Microstructure regulation and control method for high-energy beam metal additive manufacturing

A microstructure and metal additive technology, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement, and can solve problems that do not involve dual heat source processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

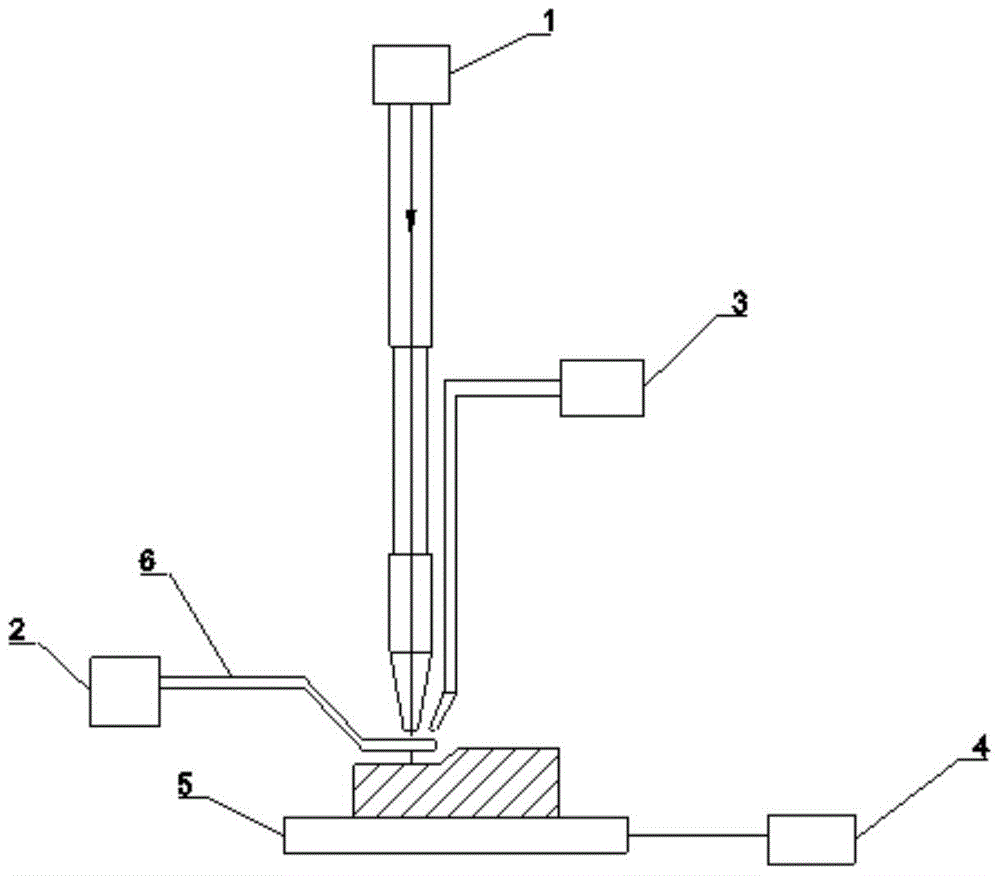

[0042] Step 1. Set the target solidification structure of TC4 as small columnar crystals and equiaxed crystal inclusions, and the aspect ratio of the phase structure to 1-50, and select the laser induction composite forming process parameters.

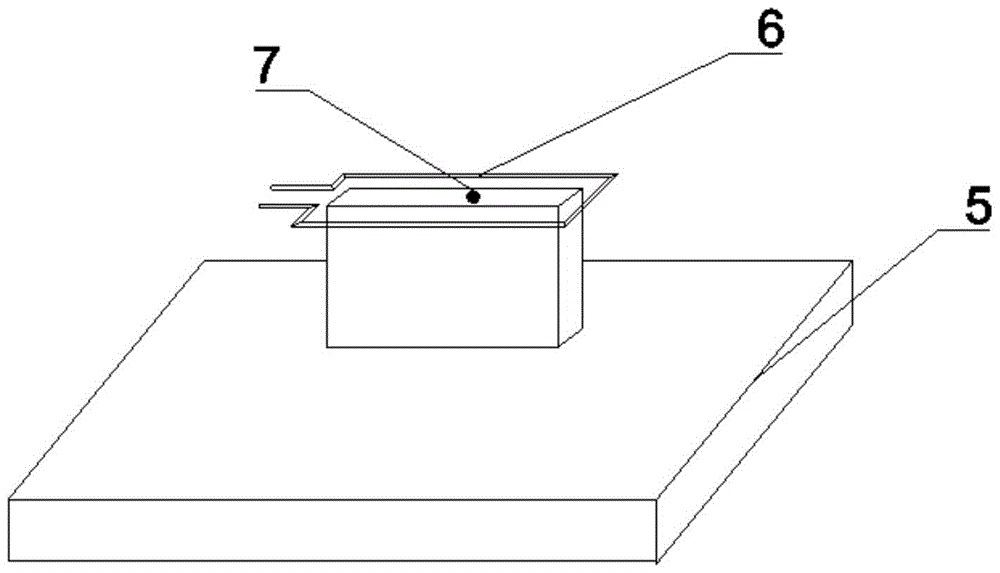

[0043] Step 2. This time the formed part is a thin-walled part, so a rectangular coil made of a copper tube with a diameter of 10 mm is selected and the distance between the coil and the formed part is set at 10 mm. Install the selected coil on the induction heater.

