Carbon nanotube composite material and heat conductor

A technology of carbon nanotubes and composite materials, applied in the direction of nanotechnology, nanotechnology, heat exchange materials, etc., can solve the problems of uneven distribution of carbon fibers, increased thermal resistance of heating components and cooling components, etc., to achieve excellent uniformity , the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

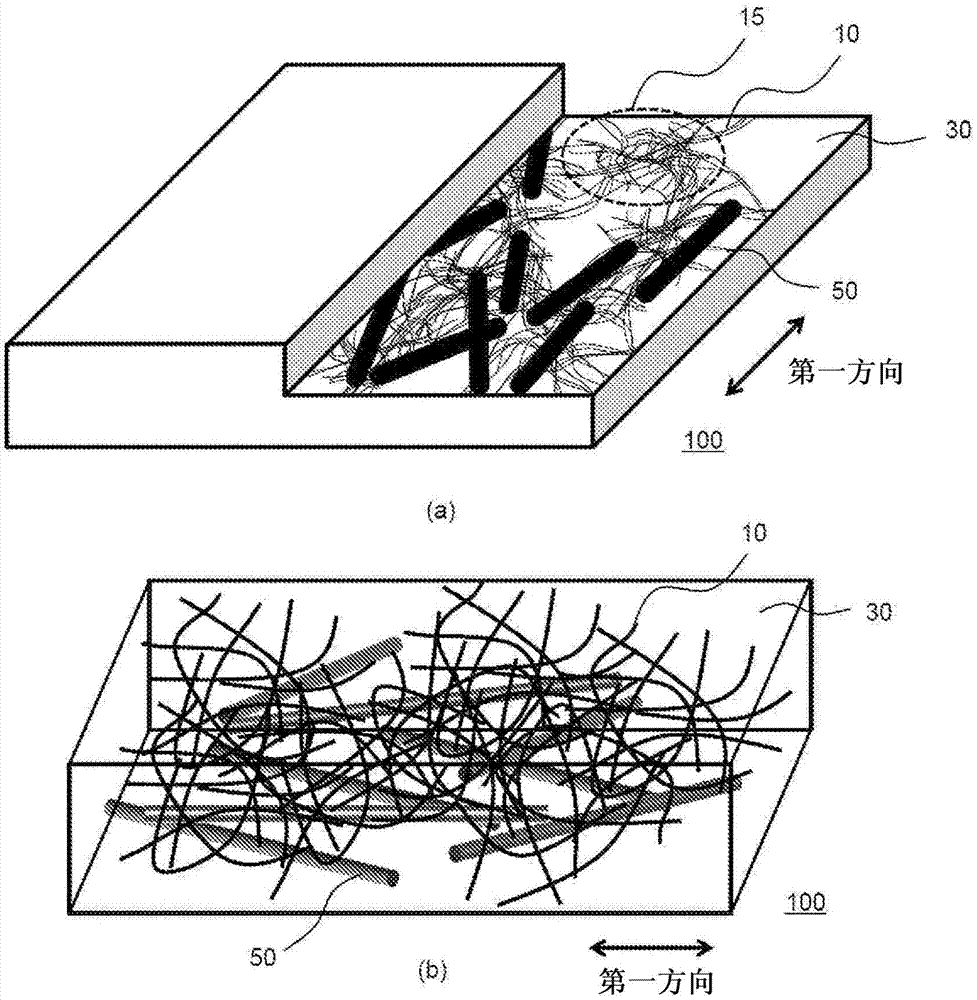

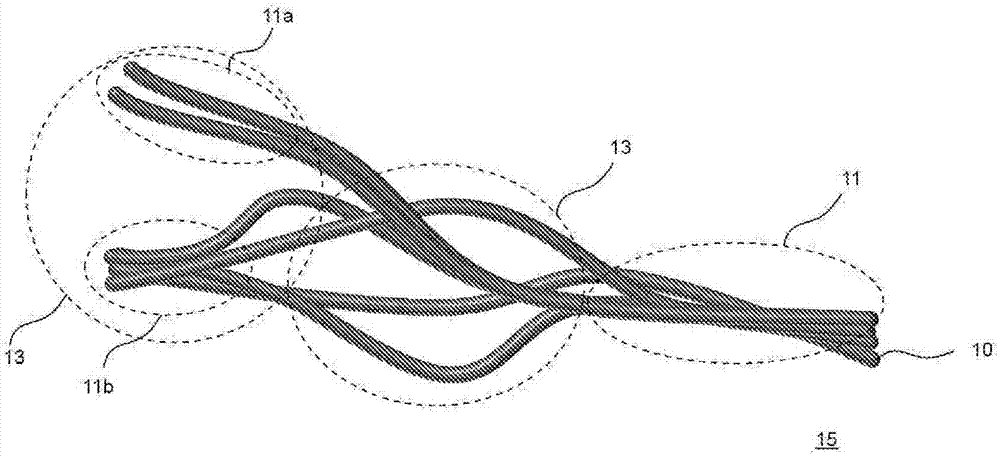

Method used

Image

Examples

Embodiment 1)

