Sorting apparatus for wear-resistant balls

A sorting device and wear-resistant ball technology, applied in the field of wear-resistant balls, can solve the problems of no follow-up conveying device, etc., and achieve the effect of easy follow-up packaging, simple structure, and easy selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described further below:

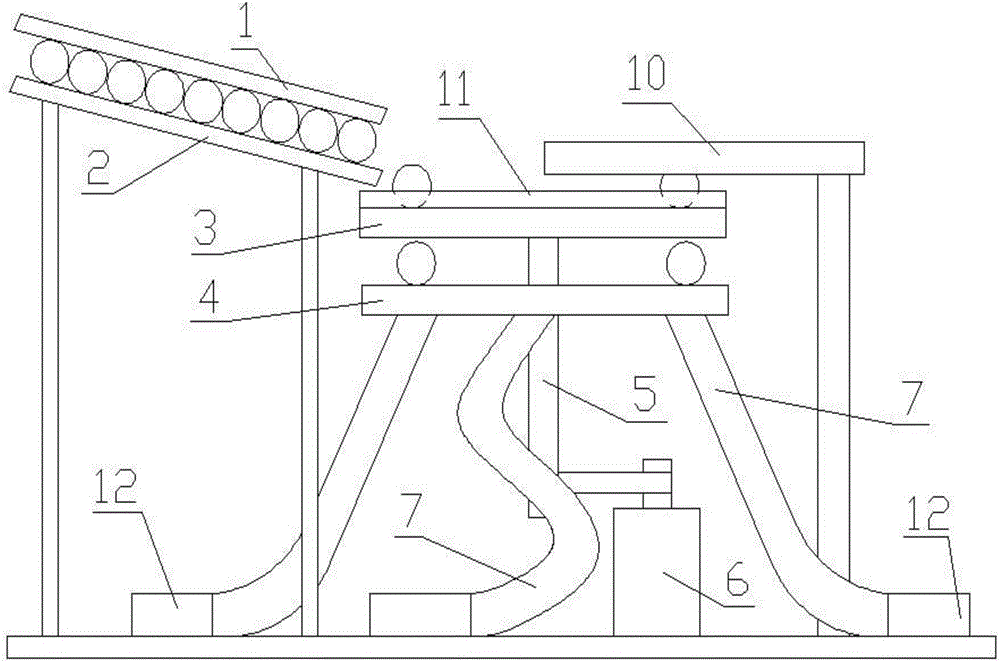

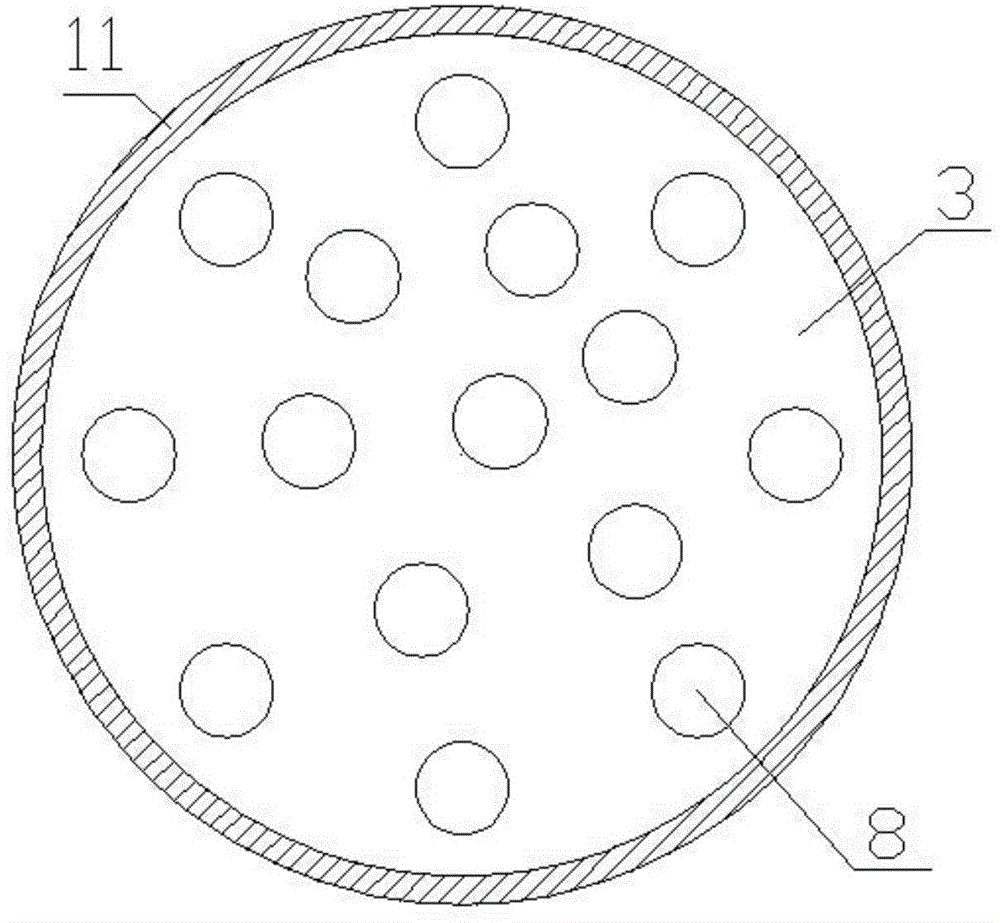

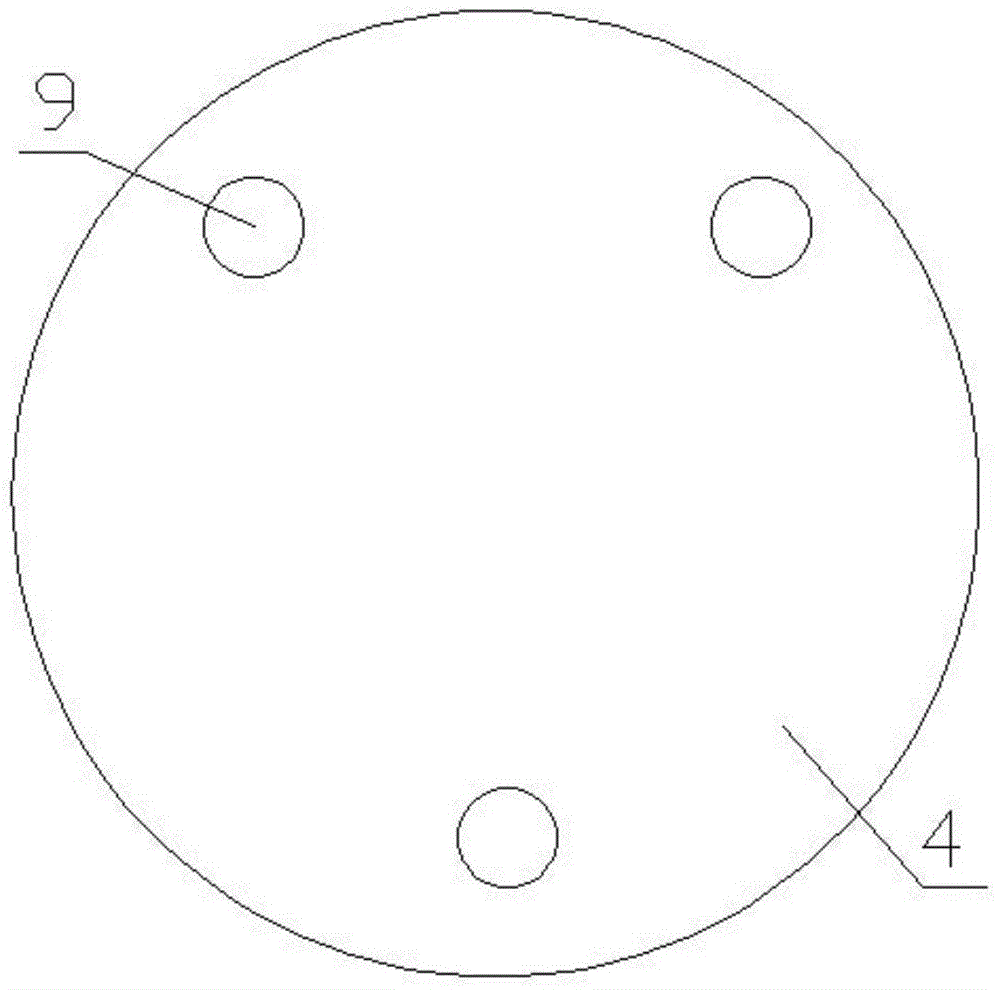

[0023] combine figure 1 , figure 2 , image 3 : A sorting device for wear-resistant balls, relating to wear-resistant balls, comprising a first baffle 1, a second baffle 2, a first panel 3, a second panel 4, a connecting rod 5, a rotating device 6, and a chute 7 , partition 10, the distance between the first baffle 1 and the second baffle 2 is slightly larger than the diameter of the wear-resistant ball, the first baffle 1, the second baffle 2 form an angle a with the horizontal plane, and a is 3- 10 degrees; the first panel 3 is provided below the lower ends of the first baffle 1 and the second baffle 2, and a number of first through holes 8 are provided on the first panel 3, and the second panel 4 is located below the first panel 3 , the second panel 4 is provided with a plurality of second through holes 9, the diameters of the first and second through holes are equal, and are equal to the diameter of the wear-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com