Marble pillar cutter

A technology of column cutting machine and cutting saw, applied in the field of Roman column cutting machine, can solve the problems of low processing efficiency and high labor intensity, and achieve the effects of improving processing efficiency, reducing production cost and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

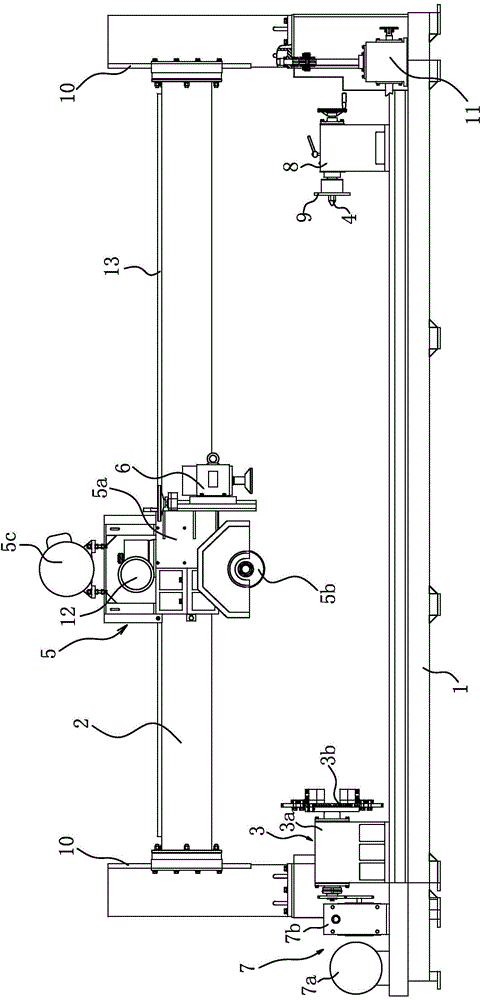

[0020] like figure 1 As shown, the Roman column cutting machine includes a frame 1, a beam 2, a head assembly 3, a thimble 4, a power head device 5 and a polishing device 6.

[0021] The frame 1 is a basic part and can be directly placed on the ground. The frame 1 is roughly in the shape of a strip, and the head assembly 3 is arranged at one end of the frame 1 and positioned at the other end of the frame 1 .

