a large charter

A charter and rack technology applied to large charter aircraft. It can solve the problems of reducing packaging efficiency, low packaging efficiency, low packaging efficiency, etc., and achieve the effect of improving packaging efficiency, saving man-hours, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

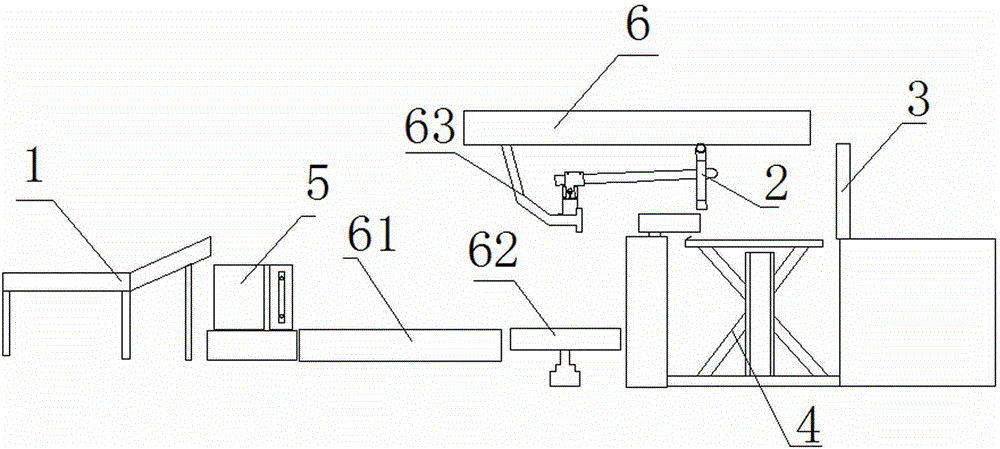

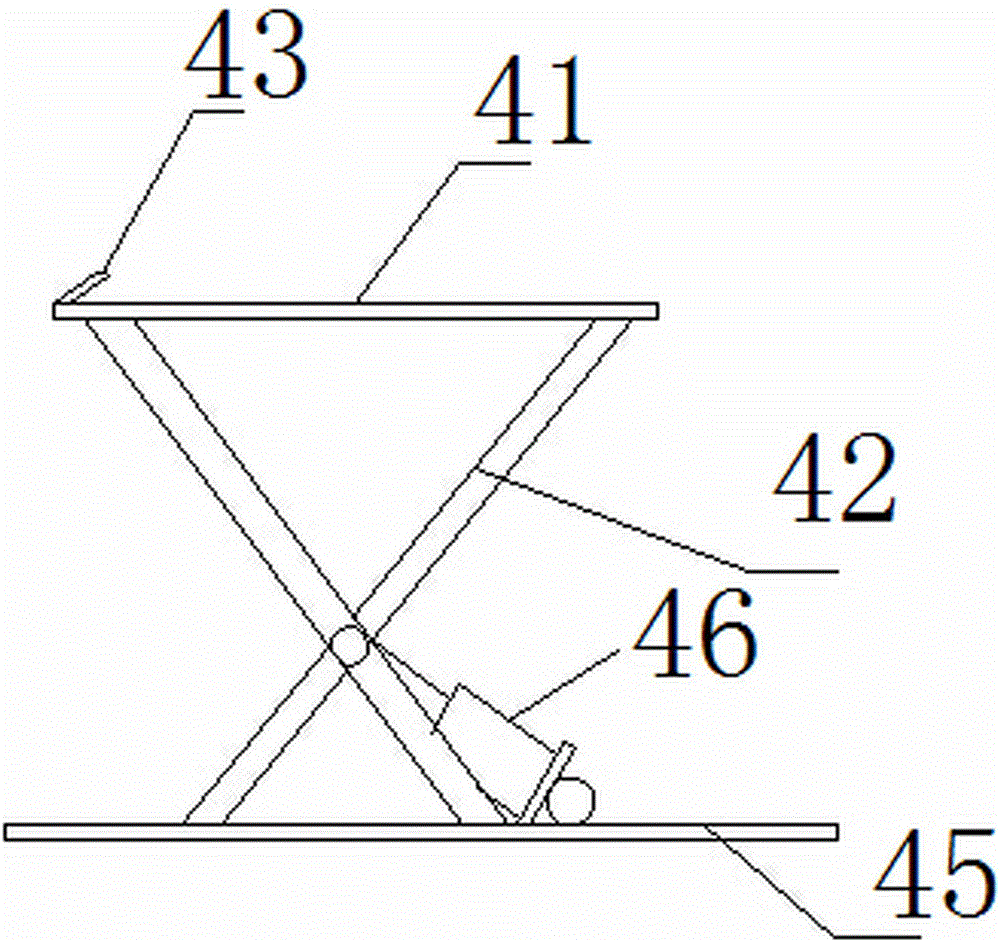

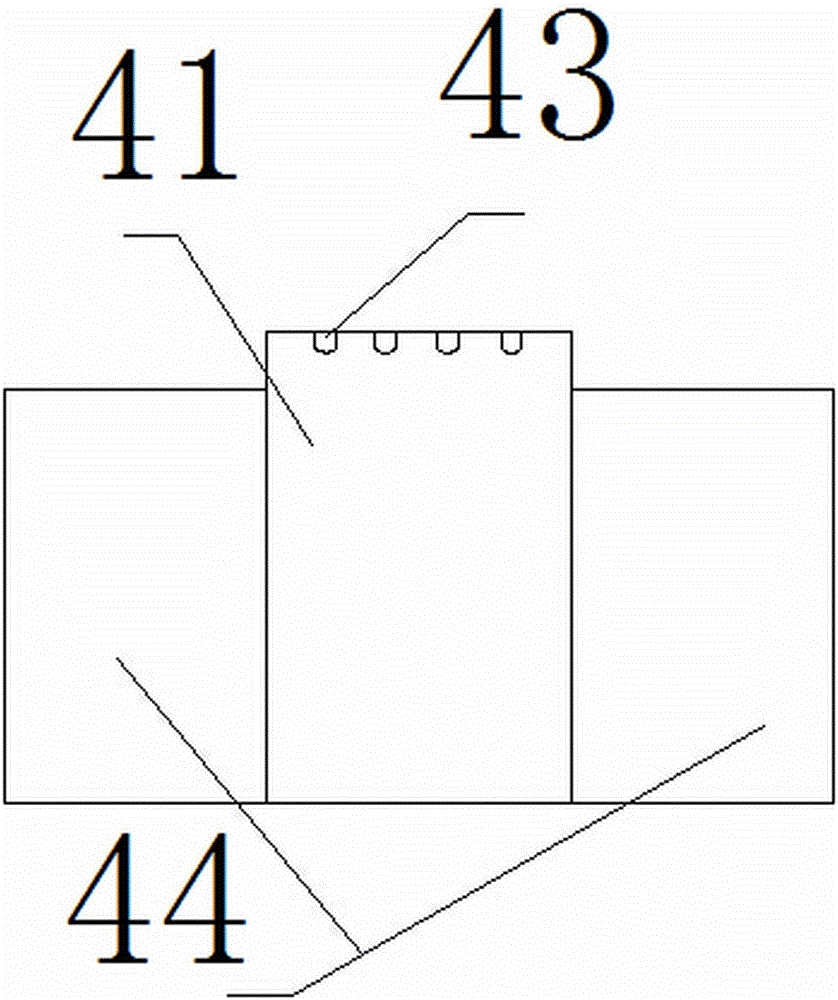

[0023] As a preferred embodiment of the present invention, the present invention includes material sorting and conveying device 1, bag pushing and conveying device 6, bag opening device 2, sealing device 3 and frame, and is characterized in that: it also includes bracket type bag feeding device 4, so The bracket type bag feeding device 4 is arranged after the bag opening device 2, and the bracket type bag feeding device 4 includes a support template 41 and an "X" type bracket 42, and one side of the support template 41 is provided with a Grab bag piece 43; Described support template 41 both sides are respectively provided with bagging storehouse 44; Described " X " type support 42 one end is fixedly connected with support template 41, and the other end is fixed on the frame by slide rail 45; The bottom of the "X"-shaped support 42 is provided with a cylinder 46, one end of the cylinder 46 is fixedly connected to the intersection of the "X"-shaped support 42, and the other end i...

Embodiment 2

[0027]As another preferred embodiment of the present invention, the present invention includes a material sorting and conveying device 1, a bag pushing and conveying device 6, a bag opening device 2, a sealing device 3 and a frame, and is characterized in that it also includes a bracket type