Large-area online measurement device and method for geometrical parameters of nano-structure

A technology of nanostructure and geometric parameters, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems affecting the efficiency of sample analysis and testing, meet the requirements of non-contact and non-destructive measurement, broad application prospects, and promote the expansion of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0054] In the first step, the nanostructure 111 to be tested is placed on the rotating sample stage 112;

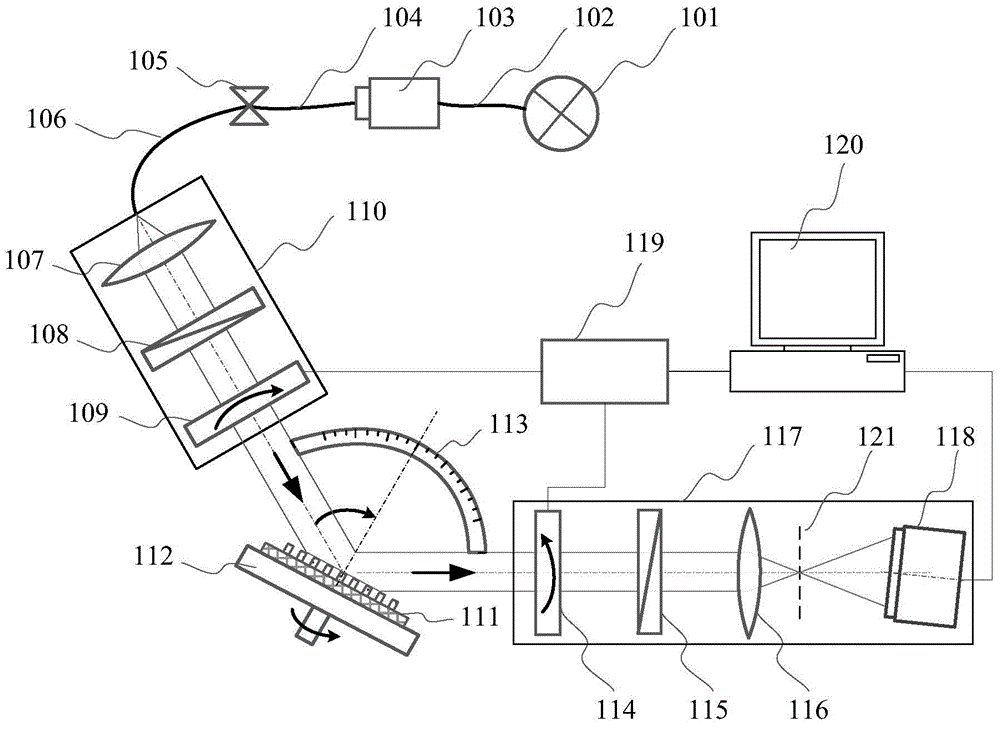

[0055] In the second step, the light emitted by the xenon lamp light source is turned into monochromatic light by the monochromator, and the monochromatic light is introduced into one end of the polarizer arm 110 through the fiber coupler 105 and the outgoing fiber 106, and then becomes parallel through the collimating mirror 107 The light beam is polarized by the polarizer 108, and the phase compensator 109 at the end of the polarizer arm is phase-modulated and projected onto the surface of the nanostructure 111 to be tested;

[0056] In the third step, after the parallel light beam is reflected from the surface of the nanostructure 111 to be tested, it is phase-modulated by the phase compensator 114 at the end of the analyzer arm, and analyzed by the analyzer 115, and enters the area array detector 118 through the imaging lens 116. The image collected by the CCD detecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com