Novel minced meat processing device

A kind of processing equipment and minced meat technology, which is applied in the field of new minced meat processing equipment, can solve the problems of single stirring direction of the mixing sheet, large manpower consumption, low stirring efficiency of minced meat, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

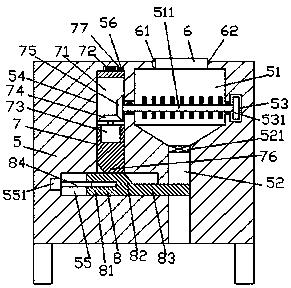

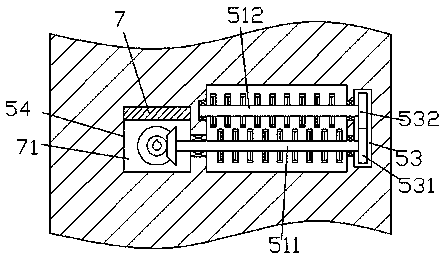

[0012] Combine below Figure 1-Figure 3 The present invention will be described in detail.

[0013] refer to Figure 1-Figure 3 , a new type of minced meat processing equipment according to an embodiment of the present invention, including a processing seat 5, a stirring chamber 51 is arranged inside the processing seat 5, and the top end surface of the processing seat 5 on the upper side of the stirring chamber 51 An opening 62 is provided in the internal communication, and a cover plate 6 can be turned up in the opening 62 through a hinge 61. The inner bottom wall of the stirring chamber 51 is connected with a discharge chamber 52 that expands downwards. The extended end of the bottom of the discharge chamber 52 runs through the end surface of the bottom of the processing seat 5, and an opening and closing valve 521 is fixed at the connection between the discharge chamber 52 and the stirring chamber 51. The left side of the stirring chamber 51 The inner wall of the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com