Failure analysis method for suspended structural member of subway power supply network and application thereof

A technology for suspension structure and failure analysis, which is applied in the direction of material analysis, material analysis by optical means, material analysis by wave/particle radiation, etc. The effect of accurate positioning and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

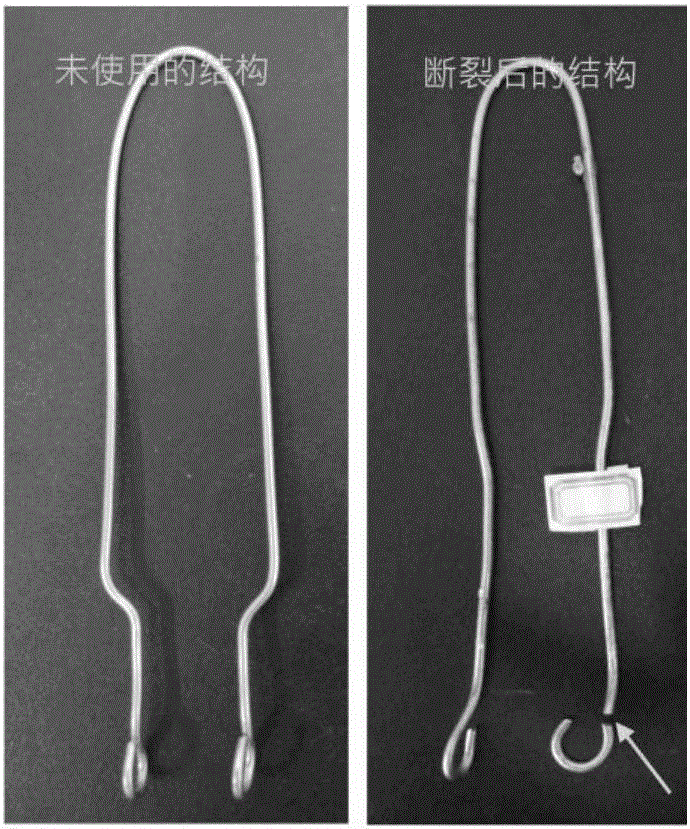

[0028] 1) The present invention provides the damaged stainless steel suspension structure in practice, such as figure 1 shown. The suspension structure is a catenary sliding suspension structure in an underground section of a subway, which breaks during use. It can be seen from the macroscopic inspection that the fracture position of the suspension structure is close to the part clamped by the clamp bolt (that is, close to the ear ring formed by the processing of the suspension structure).

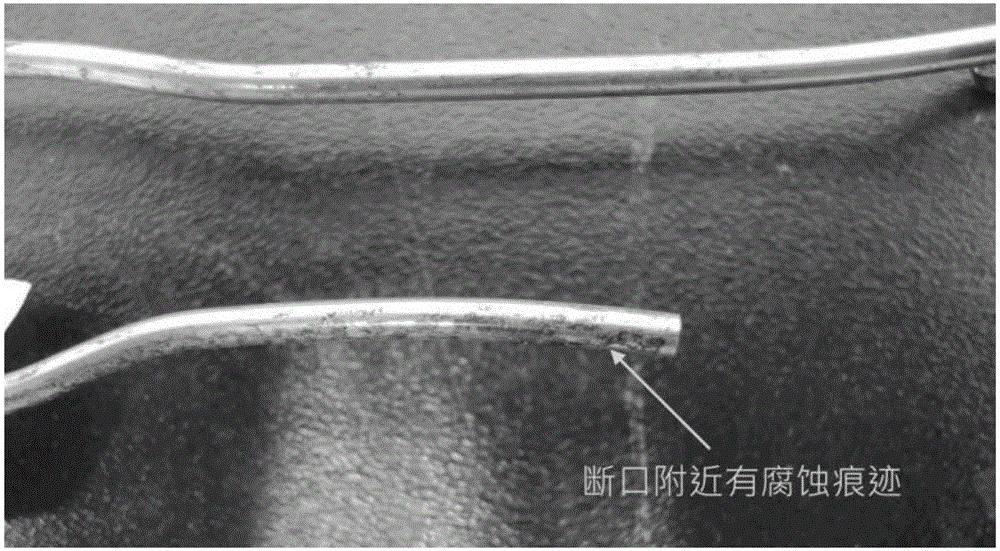

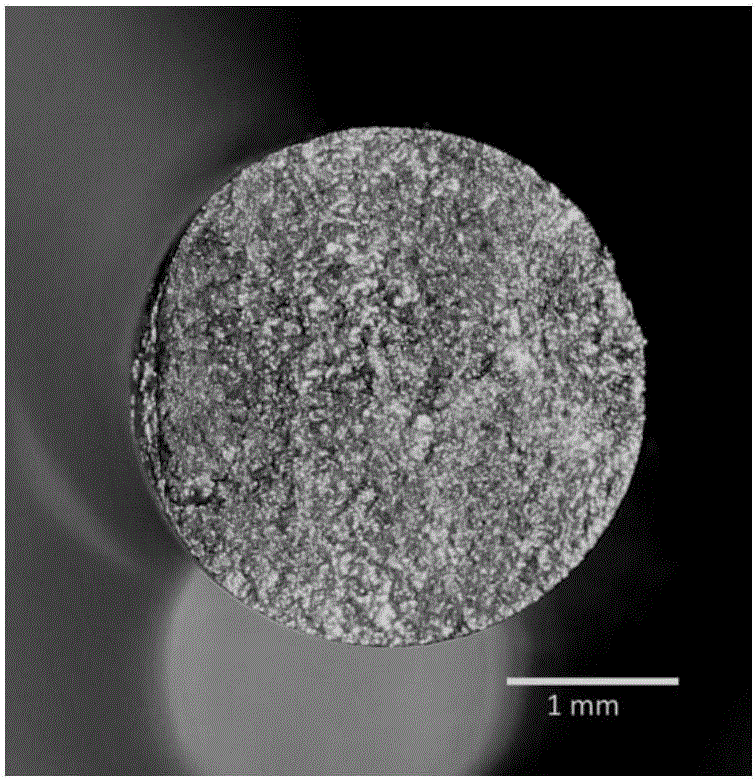

[0029] 2) Collect all the broken fragments of the damaged suspension structure and observe its macroscopic appearance. The fracture surface and sides of the failed suspension structure were carefully inspected with the naked eye and a stereomicroscope under strong light. The inspection results showed that, compared with the used but unfractured structura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com