Method for determining the chemical composition of liquid water glass

A technology of chemical composition and water glass, applied in the field of spectral analysis, can solve the problems of manpower, material resources, long analysis time, environmental pollution, etc., achieve high precision and accuracy, fast analysis speed, and improve the efficiency of analysis and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

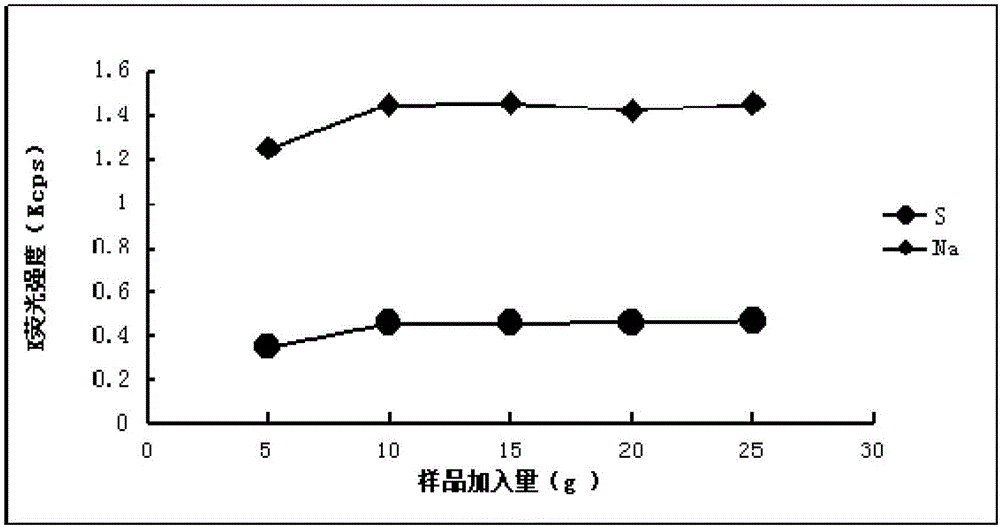

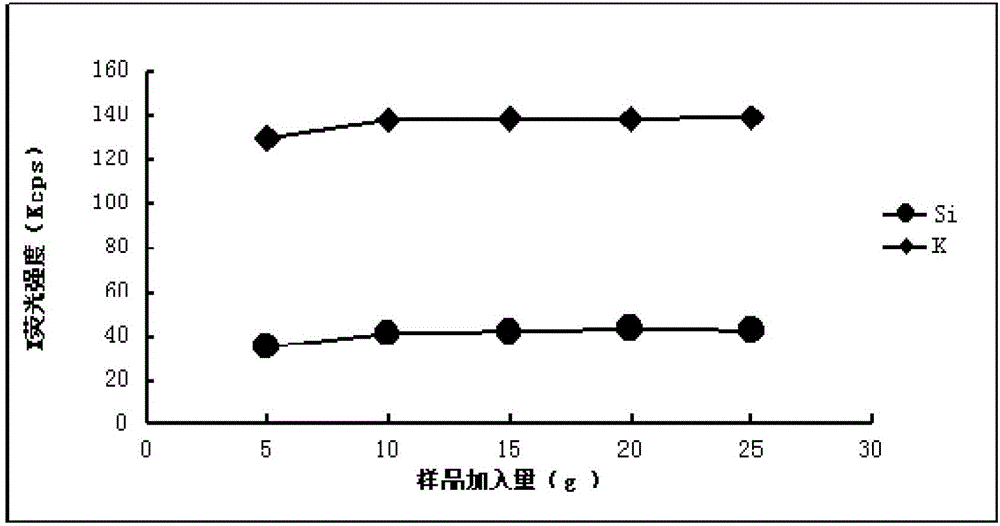

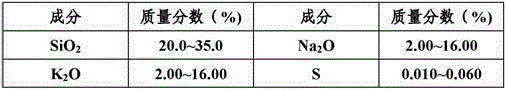

Image

Examples

Embodiment 1

[0037] Take the detection of high modulus liquid water glass samples produced by a certain factory as an example:

[0038] Firstly, the viscosity of the high modulus liquid water glass is detected. After testing, its viscosity is 3850mPa.s, so the sample needs to be diluted. Accurately weigh 30g of the high modulus liquid water glass sample and place it in a polytetrafluoroethylene beaker. Add 30g of deionized water to it, place the polytetrafluoroethylene beaker on an electric heating plate and heat it at a low temperature, the temperature does not exceed 80°C, and at the same time stir with a glass rod to promote dissolution. After fully dissolving, cool and stand for later use.

[0039] Spread a piece of filter paper on the loading tray of the electronic balance, place the liquid measuring cup on the filter paper, weigh 15g of the prepared liquid water glass sample into the measuring cup, cover the plastic cover, let it stand for 3 minutes, pass Observe whether the filter p...

Embodiment 2

[0046] Take the detection of low-mode liquid water glass samples produced by a certain factory as an example:

[0047] First, the viscosity of the low-mode liquid water glass is tested, and its viscosity is 500mPa.s, so there is no need to dilute the sample.

[0048] Spread a piece of filter paper on the loading plate of the electronic balance, place the liquid measuring cup on the filter paper, weigh 15g of liquid water glass sample into the measuring cup, cover the plastic cover, let it stand for 3 minutes, and observe whether the filter paper has Absorb water to confirm that there is no liquid sample leakage from the measuring cup.

[0049] Start the working software that comes with the instrument. Before the measurement, change the analytical medium to helium, check the parameters of the instrument, and start the quantitative working curve analysis program after the startup is stable, and use the drift correction sample to calibrate the instrument. Select a standard sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com