Integrated machine for packaging and cutting heating bag

An all-in-one machine and encapsulation technology, which is applied in the direction of pressurized/gasification packaging, packaging, and multiple packages, can solve the problems of cumbersome manufacturing technology of heat packs, large quality defects of heat packs, and long production and processing cycles. Achieve the effects of simple structure, good bag quality and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

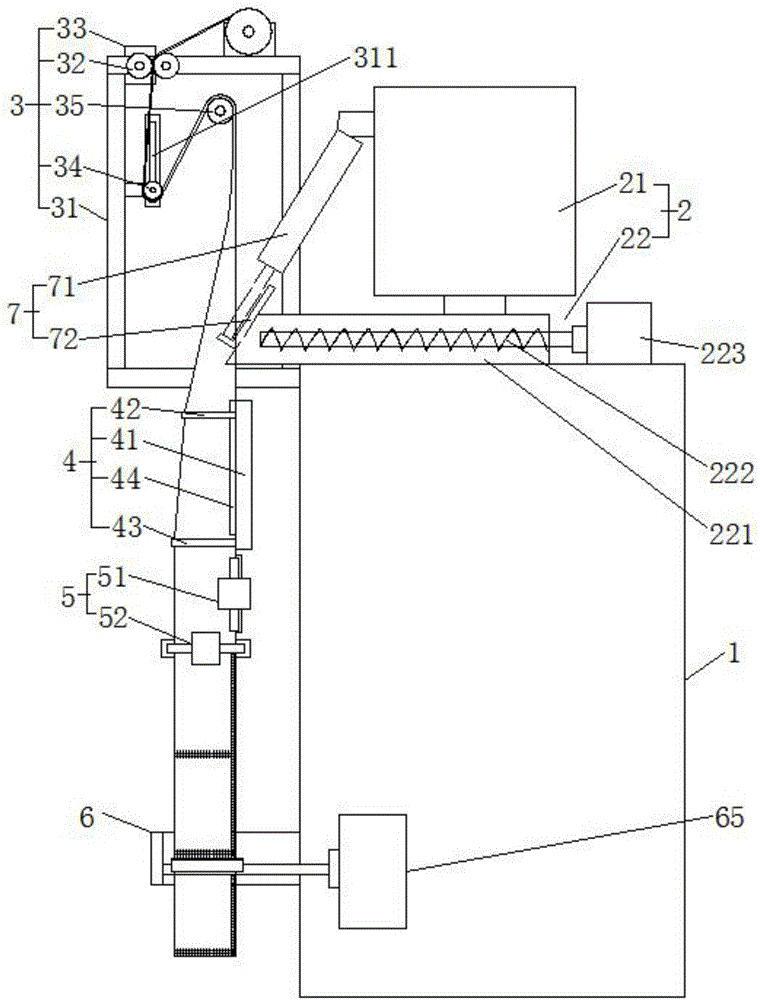

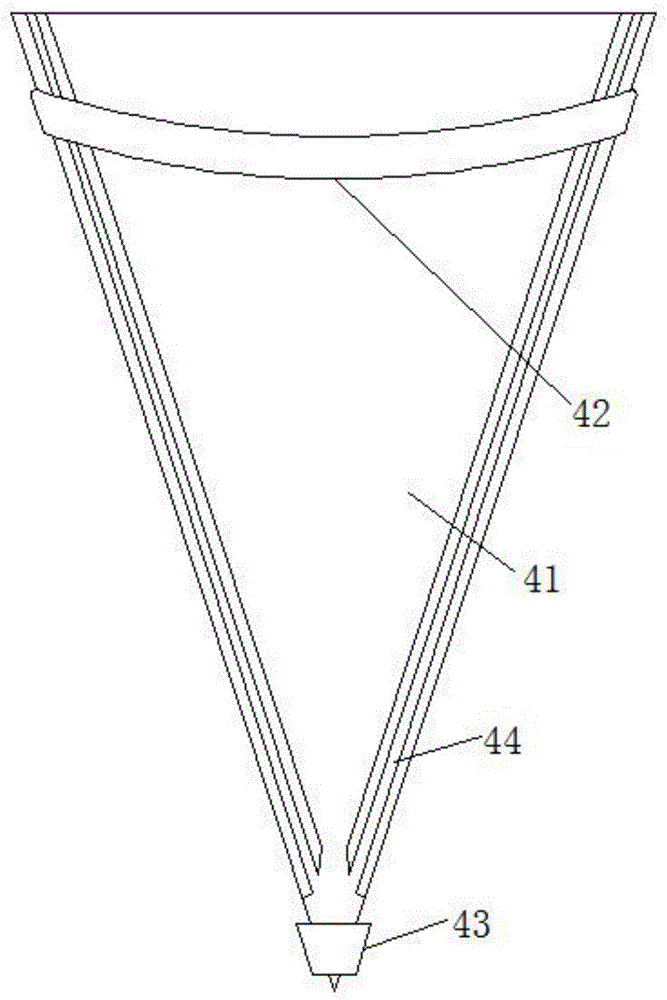

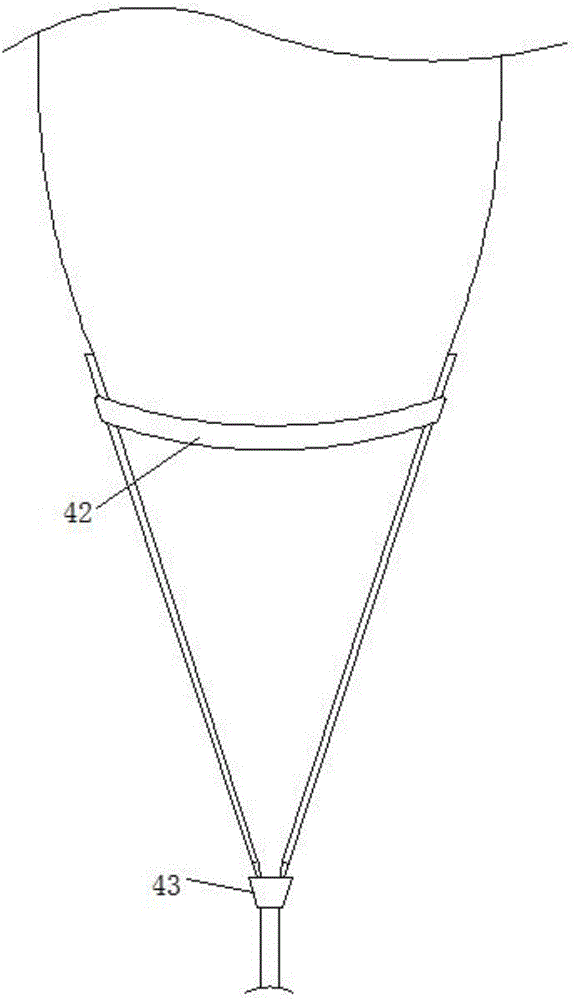

[0044] Example: such as figure 1 As shown, the heating, packaging, and shearing integrated machine of this embodiment includes a chassis 1, a feeding system 2, a bag cloth conveying mechanism 3, a sealing plate mechanism 4, a vacuum packaging system 5, and a shearing device 6. The sealing plate The mechanism 4 is installed on the upper end of the front side of the above-mentioned case 1, the above-mentioned bag cloth conveying mechanism 3 is installed on the front side of the top of the above-mentioned case 1, the above-mentioned vacuum packaging system 5 is fixed on the front side of the above-mentioned case 1, and is located under the above-mentioned sealing plate mechanism 4 The above-mentioned shearing device 6 is installed on the front side of the above-mentioned cabinet 1, and is located below the above-mentioned vacuum packaging system 5. The bag cloth on the bag cloth roll to be processed enters the above-mentioned bag cloth conveying mechanism 3, and is conveyed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com