Preparation method for microarc oxidation/hydrothermal treatment composite film on surface of magnesium alloy

A technology of micro-arc oxidation and hydrothermal treatment, which is applied in anodic oxidation, metal material coating process, coating, etc., can solve the problems of poor biological activity and poor corrosion resistance of magnesium alloys, and achieve improved corrosion resistance and good uniformity , the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

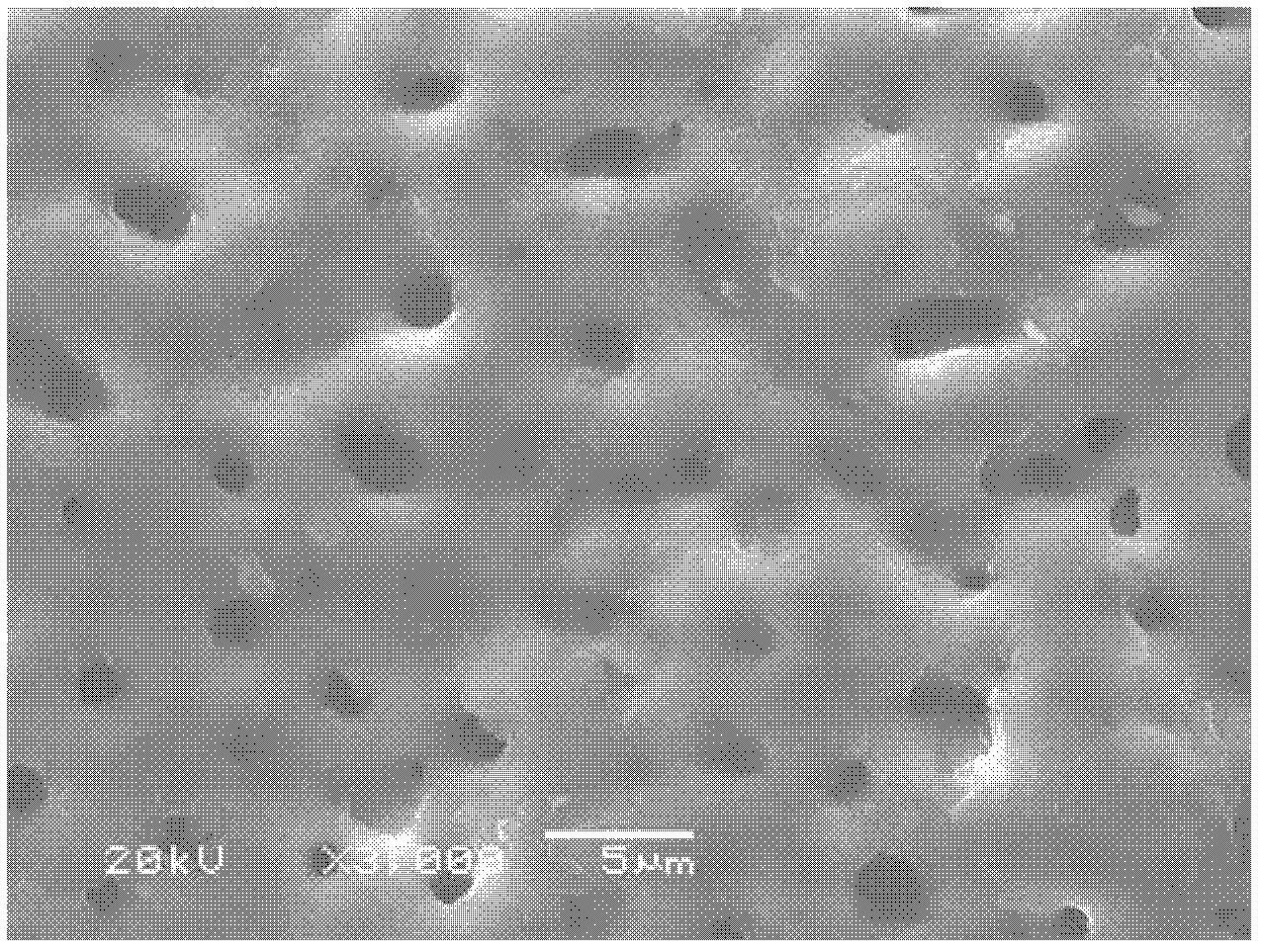

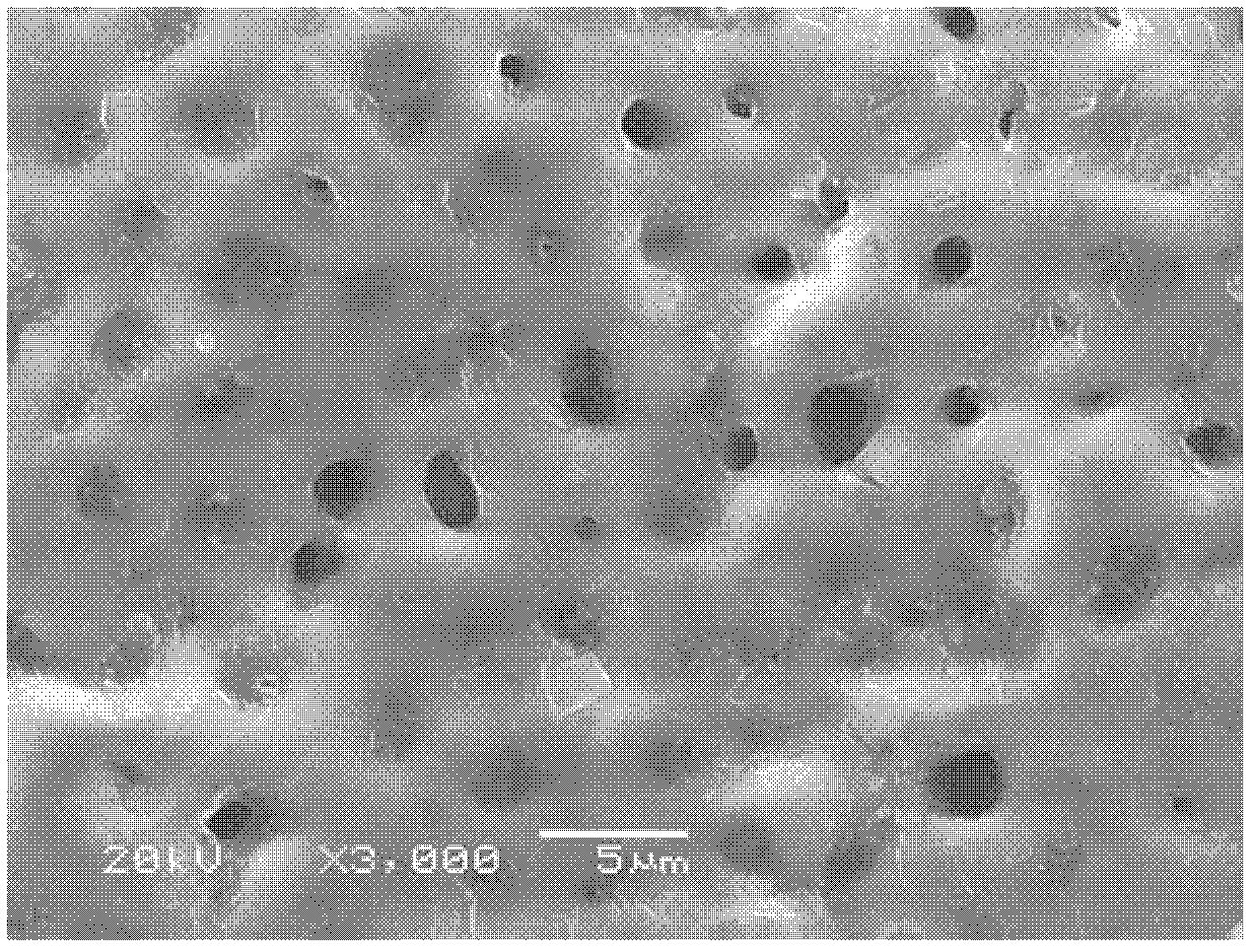

[0020] Specific embodiment one: this embodiment is the preparation method of the micro-arc oxidation / hydrothermal treatment composite film on the surface of magnesium alloy, which is realized through the following steps: 1. Preparation of the micro-arc oxidation film on the surface of magnesium alloy: the oxide film will be removed The magnesium alloy is placed in the electrolyte as the anode, and the stainless steel plate is used as the cathode, and the micro-arc oxidation reaction is carried out for 5-20 minutes, and then the magnesium alloy is taken out, rinsed and dried, and the micro-arc oxidation film is obtained on the surface of the magnesium alloy; The concentration is 3.5g / L~4.5g / L sodium hydroxide and 4.5g / L~5g / L sodium hexametapolyphosphate, the solvent is water, the temperature of the electrolyte is controlled at 15~40℃, micro arc Oxidation process parameters are: constant power 136W, current density 2A / cm 2 , the frequency is 2000Hz;

[0021] 2. Place the magnes...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the electrolyte is composed of sodium hydroxide with a concentration of 3.8g / L~4.2g / L and hexabia Sodium polyphosphate. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, the electrolyte consists of sodium hydroxide with a concentration of 4g / L and sodium hexametapolyphosphate of 4.8g / L. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com