Method for preparing catalyst and application thereof

A catalyst and catalytic activity technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of powder falling off of active components, reducing the utilization efficiency of active components, etc., to achieve uniform shell layer, preparation of The process is easy to control and the repeatability is good

Active Publication Date: 2010-08-11

DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, compared with the eggshell catalyst prepared by the solution of the active component, this method of preparing the active component powder reduces the utilization efficiency of the active component on the one hand, and the active component is washed away by the air flow during use. Powder is also easier to shed from the surface of inert solid particles

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

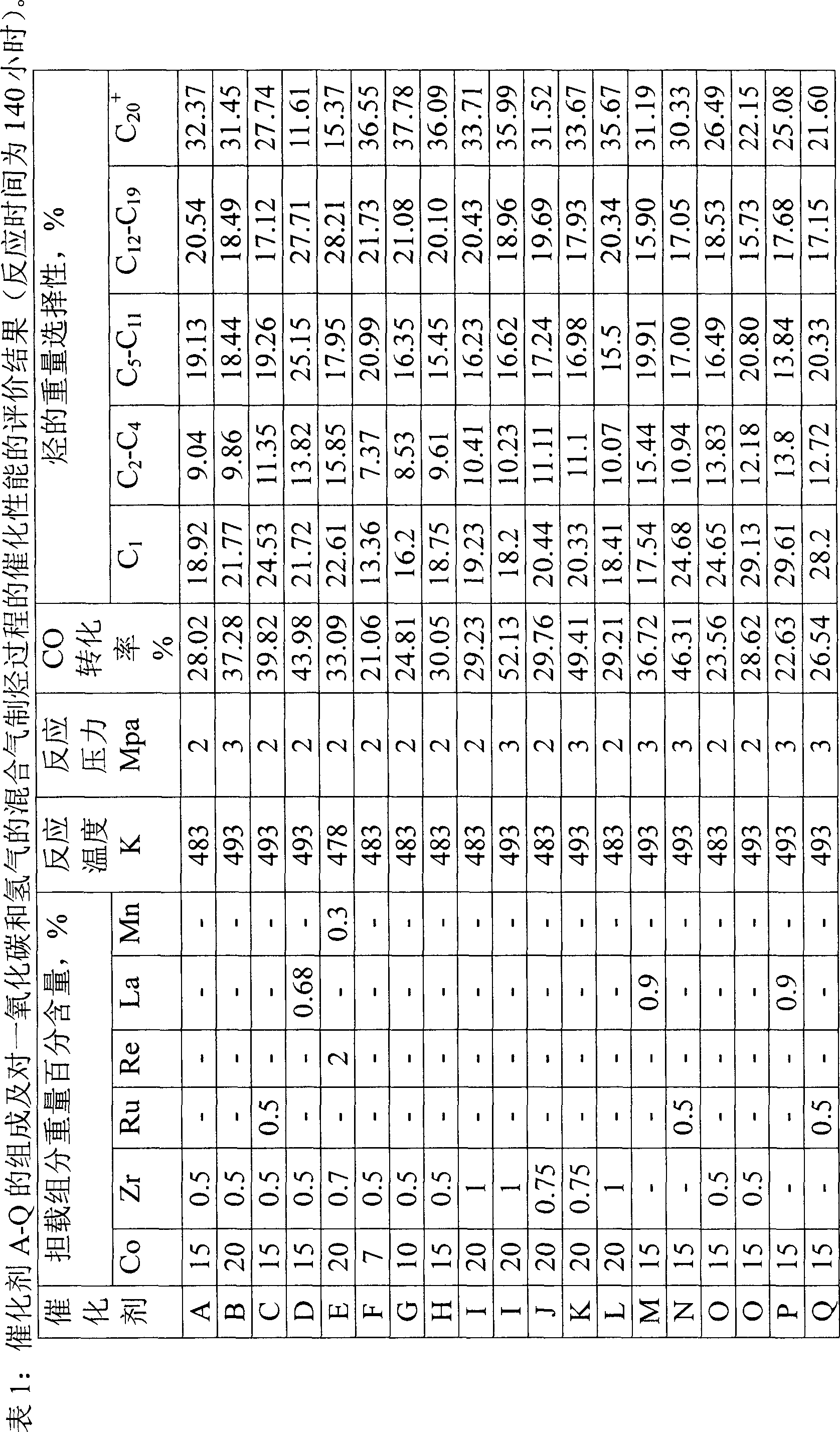

The invention provides a catalyst preparation method. The procedure is that:1} a solution containing soluble compounds with loaded components is prepared; 2} the solution produced in procedure 1 is sprayed on a rolling carrier or a carrier preloading one or a plurality of components and the carrier is heated in the process of spraying; 3) the product produced in procedure 2 is dried or roasted; and 4) the procedures 2 and 3 are repeated. The active components of the catalyst prepared in the method of the invention contain group eight elements. When the catalyst preparation method of the invention is applied in the hydrocarbon preparation procedure from mixed gas of carbon monoxide and hydrogen, the active components of the catalyst prepared contain group eight elements. The invention provides a better shell catalyst preparation technique to solve the problem of internal diffusion in certain chemical conversion procedures. The catalyst can be applied in hydrocarbon preparation reactionof gas mixture of carbon monoxide and hydrogen.

Description

technical field The invention relates to a method for preparing a catalyst. The present invention also relates to a catalyst prepared by the above method and a process for producing hydrocarbons from a mixture of carbon monoxide and hydrogen using the catalyst. technical background Solid catalysts are used in many chemical transformation processes. Currently commonly used solid catalyst preparation methods include impregnation method, precipitation method, crystallization method, sol-gel method and simple roasting method. The composition of the catalyst usually includes catalytically active components or simultaneously contains auxiliary components or simultaneously contains supports. Carriers are generally solid particles with a porous structure. Supported catalysts containing supports are usually prepared by conventional impregnation methods. When preparing supported catalysts by impregnation, it is generally hoped that the supported components can be distributed as un...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J23/83B01J23/84C07C1/04B01J32/00

Inventor 吕元丁云杰王涛朱何俊金明

Owner DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com