Cigarette paper with low ignition tendency and preparation method thereof

A low ignition tendency, cigarette paper technology, applied in the field of cigarettes, can solve the problem of falling on clothes, furniture or paper, easily causing fire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

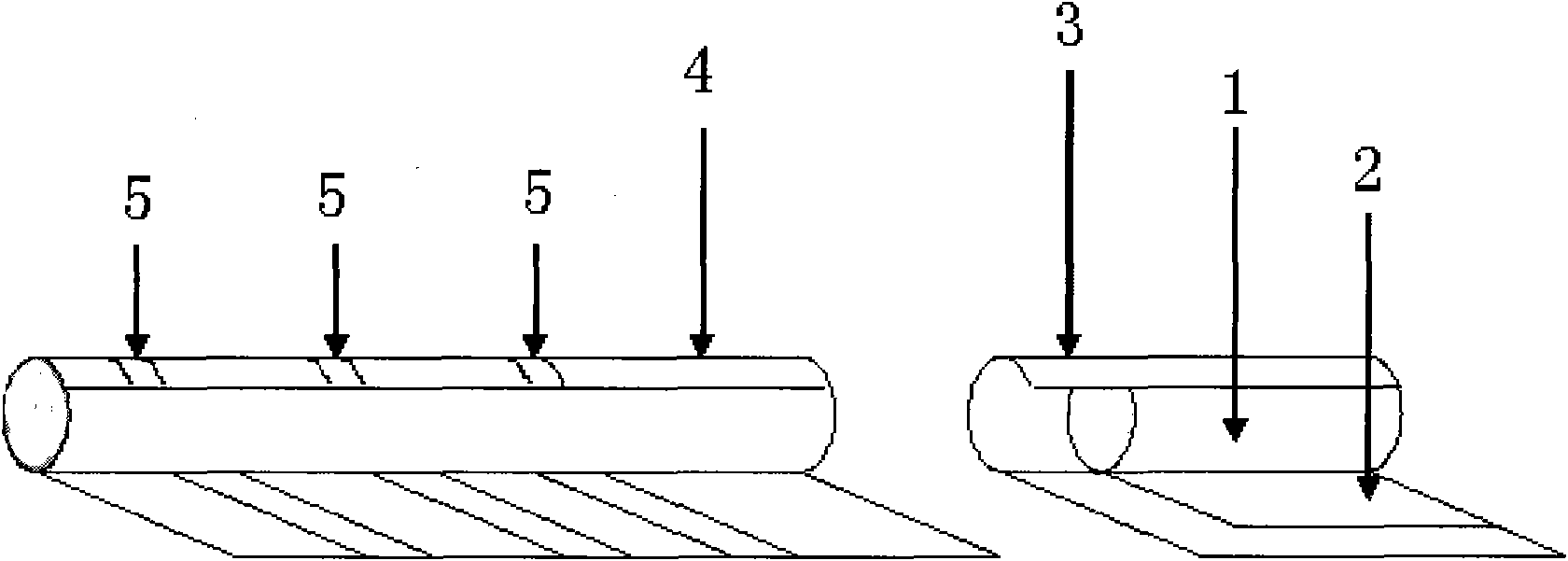

[0015] The present invention utilizes the existing flexo printing technology to print two printing tapes on the front and back of the tipping paper at the same position simultaneously to form a flame-retardant tape. more) such a flame retardant tape. The intervals between the three fire-retardant belts are the same.