bag feeding device 4, The bracket type bag feeding device 4 is arranged behind the bag opening device 2, and the bracket type bag feeding device 4 includes a support template 41 and an "X"-shaped bracket 42, and one side of the support template 41 is set close to the bag opening device 2 There is a bag grab piece 43; the two sides of the support template 41 are respectively provided with bagging warehouses 44; one end of the "X" type bracket 42 is fixedly connected with the support template 41, and the other end is fixed on the frame through a slide rail 45 The bottom of the "X"-shaped support 42 is provided with a cylinder 46, one end of the cylinder 46 is fixedly connected to the intersec...

Embodiment 3

[0033] As another preferred embodiment of the present invention, the present invention includes a material sorting and conveying device, a bag pushing and conveying device, a bag opening device, a sealing device and a frame, and is characterized in that it also includes a rack-type bag feeding device, and the rack-type feeding device The bag device is arranged behind the bag opening device, and the bracket-type bag feeding device includes a support template and an "X"-shaped bracket. One side of the support template is provided with a bag grabbing piece close to the bag opening device; the two sides of the support template are respectively A bagging warehouse is provided; one end of the "X"-shaped bracket is fixedly connected with the support template, and the other end is fixed on the frame through a slide rail; the bottom of the "X"-shaped bracket is provided with a cylinder, and one end of the cylinder is fixed It is connected at the intersection of the "X"-shaped bracket, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com