Preparation method of CrAlN coating based on HIPIMS technology

A kind of coating and technical technology, which is applied in the field of CrAlN coating preparation based on HIPIMS technology, can solve the problems of poor adhesion of film base, high internal stress of coating, rough coating surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

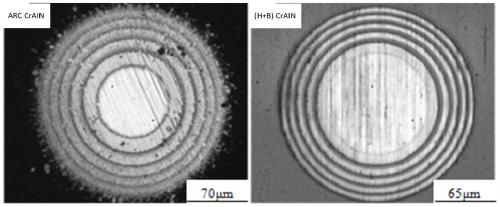

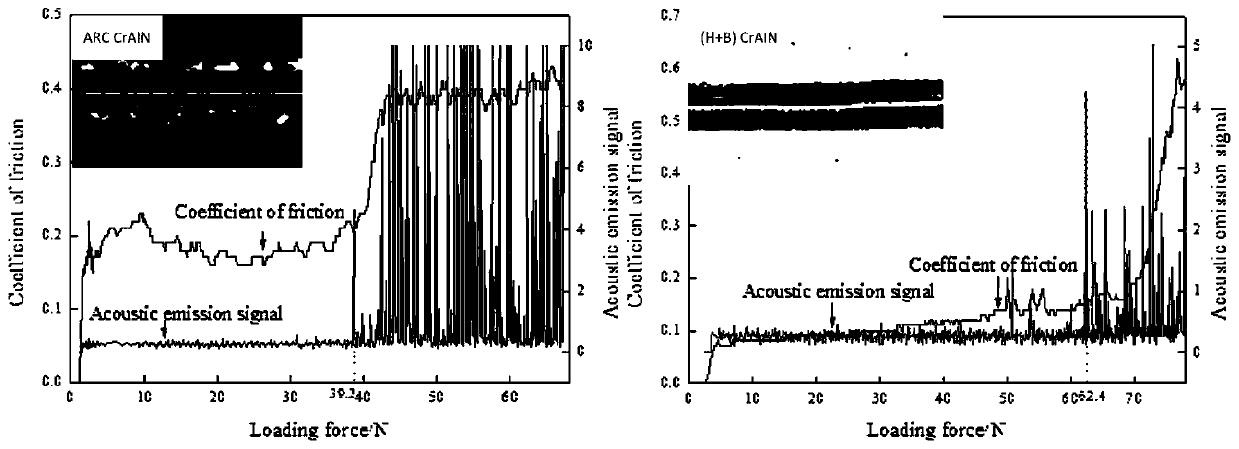

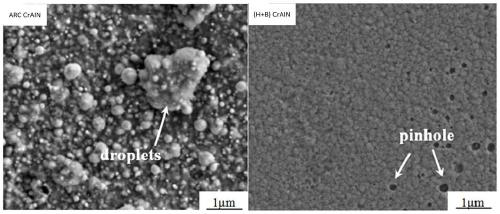

Image

Examples

Embodiment 1

[0022] The preparation method of the CrAlN coating based on HIPIMS technology of the present embodiment comprises the following steps:

[0023] Step S1: clean the surface of the high-speed steel substrate;

[0024] Step S2: The coating process is carried out in a vertical cylindrical vacuum chamber with an effective coating space of φ600mm×600mm. The vacuum chamber is equipped with a fourth-generation arc ionization source cathodic arc system, a bipolar pulse power supply system Bipolar 4020 and a high-energy pulse magnetron power supply Highpulse 4002 , CrAlN coating adopts alloy CrAl target;

[0025] Step S3: Clamp the high-speed steel substrate on a turntable with a rotation speed of 2pm, the background vacuum is 5×10-4Pa before deposition, and the deposition temperature is 400°C; the atmosphere environment controlled by pure Ar in the vacuum chamber is controlled at 2Pa Under the condition of -1000V bias, bombard for 10min;

[0026] Step S4: Depositing a layer of alloy m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com