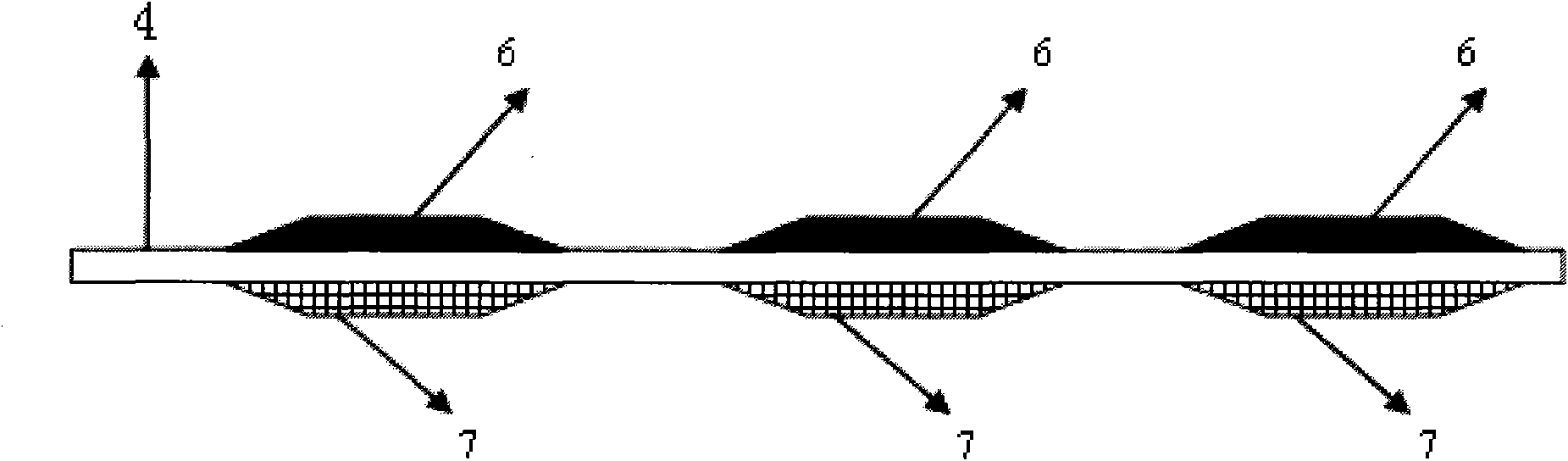

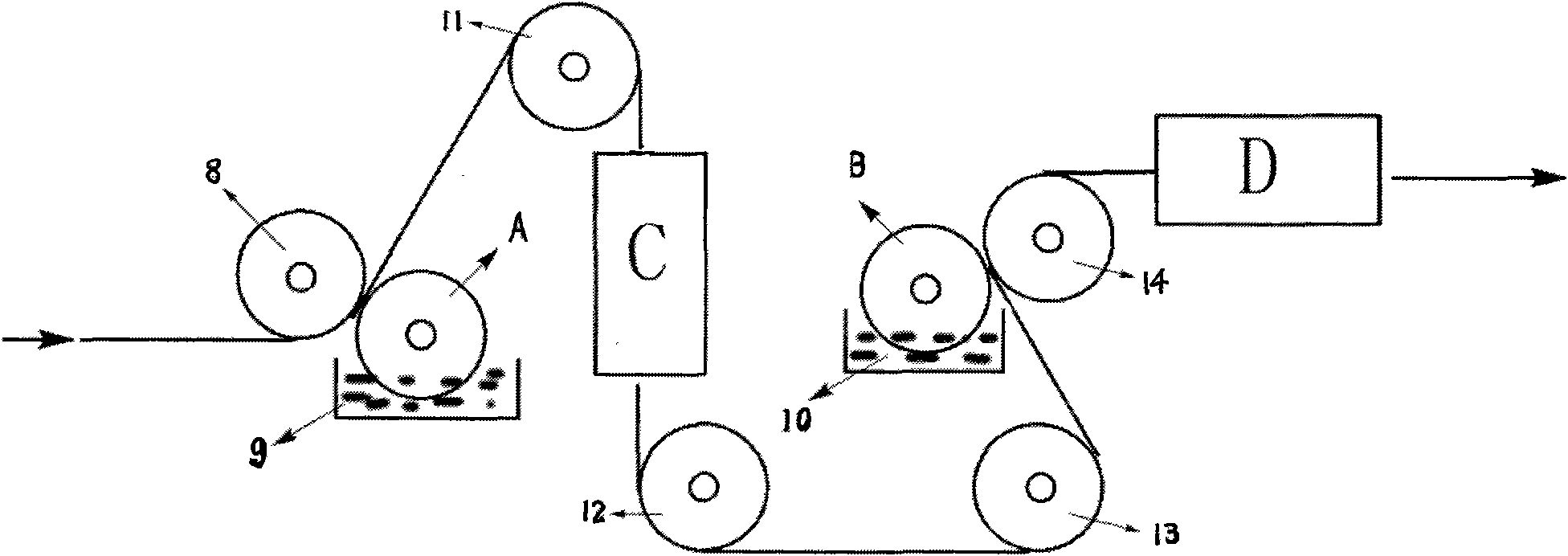

[0016] The material used for the inner flame retardant layer is cigarette flame retardant adhesive with low tendency to ignite. image 3 The shown flexo printing device simultaneously prints and coats both sides of the cigarette paper at the same position, and places cigarette flame-retardant adhesive with low ignition tendency and high thermal conductivity material at the troughs (9 and 10) of the two flexo printing devices respectively , roller A is coated on the inner layer of cigarette paper 4 to form a printing layer 6, and then dried quickly by drying equipment; and then the second flexo printing roller B is applied to the outer printing layer at the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com