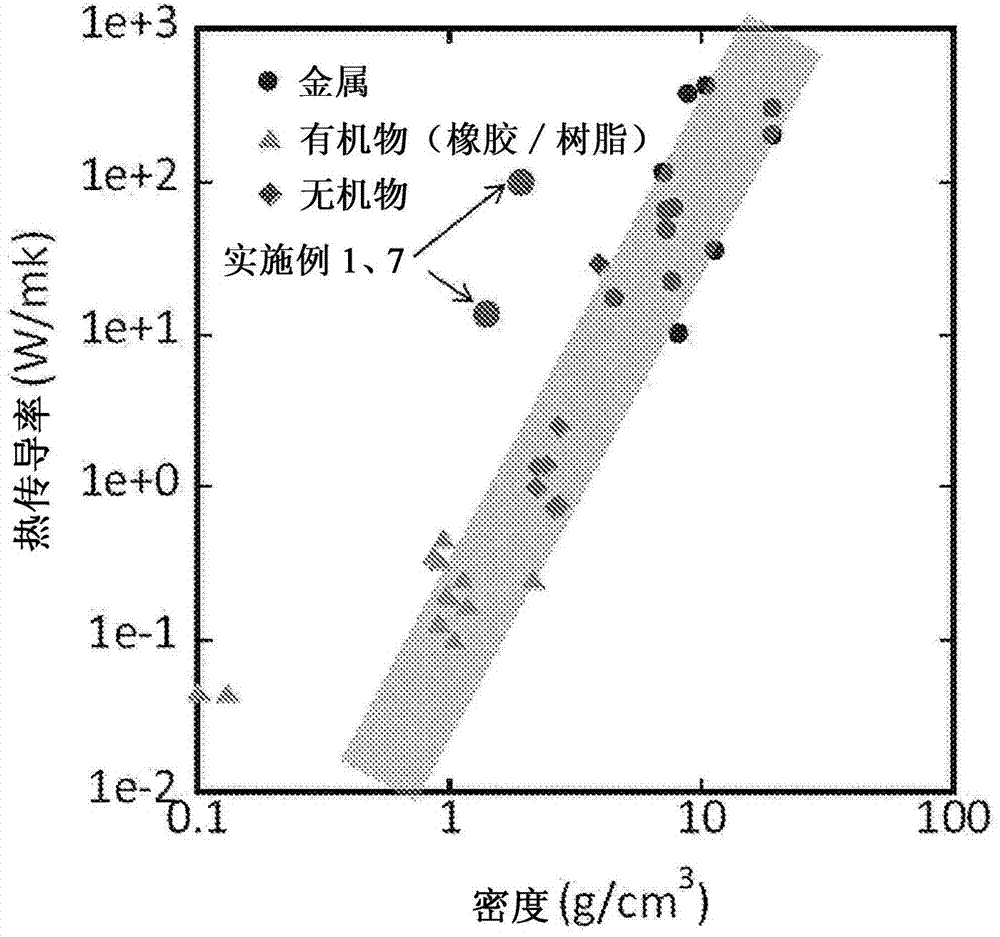

[0120] [Characteristics of CNTs used in Example 1]

Embodiment 1

[0121] The representative values of CNTs used in Example 1 are: length 100 μm, average diameter 3.0 nm, thermal conductivity 80 W / mK.

[0122] [Raman spectrum evaluation of CNT aggregates]

[0123] The Raman spectrum of the CNT aggregate used in Example 1 was measured. at 1590cm -1 A sharp G-band peak was observed in the vicinity, indicating that a graphite crystal structure exists in the CNTs constituting the CNT aggregate of the present invention.

[0124] In addition, since at 1340cm -1 Nearby, D-band peaks originating from defect structures and the like were observed, thus indicating that intentional defects are contained in CNTs. Due to the low wavelength side (100 ~ 300cm -1 ) RBM modes originating from multiple single-layer CNTs were observed, which shows that the above-mentioned graphite layer is a single-layer CNT. The G / D ratio was 8.6.

[0125] [Purity of CNT aggregates]

[0126] The carbon purity of the CNT aggregate was determined from the result of eleme...

Embodiment 2)

[0139] As Example 2, using the same manufacturing method as in Example 1, carbon nanotube dispersion and carbon fiber were added to the fluororubber solution, so that when the mass of the carbon nanotube composite material as a whole is 100% by mass, the carbon The nanotube content was 4.8%, the carbon fiber content was 28.6%, and a carbon nanotube composite material 210 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com