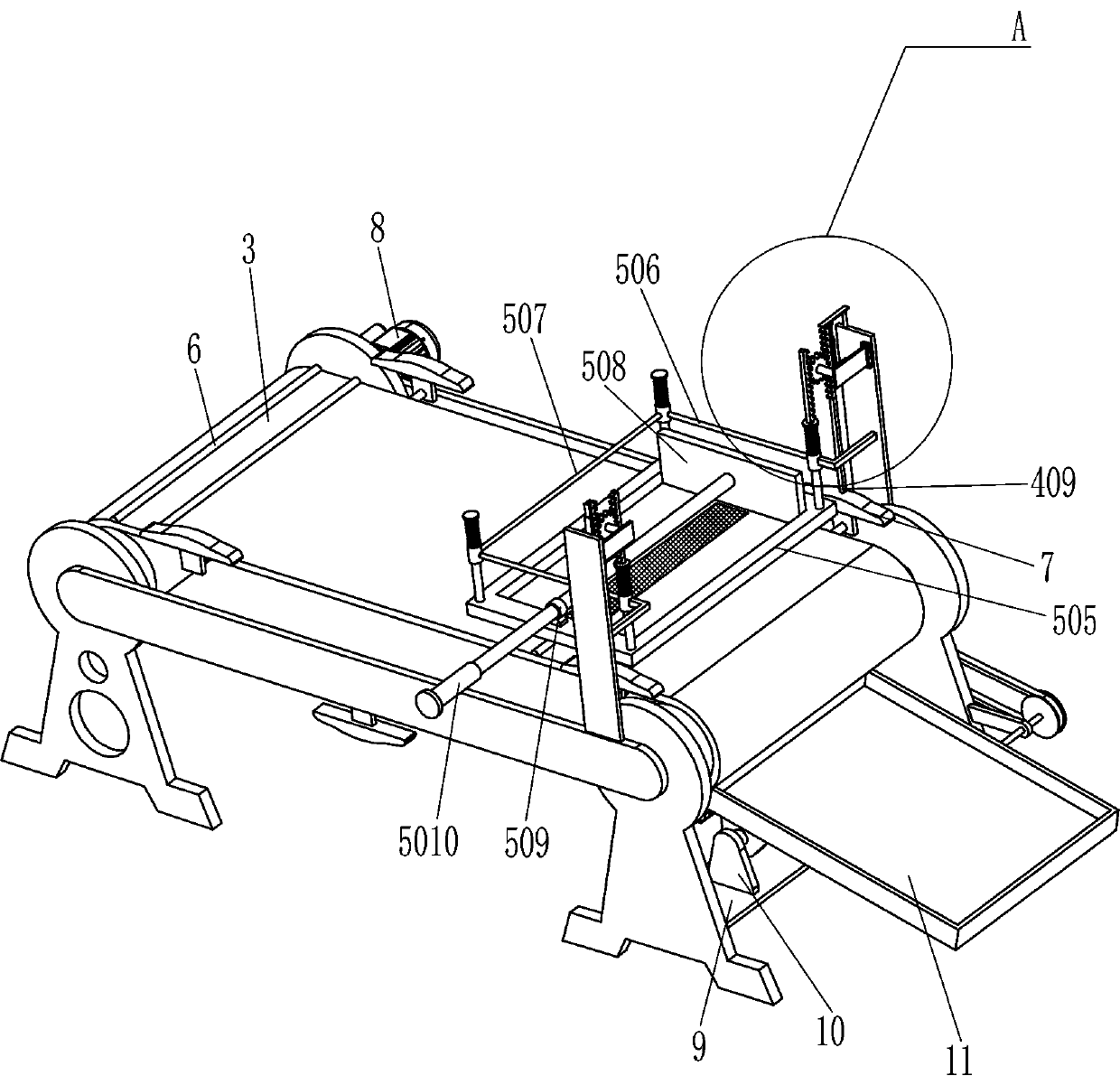

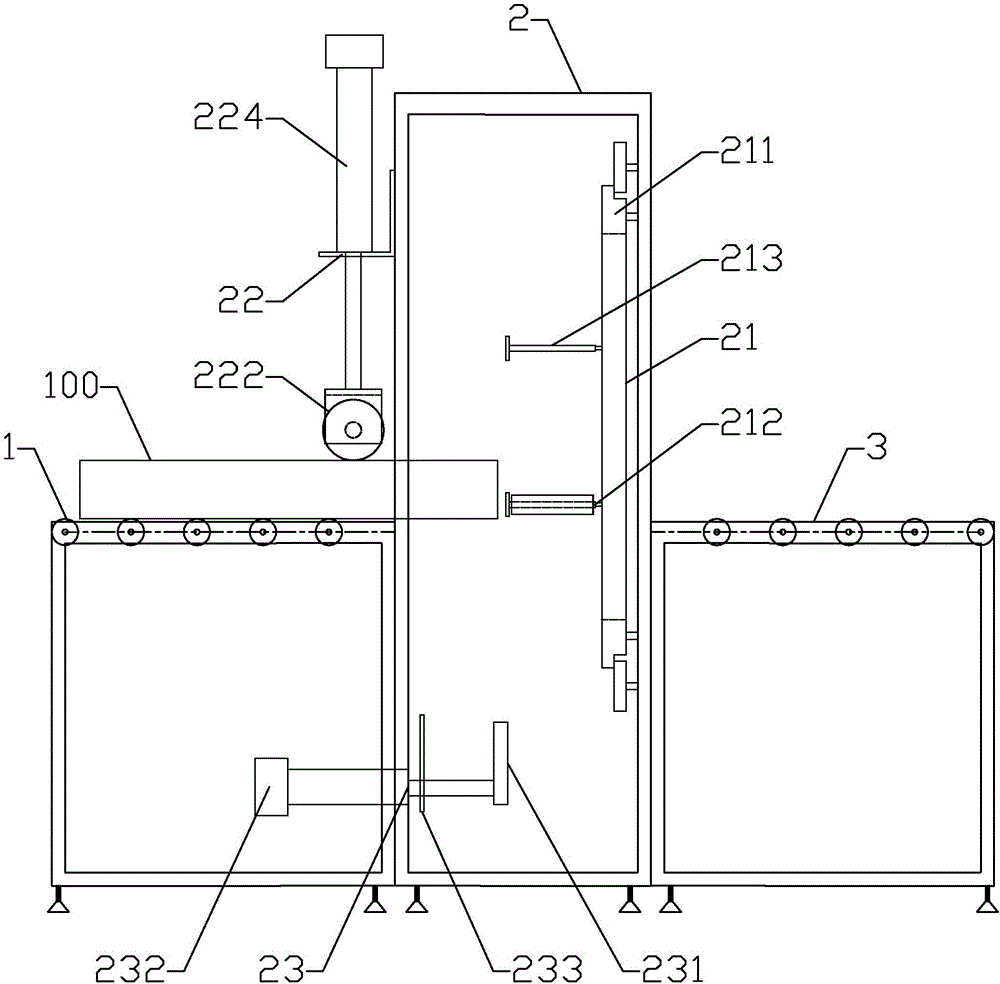

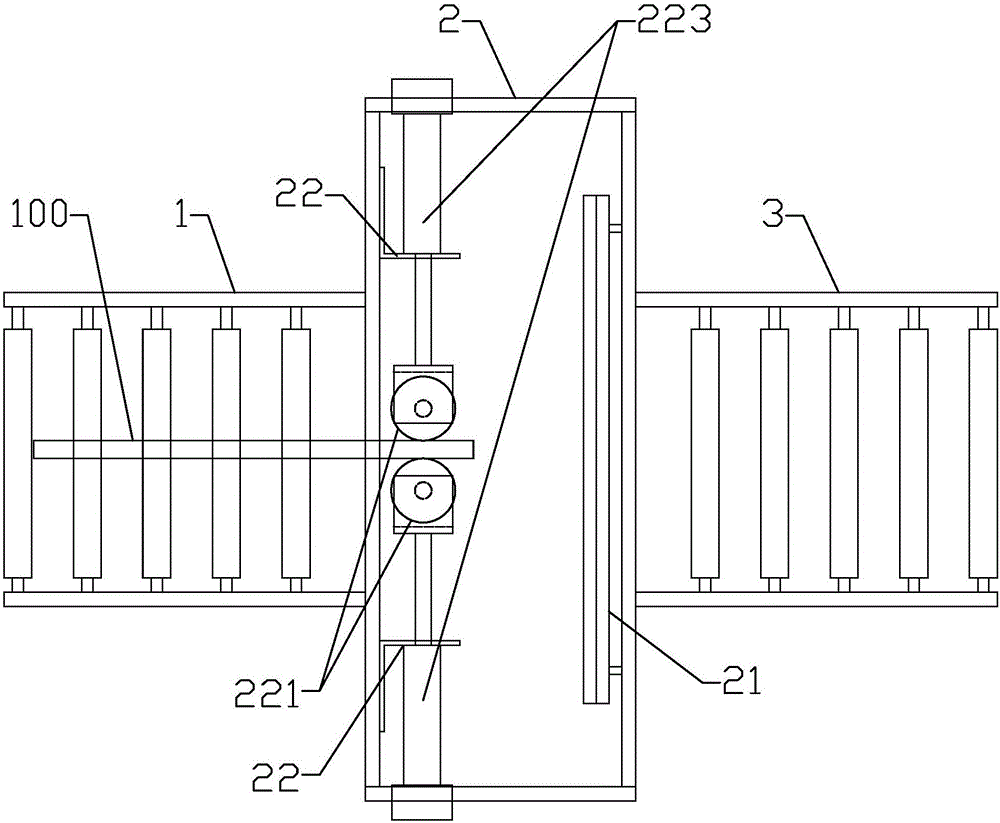

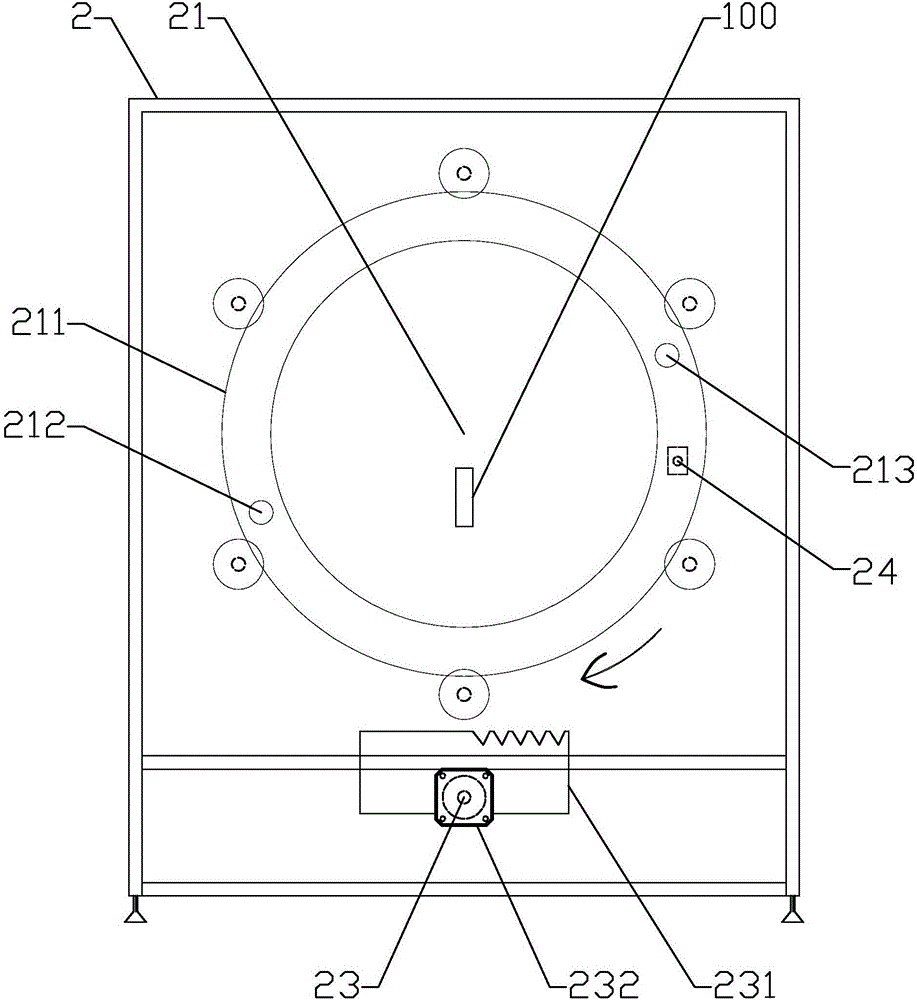

Hard box screen printing auxiliary packaging equipment

ActiveCN111498377AEasy to collectPrecise screen printingConveyorsScreen printersScreen printingEngineering

The invention relates to auxiliary packaging equipment, in particular to hard box screen printing auxiliary packaging equipment. The technical problem of the invention is to provide the hard box screen printing auxiliary packaging equipment capable of accurately performing screen printing and convenient for collecting and packaging. The hard box screen printing auxiliary packaging equipment comprises bases, transmission rollers, a conveying steel belt and a screen printing device, wherein the bases are used for supporting the whole equipment; the transmission rollers are arranged between the bases; the number of the transmission rollers is two; the conveying steel belt is around on the transmission rollers; the screen printing device is arranged between pushing devices and is used for carrying out screen printing on hard boxes. According to the hard box screen printing auxiliary packaging equipment, effects of accurate screen printing and convenient collecting and packaging are achieved; under coordination effect of push rods and push plates, a speed reduction motor just stops working when the screen printing device is in close contact with the hard box; and therefore, an effect ofaccurate screen printing can be achieved by performing screen printing on the hard box.

