Method of analyzing surface coating of electrical steel

A surface coating and analysis method technology, which is applied in the field of analysis of electrical steel surface coatings, can solve the problems of inability to observe electrical steel coatings with a transmission electron microscope, different shapes and structures, and inability to observe high-resolution topography images of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

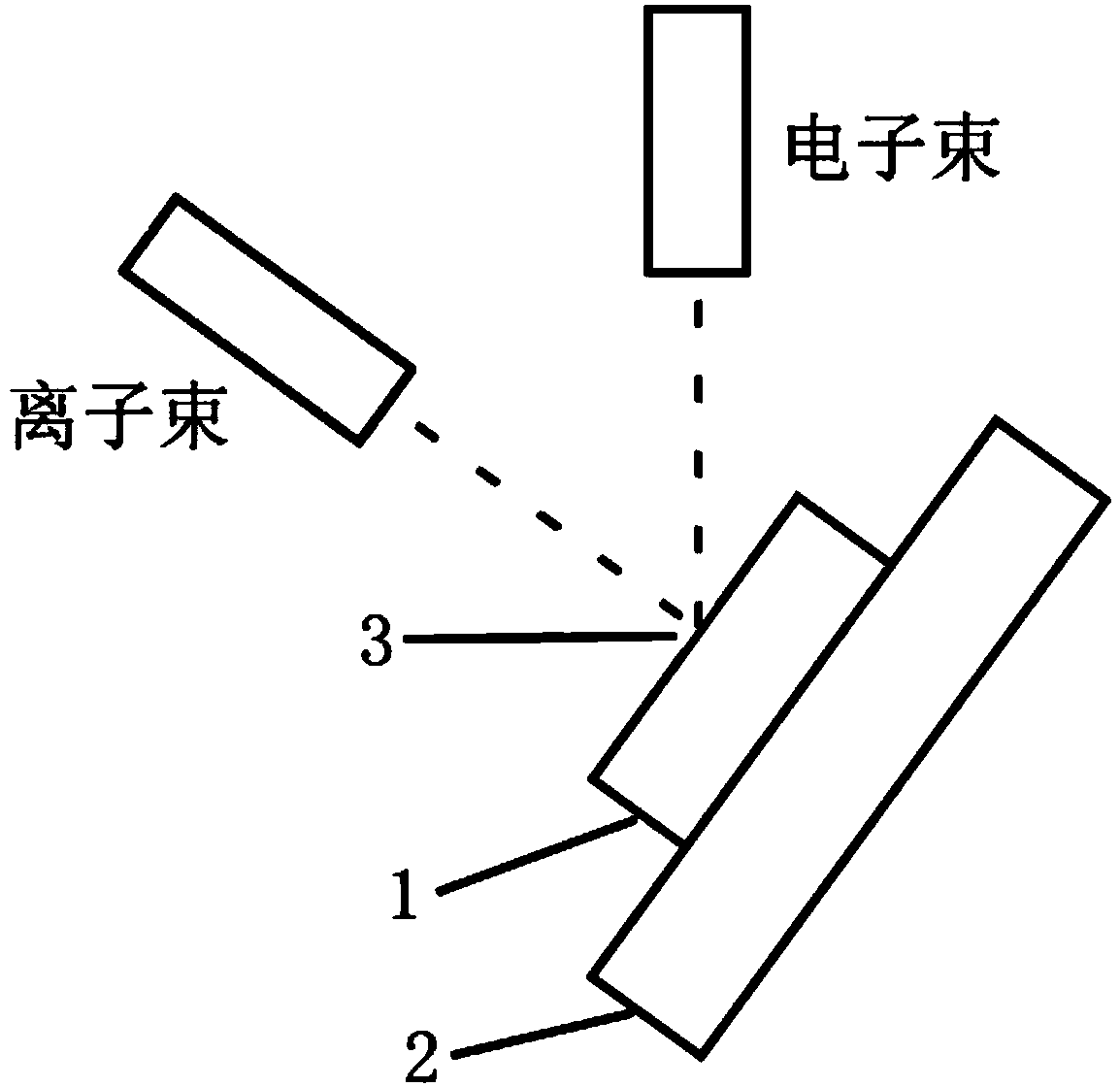

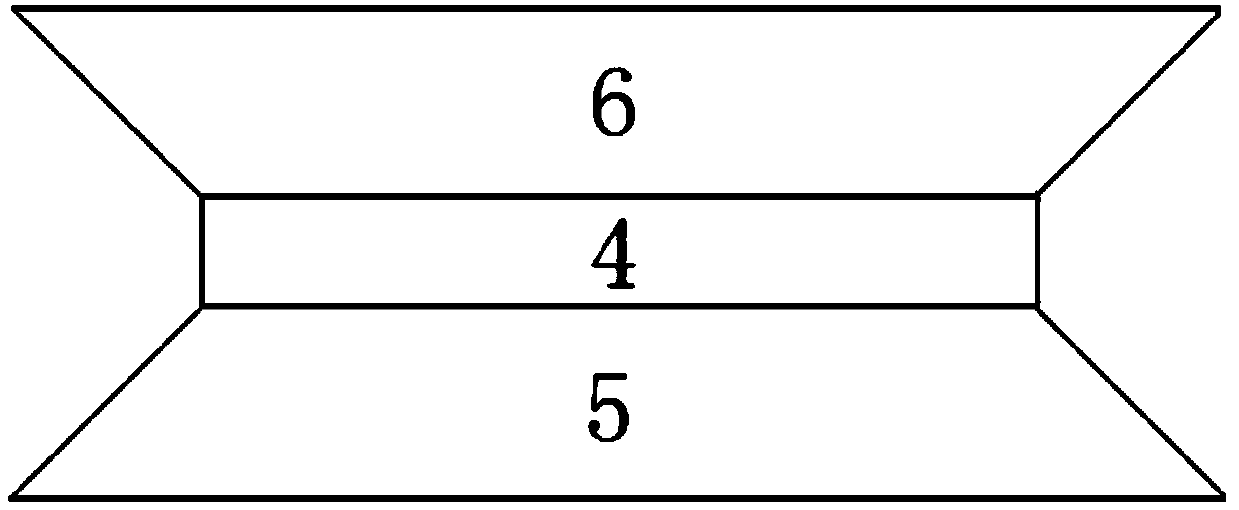

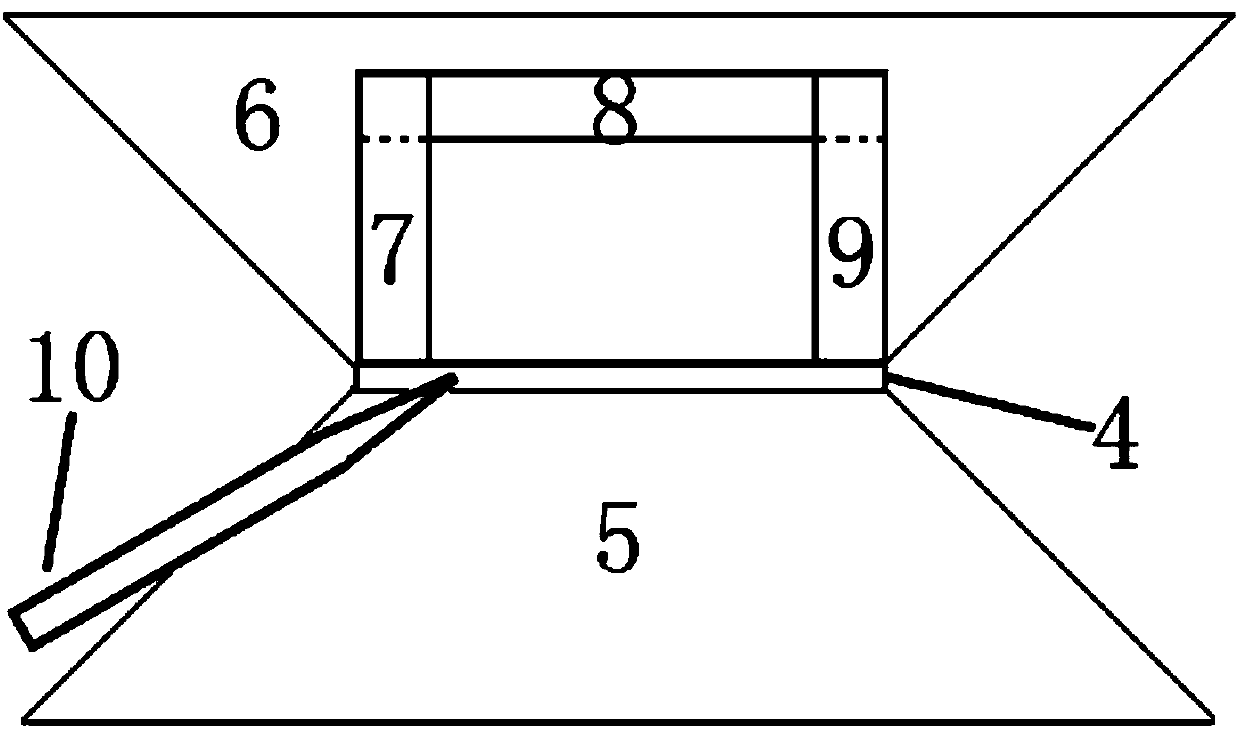

[0045] In the embodiment of the present invention, a Zeiss AURIGA dual-beam system is used to prepare a transmission electron microscope sample on the surface coating of electrical steel, and the transmission electron microscope sample is a JEM-2100F field emission transmission electron microscope.

[0046] This embodiment discloses an analysis method for the surface coating of electrical steel. The analysis method is to prepare a transmission electron microscope sample of the surface coating of electrical steel by using a focused ion beam for precise positioning, and then analyze the surface coating of electrical steel in combination with conventional analytical instruments. The microscopic appearance, it comprises the following steps:

[0047] 1) Pretreatment of the surface coating sample of electrical steel: specifically, the sample is cut into a length × width of 10 × 10mm, and the pollutants on the surface of the sample are removed by an ultrasonic cleaner, and the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com