Model selection method and device of coating silicone grease/silicone oil for cable accessory installation

A technology for cable accessories and installation, which is applied in the field of cable accessories testing, can solve problems such as inability to simulate corona discharge, lack of silicone grease/silicone oil selection methods, immature technical specifications and standards for silicone grease coating performance testing, etc., to achieve The effect of high long-term reliability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

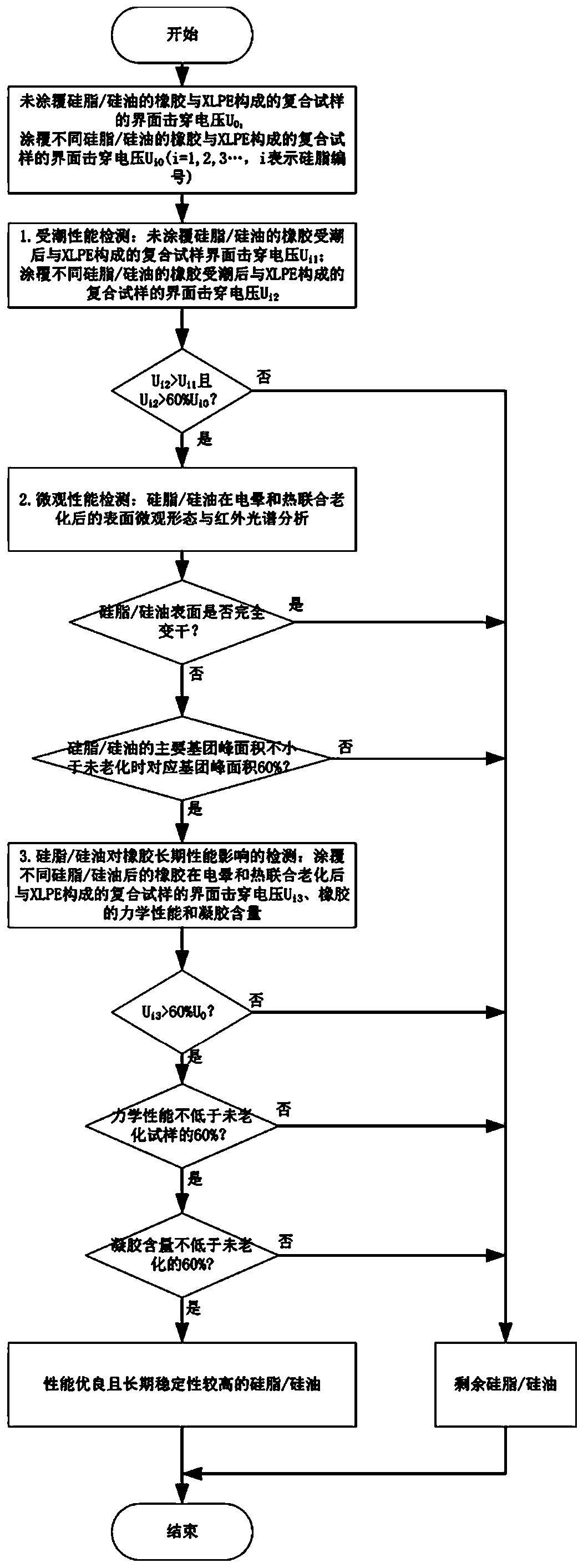

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

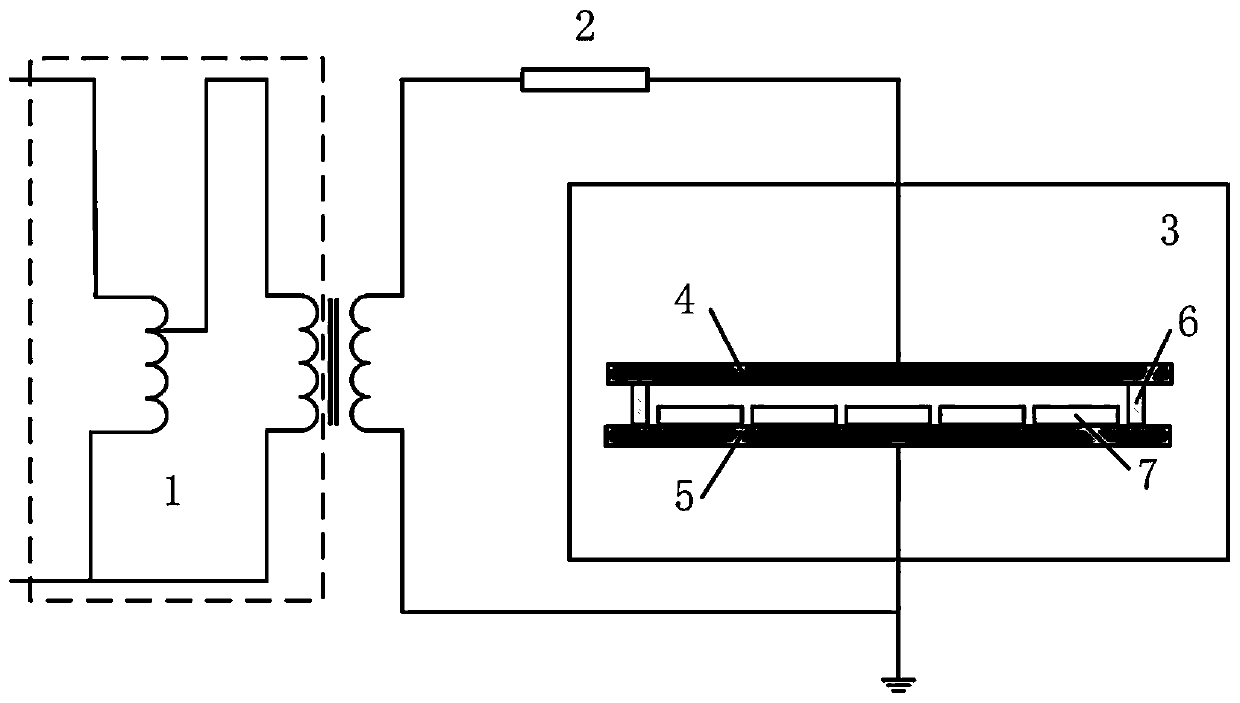

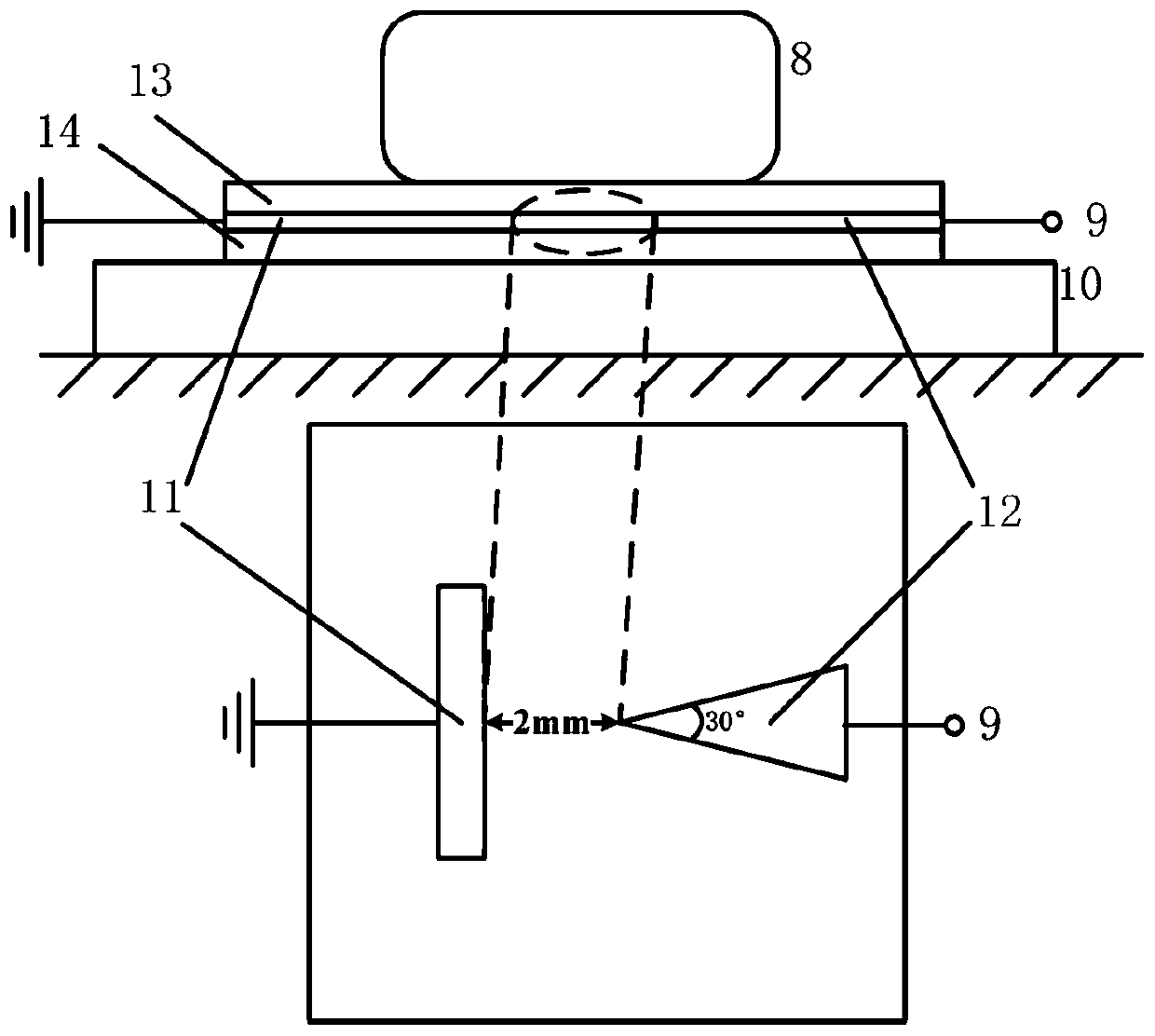

[0023] see figure 1 , the type selection method of coating silicone grease / silicone oil for the installation of cable accessories of the present invention includes breaking down the composite interface formed by the rubber material coated with silicone grease / silicone oil after being damp and the main insulation cross-linked polyethylene (XLPE) of the cable body Characteristic test and comparison with interface breakdown voltage when not exposed to moisture, observation of surface microscopic morphology and molecular group changes after aging of silicone grease / silicone oil, acceleration of rubber materials coated with silicone grease / silicone oil in an environment that simulates long-term operation of cable accessories After aging, the interface electrical strength, mechanical properties, and gel content inspection are tested in 5 stages, and the silicone gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com