Method for preparing mesoporous MCM-22 silicon aluminum molecular sieve

A technology of MCM-22 and silica-alumina molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems such as the difficulty of using supercage acid sites, achieve the improvement of internal diffusion limit, reduce the diffusion distance, and keep the crystallinity intact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

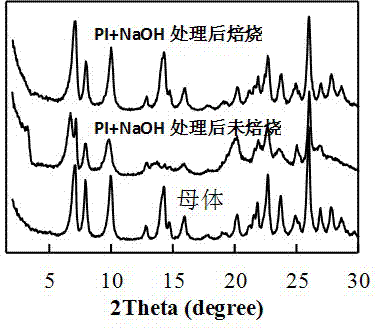

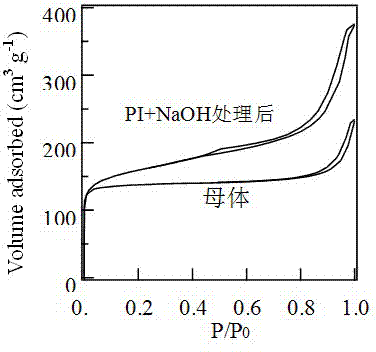

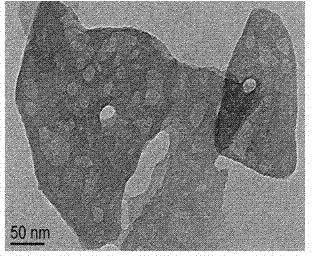

[0020] Mix the reaction mixture of 1 g of MCM-22 molecular sieve synthesized by conventional hydrothermal method, 1.42 g of PI and 50 mL of 0.1M NaOH solution evenly, put it into a closed reaction autoclave, react at 170 ° C for 1 h under autogenous pressure, and cool with tap water. After filtering, washing, drying at 100°C overnight, calcining at 550°C for 6 hours, 4 Cl 3 After secondary ammonium exchange, it is calcined again at 550° C. for 6 hours to obtain the mesoporous molecular sieve of the present invention. Its BET specific surface area is 523 square meters per gram, and the outer specific surface is 242 square meters per gram. The X-ray diffraction spectrum of the product is shown in figure 1 ; The adsorption-desorption spectrum of nitrogen adsorption at low temperature is shown in figure 2 ; transmission electron microscope photos see image 3 .

Embodiment 2

[0022] Mix the reaction mixture of 1g of MCM-22 molecular sieve synthesized according to the conventional hydrothermal method, 1.42g of PI and 50 mL of 0.1M NaOH solution evenly, put it into a closed reaction autoclave, react at 170°C for 2h under autogenous pressure, and cool with tap water. After filtering, washing, drying at 100°C overnight, calcining at 550°C for 6 hours, 4 After three times of ammonium exchange with Cl, it was calcined again at 550° C. for 6 hours to obtain the mesoporous molecular sieve of the present invention. Its BET specific surface area is 535 square meters per gram, and the outer specific surface is 245 square meters per gram, and the X-ray diffraction spectrum of the product has figure 1 characteristics; the adsorption-desorption spectrum of low-temperature nitrogen adsorption has figure 2 characteristics; transmission electron microscope photos have image 3 Characteristics.

Embodiment 3

[0024] Mix the reaction mixture of 1 g of MCM-22 molecular sieve synthesized by conventional hydrothermal method, 1.42 g of PI and 50 mL of 0.1M NaOH solution evenly, put it into a closed reaction autoclave, react at 170 ° C for 8 h under autogenous pressure, and cool with tap water. After filtering, washing, drying at 100°C overnight, calcining at 550°C for 6 hours, 4 After three times of ammonium exchange with Cl, it was calcined again at 550° C. for 6 hours to obtain the mesoporous molecular sieve of the present invention. Its BET specific surface area is 530 square meters per gram, and the outer specific surface is 243 square meters per gram, and the X-ray diffraction spectrum of the product has figure 1 characteristics; the adsorption-desorption spectrum of low-temperature nitrogen adsorption has figure 2 characteristics; transmission electron microscope photos have image 3 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com