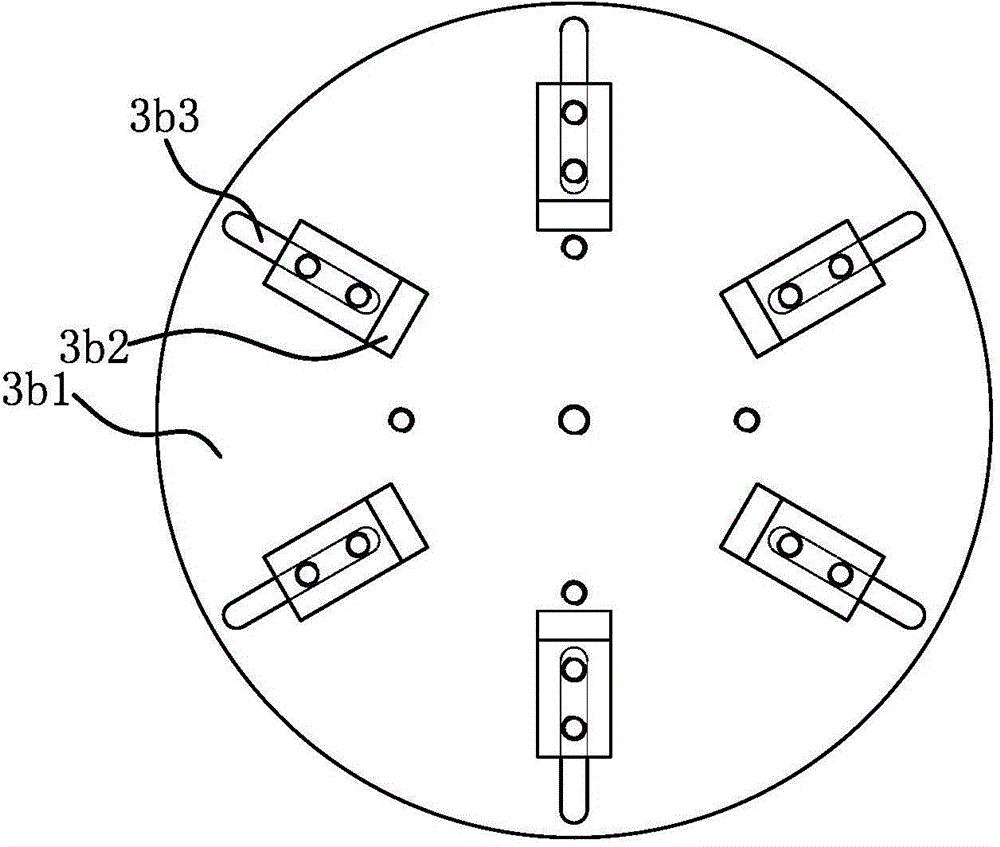

[0022] The head assembly 3 comprises a head case 3a fixed on the frame 1, a rotating shaft capable of rotation is positioned in the head case 3a, the rotating shaft is horizontally arranged, and one end of the rotating shaft is fixedly connected with a chuck 3b, and the shaft core of the chuck 3b is also horizontal setting. The frame 1 is provided with a first driving device 7 that can drive the chuck 3b to rotate. Specifically, the first driving device 7 includes a first motor 7a and a first reduction box 7b, and the main shaft of the first motor 7a is connected to th...

Embodiment 2

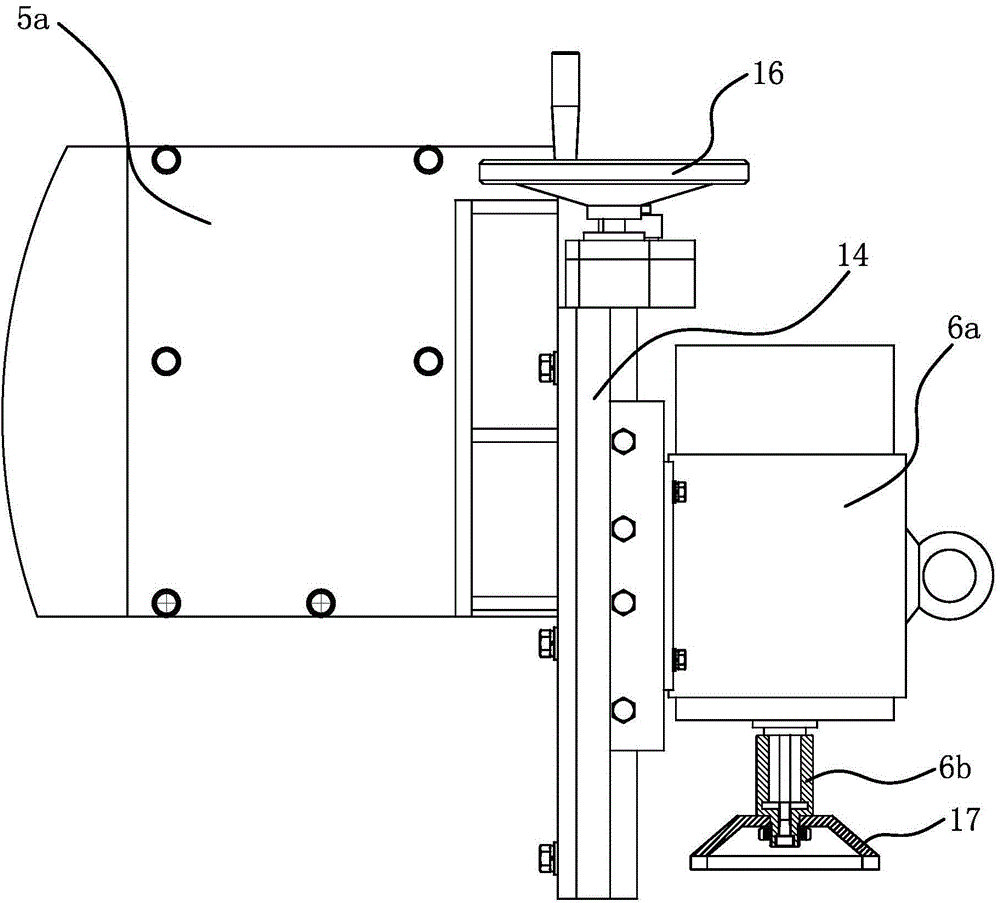

[0030] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, the difference is that the power head device 5 moves along the beam 2 without relying on gears and racks 13 transmission, but on the main shaft of the fourth motor 12, a friction wheel abutting against the top surface of the beam 2 is fixed, so that when the feed speed is too fast, slippage will occur between the friction wheel and the beam 2, thereby preventing the saw from cutting The chip is subjected to excessive impact force, resulting in tooth chipping, and the problem of insufficient cutting depth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com