Owner:WENZHOU WAPRO TECH CO LTD

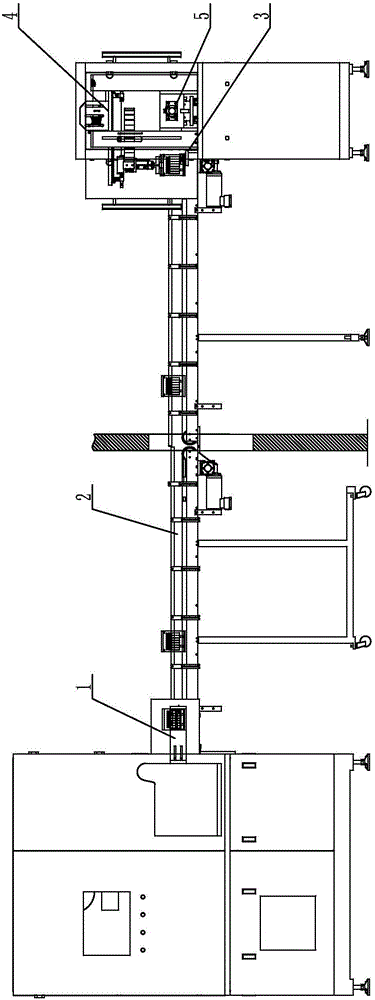

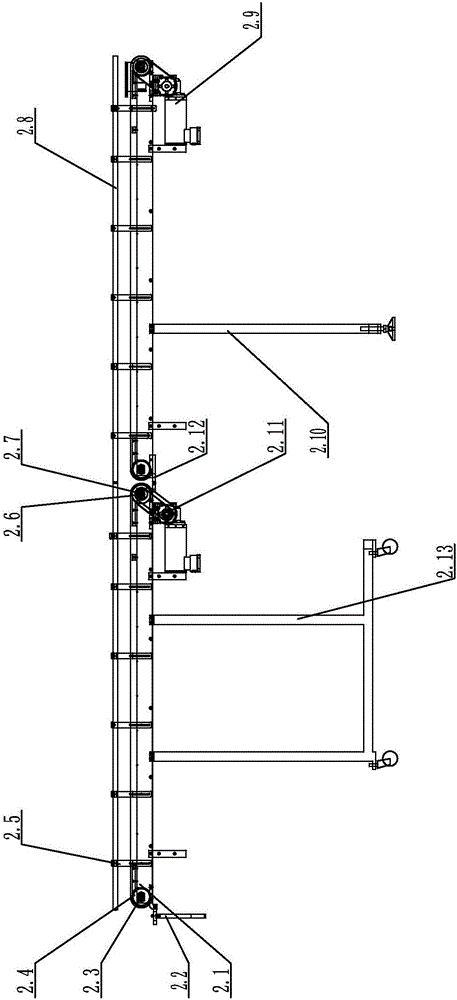

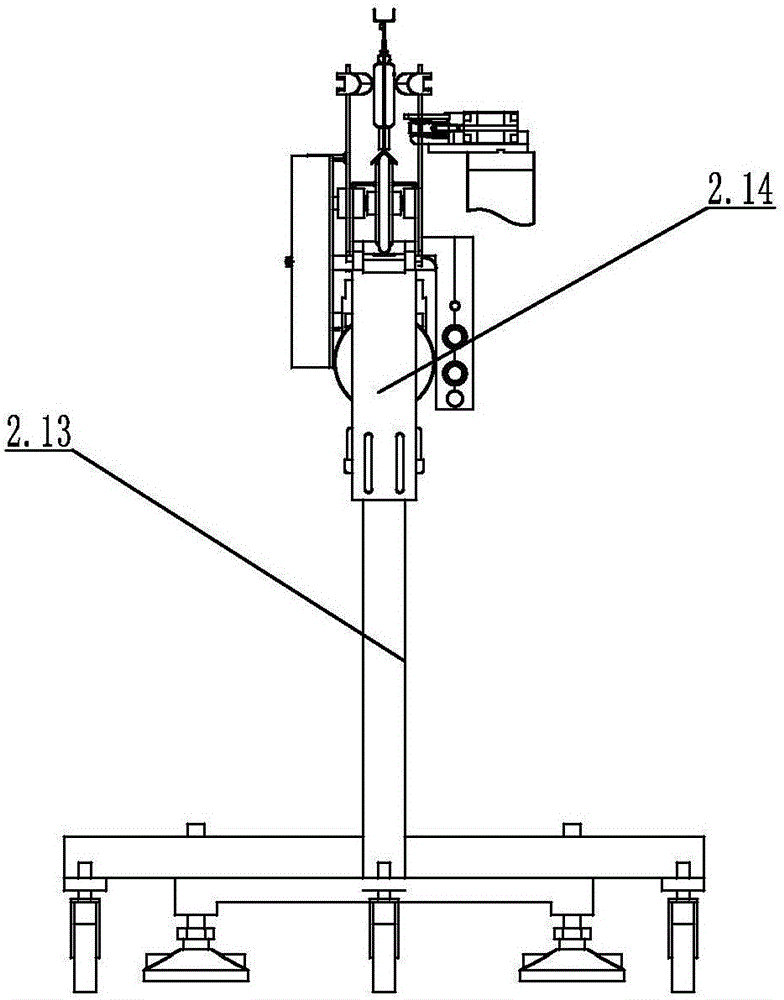

Winding packager

PendingCN106697401AEasy to operateReduce labor intensityWeb rotation wrappingPackaging automatic controlConductor CoilMechanical engineering

Owner:ZHAOQING CITY ZHONGNANTIAN IND CO LTD

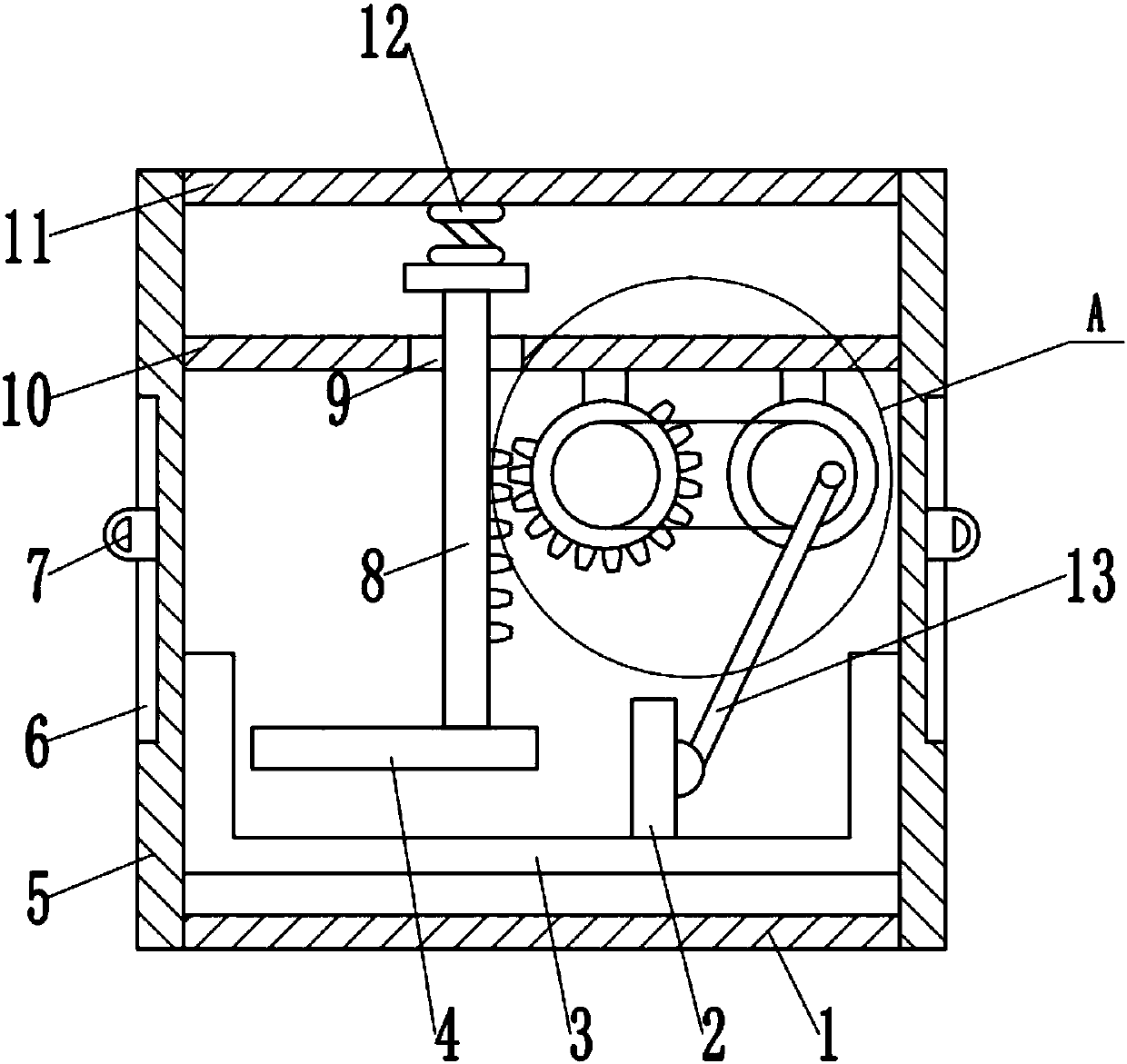

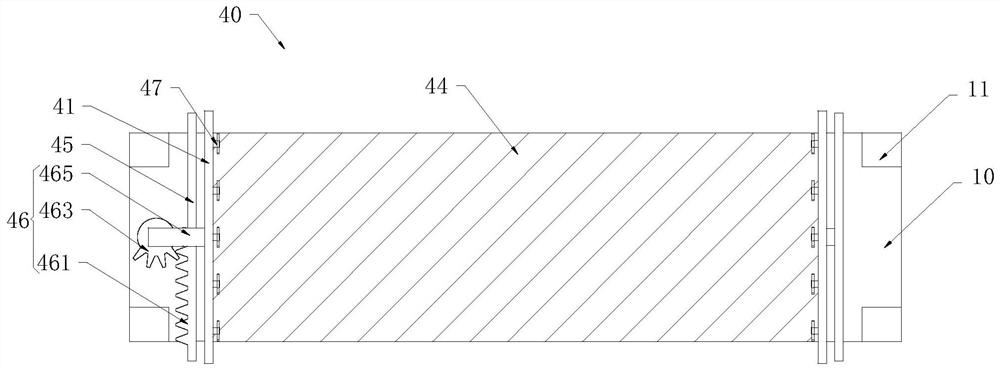

Multi-angle wool compaction device

The invention discloses a multi-angle wool compaction device which comprises a pedestal and a placement seat, wherein two side plates are symmetrically mounted on the left side and the right side of the pedestal; the placement seat is fixedly mounted on the inner sides of the two side plates; a through slot is formed in a partition; a rack is mounted in the through slot in a sliding manner; the upper end of the rack is fixedly connected with a top plate through a spring; a second pressing plate is fixedly mounted at the lower end of the rack; a fan-shaped gear is mounted at a position, which is located on the right side of the through slot, at the bottom of the partition; a tooth part of the fan-shaped gear meshes with the rack; a cylindrical pin is fixedly mounted at a position, which isfar away from the circle center, on the right side of a driven belt wheel; the cylindrical pin is connected with a push rod in a rotatable manner; a first pressing plate is mounted on the right side of the placement seat in a sliding manner; and the other end of the push rod is hinged with the right side of the first pressing plate. The multi-angle wool compaction device disclosed by the inventioncompacts wool in multiple angles through the first pressing plate and the second pressing plate, so that the wool can be completely compacted; and the multi-angle wool compaction device is compact instructure, excellent in compaction effect and favorable for subsequent packaging.

Owner:阜南华翔羊毛衫有限公司

Control valve superior and inferior product checking and sorting mechanism, control valve machining equipment and machining and control method

InactiveCN105881020AIncrease productivityImprove product qualityAssembly machinesGeological measurementsMachine controlEngineering

