Nickel catalyst for C5 petroleum resin hydrogenation as well as preparation method and application thereof

A petroleum resin and nickel catalyst technology, which is applied in the field of nano-metal catalyst preparation, can solve the problems of harsh hydrogenation conditions, less catalyst recovery, and large safety hazards, and achieve the effects of improving activity, reducing costs and safety hazards, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

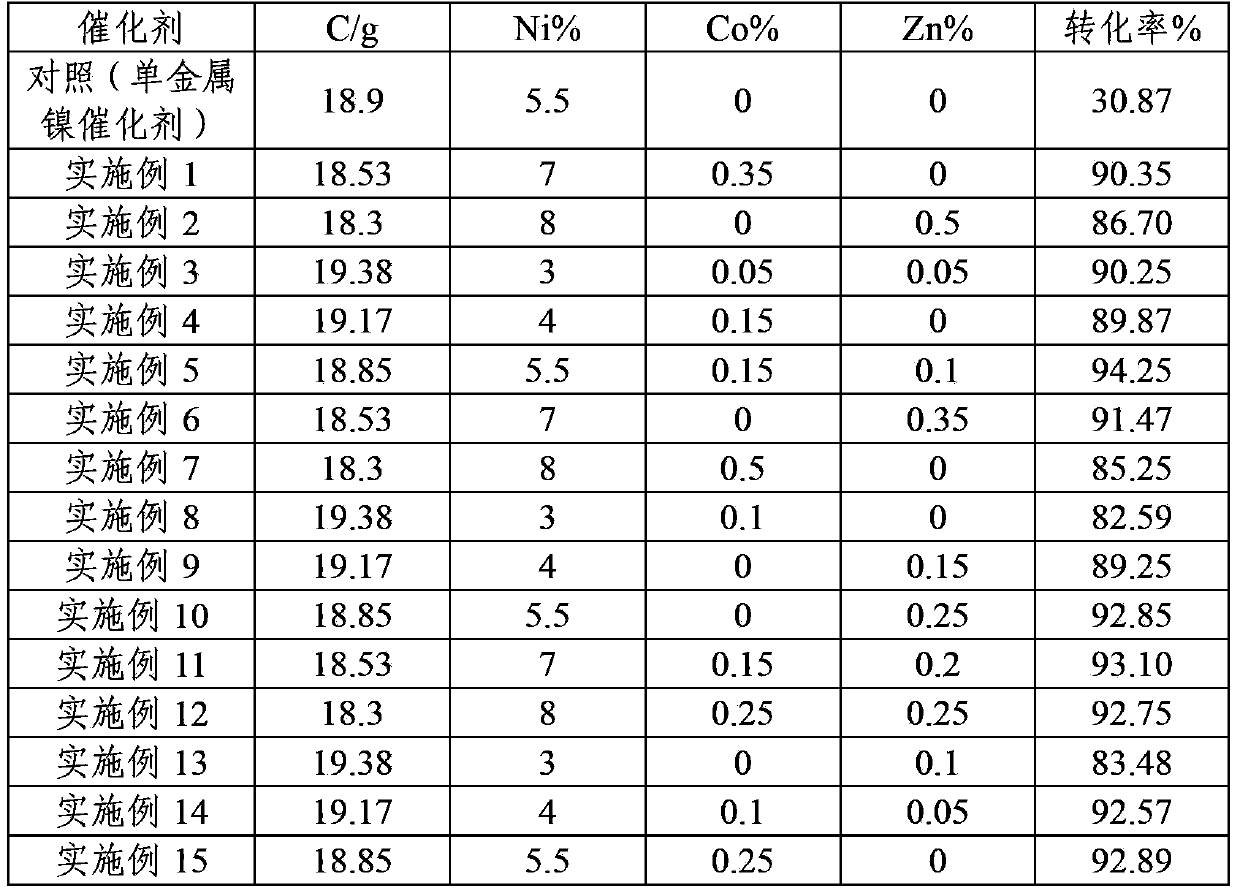

[0033] C in this example 5 The nickel catalyst for hydrogenation of petroleum resin is composed of activated carbon carrier, Ni nanoparticles attached to the activated carbon carrier, and amorphous alloy nanoparticles of Ni and metal additives attached to the activated carbon carrier; the mass of Ni in the catalyst The percentage content is 7%, and the mass percentage content of the metal additive is 0.35%; the metal additive is cobalt.

[0034] The preparation method of the nickel catalyst of the present embodiment is:

[0035] Step 1. Reflux 20 g of activated carbon with boiling nitric acid aqueous solution with a mass concentration of 15% for 2 hours, then wash the activated carbon after the reflux treatment with pure water until the pH is 6, and dry it for later use; the activated carbon has a particle size of 300- 400 mesh coconut shell charcoal;

[0036] Step 2, NiSO containing 1.4g of nickel 4 (NiCl available 2 or Ni(NO 3 ) 2 instead) and CoSO containing 0.07g of ...

Embodiment 2

[0044] C in this example 5 The nickel catalyst for hydrogenation of petroleum resin is composed of activated carbon carrier, Ni nanoparticles attached to the activated carbon carrier, and amorphous alloy nanoparticles of Ni and metal additives attached to the activated carbon carrier; the mass of Ni in the catalyst The percentage content is 8%, and the mass percentage content of the metal additive is 0.5%; the metal additive is zinc.

[0045] The preparation method of the nickel catalyst of the present embodiment is:

[0046] Step 1. Reflux 20 g of activated carbon for 1 hour with boiling nitric acid aqueous solution with a mass concentration of 20%, then wash the activated carbon after the reflux treatment with pure water until the pH is 7, and dry it for later use; the activated carbon has a particle size of 300- 400 mesh coconut shell charcoal;

[0047] Step 2, Ni(NO 3 ) 2 (NiCl available 2 or NiSO 4 instead) and ZnSO containing 0.1 g of Zn 4 (available Zn(NO 3 ) 2...

Embodiment 3

[0055] C in this example 5 The nickel catalyst for hydrogenation of petroleum resin is composed of activated carbon carrier, Ni nanoparticles attached to the activated carbon carrier, and amorphous alloy nanoparticles of Ni and metal additives attached to the activated carbon carrier; the mass of Ni in the catalyst The percentage content is 3%, and the mass percentage content of metal additives is 0.1%. The metal additives are zinc and cobalt.

[0056] The preparation method of the nickel catalyst of the present embodiment is:

[0057] Step 1: reflux 20 g of activated carbon with boiling nitric acid aqueous solution with a mass concentration of 10% for 3 hours, then wash the activated carbon after the reflux treatment with pure water until the pH is 5, and dry it for later use; the activated carbon has a particle size of 300- 400 mesh coconut shell charcoal;

[0058] Step 2, the NiCl containing nickel 0.6g 2 (Usable Ni(NO 3 ) 2 or NiSO 4 instead), Zn(NO 3 ) 2 (ZnSO 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com