[0044] Step 3: Put the TC4 powder into the powder feeder, and put the TC4 substrate plate into the argon-filled inert atmosphere processing chamber, where the oxygen content during the additive manufacturing process is kept below 100 ppm;

[0045] Step 4. Set the scanning path on the CNC system and confirm that the scanning speed is 2000mm / min. Turn on the powder feeder and set the powder feed rate to 40g / min. Set the laser power to 8000W, the spot diameter to 7mm, the inducti...

Embodiment 2

[0049] Step 1. Set the coarse columnar crystals of the TC4 target solidified structure epitaxial growth, and the phase structure aspect ratio is 100-1000, and thus select the laser induction composite forming process parameters.

[0050] Step 2. This time the formed part is a thin-walled part, so a rectangular coil made of a copper tube with a diameter of 3mm is selected and the distance between the coil and the formed part is set at 5mm. Install the selected coil on the induction heater.

[0051] Step 3: Put the TC4 powder into the powder feeder, and put the TC4 substrate plate into the argon-filled inert atmosphere processing chamber, where the oxygen content during the additive manufacturing process is kept below 100 ppm.

[0052] Step 4. Set the scan path on the CNC system and determine the scan speed to be 300mm / min. Turn on the powder feeder and set the powder feed rate to 2g / min. Set the laser power to 300W, the spot diameter to 2.9mm, the induction heating power to 30KW, an...

Embodiment 3

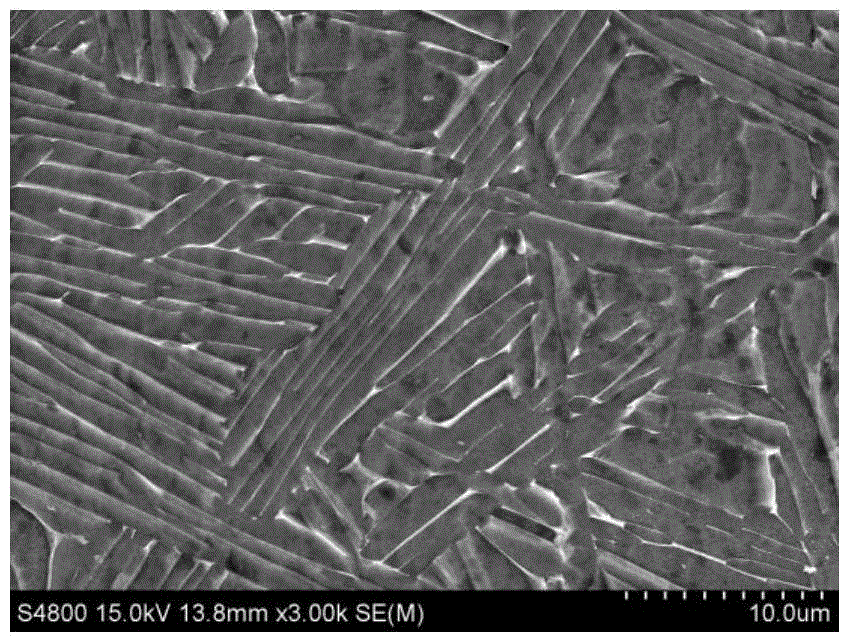

[0056] Step 1. Set the GH4169 target solidified structure epitaxially grown coarse columnar crystals, and obtain the γ+δ phase, with an aspect ratio of 0.25 to 0.30, and select the laser induction composite forming process parameters.

[0057] Step 2. This time the formed part is a three-dimensional part, so a circular coil with a diameter of 2 cm is made from a copper tube with a diameter of 4 mm and the distance between the coil and the processing plane is set at 5 mm. Install the selected coil on the induction heater.

[0058] Step 3: Put the GH4169 powder into the powder feeder, and put the GH4169 base plate into the argon-filled inert atmosphere processing chamber, where the oxygen content during the additive manufacturing process is kept below 100 ppm;

[0059] Step 4. Set the scan path on the CNC system and determine the scan speed to be 700mm / min. Turn on the powder feeder and set the powder feed rate to 20g / min. Set the laser power to 2200W, the spot diameter to 3mm, the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com