Simultaneous determination of multi-element content in aluminum bronze by icp method

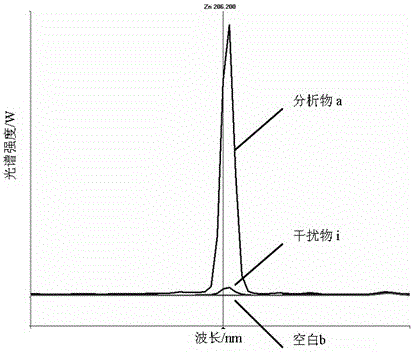

An aluminum bronze and multi-element technology is applied in the field of simultaneous determination of multi-element content in aluminum bronze, which can solve the problems of undetermined lead and silicon impurity elements, unable to measure elements at the same time, and the accuracy of the method needs to be improved, so as to overcome atomization. Interference, improve analysis accuracy, and eliminate the effect of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

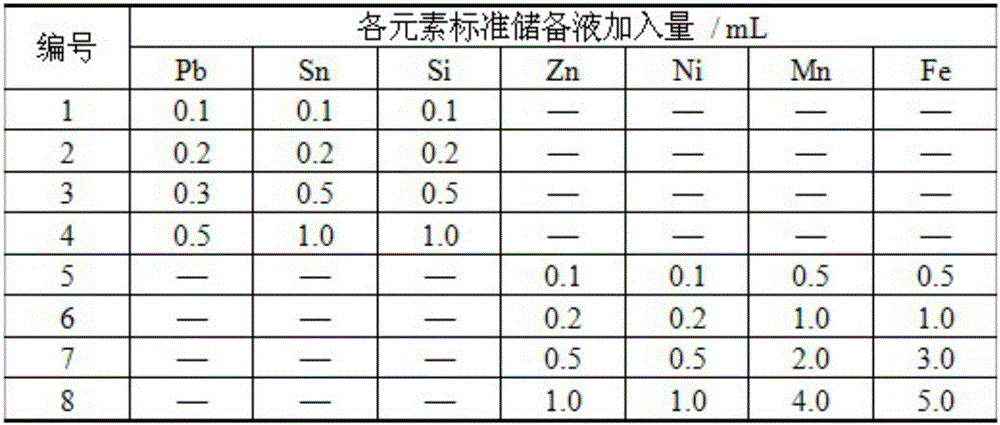

[0041] (1) Instruments and reagents:

[0042] Optima 7000DV inductively coupled plasma emission spectrometer (Perkin-Elmer, USA). Single element standard stock solution of lead, tin, silicon, zinc, nickel, manganese and iron with a concentration of 1.00mg / mL was developed by the National Nonferrous Metals and Electronic Materials Analysis and Testing Center. High-purity metallic copper with a purity of 99.99% was purchased from the Shandong Academy of Metallurgical Sciences. Nitric acid was of superior grade, and the experimental water was 18.25MΩ·cm deionized water.

[0043] (2) Experimental method

[0044] Accurately weigh 0.1 g of the national standard substance of aluminum bronze numbered GBW02118 into a beaker, add 10 mL of nitric acid solution (volume ratio of nitric acid to water: 1:1), cover the beaker with a watch glass, and place it on an electric heating plate to heat the sample completely. Dissolve; after cooling, transfer the solution into a 100mL volumetric fl...

Embodiment 2

[0054] As described in Example 1, the method of using the ICP method to simultaneously determine the element content in aluminum bronze, the difference is that the sample is GBW02119 aluminum bronze national standard substance, and the nitric acid solution used to prepare the sample solution is a volume ratio of nitric acid to water of 1.2: 1. The measurement results are shown in Table 5:

[0055] Table 5 Determination results of element content in GBW02119 aluminum bronze standard substance (n=10)

[0056]

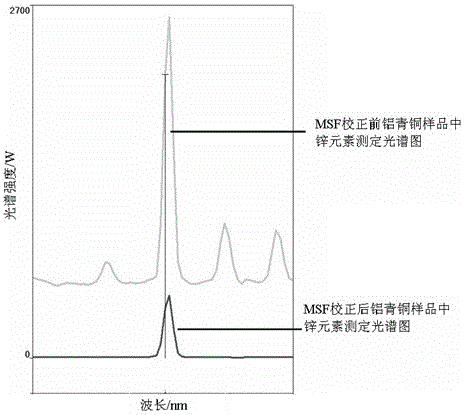

[0057] Same as Example 1, the relative error of the determination result of zinc content is the largest, and the multivariate spectral fitting method is used to correct the spectral interference. After MSF correction, the determination results of zinc content in the GBW02119 aluminum bronze sample are consistent with the standard value, indicating that spectral interference correction can effectively improve the accuracy of the analytical method, as shown in Table 6. ...

Embodiment 3

[0061] As described in Example 1, the method for simultaneously determining element content in aluminum bronze by using the ICP method is different in that the sample is QAl10-3-1.5 aluminum bronze, and the measurement results are shown in Table 7. The content of lead, tin, and nickel impurity elements in the sample was not detected, and the recovery rate experiment of the four detected elements of silicon, zinc, manganese, and iron was carried out to investigate the accuracy of the analysis method.

[0062] Table 7 QAl10-3-1.5 Aluminum bronze samples in the recovery of element content determination results (n = 6)

[0063]

[0064] The recovery rate of the addition of standard zinc content was poor. Using the established MSF model, the analysis method was re-run to reprocess the zinc content test data of the aluminum bronze sample.

[0065] Table 8 The MSF method calibration results in the determination of zinc content in QAl10-3-1.5 aluminum bronze samples

[0066]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com