Phosphide with hierarchical structure, and preparation method and applications thereof

A hierarchical structure, phosphide technology, applied in phosphide, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of complex experimental process, high cost, long reaction period, etc., to achieve rich pore structure, low price, and commercialization the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of hierarchical structure phosphide provided by the invention comprises the following steps:

[0036] (1) Prepare nano-transition metal alkoxides by solvothermal method: dissolve transition metal salts and polyols in a solvent to obtain a mixed solution, heat to 130-190°C for 5-10 hours, after the reaction, wash and dry Obtain transition metal alkoxide nanospheres;

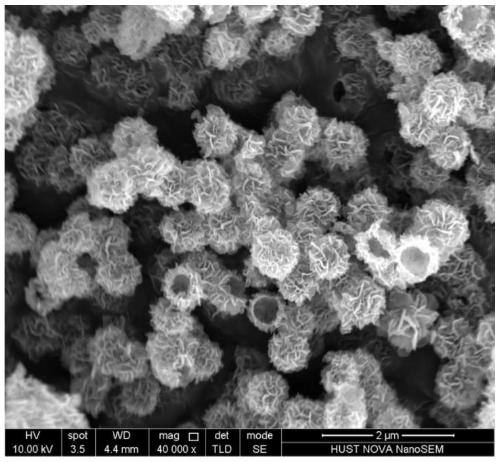

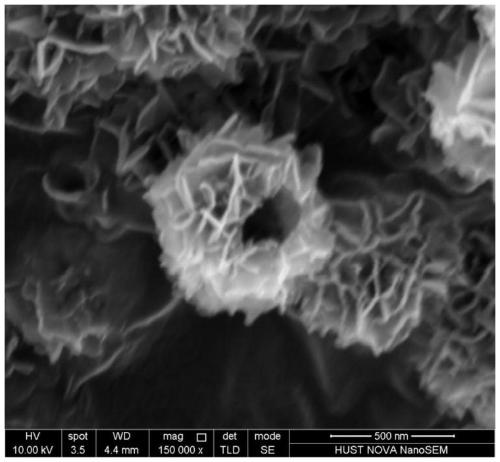

[0037] (2) Treat transition metal alkoxides with hydrothermal method to prepare hierarchical structure hydroxides: disperse the transition metal alkoxides obtained in step (1) in water, heat and keep warm for 3-10 hours, after the hydrothermal reaction ends, wash and dry Obtain hierarchical structure hydroxide;

[0038] (3) Utilize the gas-solid phosphating method to process the hierarchical structure hydroxide to obtain the hierarchical structure phosphide: the hierarchical structure hydroxide and the phosphorus source obtained in step (2) are respectively placed in different ...