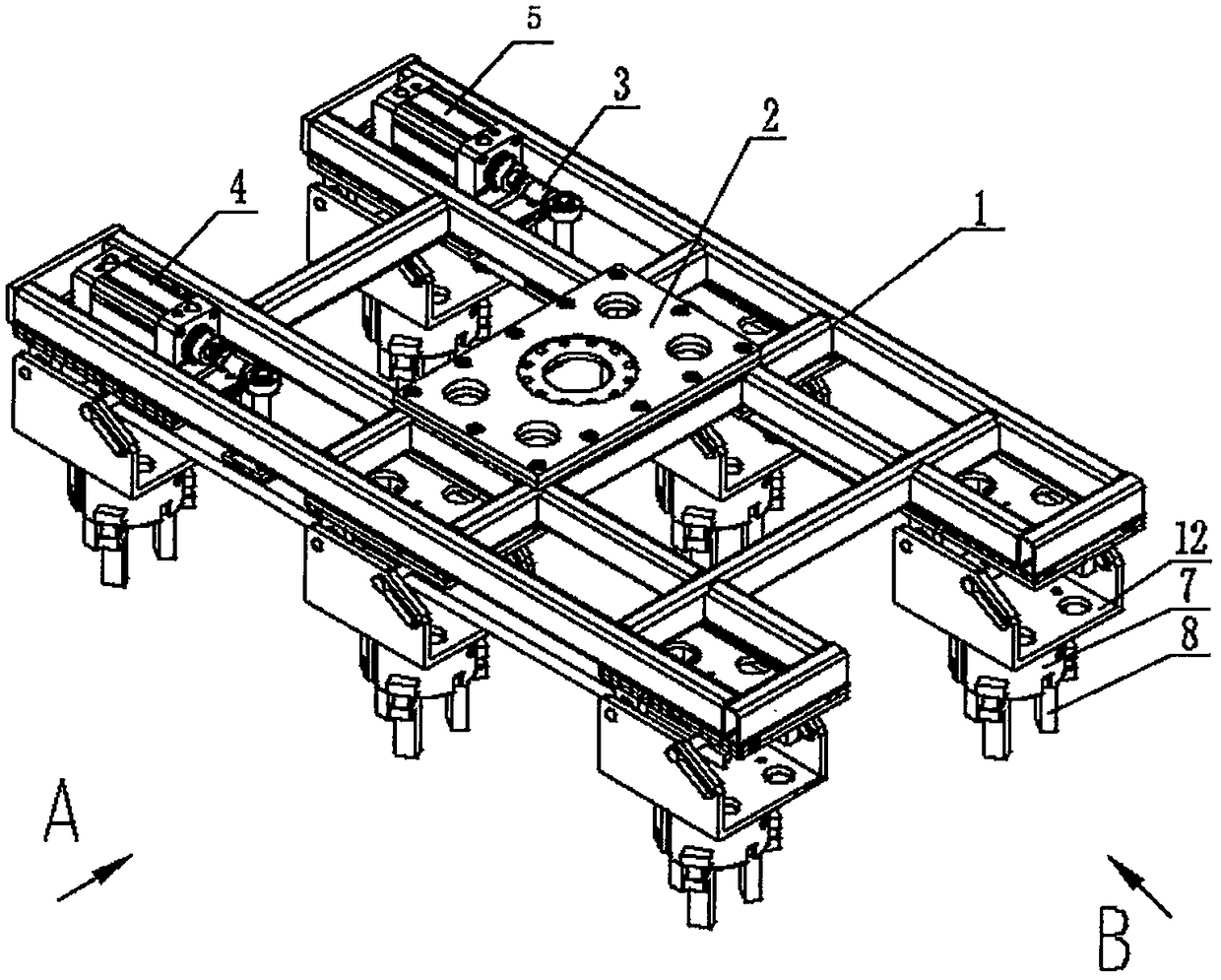

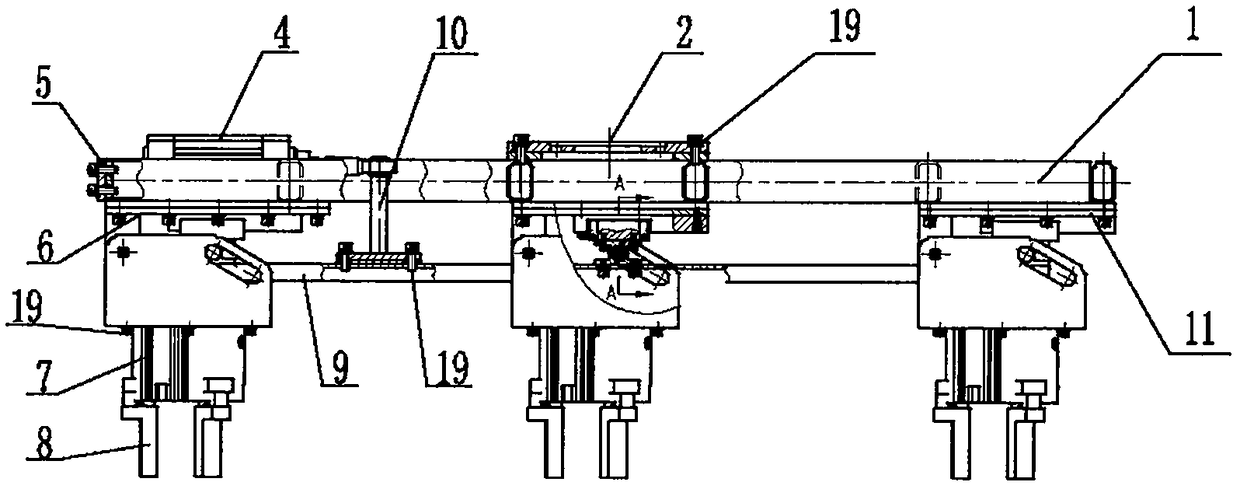

The invention discloses a quality control valve inspection and classification mechanism, control valve processing equipment and a processing and control method, and belongs to the technical field of control valve assembly equipment. It includes a turntable dividing mechanism and an electric control system, as well as an automatic feeding and installation mechanism and a valve control outlet mechanism. The automatic feeding equipment of the mechanism receives the control valve to be processed, and the installation equipment of the automatic feeding and installation mechanism installs and processes the components on the control valve. The control valve is discharged, and the turntable dividing mechanism is evenly equipped with control valve fixtures, and the automatic feeding equipment of the automatic feeding and installation mechanism places the control valves on the control valve fixtures. It uses a manipulator to place it precisely, saves labor, realizes automation, and improves production efficiency and quality.

