Environment-friendly new energy biofuel processing system

A biofuel and processing system technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of large electric energy consumption, high manufacturing cost, deformation, and temperature rise of the motor, and achieve the effect of preventing deformation and facilitating subsequent packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

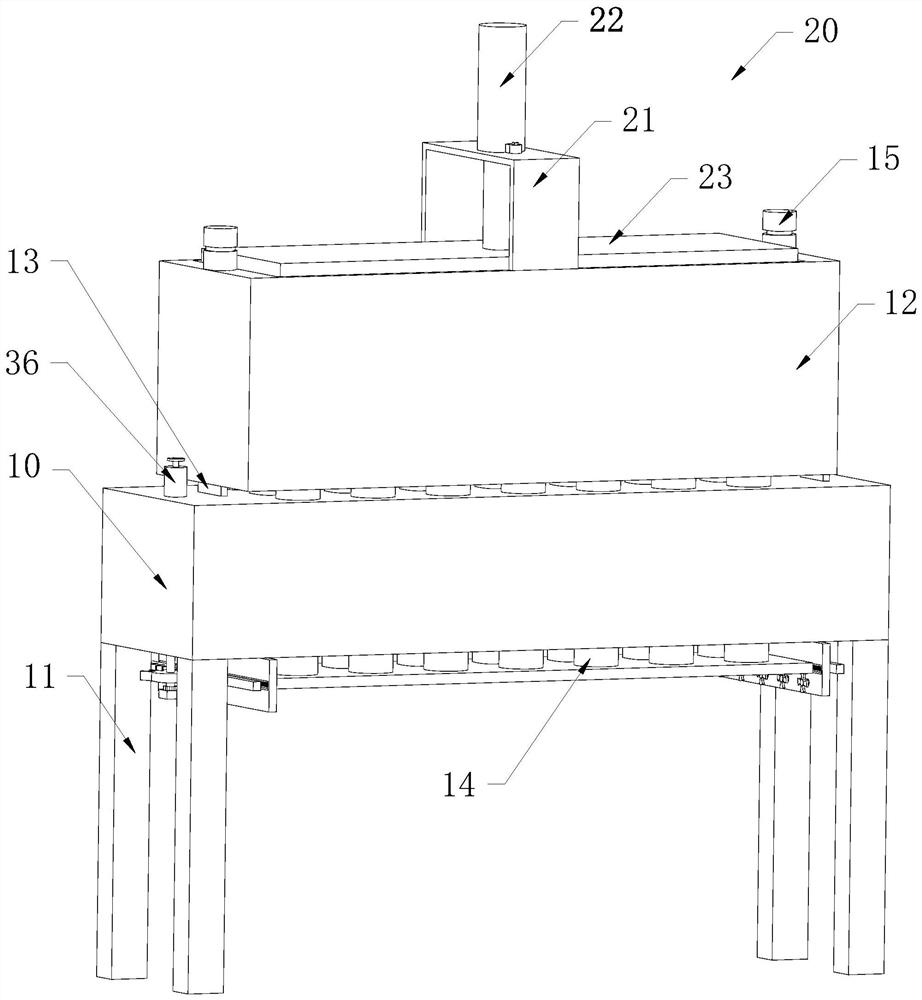

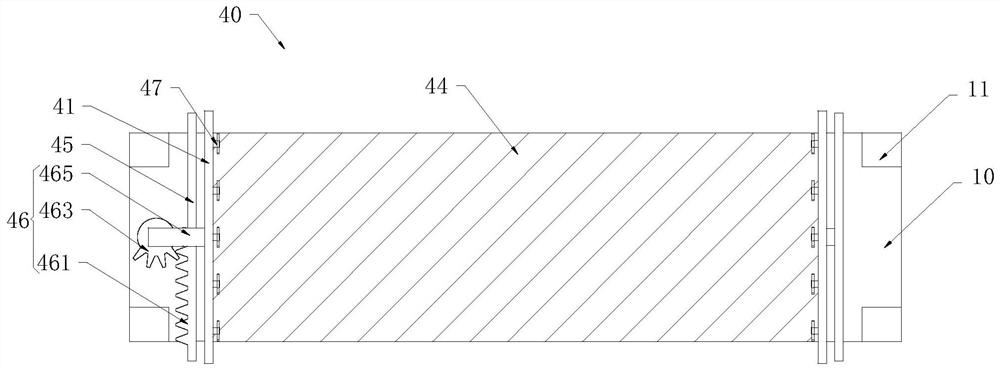

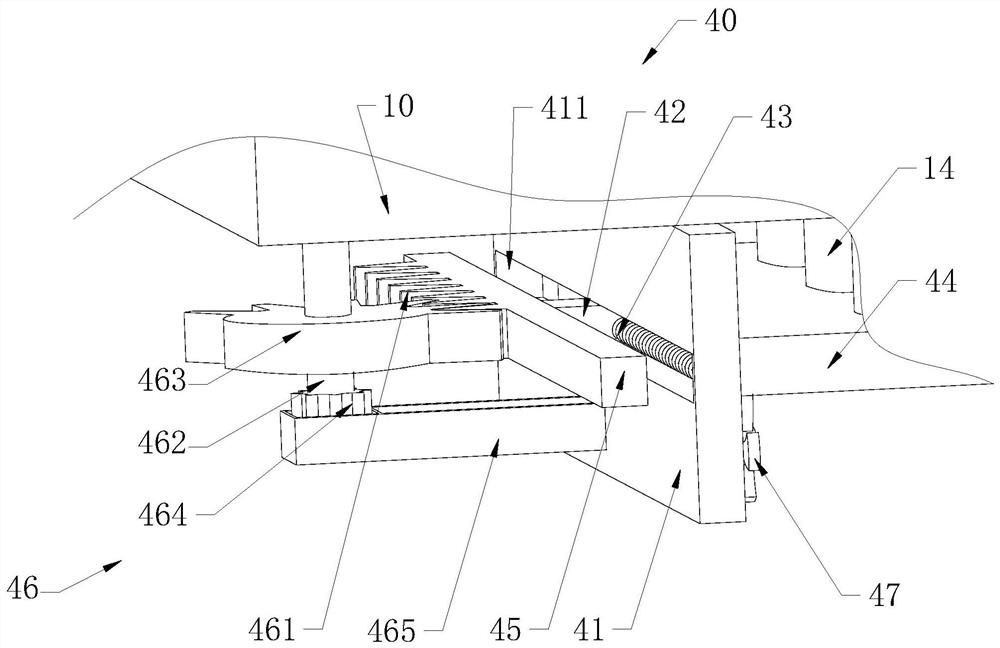

[0034] Such as Figure 1 to Figure 9 As shown, an environment-friendly new energy biofuel processing system includes a hollow rectangular box 10 and a fixed plate 11 arranged at the bottom corner of the hollow rectangular box 10, a rectangular box 12 is arranged above the hollow rectangular box 10, and the rectangular box 12 The top is provided with a rectangular groove 122, and the inside of the rectangular box 12 is provided with a groove 121 with the opening facing upwards. The length direction is evenly arranged, the two ends of the bottom of the rectangular box 12 are fixedly connected with the top of the hollow rectangular box 10 through the support frame 13, and the position corresponding to the round hole 123 between the rectangular slot 122...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com