Plastic bag arranging mechanism used for bag making machine

A sorting mechanism and bag making machine technology, applied in container manufacturing machinery, thin material processing, box making operations, etc., can solve the problems of easy mess of plastic bags, affecting finishing efficiency, processing quality, and inability to segment glue, etc., to achieve Facilitate subsequent packaging, improve finishing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

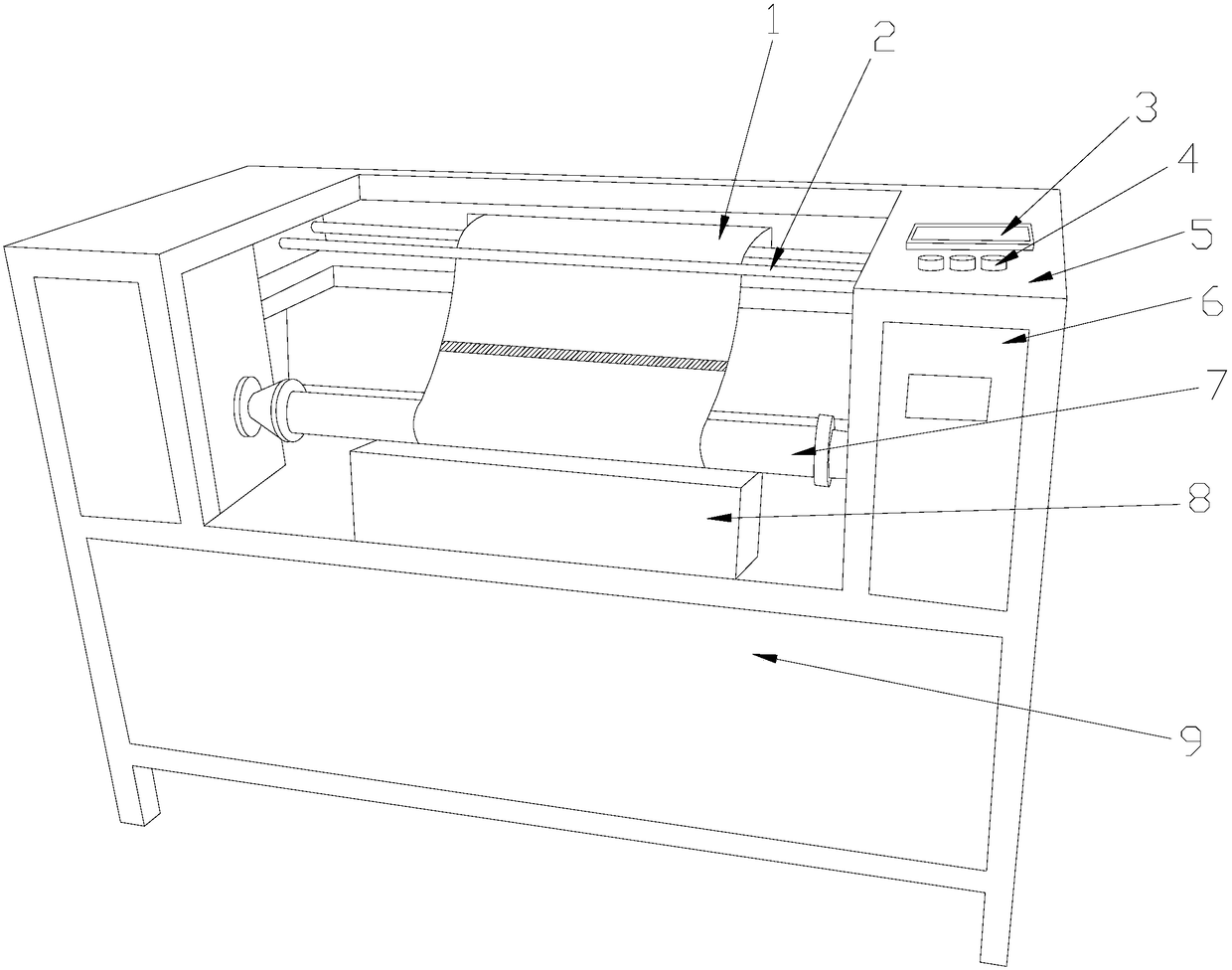

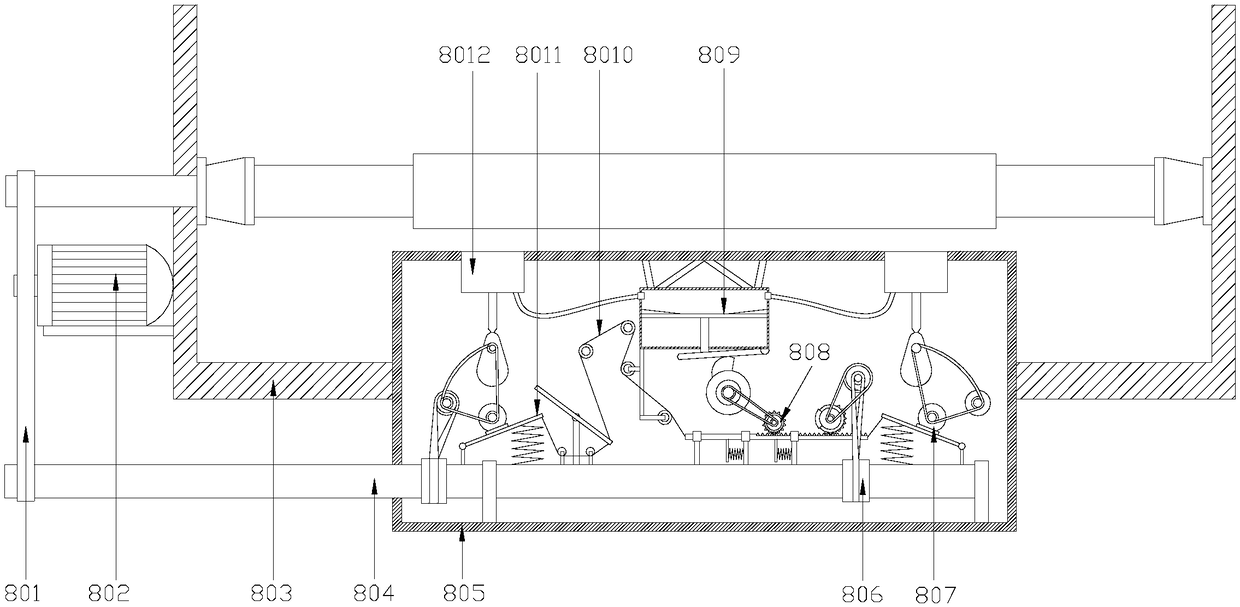

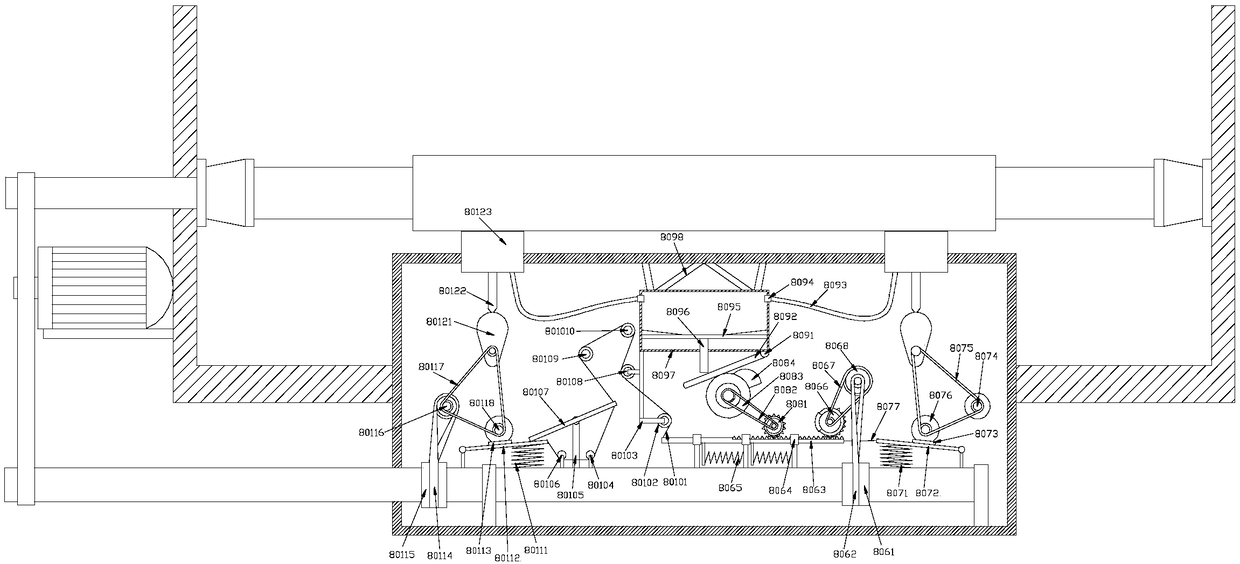

[0025] see Figure 1-Figure 5 , the present invention provides a plastic bag sorting mechanism for a bag making machine: its structure includes a plastic bag 1, a plastic bag driving roller 2, a display screen 3, an operation button 4, an operation panel 5, a main machine 6, and a plastic bag winding roller 7. Adhesive device 8, body 9, the host 6 is provided with two and installed on both ends of the top of the body 9 by fastening, the middle part of the body 9 is provided with a concave hole for movable installation of the gluing device 8 Groove, the plastic bag winding roller 7 is a cylindrical structure and both ends are fastened with the two hosts 6 by embedding, and the display screen 3 is installed on the top of the host 6 on the right side by embedding , the upper end of the main machine 6 is provided with a groove for the movable installation operation button 4, and the plastic bag driving roller 2 is provided with two and the two ends are respectively fastened with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com