Fracture sample preparation method based on crack resistance of basalt fiber and asphalt mixture

A technology for asphalt mixture and basalt fiber, which is applied in the fields of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc. The sample method is simple, the operation is convenient, and the fracture morphology is diverse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A fracture sample preparation method based on the anti-crack performance of basalt fiber asphalt mixture according to the present invention will be further described below in conjunction with specific examples.

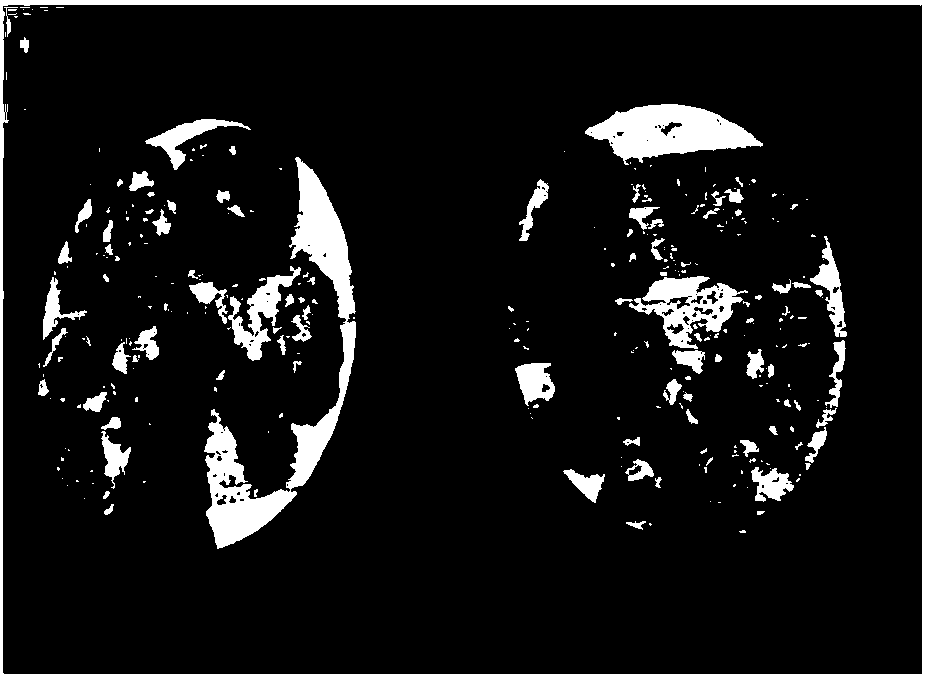

[0028] In this example, basalt fiber permeable asphalt mixture is taken as an example to study the influence of basalt fiber permeable asphalt mixture fracture morphology and crack resistance. The steps of the present invention are as follows:

[0029] (1) According to JTG E20-2011 "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", the standard compaction method is used to make asphalt mixture specimens. The specimens are cylindrical, with a diameter of 101.6mm±0.25mm and a height of 63.5mm ±1.3mm.

[0030] (2) Then conduct splitting tests at different temperatures, using the UTM-25 servo-type material dynamic testing system, the test temperatures are -5°C, 5°C, 15°C, etc., and the loading rate is 50mm / min, and record the relevant test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com