Disposable spoon production line

A production line, one-time technology, applied in the direction of metal processing, etc., can solve the problem of high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The following is attached Figure 1-9 The application is described in further detail.

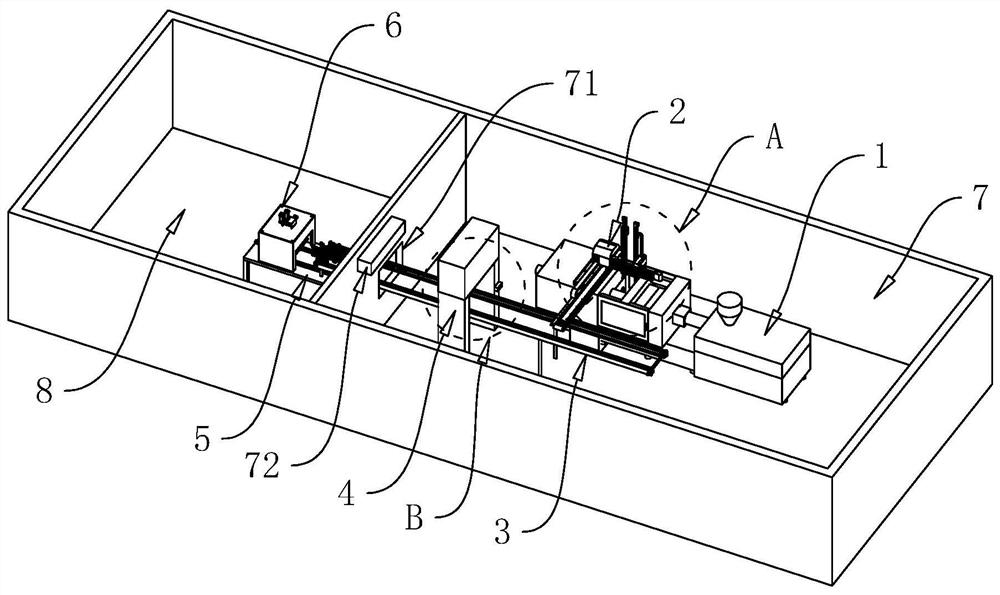

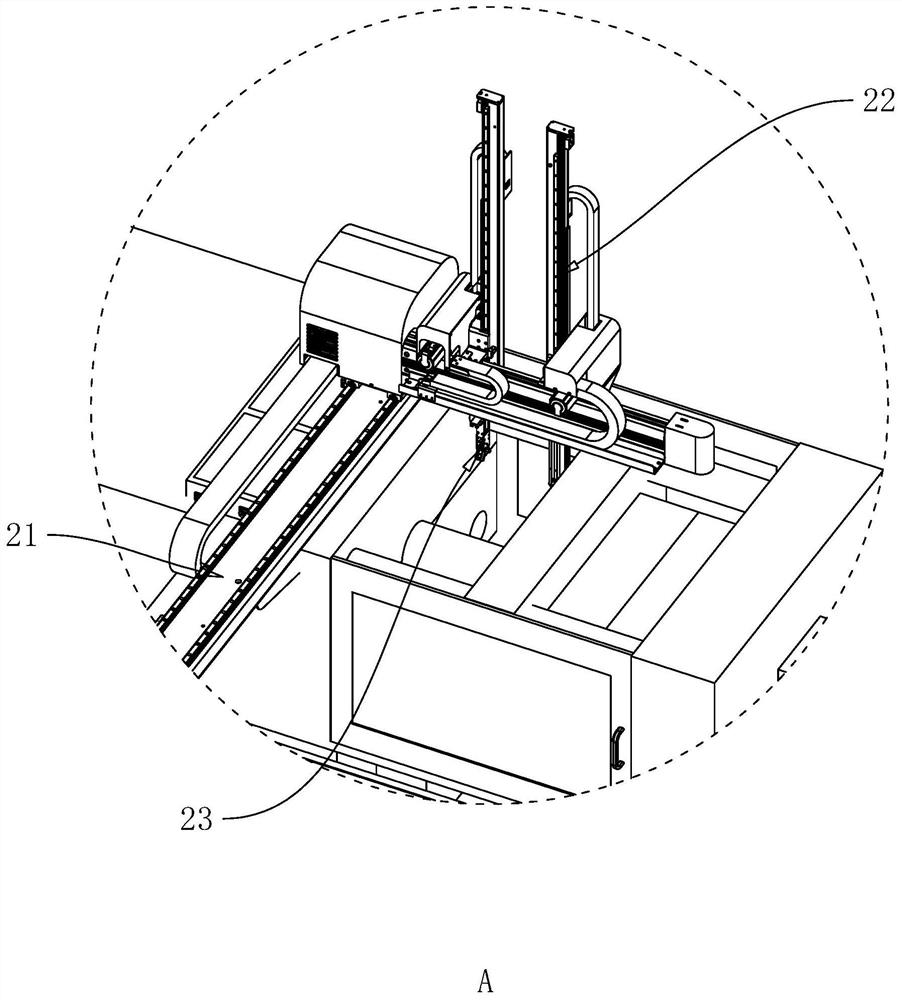

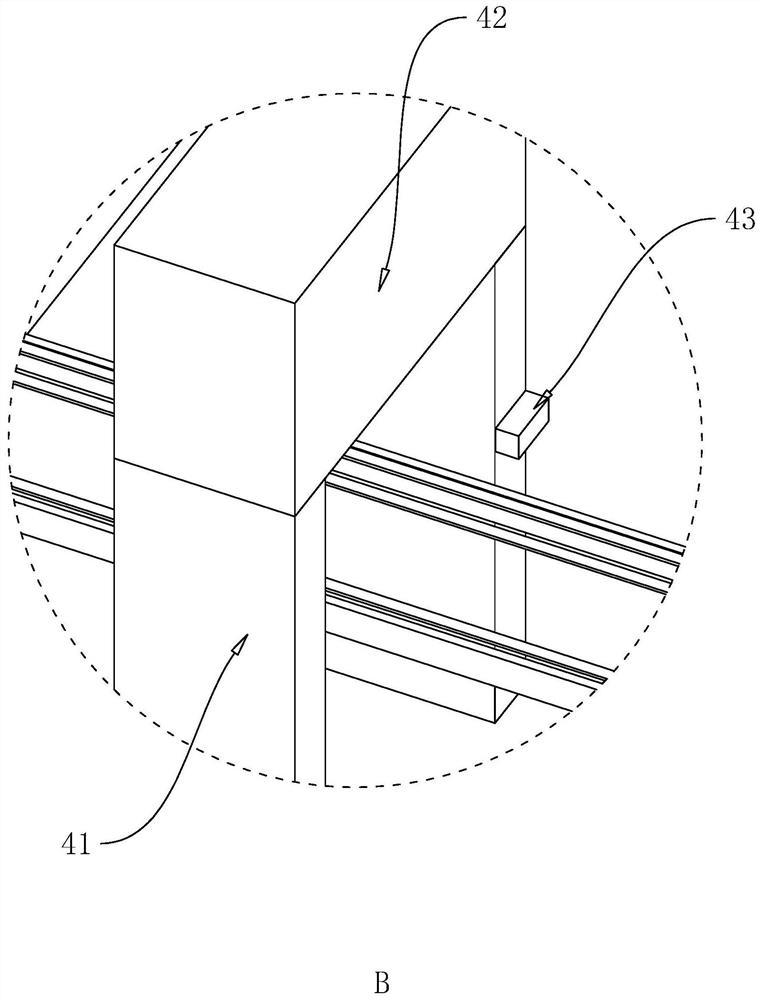

[0068] The embodiment of the present application discloses a disposable spoon production line. refer to figure 1 , the production line includes an injection molding machine 1, a retrieving manipulator 2, a conveyor 3, a disinfection device 4, a transfer frame 5 and a cutting device 6, the injection molding machine 1 is used for injection molding disposable spoons, and the retrieving manipulator 2 is used for taking out and Stacking disposable spoons, the conveyor 3 is used to send out the stacked disposable spoons intermittently, the disinfection device 4 is used to sterilize the stacked disposable spoons, and the transfer frame 5 is used to receive and be transported by the conveyor 3 The disposable spoons, the cutting device 6 is used to cut off the stacked disposable spoons from the connecting auxiliary material 10.

[0069] refer to figure 1 , the production line also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com