Owner:ANHUI LAITE GAS SPRING CO LTD

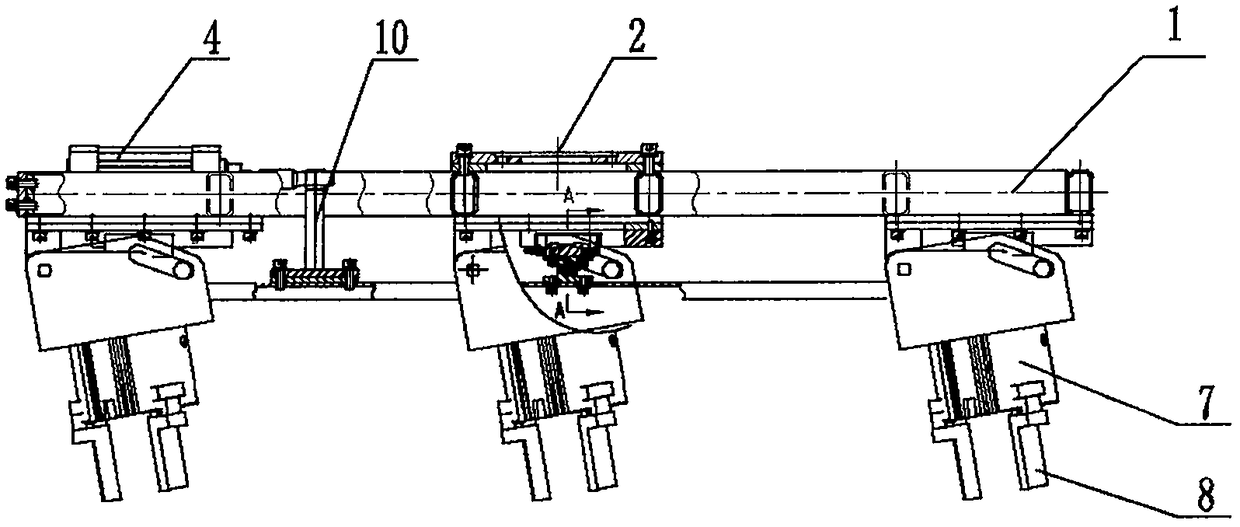

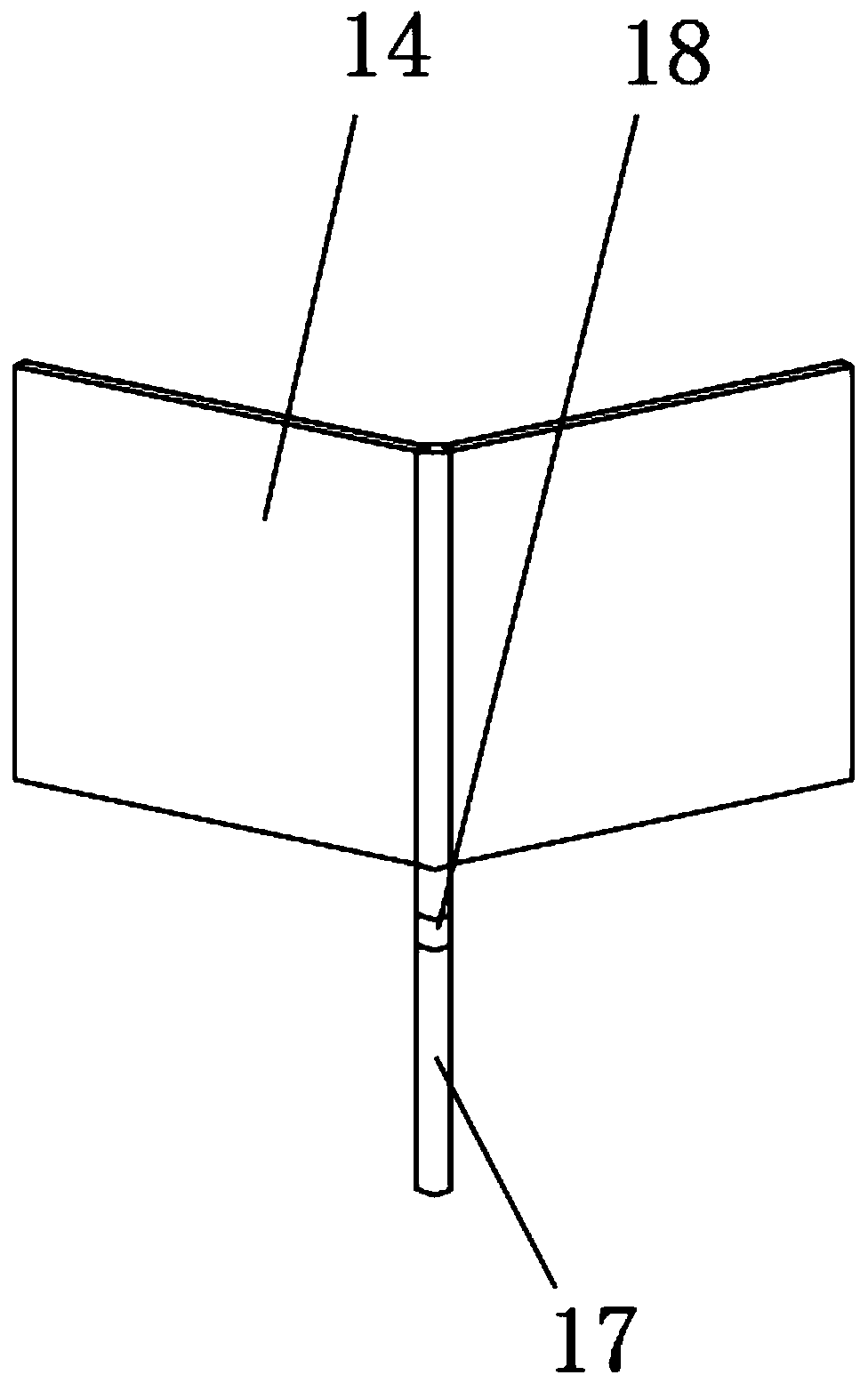

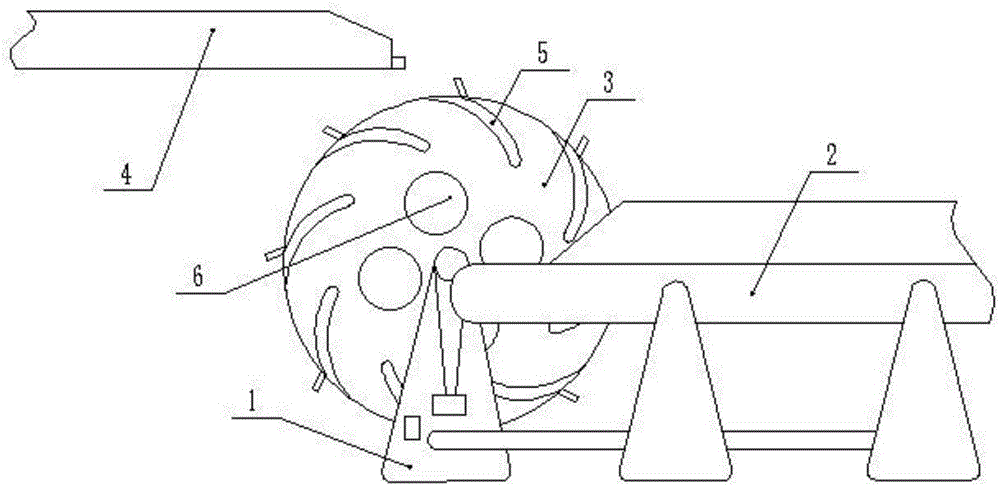

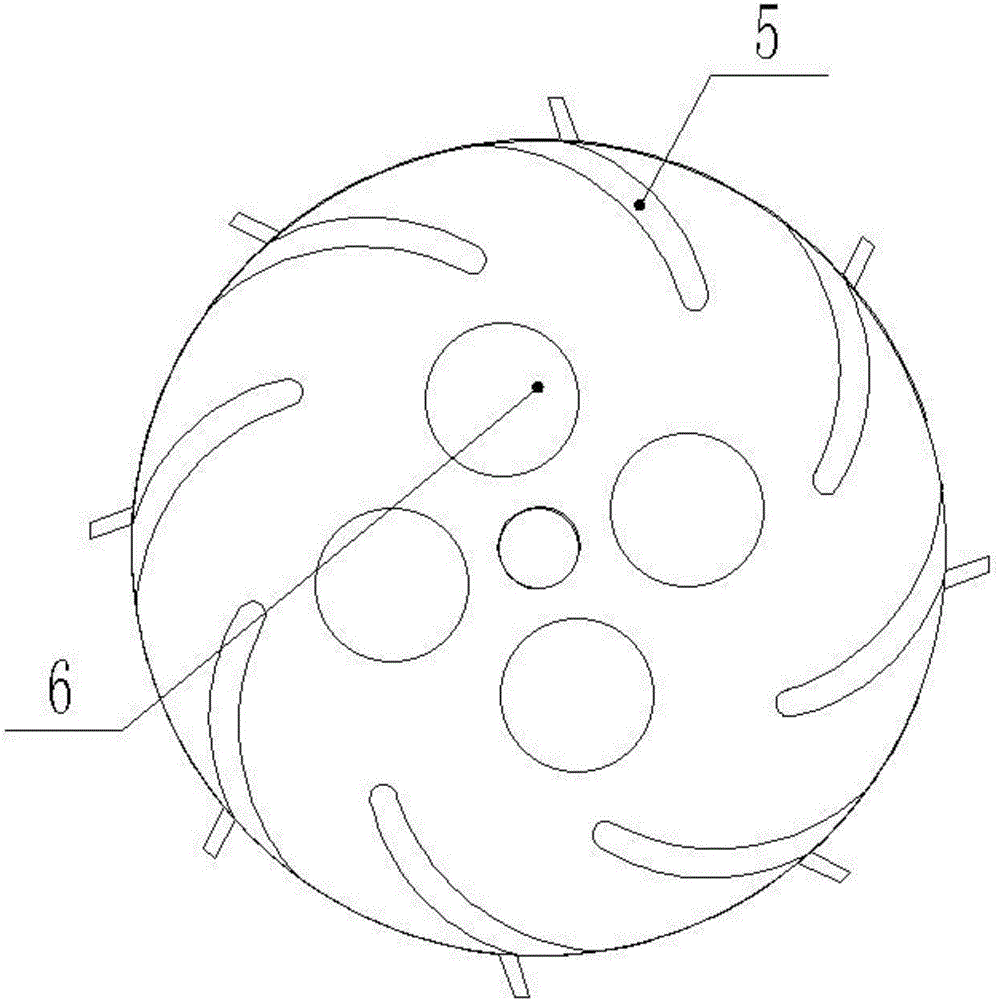

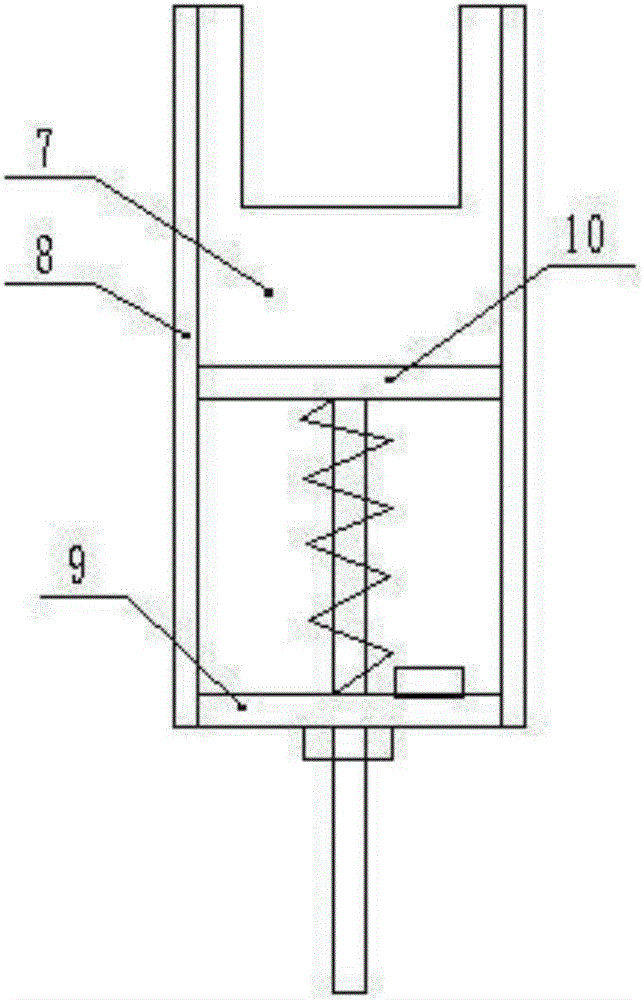

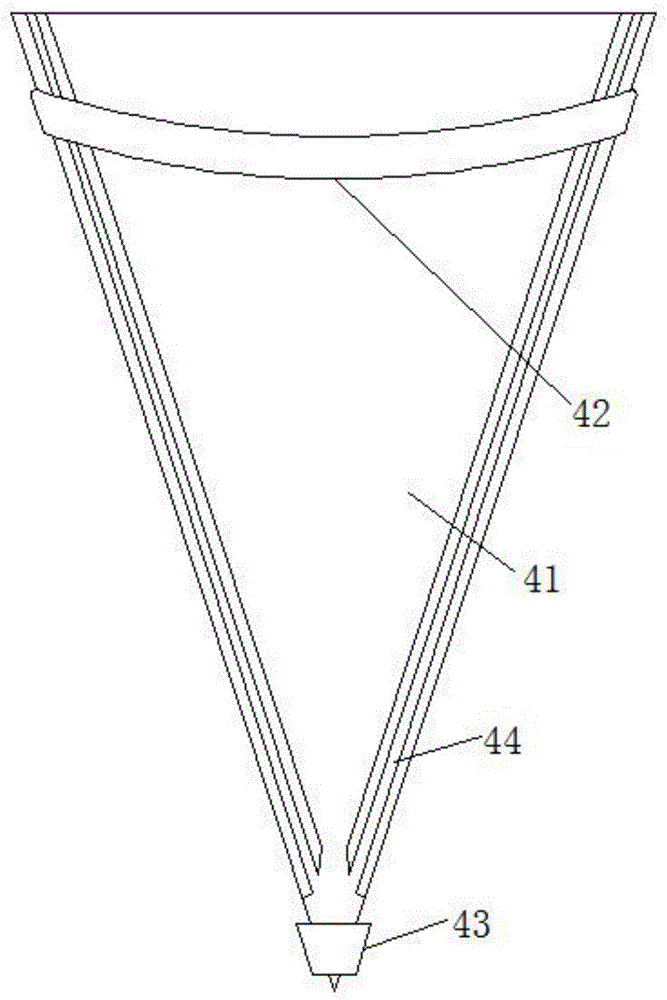

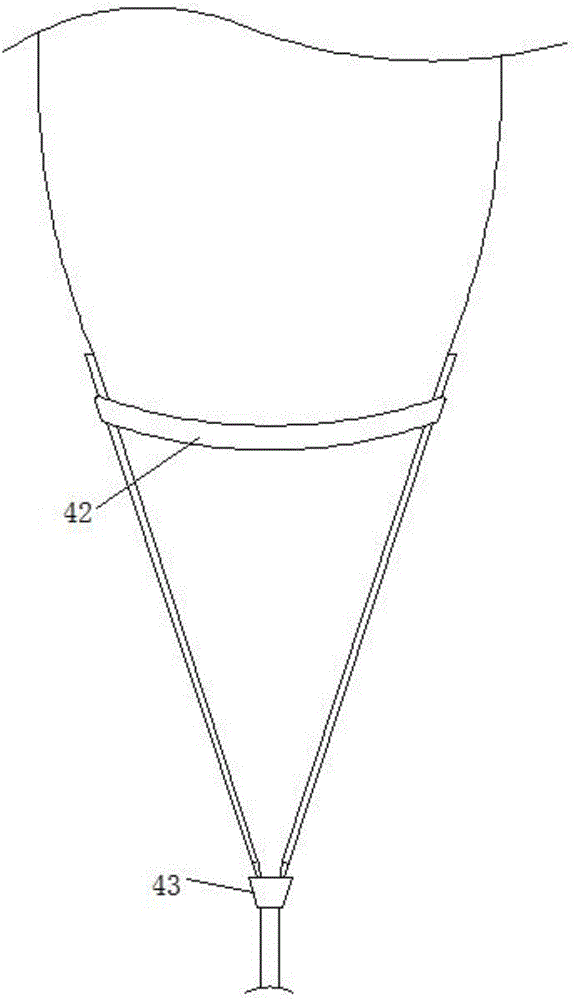

Chemical fiber cake robot unloading clamp

The invention provides a chemical fiber cake robot unloading clamp. The clamp comprises a frame, a robot connecting plate, a corner driving cylinder, a fish-eye joint, a connecting pull rod, a movingshaft, a moving shaft connecting block, a fixed shaft, a pneumatic claw connecting frame, a sliding rail installation frame, a linear sliding rail, a sliding block, a three-claw cylinder and pneumaticclaw bodies. Under the action of the corner driving cylinder, the moving shaft is driven by the connecting pull rod, the sliding block moves along the linear sliding rail, and the pneumatic claw connecting frame rotates around the fixed shaft, so that the pneumatic claw bodies are inclined at a certain angle to achieve angle control for picking of a chemical fiber cake on the fiber cake trolley side and placing of the chemical fiber cake on the conveying line side. The three-claw cylinder controls dip angle change of the three pneumatic claw bodies to achieve high synchronization. The fixed shaft is provided with a bearing and an elastic collar to improve the reliability of the clamp. The three-claw cylinder is controlled by a three-position five-way solenoid valve, the pneumatic claw bodies are provided with friction patterns to prevent the chemical fiber cake from falling during the movement. The clamp is simple in structure and can effectively save cost, reduce labor intensity andimprove the quality of the chemical fiber cake.

Owner:BEIJING AREOSTANARD NEW TECH +1

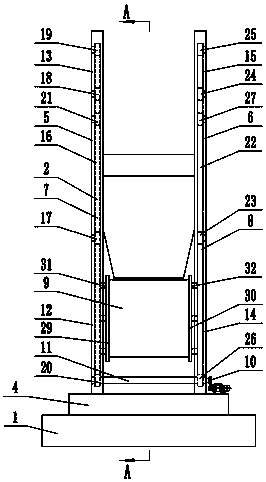

Shredded preserved vegetable carrying and stirring device

InactiveCN108378326AAchieving stirringRealize blankingConveyorsRotary stirring mixersVegetable processingEngineering

The invention provides a shredded preserved vegetable carrying and stirring device, and belongs to the technical field of preserved vegetable processing equipment. The shredded preserved vegetable carrying and stirring device comprises a carrying and dumping mechanism and a stirring and seasoning mechanism, wherein a first lifting chain of the carrying and dumping mechanism is arranged on a firstbearing chain wheel, a first guiding chain wheel, a second guiding chain wheel, a third guiding chain wheel and a second supporting chain wheel in a closed surrounding manner; a second lifting chain is arranged on a third supporting chain wheel, a fourth guiding chain wheel, a fifth guiding chain wheel, a sixth guiding chain wheel and a fourth supporting chain wheel in the closed surrounding manner; a hopper of a discharging hopper assembly is mounted between a hopper first supporting plate and a hopper second supporting plate; stirring blades of the stirring and seasoning mechanism are mounted on a stirring supporting shaft at equal intervals; a sauce collecting opening of a sauce circulating assembly is connected with a sauce collecting tank through a sauce collecting pipe; and a sauce feeding opening is connected with the sauce collecting tank through a sauce feeding pipe. Through the adoption of the shredded preserved vegetable carrying and stirring device provided by the invention, shredded preserved vegetables can be quickly carried and lifted, and can be automatically dumped into a stirrer.

Owner:桐乡市大周商贸有限公司

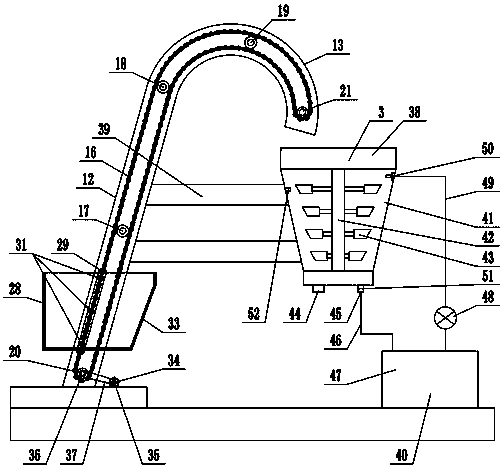

Feeding, weighing and packaging device

The invention discloses a feeding, weighing and packaging device. The feeding, weighing and packaging device comprises a conveying belt, a feeding slope, a weighing hopper, a weighing sensor, a pressing device, a receiving hopper and a controller. The upper end of the feeding slope is connected with the tail end of the conveying belt, and the lower end of the feeding slope is connected with the top end of the weighing hopper. The pressing device is arranged above the weighing hopper. The receiving hopper is arranged below the weighing hopper. A discharge valve is arranged on the inner wall of the weighing hopper and located at the lower end. The weighing sensor is installed on the weighing hopper. A driving mechanism of the conveying belt, the weighing sensor, the discharge valve and the pressing device are all connected with the controller. The feeding, weighing and packaging device integrates feeding, weighing and bagging, achieves automatic operation, is easy and fast to operate and improves packaging precision and increases packaging speed on the premise of lowering labor cost.

