Geomechanical magnetic field testing device and method

A technology of geomechanics and test equipment, applied in measurement equipment, scientific instruments, instruments, etc., can solve the problems of Coriolis acceleration centrifugal model error, acceleration, inability to obtain a uniform force field, etc., to improve the stress level and reduce the system error. Small, wide-ranging effects

Inactive Publication Date: 2011-10-12

CHINA THREE GORGES UNIV

View PDF3 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are many defects in the geotechnical centrifugal model test. First, the centrifugal inertial force field and the gravity field cannot be completely similar. The centrifugal inertial force field is proportional to the inertial radius. The geotechnical centrifugal model test cannot obtain a uniform force field, which is quite different from the actual engineering; secondly, the Coriolis acceleration generated during the feeding process will also cause errors in the centrifugal model; finally, acceleration and braking are also one of the problems of the centrifugal model test. one

It takes a certain amount of time to increase and decrease the rotation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

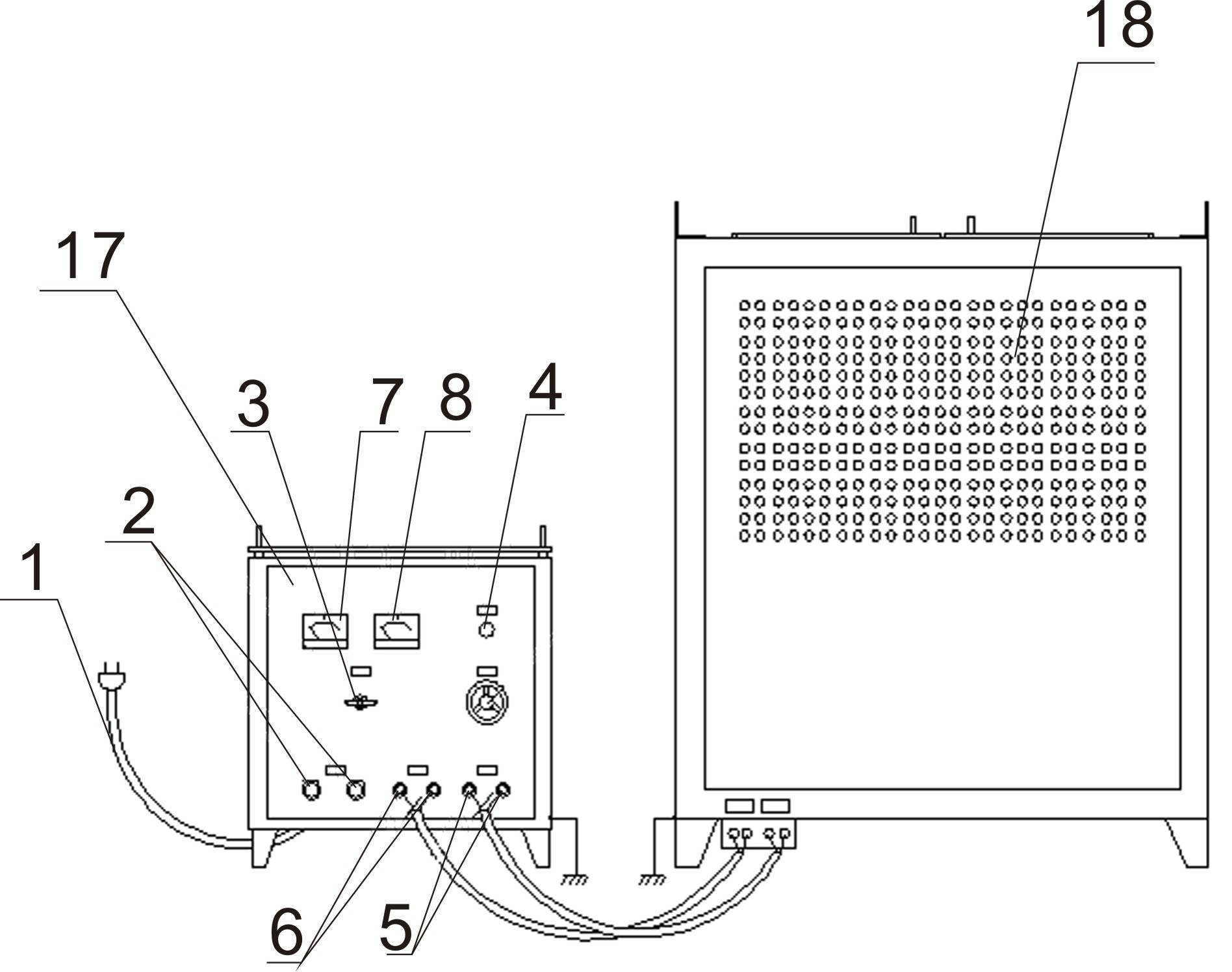

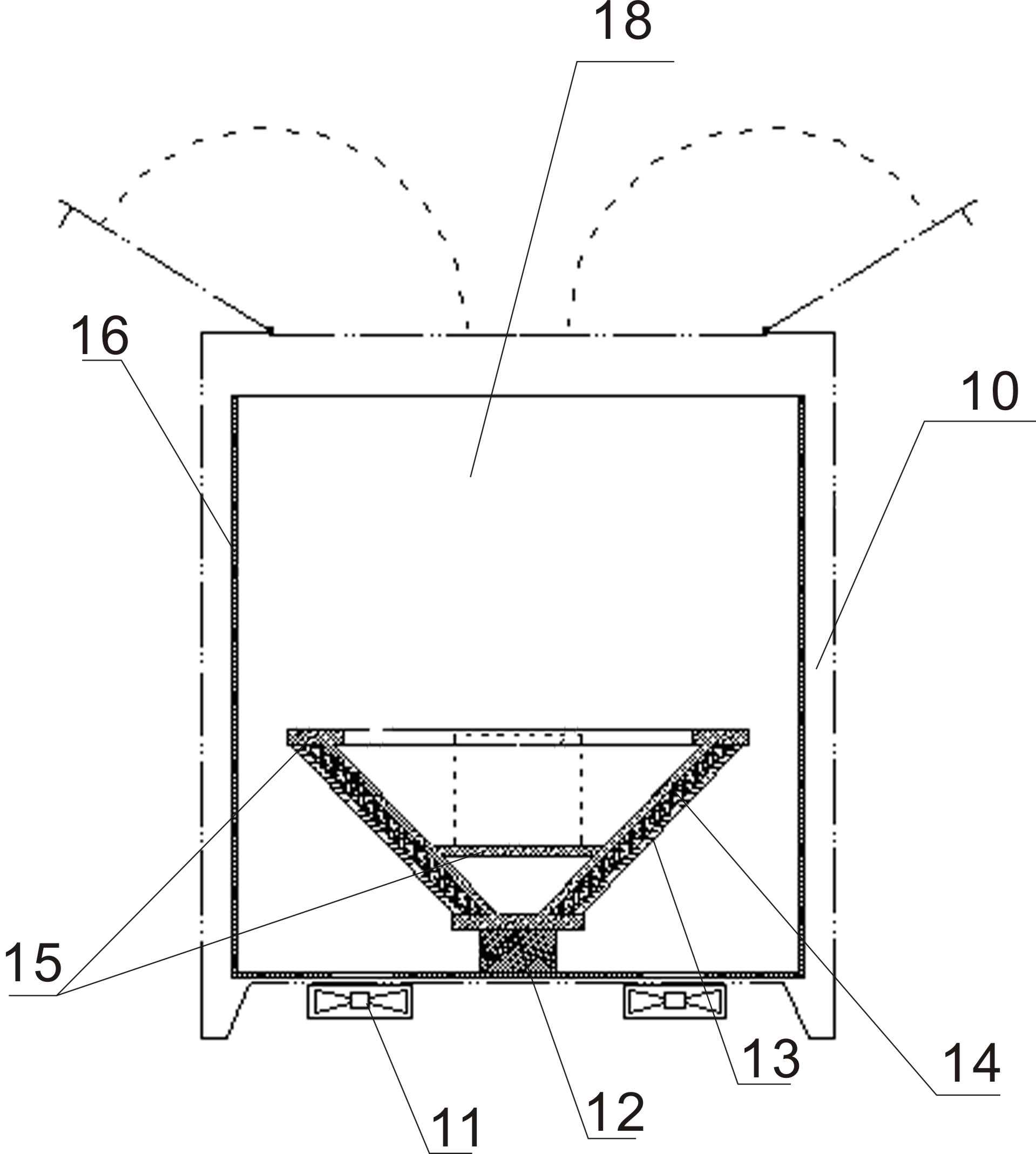

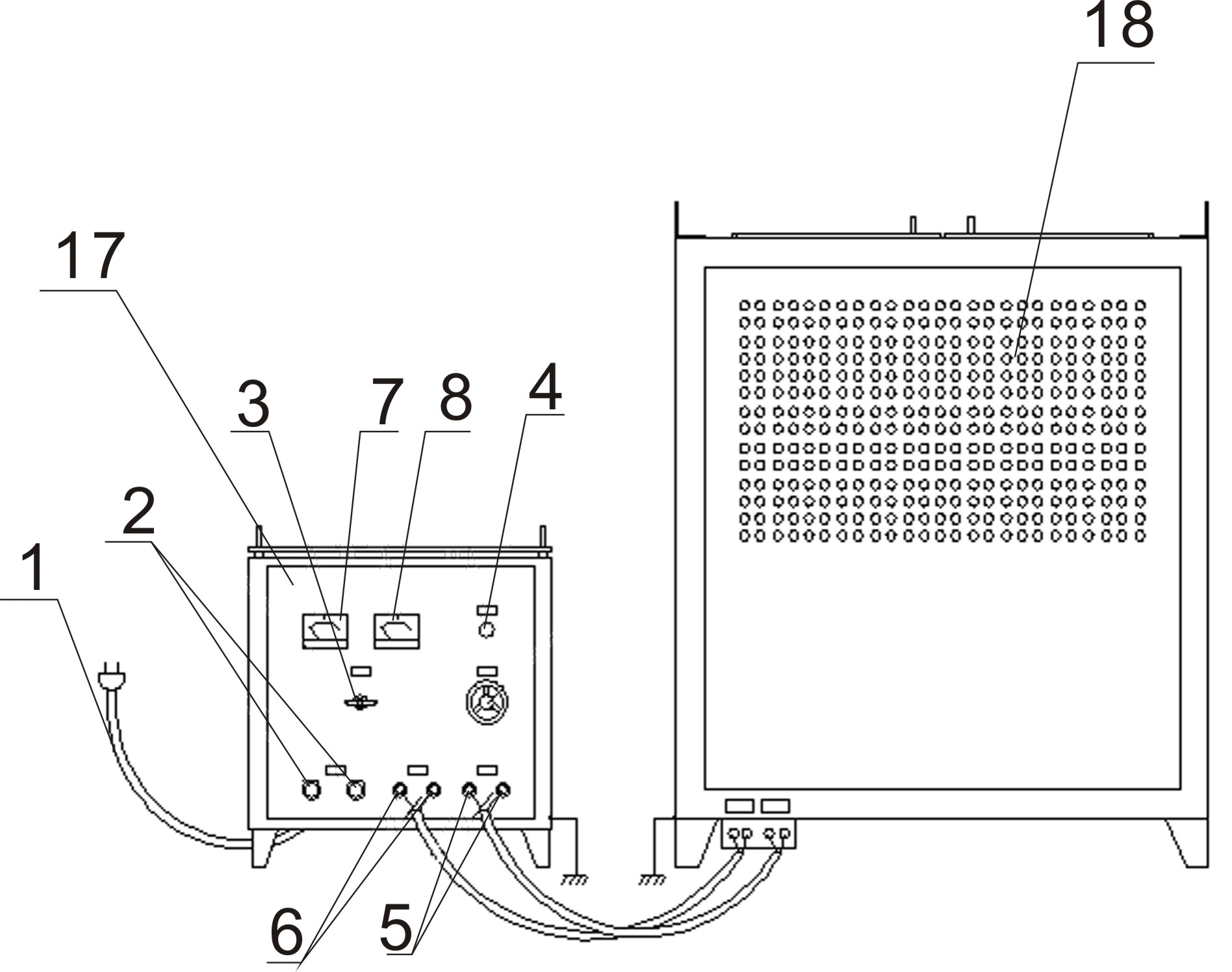

The invention relates to a magnetic field testing device and method. The testing device provided by the invention comprises a control power supply and a host which is connected with the control power supply, wherein the host comprises a cabinet; the inner wall of the cabinet is provided with a shielding layer; a support is arranged on the base of the cabinet; the support is connected with a framework; a coil winding is arranged on the framework; the outer side of the framework is provided with an insulating layer; and a cooling fan is arranged below the base of the cabinet. In the invention, the simulation of the actual physical and mechanical properties of geomechanics is realized based on the principles of simulating gravity by utilizing an electromagnetic force and simulating a gravityfield by utilizing an electromagnetic force field. A powdery magnetic material is blended into rock soil so that the magnetic force action on the rock soil in the magnetic field is overlapped on the original gravity, thereby achieving the effect of simulating the ng gravity field, improving the stress level of a model test material, and providing basic equipment for the magnetic force model test of the geomechanics.

Description

technical field [0001] The invention relates to a geomechanical magnetic field test device and a test method, belonging to the field of geomechanics. Background technique [0002] Model test has always been an important research method in geotechnical engineering. It can be used not only to test the results of various theoretical analysis and numerical calculations, but also to directly guide the design and construction of actual projects. [0003] The existing model tests are divided into two categories: one is the model test under 1g. In the usual gravity field, the geotechnical building or foundation is simulated under certain boundary conditions, and the relevant stress and strain data are measured. Theoretical calculation or data calculation to test the theoretical calculation results. This test is divided into small scale test and full scale test. Due to the low stress level and the difficulty in satisfying the similarity of the strength index in the small-scale test...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/00

Inventor 罗先启张振华

Owner CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com