Line type conveying cutting machine for plastic bottles

A punching machine, plastic bottle technology, applied in the direction of conveyors, transportation and packaging, metal processing, etc., can solve the problems of high requirements for product transfer and connection, limited conveying distance, difficult to remove products, etc., to achieve novel structure, convenient packaging and The effect of using and punching stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

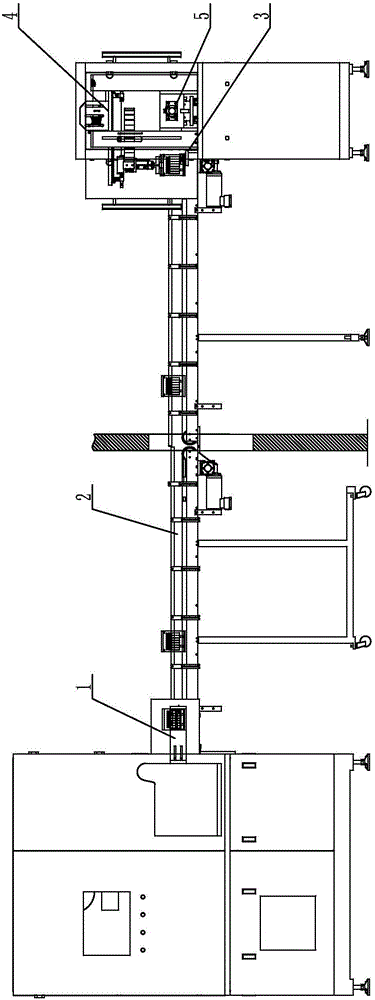

[0028] Such as Figure 1-10 As shown, the plastic bottle line conveying punching machine of the present invention includes a transfer fixture 1, a line conveying line 2, a bottle retaining mechanism 3, a punching transfer mechanism 4 and a punching mechanism 5;

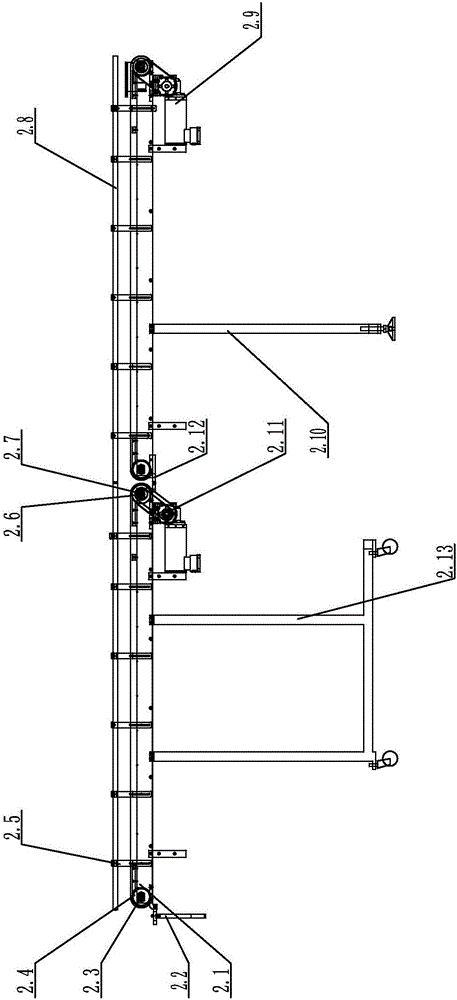

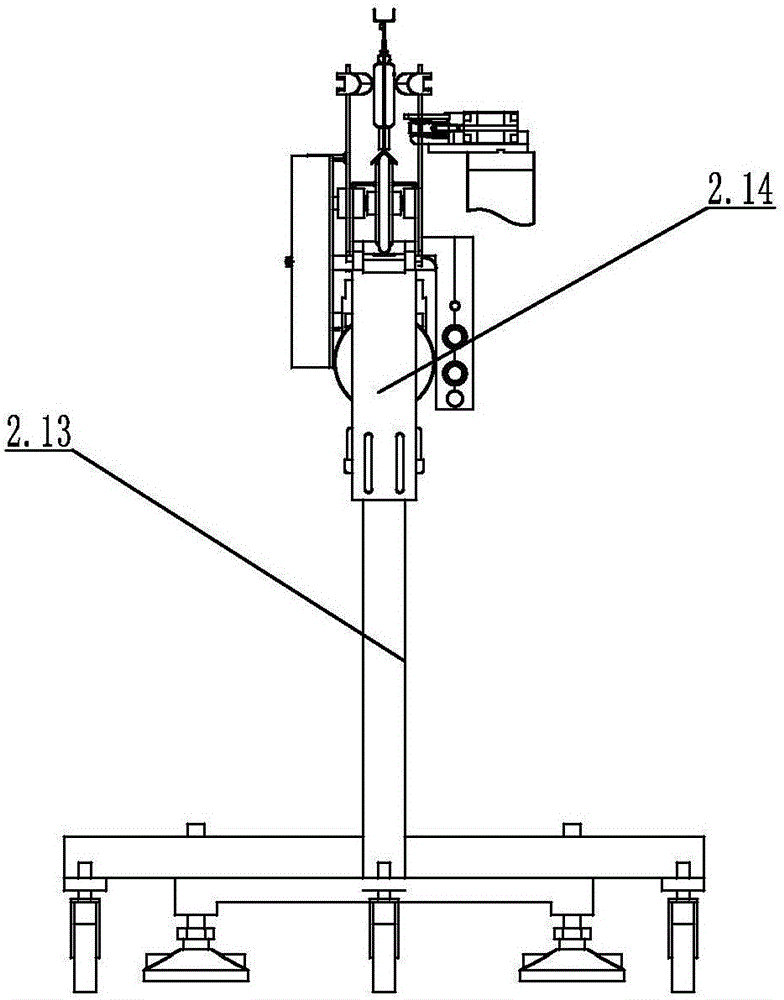

[0029] The wire type conveying line 2 comprises a conveying line bottom plate 2.1, one side of the upper end of the conveying line bottom plate 2.1 is provided with a pulley shaft 2.3, the pulley rotating shaft 2.3 is connected with a pulley 2.4, and the other side of the upper end of the conveying line bottom plate 2.1 is provided with a motor 2.9, the motor 2.9 is connected with the round belt 2.14 through the driving sprocket 2.11 and the driven sprocket 2.7, the lower end of the transmission line bottom plate 2.1 is respectively provided with a fixed support 2.10 and a movable support 2.13, and the movable support 2.13 is connected to the transmission line bottom plate 2.1. The front part is connected, the front p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com