Owner:ANHUI ZENGRAN PACKAGING SCI & TECH

Plastic bag arranging mechanism used for bag making machine

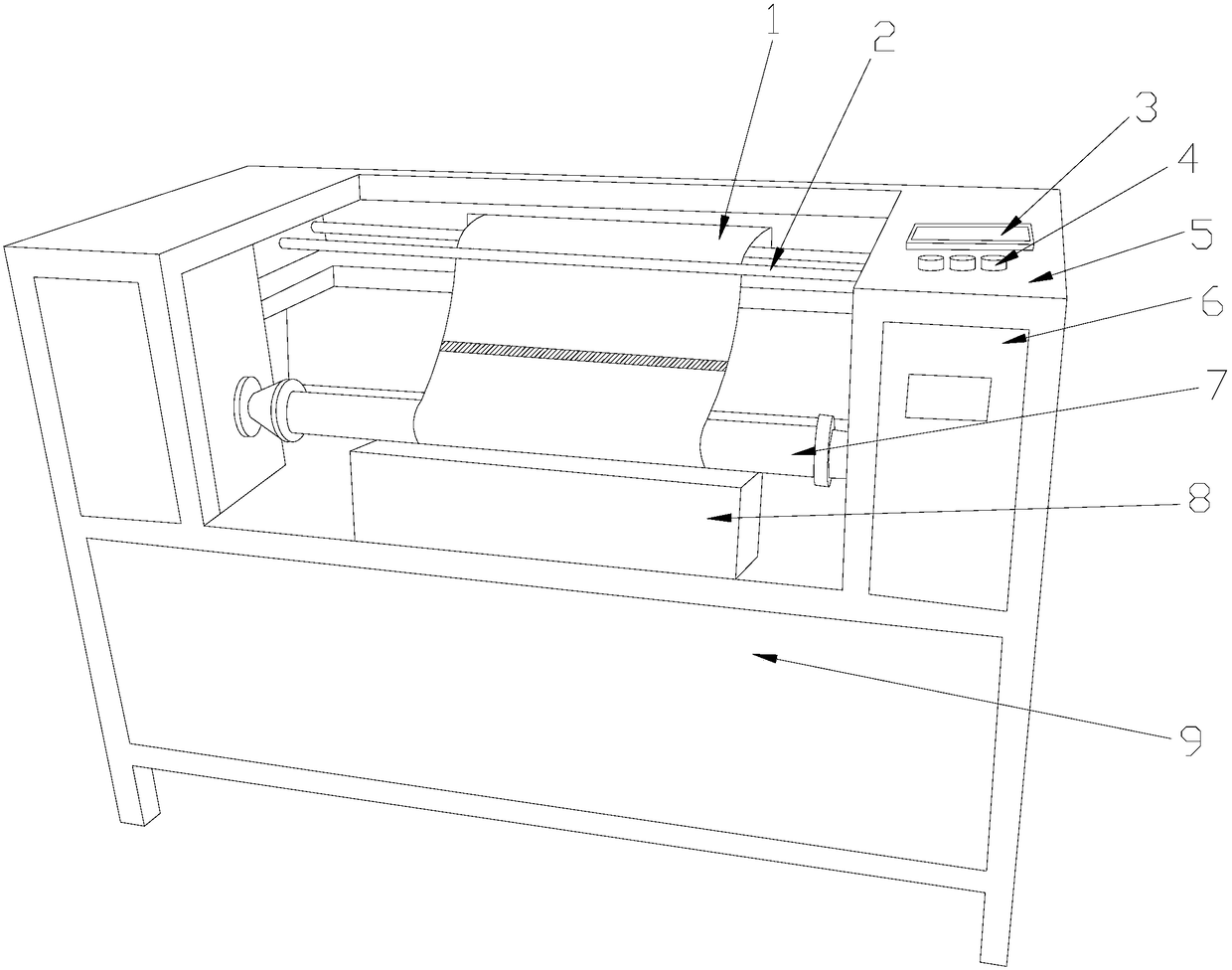

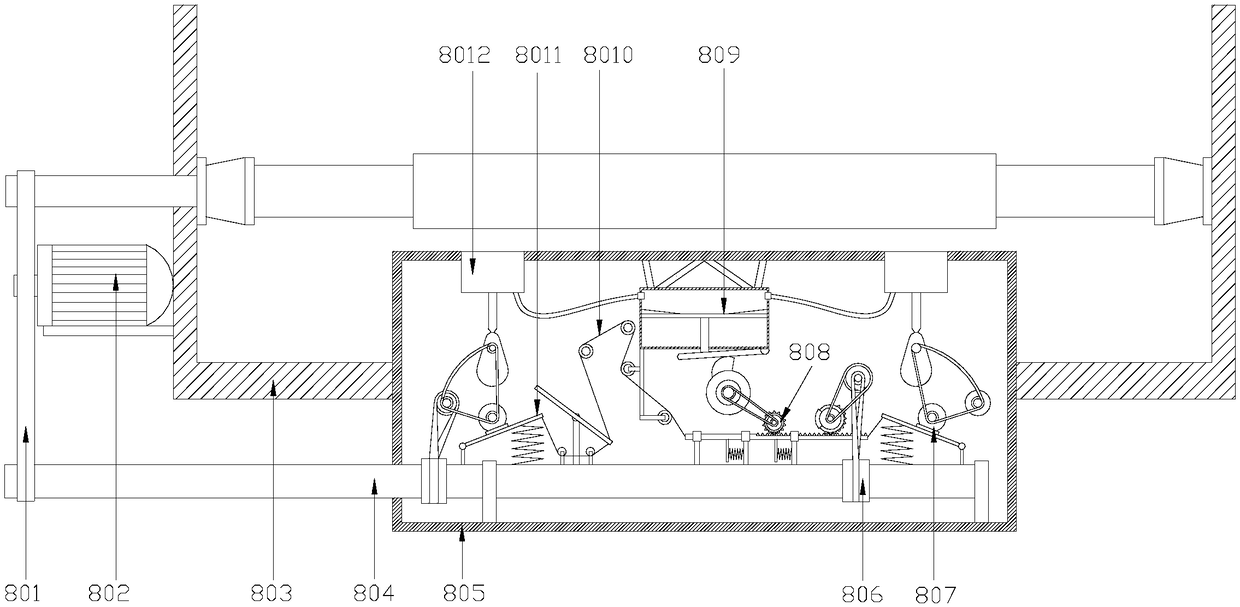

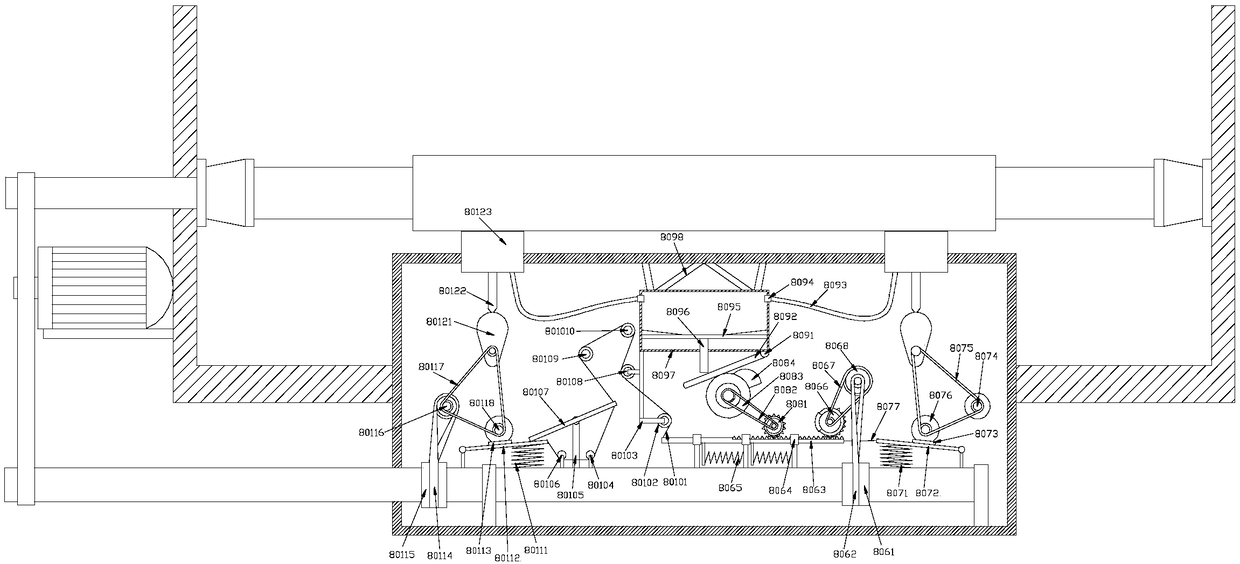

InactiveCN108312634AAvoid messy situationsRealize Segmented ViscosePaper-makingBox making operationsEngineeringPlastic bag

The invention discloses a plastic bag arranging mechanism used for a bag making machine. The plastic bag arranging mechanism structurally comprises plastic bags, a plastic bag transmission roller, a display screen, an operating button, an operating panel, main machines, a plastic bag wind-up roller, a gluing device and a machine body, wherein the two main machines are mounted at the two ends of the top of the machine body in a buckling mode, and a groove for movably arranging the gluing device is arranged in the middle of the machine body. The plastic bag arranging mechanism has the beneficialeffects that in the gluing device, a main transmission mechanism is driven through a main transmission shaft pipe, and the running of a second transmission mechanism and an adhesive supply mechanismis accordingly controlled and driven; the left side of the main transmission mechanism drives a fourth transmission mechanism to carry out tightness control on adhesive appliers through a third transmission mechanism, the simultaneous upward and downward movement of the two adhesive appliers is finally ensured, and segmented gluing is realized; and the condition that the wound plastic bags are conveyed in a mess is avoided, the arranging efficiency is increased, the processing quality is improved, and following packaging is also facilitated.

Owner:曾淑敏

Reciprocating ejector for cylindrical packaging boxes

InactiveCN112224539AFor subsequent packagingSimple structurePackagingStructural engineeringPackaging Case

Owner:安徽鳌鸟信息科技有限公司

Environment-friendly new energy biofuel processing system

InactiveCN112354483AAvoid deformationFor subsequent packagingBiofuelsDrying gas arrangementsThermodynamicsNew energy

The invention relates to an environment-friendly new energy biofuel processing system which comprises a hollow rectangular box and a fixing plate arranged at the corner of the bottom of the hollow rectangular box, the rectangular box is arranged above the hollow rectangular box, an extrusion device is arranged at the top of the rectangular box, and a drying device is arranged in the hollow rectangular box. A cutting device is arranged at the bottom of the hollow rectangular box. Hot air at a specific temperature is introduced into the hollow rectangular box, the cylindrical sleeve moves downwards under the pressure effect of airflow and the elastic force effect of the lifting spring, the movable plate also moves downwards to the top of the second positioning baffle along with the cylindrical sleeve, and at the moment, the vent hole is not attached to the movable plate; hot air passes through the vent holes to dry the biomass fuel in the hollow column, moisture in the biomass fuel is dried, and therefore the drying purpose is achieved.

