Easily assembled composite material box structure

A composite material and box structure technology, applied in the field of structure, can solve problems such as large metal plates, achieve good sealing, high mechanical strength, and facilitate subsequent assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0020] Example.

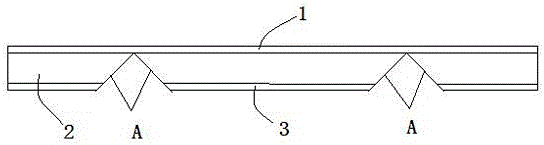

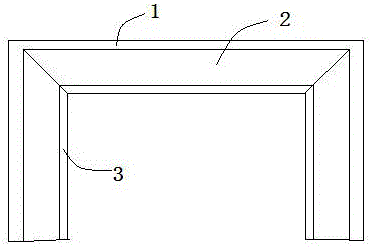

[0021] see Figure 1 to Figure 2 , the easy-to-assemble composite box structure in this embodiment mainly includes a surface layer 1 , a reinforcing layer 2 and an inner layer 3 .

[0022] Such as figure 1 As shown, the structure from top to bottom is: surface layer 1, reinforcement layer 2 and inner layer 3, wherein surface layer 1 is a continuous fiber reinforced thermoplastic prepreg tape, and the continuous fiber is one of glass fiber, carbon fiber or aramid fiber. species or several;

[0023] The thermoplastic material in this embodiment includes any one of PP, PE, PA, PET, PC, PPS, PBT, and PVC.

[0024] The fiber direction in this embodiment is perpendicular to the bending direction of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com