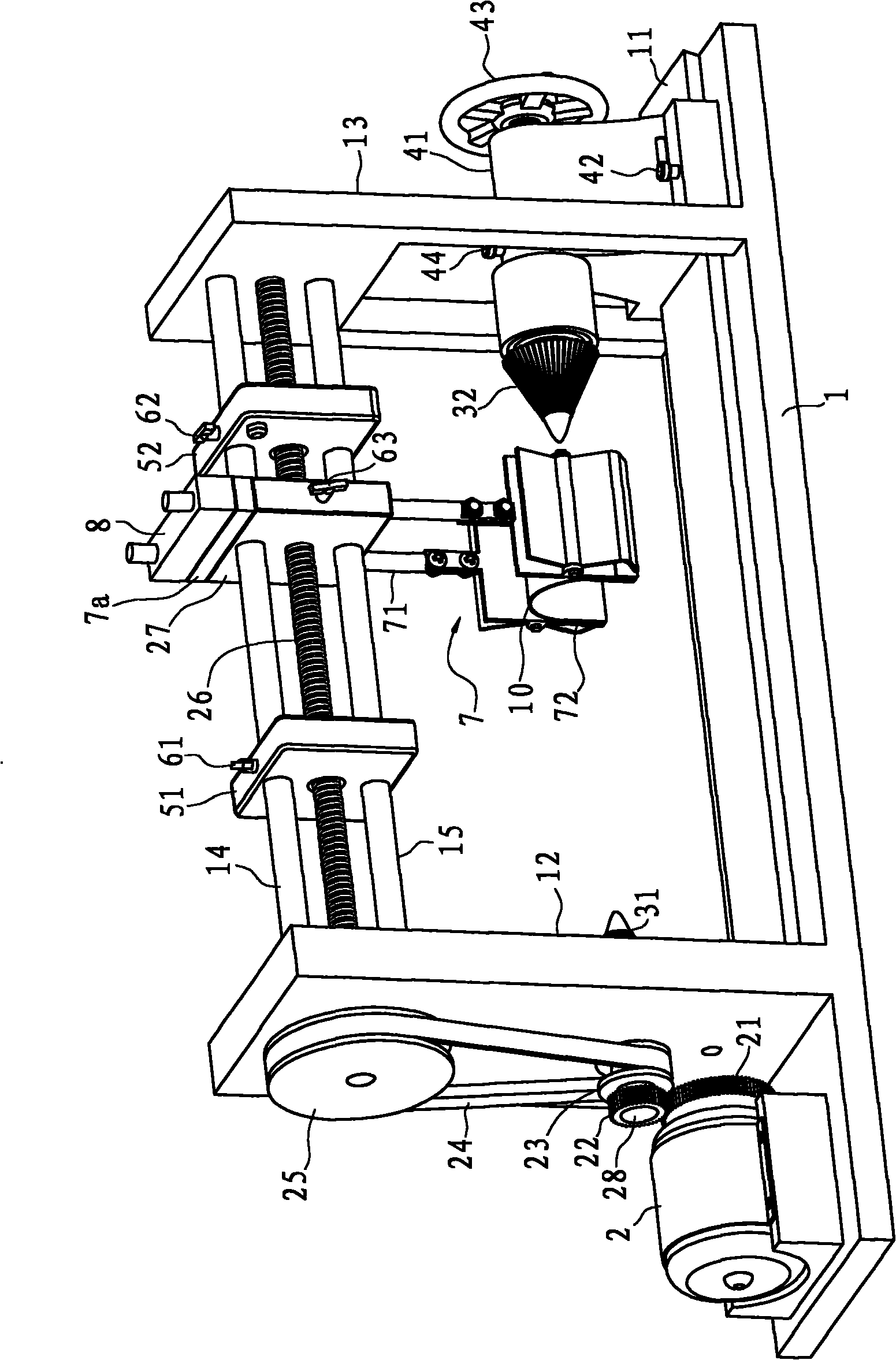

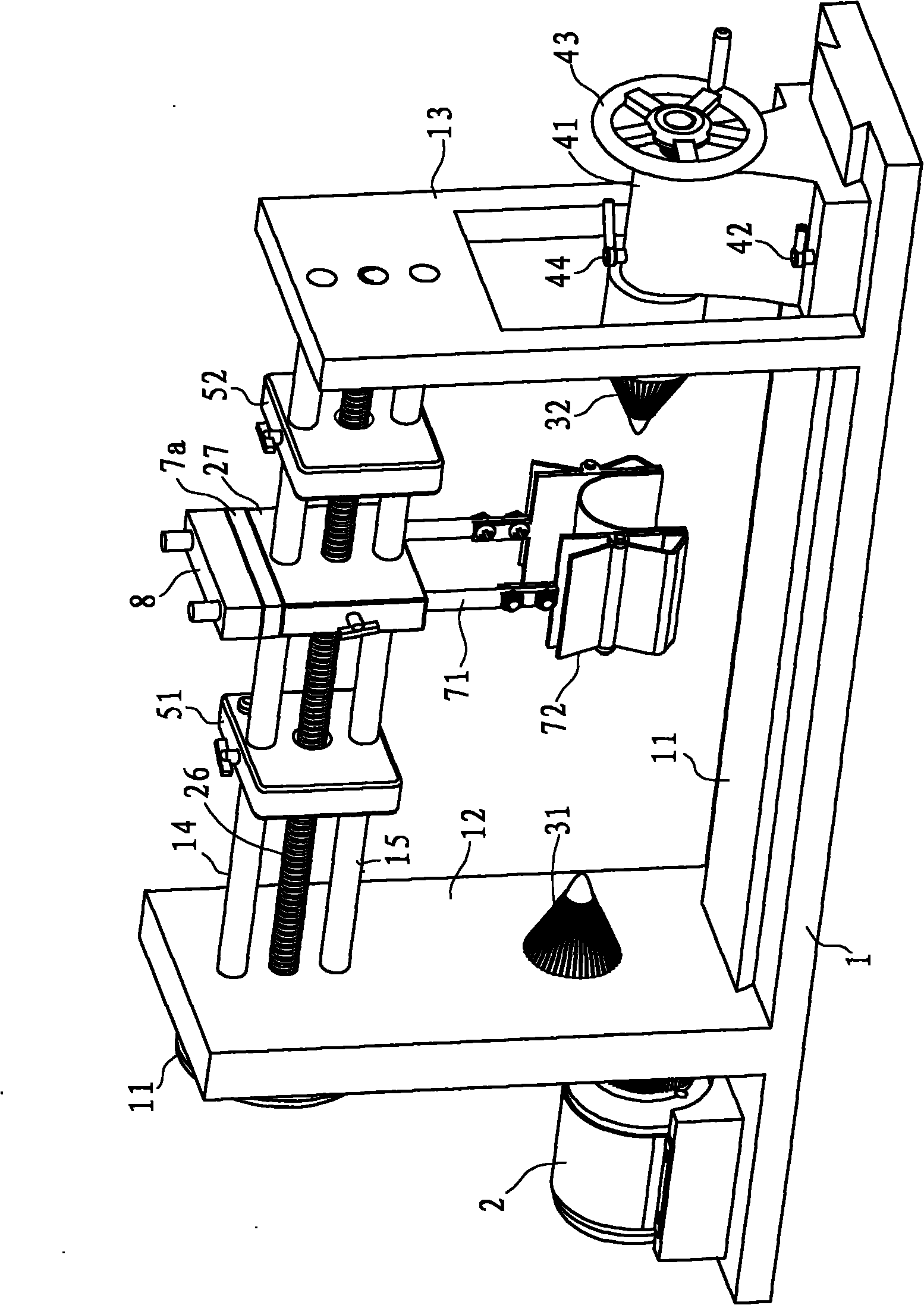

Grinding device of pipes used for curved surface anti-buckling tests of adhesive tapes

A curved surface and adhesive tape technology, which is applied in the direction of grinding machines, portable grinding machines, grinding/polishing equipment, etc., can solve the problems of no grinding device, data reliability impact, and large randomness of grinding effect, so as to improve grinding efficiency and test data Accurate and reliable, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

