Ultrathin silicon oxynitride film material and preparation method and application thereof

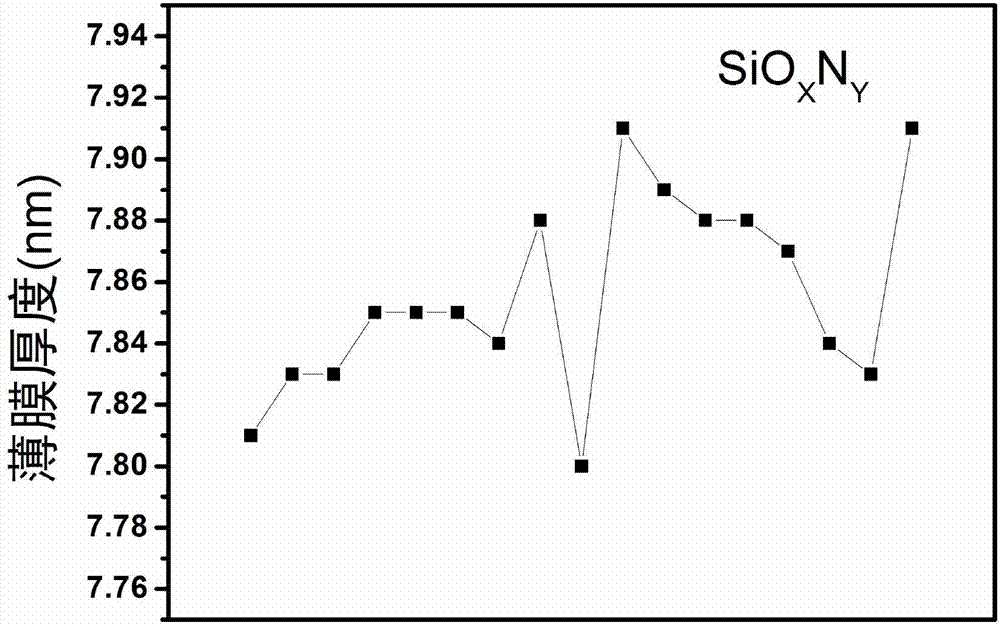

A silicon oxynitride and film material technology, which is applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem of large non-uniformity of silicon oxynitride film, and achieves a simple and easy preparation process and large size. Application potential, effect of improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A silicon oxynitride film material prepared by the following method:

[0046] (1) Use polished P-type (100) doped single crystal silicon as the substrate, and carry out the following pretreatment: first, the substrate is soaked in 5wt% HF acid for 3min, then cleaned with deionized water, and finally dried its surface;

[0047] (2) Put the pretreated substrate obtained in step (1) into the cavity of the high-density plasma enhanced chemical vapor deposition equipment, and evacuate the deposition chamber so that the vacuum degree of the background is 1×10 -5 Pa is about, and the substrate is heated to 230°C;

[0048] (3) SiH containing SiH with a purity greater than 99.99% 4 Gas, NH 3 Gas, O 2 Gas and Ar 2 Gas is the gas source; among them, containing SiH 4 gas, O 2 Gas, NH 3 Gas is the reactive gas, Ar 2 Gas is carrier gas and shielding gas, supplied Ar 2 Gas, O 2 Gas, NH 3 Gas and containing SiH 4 The gas flow rates are: 400sccm, 1.2sccm, 26.8sccm, 130.5scc...

Embodiment 2

[0053] A silicon oxynitride film material prepared by the following method:

[0054] (1) Prepare a 200nm thick Ti film on the polished P-type (100) doped single crystal silicon wafer, and use this as the substrate, and carry out the following pretreatment: first use acetone and isopropanol to sonicate for 5min respectively, Then wash with deionized water, and finally dry the surface;

[0055] (2) Put the pretreated substrate obtained in step (1) into the cavity of the high-density plasma enhanced chemical vapor deposition equipment, and evacuate the deposition chamber so that the vacuum degree of the background is 1×10 -5 Pa is about, and the substrate is heated to 150°C;

[0056] (3) SiH containing SiH with a purity greater than 99.99% 4 Gas, NH 3 Gas, O 2 Gas and Ar 2 Gas is the gas source; among them, containing SiH 4 gas, O 2 Gas, NH 3 Gas is the reactive gas, Ar 2 Gas is carrier gas and shielding gas, supplied Ar 2 Gas, O 2 Gas, NH 3 Gas and containing SiH 4 ...

Embodiment 3

[0060] A silicon oxynitride film material prepared by the following method:

[0061] (1) Use polished sapphire as the substrate, and carry out the following pretreatment: first, the substrate is ultrasonically 5 min each with acetone and isopropanol, then cleaned with deionized water, and finally the surface is dried;

[0062] (2) Put the pretreated substrate obtained in step (1) into the cavity of the high-density plasma enhanced chemical vapor deposition equipment, and evacuate the deposition chamber so that the vacuum degree of the background is 1×10 -6 Pa is about, and the substrate is heated to 260°C;

[0063] (3) SiH containing SiH with a purity greater than 99.99% 4 Gas, NH 3 Gas, O 2 Gas and Ar 2 Gas is the gas source; among them, containing SiH 4 gas, O 2 Gas, NH 3 Gas is the reactive gas, Ar 2 The gas is carrier gas and shielding gas, the supplied Ar 2 Gas, O 2 Gas, NH 3 Gas and containing SiH 4 The gas flow rates are: 450sccm, 10.5sccm, 17.5sccm, 130.5sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com