Chemical fiber cake robot unloading clamp

A technology of robots and silk cakes, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of affecting the quality of chemical fiber silk cakes, high labor intensity of workers, and low degree of automation, so as to achieve stable work, high synchronization and prevent accidents The effect that occurs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

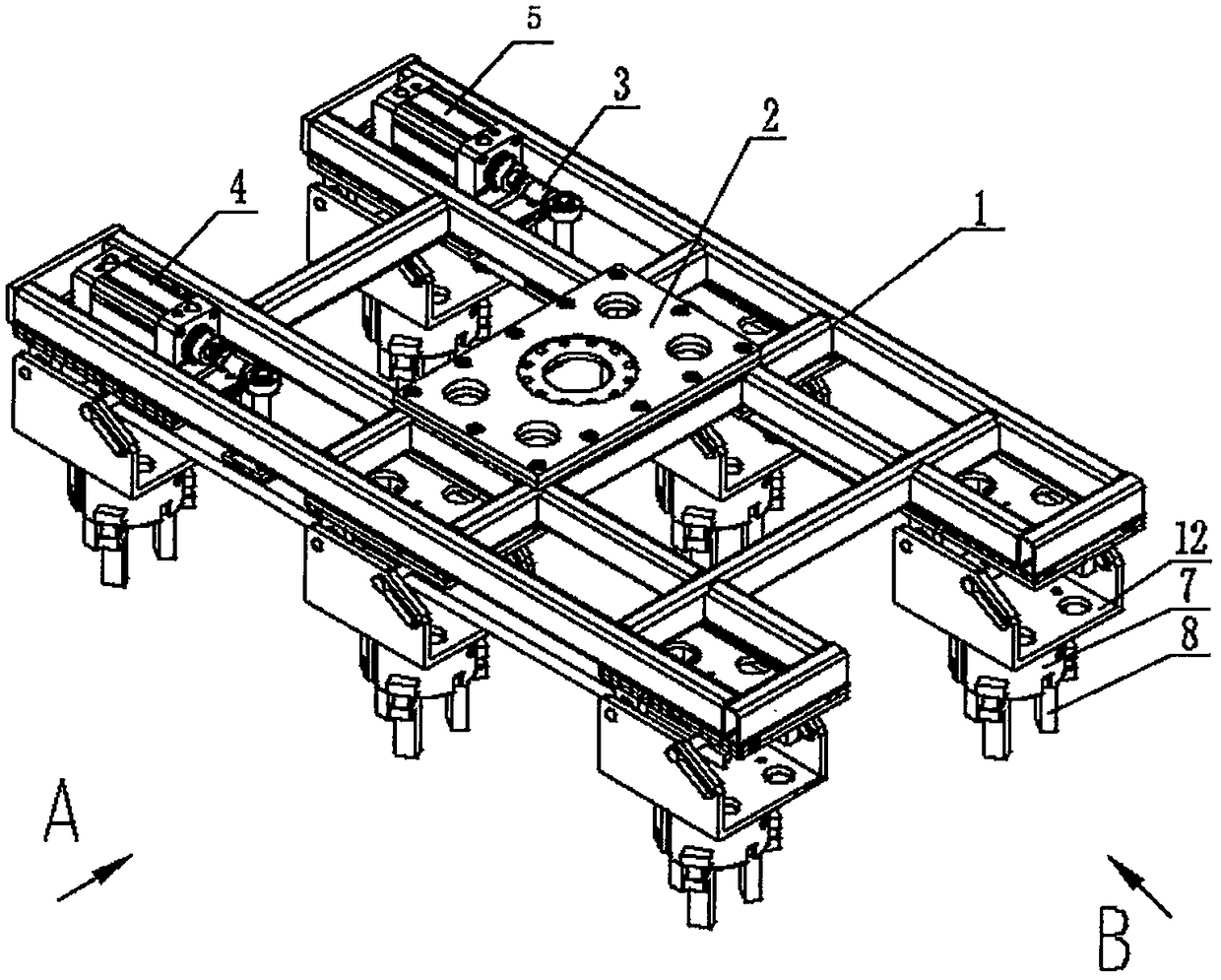

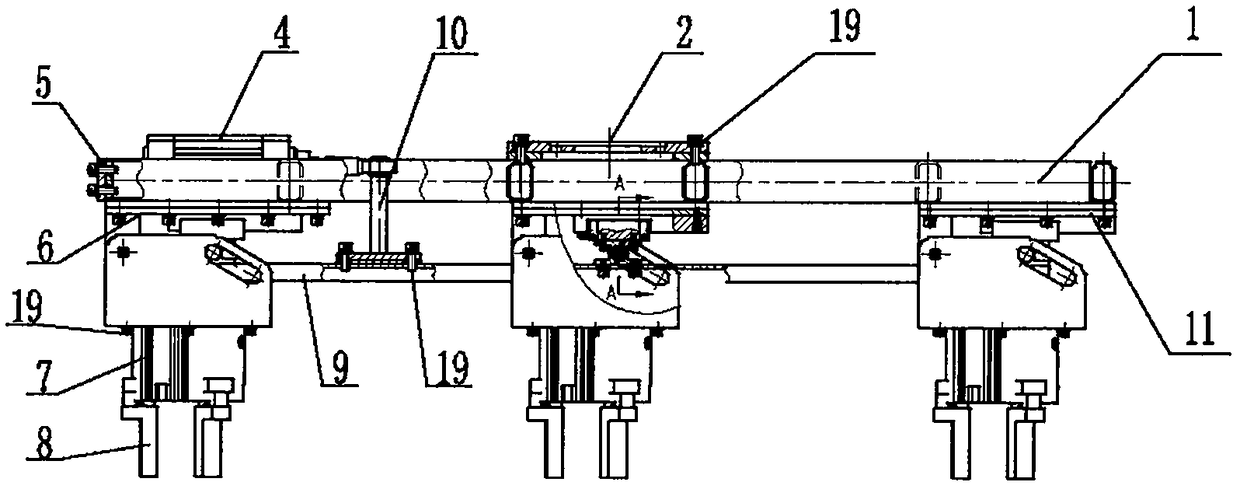

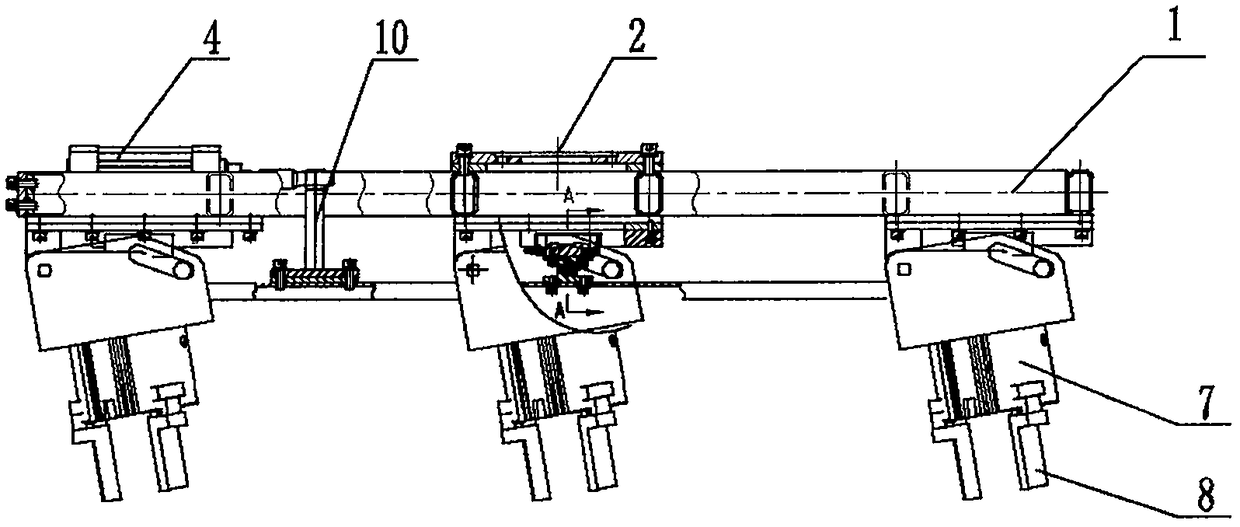

[0040] This embodiment provides a chemical fiber silk cake robot unloading fixture, such as figure 1 , the unloading fixture includes a frame 1, a robot connecting plate 2, a corner driving cylinder, a fisheye joint, a connecting rod, a moving shaft 15, a moving shaft connecting block 16, a fixed shaft, an air claw connecting frame 12, and a second corner driving cylinder 6 , the second slide rail mounting frame 11, linear slide rail 17, slide block 22, three-jaw cylinder 7 and air claw claw body 8; the specific connection relationship between each part is as follows:

[0041] The robot connecting plate 2 is connected with the robot flange, and is fixed at the center of the frame 1 by screws 19. Both the robot connecting plate 2 and the frame 1 are hollowed out and made of carbon steel, which ensures the rigidity of the fixture. The second corner The driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com