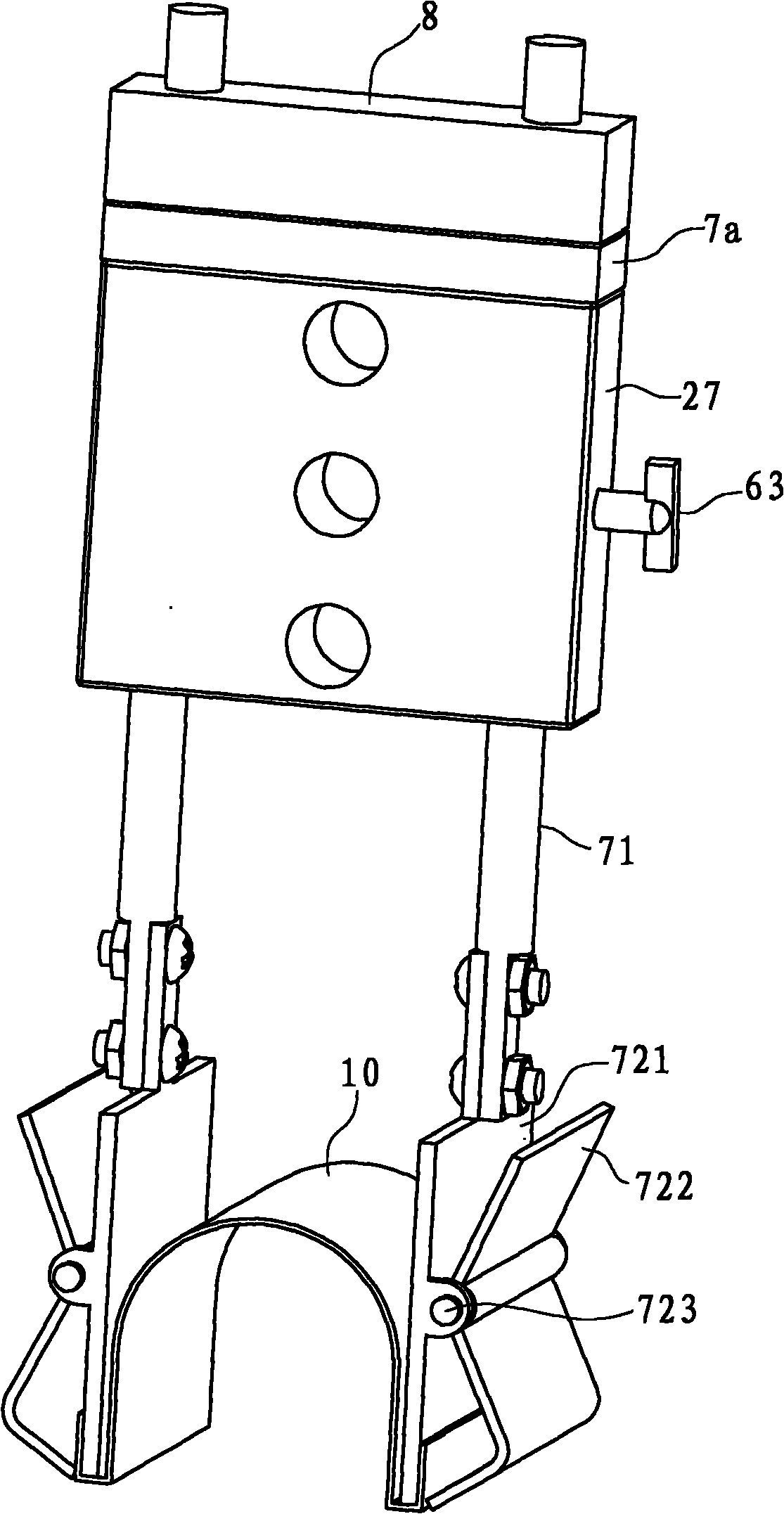

[0049] Example 2, such as Figure 5 As shown, the upper end of each vertical rod 71 in the present embodiment passes through the slider 27 and protrudes to form the top. It is an upside-down right-angle U-shape, the two ends of the bottom are respectively set on the slider 27, the lower pressure block 84 is horizontally set in the bracket 81 and can move back and forth, the booster screw 83 is installed on the upper bottom of the bracket 81 from top to bottom And be connected with lower pressing block 84, handle 82 is arranged on the top of pressurization screw rod 83, and spring 85 is two, and each spring 85 is respectively sleeved on the top of respective upright bar 71, and one end is offset against the bottom surface of lower pressing block 84 , the other end abuts against the top surface of the slider 71. Other structures can refer to Embodiment 1.

Embodiment 3

[0050] Example 3, such as Image 6 As shown, the first clamping member 31 in this embodiment is a chuck. Other structures can refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com