Application of triphenylamine derivative polymer as lithium ion batteries cathode material

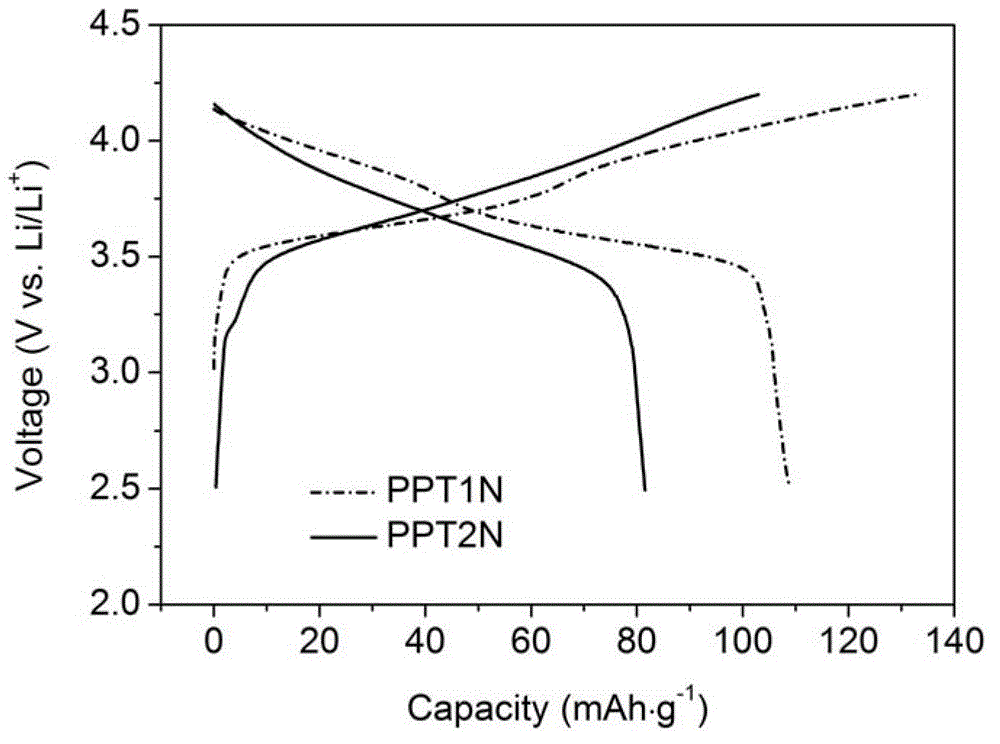

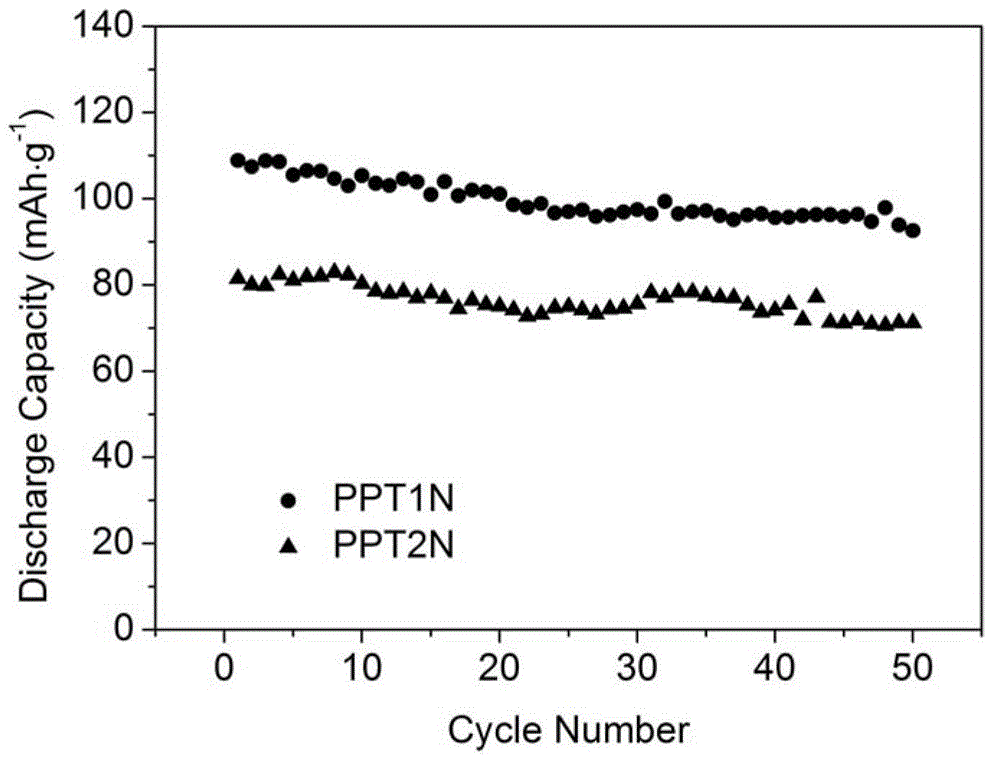

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as large particles and inter-particle agglomeration, and achieve high charge-discharge specific capacity, significant charge-discharge voltage platform, good fast charge and discharge. The effect of discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

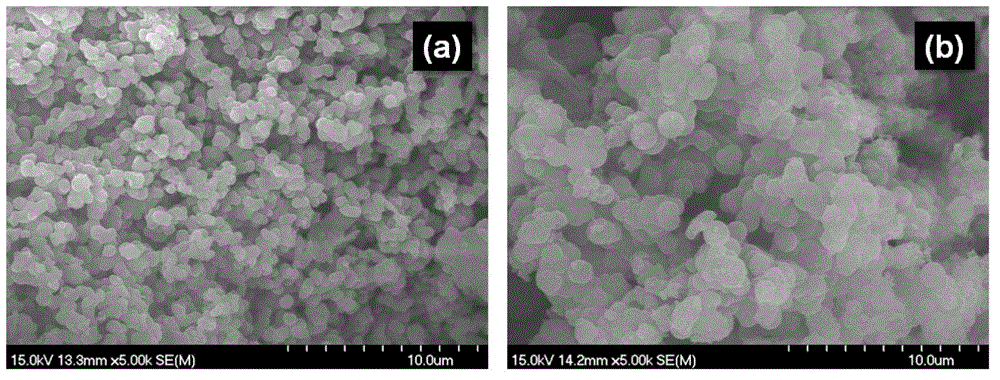

[0034] PPT1N

[0035] PT1N monomer synthesis. Add 30 mL of anhydrous tetrahydrofuran to a previously dried 250 mL three-neck flask, and then add excess magnesium powder (3.02 g). 2-Bromothiophene (6 mL) was added dropwise while stirring, and the reaction released a lot of heat. To prevent the temperature from being too high, the temperature should be cooled with a cold water bath to control the reaction to proceed steadily for 5 hours. The prepared Grignard reagent suspension was quickly transferred to a dry constant pressure separatory funnel, and added dropwise to 50 mL of 4,4',4"-tribromotriphenylamine (5 g) and 1,1'- In the dry tetrahydrofuran solution of [bis(diphenylphosphino)ferrocene]palladium dichloride (0.5g) catalyst, the temperature of the reaction solution is controlled to be 60°C, and stirred for 12h under a nitrogen atmosphere to reach the end of the reaction. The reaction is performed with saturated chlorine The ammonium chloride aqueous solution is terminate...

Embodiment 2

[0045] PPT2N

[0046] PT1N tribromide synthesis. 30 mL of DMF was added to a pre-dried 250 mL three-necked flask, followed by the prepared PT1N (1.5 g). Add 20 mL of a DMF solution containing NBS (1.6 g) dropwise while stirring in an ice bath, and react in the dark for 5 h. After the reaction was completed, a large amount of ice water was added, the filter cake was obtained by filtration, and vacuum-dried at 60° C. for 24 hours. The yield is 92%, and the product is a light green solid powder.

[0047] PT2N monomer synthesis. Add 30 mL of anhydrous tetrahydrofuran to a previously dried 250 mL three-neck flask, and then add excess magnesium powder (1.65 g). Add 2-bromothiophene (3.33mL) dropwise while stirring, the reaction emits a lot of heat, in order to prevent the temperature from being too high, cool with a cold water bath to control the temperature, and control the reaction to proceed steadily for 5h. The prepared Grignard reagent suspension was quickly transferred to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com