Owner:珠海市宇星辉科技有限公司

Steam cleaning machine for false tooth processing

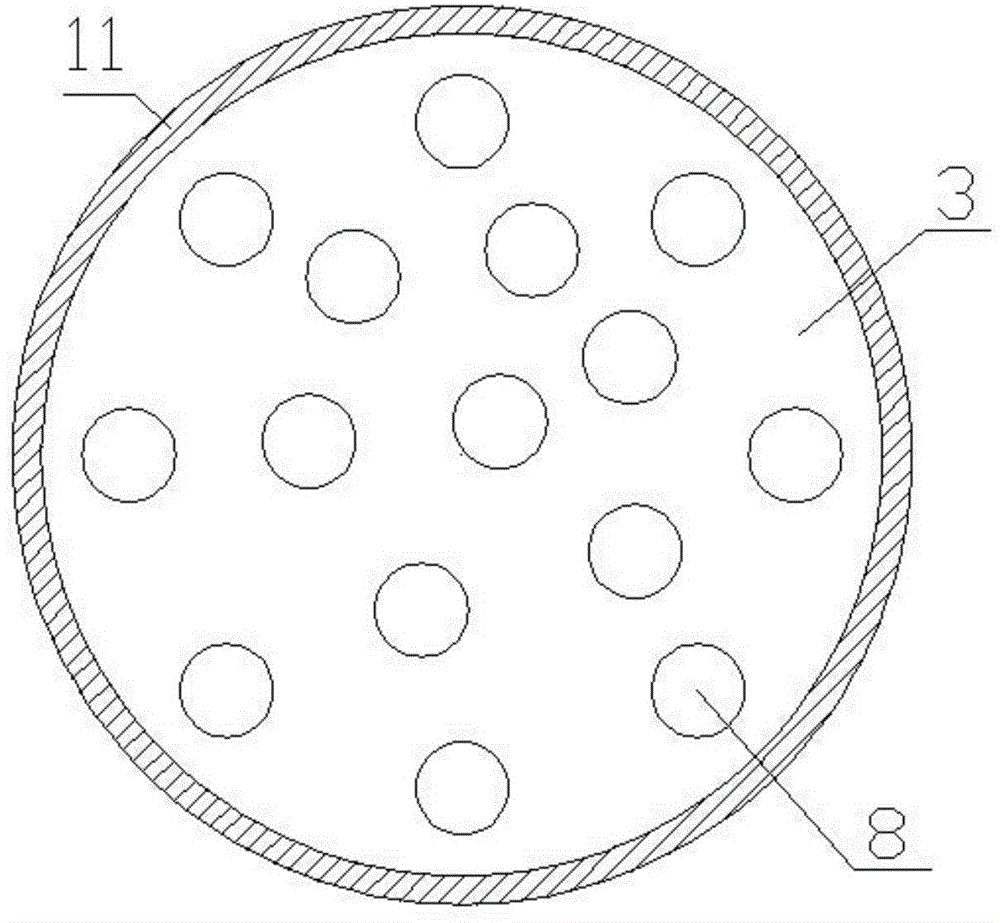

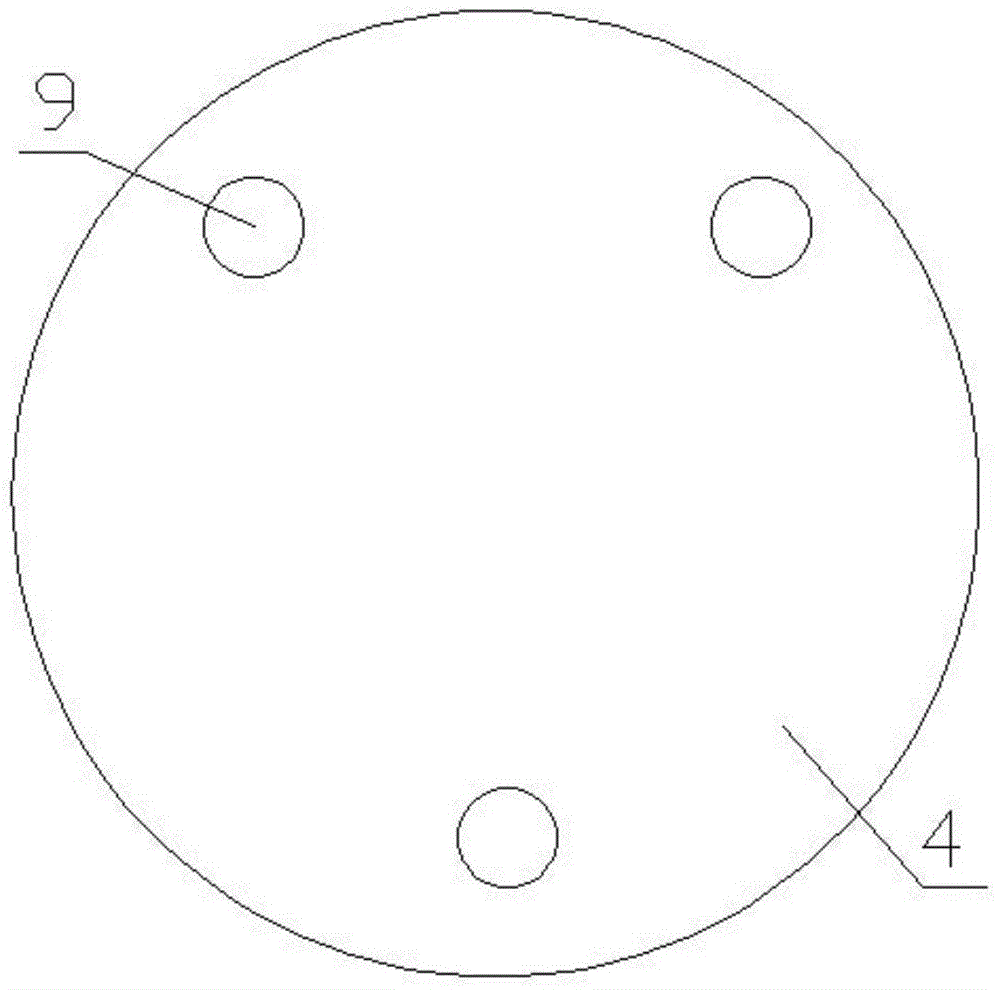

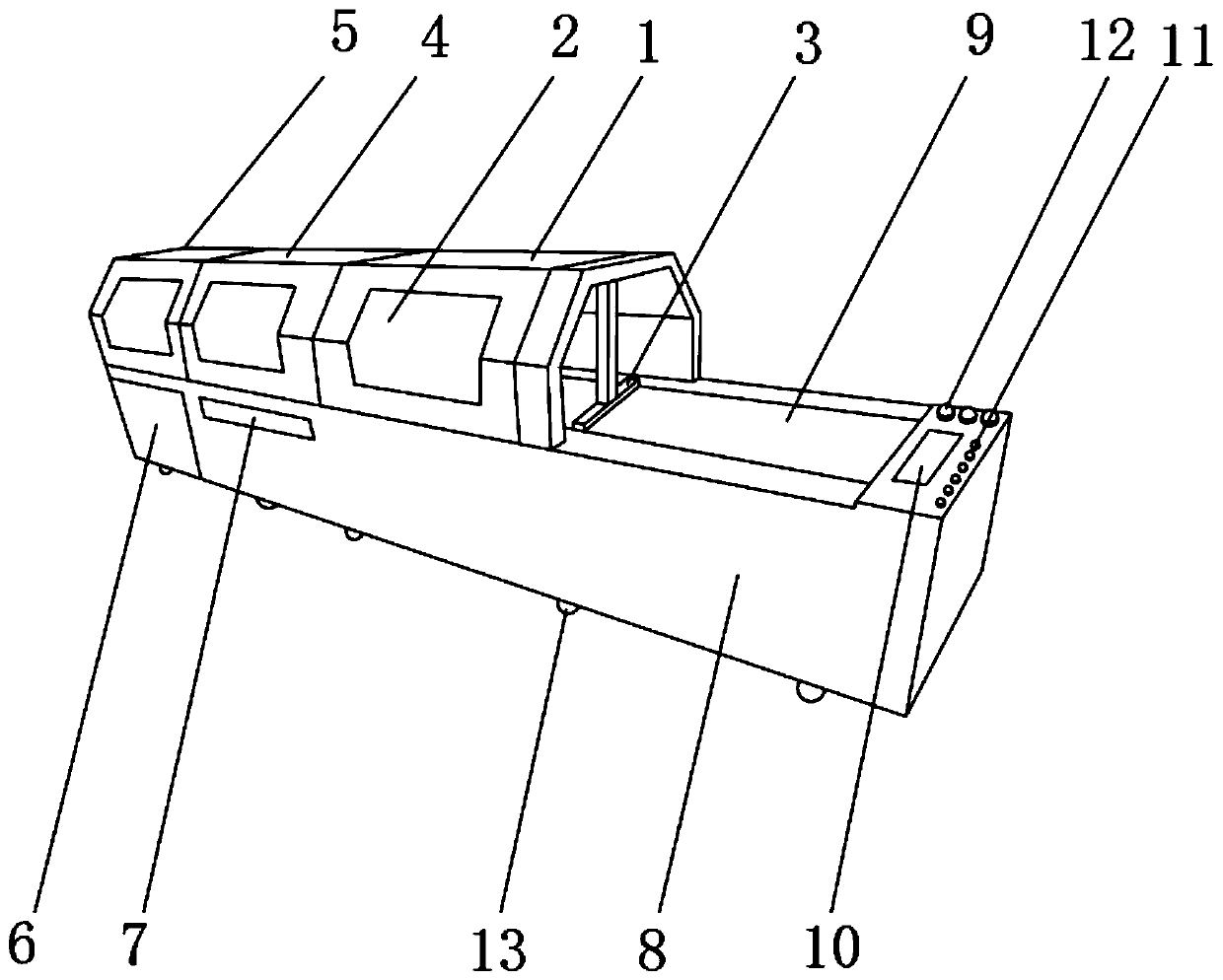

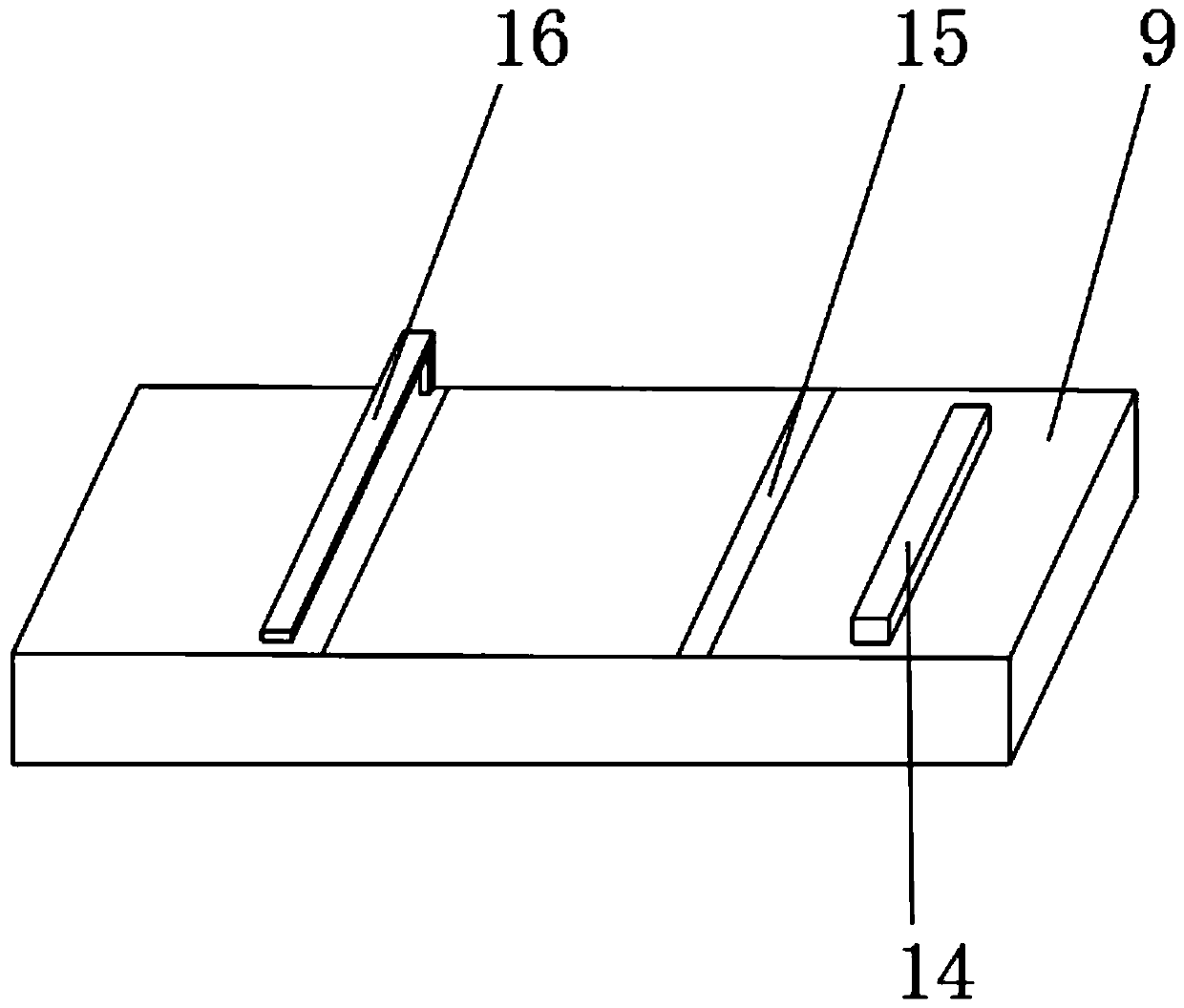

PendingCN112108432AEasy to take outAvoid wear and tearDrying gas arrangementsDrying machines with progressive movementsEngineeringSoft materials

The invention provides a steam cleaning machine for false tooth processing. The machine comprises a machine body, a storage disc detachably mounted on a cleaning disc, and the cleaning disc, a steam device, a drying device and an exhaust device which are arranged in the machine body, and the storage disc is used for storing false teeth to be cleaned. According to the steam cleaning machine for thefalse tooth processing, the false teeth are placed in storage cylinders in the storage disc, one false tooth is placed in each storage cylinder, abrasion caused by mutual contact during steam scouring is avoided, meanwhile the storage cylinders are made of high-temperature-resistant soft materials, a steam disc descends and is inserted into a positioning hole through a positioning rod for positioning, independent nozzles conduct steam scouring on the storage cylinders, the exhaust device works to exhaust water mists in the machine body, a drying disc moves to the upper end of the storage discthrough a pushing device for drying, after drying is completed, the cleaning disc is pulled out, the storage disc is taken out, and then the false teeth in each storage cylinder are taken out. The machine is high in working efficiency and easy to operate, moisture is removed through the drying device after steam cleaning, and subsequent packaging is facilitated.

Owner:合肥华特义齿加工有限公司

Disposable spoon production line

The invention relates to a disposable spoon production line, and relates to the field of automation equipment. The disposable spoon production line comprises an injection molding machine used for injection molding of disposable spoons, a material taking manipulator arranged above the injection molding machine and used for automatically taking out disposable spoons, a conveyor with the feeding end of the conveyor arranged on the side edge of the injection molding machine, and working intermittently, and a cutting device arranged at the discharging end of the conveyor, and used for cutting off the disposable spoons from a connecting auxiliary material. The disposable spoon production line has the effect of improving the higher labor cost during disposable spoon production.

Owner:厦门市碧桂环保科技有限公司

Sorting apparatus for wear-resistant balls

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

Preparation method for golden slab sugar under continuous automatic control

InactiveCN106615520AReduce labor intensityNeat appearanceConfectionerySweetmeatsAutomatic controlFixed ratio

The invention discloses a preparation method for golden slab sugar under continuous automatic control. The method comprises the following steps: (1) placing sugar candy molasses separated from mono-crystal rock sugar and poly-crystal rock sugar into a heat preservation tank, adding water, dissolving and diluting; (2) filtering the sugar candy molasses with a filter screen, pumping into a pre-boiling tank, adding invert syrup, the weight of which is 7-8% of the weight of the sugar candy molasses, heating and increasing the temperature to 80-95 DEG C; (3) pumping the prepared syrup into a continuous sugaring device for sugaring and setting the temperature at 130-140 DEG C; and (4) conveying the boiled syrup into a charging basket of a forming machine, stirring by a paddle, adopting a filling head for quantitatively filling a mold conveyor belt, adopting a stepping motor for driving the filled mold to enter into a cooling channel and then cooling. According to the preparation method, the stable reduced sugar in the product can be realized on the basis of the method for adding and blending the invert syrup at a fixed ratio. Under the synergic effect of the production equipment, such as, the pre-boiling tank, the continuous sugaring device, a pouring forming machine, the cooling channel and a de-molding device, the integrated production under the continuous automatic control can be realized.

Owner:广东南字科技股份有限公司

A finished product packaging equipment based on garment production

The invention discloses clothing production based finished product packaging equipment. The clothing production based finished product packaging equipment comprises a folding compartment, wherein a glass window is arranged on the outer surface of the front end of the folding compartment; an iron is movably mounted on the outer surface of the upper end inside the folding compartment; a printer is movably mounted on the outer surface of one side of the folding compartment; the outer surface of one side of the printer is movably equipped with a press-fitting compartment; the outer surface of thebottom end inside the press-fitting compartment is movably equipped with an encapsulating box; and a bag inlet is formed in a position, at one side of the encapsulating box, of the bottom end inside the printer. According to the clothing production based finished product packaging equipment disclosed by the invention, the printer, a clothing folding plate and a pressure plate are arranged, patterns and characters can be printed on the packaging bag, the clothing can be folded before the clothing is packaged, and the clothing does not need to fasten through a paperboard, so that packaging costis reduced, and the packaged clothing can be tidied and transported conveniently, and therefore, a better use prospect is brought.