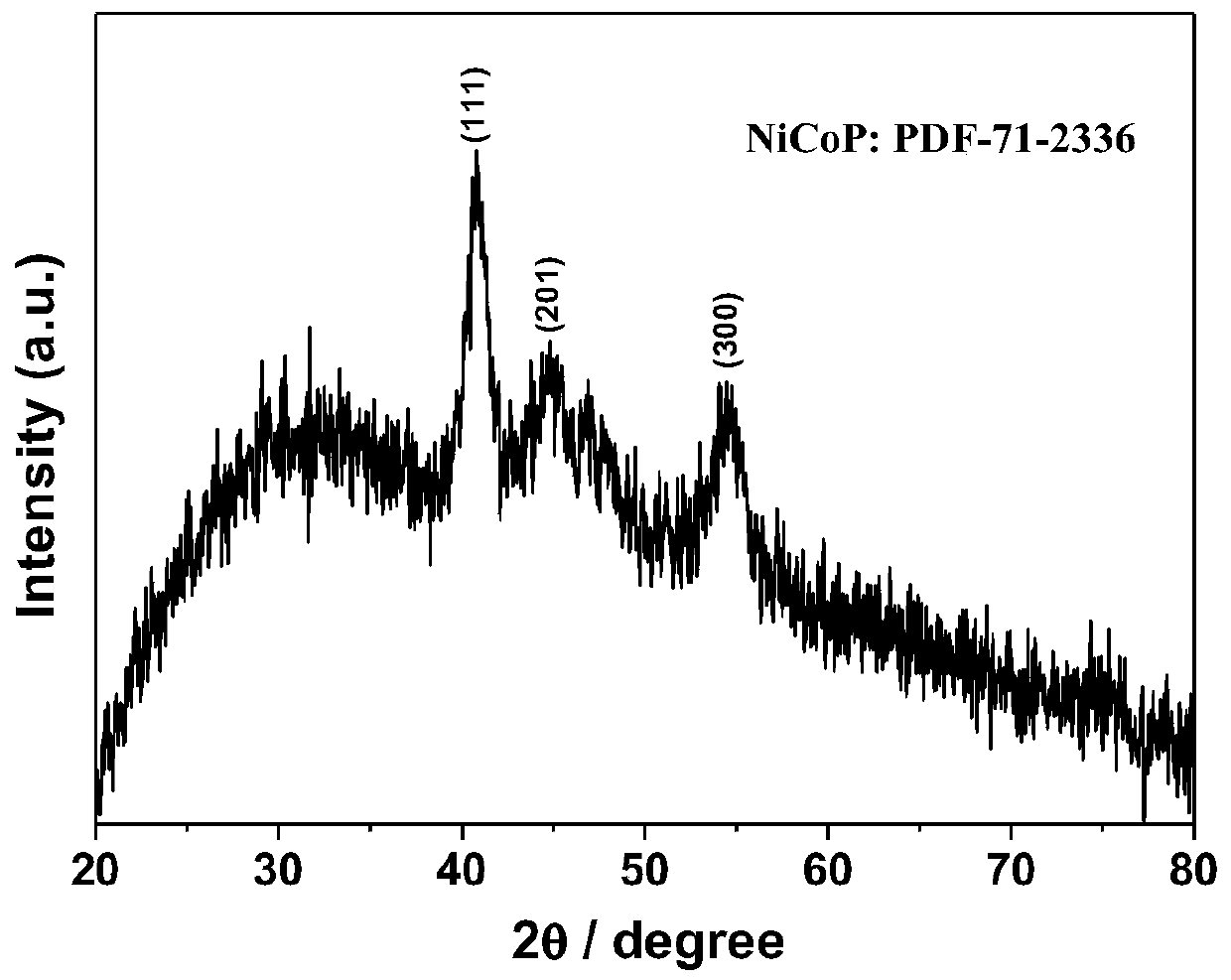

Embodiment 1

[0053] In this embodiment, the reaction raw materials are nickel nitrate, cobalt nitrate, glycerol and isopropanol, the concentration of nitrate is 2.25mg / mL, the molar ratio of nickel nitrate and cobalt nitrate is 1:1; The ratio is 1:5.

[0054] A preparation method of NiCoP with hierarchical structure, comprising the following steps:

[0055] (1) Preparation of nano-nickel-cobalt glycerate by solvothermal method:

[0056] Put cobalt nitrate, nickel nitrate, 6mL glycerin and 30mL isopropanol in a 50mL reaction kettle, heat it to 170°C and keep it warm for 5 hours. After the reaction, wash it with a large amount of ethanol and dry it in vacuum at 60°C to obtain nickel-cobalt glycerate nanospheres.

[0057] (2) adopting hydrothermal method to process glycerate to prepare hierarchical structure nickel-cobalt hydroxide:

[0058] Disperse the nickel-cobalt glycerate obtained in step (1) evenly in 30mL of water, pour it into a reaction kettle, heat it to 150°C and keep it warm f...

Embodiment 2

[0066] In this embodiment, the reaction raw materials are nickel nitrate, cobalt nitrate, glycerol and isopropanol, the concentration of nitrate is 4.5mg / mL, and the molar ratio of nickel nitrate and cobalt nitrate is 1:2; The volume of glycerol and isopropanol The ratio is 1:5. The preparation process is the same as that of Example 1. First, the metal alkoxide is prepared, and then the metal alkoxide is hydrothermally treated to obtain a hierarchical structure hydroxide, and the hierarchical structure NiCo is obtained through the gas-solid phosphating method. 2 P, the product morphology is as Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com