Zinc-based battery anode material containing Bi2O3 with self-assembled structure and preparation method

A zinc-based battery and anode material technology, which is applied to battery electrodes, secondary batteries, structural parts, etc., can effectively solve the problem of dendrites and cannot meet the requirements of use, and achieve the effect of solving the problem of zinc dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

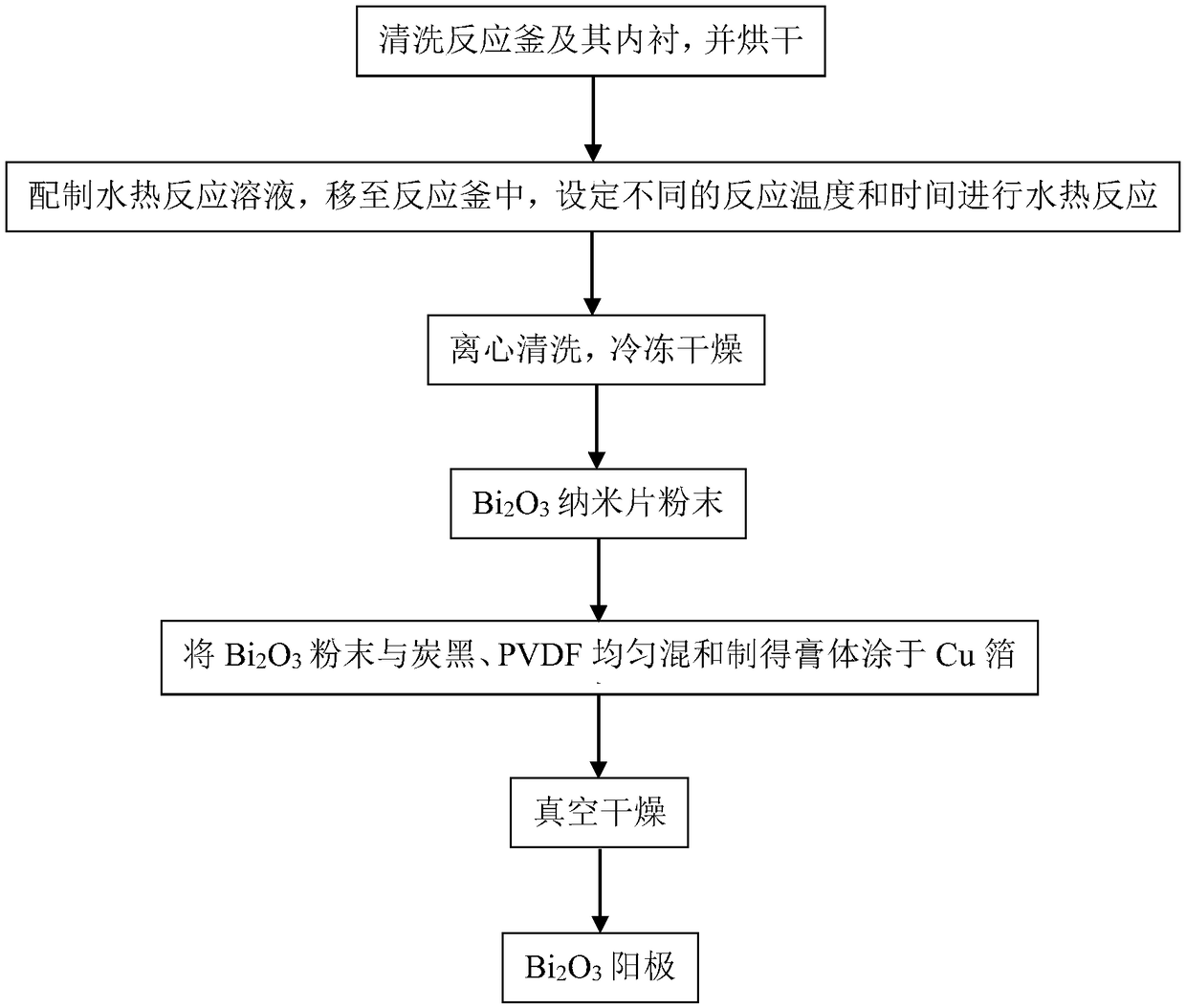

[0031]The inner lining of the reactor was washed with nitric acid, ethanol and deionized water in sequence, and dried in an oven. Preparation reaction solution, reaction solution is 0.072mol / L bismuth nitrate solution, is made up of bismuth nitrate pentahydrate, acetone and ethylene glycol of analytical grade, during preparation, in beaker, add the acetone of 36mL and the ethylene glycol of 18mL, Add the weighed bismuth nitrate pentahydrate into the mixed solution, and stir at a medium speed with a magnetic rotor to obtain a bismuth nitrate solution. The uniformly mixed reaction solution was transferred to a reaction kettle dedicated to the hydrothermal method, the reaction temperature was set at 160° C., and the reaction time was 5 h. After the reaction was complete, it was cooled to room temperature. Then the material obtained from the reaction was washed several times with ethanol and deionized water, and then freeze-dried to obtain Bi 2 o 3 Nanosheet powder. The dried ...

example 2

[0033] The inner lining of the reactor was washed with nitric acid, ethanol and deionized water in sequence, and dried in an oven. Prepare reaction solution, reaction solution is 0.072mol / L bismuth nitrate solution, is made up of bismuth nitrate pentahydrate, acetone and ethylene glycol of analytical grade, when preparing, add the acetone of 36mL and the ethylene glycol of 18mL in the beaker, will Add the weighed bismuth nitrate pentahydrate into the mixed solution, and stir at a medium speed with a magnetic rotor to obtain a bismuth nitrate solution. The uniformly mixed reaction solution was transferred to a special reaction kettle for the hydrothermal method, the reaction temperature was set at 160° C., and the reaction time was 3 h. After the reaction was complete, it was cooled to room temperature. Then the material obtained from the reaction was washed several times with ethanol and deionized water, and then freeze-dried to obtain Bi 2 o 3 Nanosheet powder. The dried ...

example 3

[0035] The inner lining of the reactor was washed with nitric acid, ethanol and deionized water in sequence, and dried in an oven. Preparation reaction solution, reaction solution is 0.072mol / L bismuth nitrate solution, is made up of bismuth nitrate pentahydrate, acetone and ethylene glycol of analytical grade, during preparation, in beaker, add the acetone of 36mL and the ethylene glycol of 18mL, Add the weighed bismuth nitrate pentahydrate into the mixed solution, and stir at a medium speed with a magnetic rotor to obtain a bismuth nitrate solution. The uniformly mixed reaction solution was transferred to a reaction kettle dedicated to the hydrothermal method, the reaction temperature was set at 120° C., and the reaction time was 5 h. After the reaction was complete, it was cooled to room temperature. Then the material obtained from the reaction was washed several times with ethanol and deionized water, and then freeze-dried to obtain Bi 2 o 3 Nanosheet powder. The dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com