Owner:三门县森波户外用品股份有限公司

Novel livestock and poultry biological veterinary drug preparation device

InactiveCN108097085ASimple structureEasy to operateRotary stirring mixersTransportation and packagingLivestockEngineering

The invention discloses a novel livestock and poultry biological veterinary drug preparation device. The device comprises a main body, wherein a stirring cavity is arranged in the main body; a feedinghopper communicated with the stirring cavity is fixedly arranged on the end surface of the top of the main body on the upper side of the stirring cavity; a discharging channel extending downward is communicated with the inner bottom wall of the stirring cavity; an extending tail end at the bottom of the discharging channel penetrates through the end surface of the bottom of the main body; an electric control valve is fixedly arranged in a position where the discharging channel is connected with the stirring cavity; a first sliding cavity extending downward is arranged in the inner wall body of the main body on the left side of the stirring cavity; a second sliding cavity extending leftward and rightward is communicated with an extending tail end at the bottom of the first siding cavity; the second sliding cavity is positioned in the inner wall body of the main body on the left side of the discharging channel; a first sliding block is glidingly connected with the interior of the firstsliding cavity in a matched manner; a through groove is formed in the end surface of the front end of the first sliding block; an inclined plane pressing part is arranged at the tail end of the bottomof the first sliding block.

Owner:东莞创想环保新材料科技有限公司

Intelligent arrangement device for pet urinal pads

The invention discloses an intelligent arrangement device for pet urinal pads, belongs to the technical field of production equipment, and aims to solve the problem of difficult arrangement of pet urinal pads straightly transported. The intelligent arrangement device for the pet urinal pads is arranged below an outlet of a pet urinal pad production line, and comprises a frame, a collecting tank formed in the frame, an arrangement clamping wheel arranged on the frame, and a control module arranged on the frame; the outlet is provided with a photoelectric door for sensing if the pet urinal pads pass through; and an arrangement groove is formed in the arrangement clamping wheel. The intelligent arrangement device for the pet urinal pads has the beneficial effect of convenience for subsequent packing, enables subsequent packing staff to directly extract the pet urinal pads with corresponding numbers for bagging, greatly improves the packing efficiency, saves labor hours, effectively reduces the production cost of enterprises, and cannot idle to save the energy.

Owner:WUHU LEISURELY NURSING SUPPLIES POLYTRON TECH INC

Bamboo shoot washing device

ActiveCN108813669AAvoid damagePlay the role of turning materialFood treatmentEngineeringMechanical engineering

The invention belongs to the technical field of food processing equipment, and particularly discloses a bamboo shoot washing device. The bamboo shoot washing device comprises an operation table, a mounting frame, a supporting frame, a supporting rod, a worm wheel, a bottom disk, a washing barrel, a push plate, a sleeve pipe, a horizontal shaft, a push rod, a motor, a rotating disk and a worm, wherein the supporting rod is hinged to an eccentric position of the rotating disk; a horizontal rod is hinged to the horizontal shaft; a feeding opening and a discharging opening are formed in the washing barrel; baffle plates for opening and closing the feeding opening and the discharging opening are separately arranged at the feeding opening and the discharging opening; a sealing strip is arrangedon each baffle plate; a first one-way valve which is in one-way conduction to the inner part of the washing barrel is arranged at the bottom of the washing barrel; a plurality of water outlet holes are formed in the bottom disk; and a second one-way valve which is in one-way conduction to the outer part of the washing barrel is arranged in each water outlet hole. The bamboo shoot washing device disclosed by the invention is mainly used for washing bamboo shoots, and the problem that when the bamboo shoots are washed, impurities are left on the bamboo shoots easily, so that the washing effect is poor is solved.

Owner:徐琼华

Line type conveying cutting machine for plastic bottles

InactiveCN106003220AFor subsequent packagingEasy to useConveyorsMetal working apparatusTransfer mechanismAutomation

The invention relates to a punching machine, in particular to a punching machine for linear conveying of plastic bottles, comprising a transfer fixture, a linear conveying line, a bottle retaining mechanism, a punching transfer mechanism and a punching mechanism; the invention has a novel structure and uses Convenience, high degree of automation, accurate positioning and punching of products, automatic removal of excess waste, convenient subsequent packaging and use of plastic bottle products, more stable subsequent punching, more smooth and beautiful products, and improved pass rate , at the same time, the open line buffer conveying of the equipment can meet the requirements of putting the blanking equipment into the low clean area, reduce the production cost of the pharmaceutical factory, and can remove unqualified products without stopping the machine, making plastic bottles The continuous production of products provides a guarantee.

Owner:SHINVA MEDICAL INSTR CO LTD

Novel minced meat processing device

InactiveCN108208106ASimple structureEasy to operateMeat mixing apparatusMeat processing devicesEngineeringMechanical engineering

A novel minced meat processing device includes a processing base. A stirring chamber is formed in the processing base. An opening is arranged in the top end surface, at the upper side of the stirringchamber, of the processing base in a communicated manner. A lid is arranged on the opening through a hinge and can be turned upwardly. A delivery chamber, which is downwardly extended, is arranged onthe inner bottom wall of the stirring chamber. A bottom extending end of the delivery chamber penetrates through the bottom end surface of the processing base. An open / close valve is fixedly arrangedat the connection position between the delivery chamber and the stirring chamber. A first sliding cavity which is downwardly extended is arranged in the inner wall body, at the left side of the stirring chamber, of the processing base. A second sliding cavity, which is arranged in a left-and-right extending manner, is arranged on the bottom extending end of the first sliding cavity in a communicated manner. The second sliding cavity is arranged in the inner wall body, at the left side of the delivery chamber, of the processing base. A first sliding piece is in sliding matched connection with the interior of the first sliding cavity. A penetrating groove is formed in the front end surface of the first sliding piece. A bevel angle is formed on the bottom end of the first sliding piece.

Owner:FOSHAN DETAO POWER TECH CO LTD

Minced meat processing equipment

InactiveCN108200940ASimple structureEasy to operateMeat mixing apparatusMeat processing devicesMechanical engineeringEngineering

The invention relates to minced meat processing equipment. The minced meat processing equipment comprises a processing seat, wherein a uniform stirring cavity is arranged in the processing seat; an opening is formed in the end surface of the top of the processing seat, on the upper side of the uniform stirring cavity in a communication manner; a cover plate which can be overturned upwards is arranged in the opening through a hinge; a discharging and transporting cavity which extends downwards is arranged on the bottom wall of the uniform stirring cavity in a communication manner; the extendingtail end of the bottom of the discharging and transporting cavity penetrates through the end surface of the bottom of the processing seat; an on-off valve is fixedly arranged at the connecting part of the discharging and transporting cavity and the uniform stirring cavity; a first sliding cavity which extends downwards is formed in the inner wall body of the processing seat, on the left side of the uniform stirring cavity; a second sliding cavity which extends left and right is formed in the extending tail end of the bottom of the first sliding cavity in a communication manner, and is locatedin the inner wall body of the processing seat, on the left side of the discharging and transporting cavity; a first sliding block is connected to the inner part of the first sliding cavity in a sliding cooperation manner; a penetrating groove is formed in the end surface of the front end of the first sliding block; and a bevel part is arranged at the tail end of the bottom of the first sliding block.

Owner:FOSHAN DETAO POWER TECH CO LTD

Plastic product anti-static containing device

InactiveCN107572097AFor subsequent packagingIncrease productivityShock-sensitive articlesRigid containersEngineeringMechanical engineering

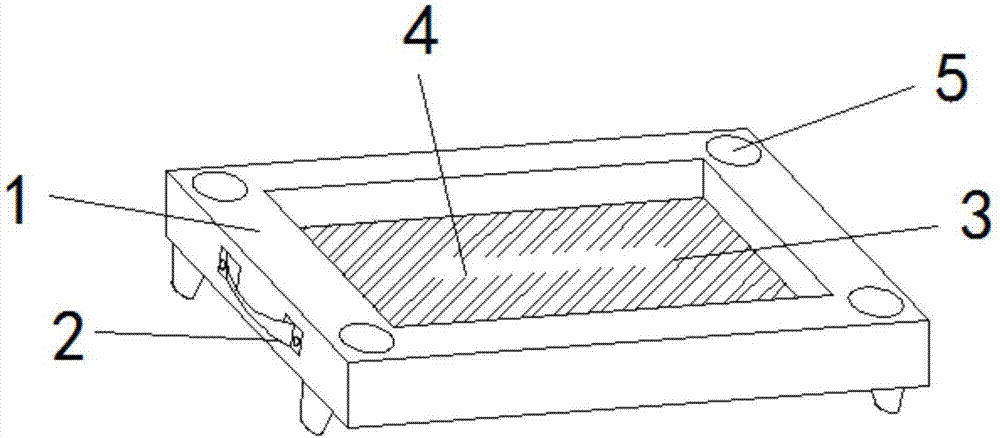

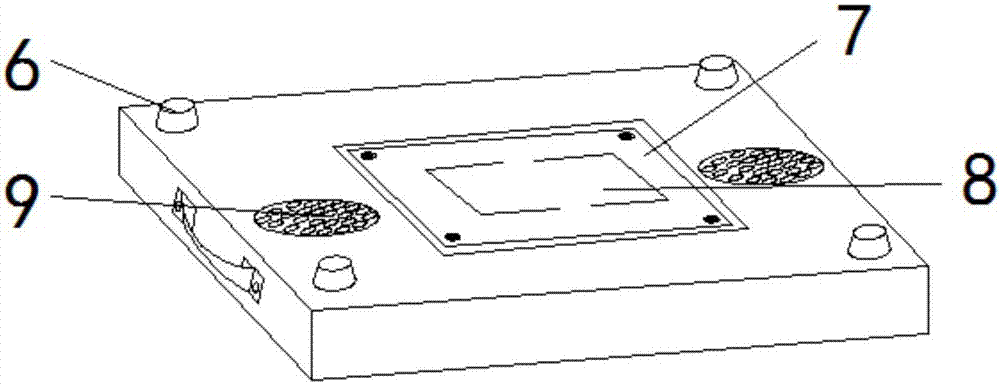

The invention discloses a plastic product anti-static containing device. The plastic product anti-static containing device comprises a box body, a placement tank and an ion generator, wherein the boxbody is cuboid, and handles are arranged on two sides of the box body; four round grooves are formed at corners of an upper edge of the box body; the placement tank is flush with the top surface of the box body, and heat dissipation holes are formed in the bottom surface of the placement tank; support legs are arranged on the bottom of the box body; the ion generator is arranged in the bottom of the box body; and a rear cover which is buckled with the box body is arranged on the part, corresponding to the ion generator, of the bottom of the box body. According to the plastic product containingdevice, the ion generator is arranged in the bottom of the box body, so that static removing can be performed on a demoulded plastic product during production, and therefore subsequent packing of theproduct is convenient; and meanwhile, during the static removing process, the plastic product can be subjected to heat dissipation and cooling, so that production efficiency of the product is improved.

Owner:ANHUI HONGYUAN MACHINERY MFG

Integrated machine for packaging and cutting heating bag

InactiveCN106043770AQuality improvementSimple structurePackaging by pressurising/gasifyingSuccessive articlesEngineeringProduction cycle

The invention relates to an integrated machine for packaging and cutting a heating bag. The machine comprises a machine box, a feeding system, a bag cloth delivering mechanism, a sealing plate mechanism, a vacuum packaging system and a cutting device. The sealing plate mechanism is mounted at the upper end of the front side of the machine box. The bag cloth delivering mechanism is mounted at the front side of the top of the machine box. The vacuum packaging system is fixed to the front side of the machine box and located below the sealing plate mechanism. The cutting device is mounted at the front side of the machine box. Bag cloth on a to-be-processed bag cloth roll enters the bag cloth delivering mechanism and then is delivered into the sealing plate mechanism. A feeding and packaging cavity is formed between the bag cloth and the sealing plate mechanism. The discharging end of the feeding system is located above the feeding and packaging cavity. Powder is added into the feeding and packaging cavity through the feeding system. Then the bag is formed out of the bag cloth through the sealing plate mechanism. The bag moves downwards, passes through the vacuum packaging system for packaging and is conveyed to the cutting device for cutting. The integrated machine for packaging and cutting the heating bag has the beneficial effects of being simple in structure, easy and convenient to operate, high in processing efficiency, short in production cycle and good in bag packaging quality.

Owner:ANLU XINXIN MACHINERY EQUIP CO LTD

Clothing production based finished product packaging equipment

The invention discloses clothing production based finished product packaging equipment. The clothing production based finished product packaging equipment comprises a folding compartment, wherein a glass window is arranged on the outer surface of the front end of the folding compartment; an iron is movably mounted on the outer surface of the upper end inside the folding compartment; a printer is movably mounted on the outer surface of one side of the folding compartment; the outer surface of one side of the printer is movably equipped with a press-fitting compartment; the outer surface of thebottom end inside the press-fitting compartment is movably equipped with an encapsulating box; and a bag inlet is formed in a position, at one side of the encapsulating box, of the bottom end inside the printer. According to the clothing production based finished product packaging equipment disclosed by the invention, the printer, a clothing folding plate and a pressure plate are arranged, patterns and characters can be printed on the packaging bag, the clothing can be folded before the clothing is packaged, and the clothing does not need to fasten through a paperboard, so that packaging costis reduced, and the packaged clothing can be tidied and transported conveniently, and therefore, a better use prospect is brought.

