Feeding, weighing and packaging device

A technology of feeding weighing and weighing buckets, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems that automatic production cannot be realized, and achieve the effect of facilitating subsequent packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

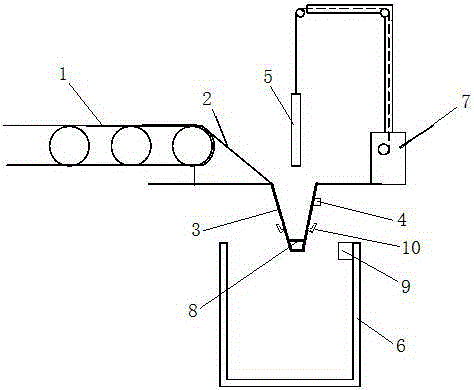

[0011] See figure 1 , a feeding weighing packaging device, including a conveyor belt 1, a feeding ramp 2, a weighing hopper 3, a load cell 4, a presser 5, a hopper 6 and a controller 7, and the load cell 4 is installed on a weighing On the bucket 3, the upper end of the unloading ramp 2 is connected to the end of the conveyor belt 1, the lower end of the unloading ramp 2 is connected to the top of the weighing bucket 3, the lower presser 5 is set above the weighing bucket 3, and the receiving hopper 6 is set on Below the weighing hopper 3, a counter 9 is installed on the top of the receiving hopper 6. The inner wall of the weighing hopper 3 is provided with a discharge valve 8 at the lower end. The drive mechanism, load cell 4, discharge valve 8, press down device 6 are all connected with controller 7.

[0012] Working principle of the present invention:

[0013] First, the opening end of the film bag is fixed on the film clip 10, then the material enters the weighing bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com