Owner:三门县森波户外用品股份有限公司

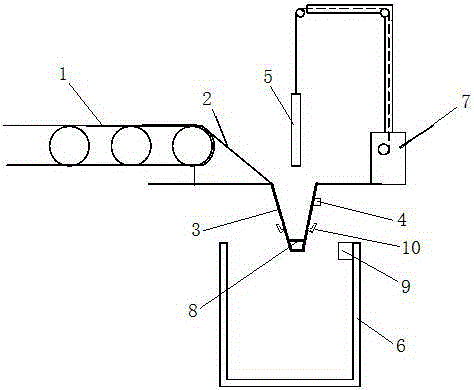

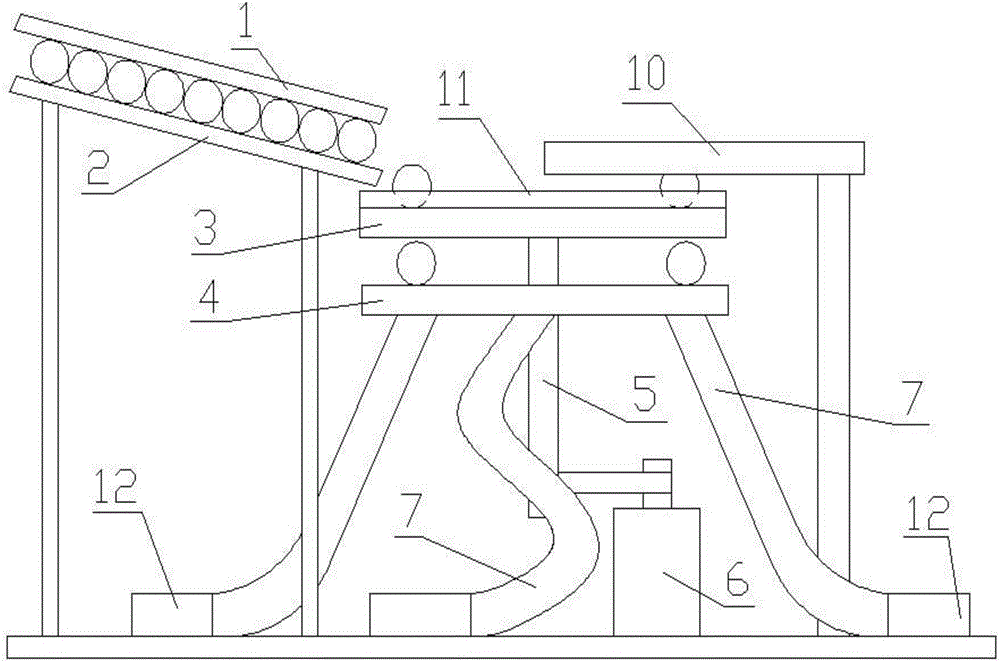

a large charter

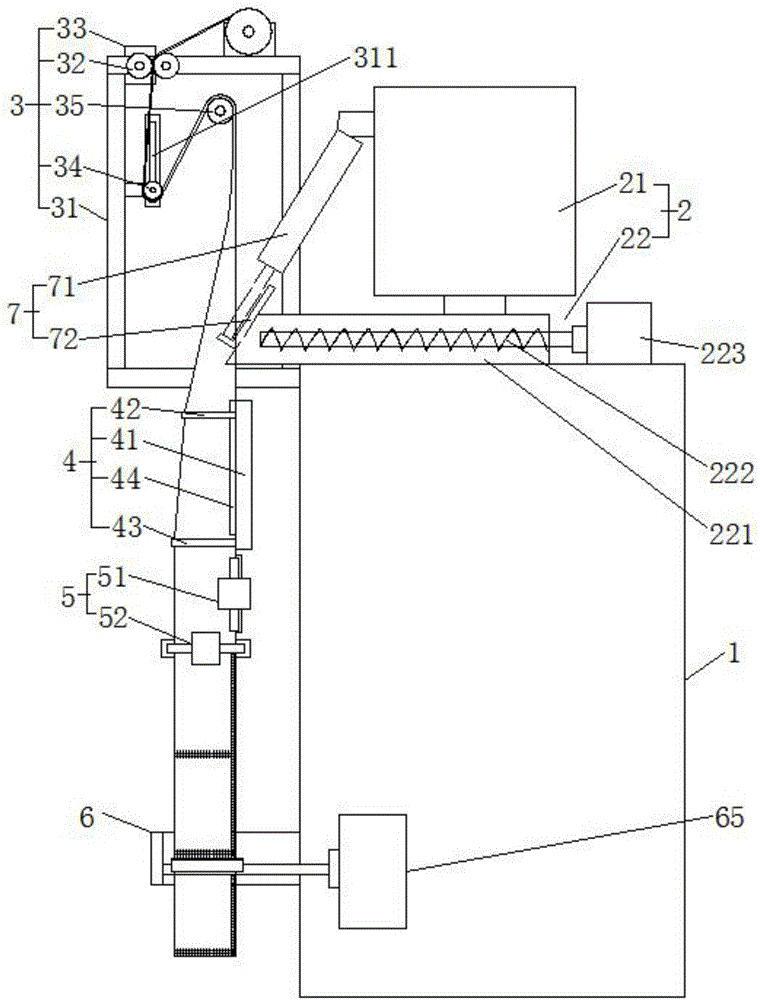

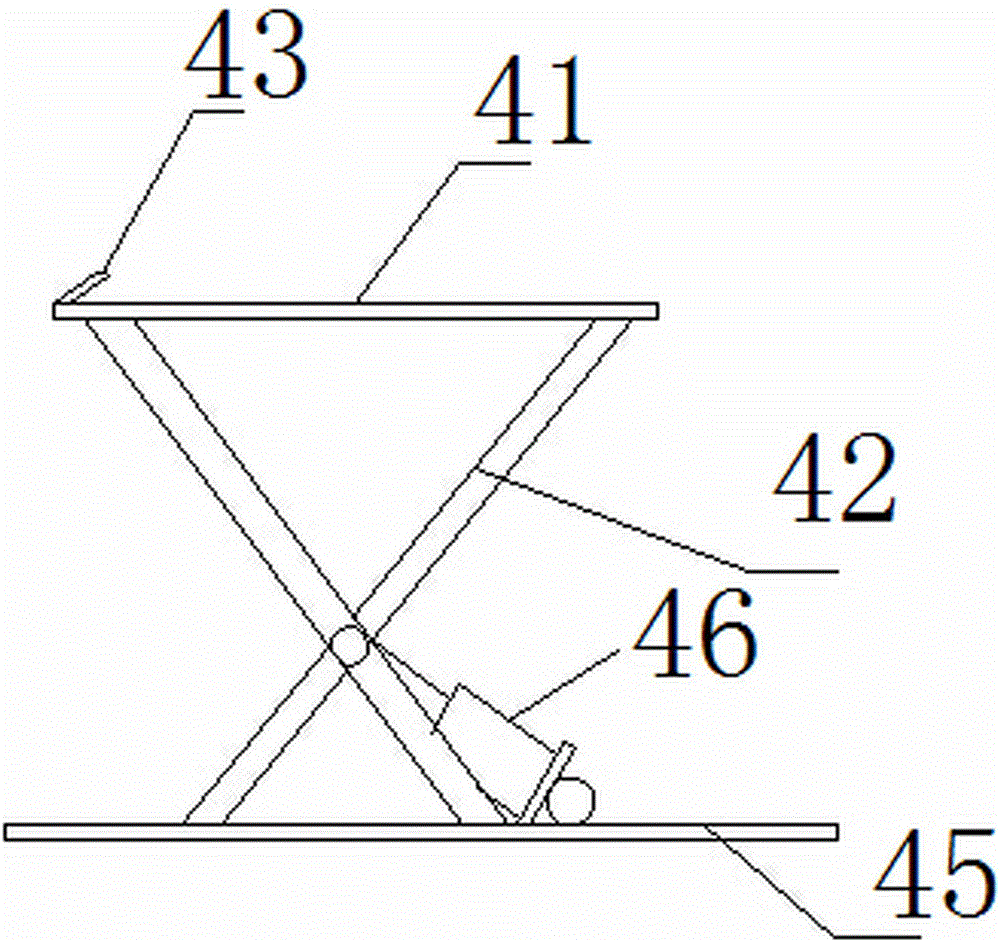

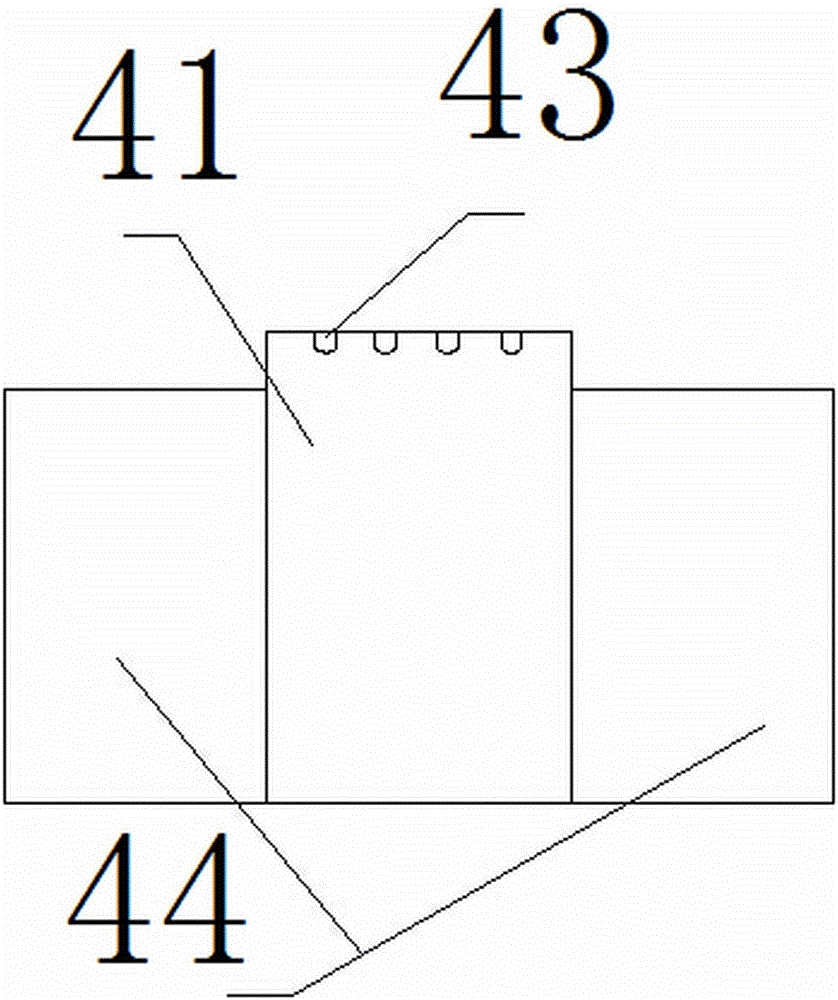

The invention provides a big package machine, and relates to the technical field of package machine machinery. The big package machine comprises a material sorting and conveying device (1), a package push and conveying device (6), a bag opening device (2), a sealing device (3) and a rack. The package machine further comprises a support type bag feed device (4). According to the big package machine, the bag-throwing type material sorting and conveying mode is adopted, materials can be stacked together orderly, multiple bags of materials can be packaged at one time, and thus packaging efficiency is improved; meanwhile, the support type bag feed structure is adopted, conveying and packaging of packages are facilitated, and production efficiency is improved.

Owner:上海松川峰冠包装自动化有限公司

A sterilization system for cooked rice dumplings

Owner:ZHEJIANG WUFANGZHAI INDAL

Equipment for bracken processing

ActiveCN108936724BPlay a role in promotingAvoid wear and tearFood treatmentBall screwStructural engineering

The invention belongs to the technical field of food processing equipment and particularly discloses a device for fiddlehead processing. The device comprises a working table, a cleaning barrel, a cross beam, an air cylinder, a ball screw, a first sleeve, a second sleeve, a flow guide pipe, a flow return pipe, a baffle, an upper cover, storage frames, a first filter net and a second filter net. Themeshes on the first filter net are smaller than those on the second filter net, a collecting plate is circumferentially arranged on the first filter net, a screw of the ball screw is located betweenthe two storage frames, a nut of the ball screw is rotationally connected with the upper cover, a push plate is arranged on the nut, the first filter net directly faces the opening of the flow returnpipe, and an inclined guide plate is arranged at the opening, located in the first sleeve, of the flow return pipe. The device is mainly used for cleaning fiddlehead and solves the problem that following packaging is affected due to the fact that fiddlehead is easy to twine together during cleaning.

Owner:义乌市牵手电子商务有限公司

Conveyor capable of taking materials and arranging and stacking for loading box with quadrangular surfaces

ActiveCN112811144AHigh degree of automationFor subsequent packagingConveyorsPackagingStructural engineeringControl theory

The invention relates to a conveyor capable of taking materials and arranging and stacking for a loading box with quadrangular surfaces. The conveyor comprises a base, the base is provided with a material storage assembly, a rear plate and a display stand; an upper rail frame and a middle sliding rail frame are fixedly installed on the rear plate; a variable-distance transportation control assembly matched with the upper rail frame and the middle sliding rail frame is arranged between the upper rail frame and the middle sliding rail frame; the variable-distance transportation control assembly is connected with a loading assembly; the variable-distance transportation control assembly comprises a carrying driving frame installed on the middle sliding rail frame in a horizontal sliding mode; the loading assembly comprises a U-shaped carrying hanging bracket welded to the lower end of the carrying driving frame; and the material storage assembly comprises a material storage box, and the material storage box is matched with an avoiding control assembly. According to the conveyor, the loading box can be fetched and driven to be transported by controlling the reciprocating sliding of the loading assembly and the lifting of the material storage assembly, and the loading box can be transported, unloaded and placed in a horizontal arrangement mode in a transportation distance adjusting mode.

Owner:安徽芜湖宝丰输送机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com