Uniform wheat rolling sowing method and special rolling sowing machine

A wheat and uniform technology, applied in sowing seeders, agricultural machinery and implements, sowing, etc., can solve the problems of arable land seed waste, delayed farming time, reduced yield, etc., to avoid deep seeds and exposed seeds, improve uniformity, improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

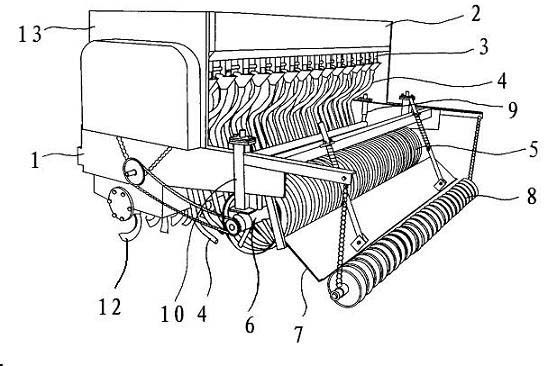

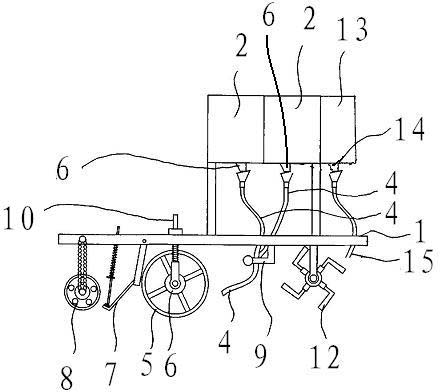

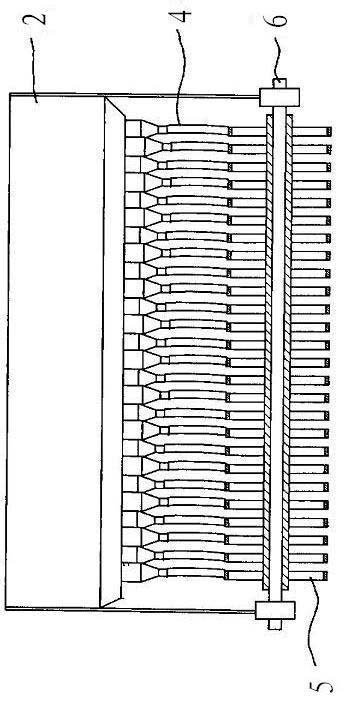

[0031] The structure of the uniform rolling sowing method of wheat and the special rolling sowing machine provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The method for even rolling sowing of wheat provided by the invention comprises the following steps:

[0033] The first step is to loosen the cultivated land

[0034] Plowing arable land to soften the soil;

[0035] The second step is to sow the seeds

[0036] Scatter wheat seeds in strips on the cultivated land surface;

[0037] The third step, rolling

[0038] pressing the wheat seeds into the soil;

[0039] The fourth step, covering the soil

[0040] Cover the seeds with mulch;

[0041] The fifth step is to suppress and compact the soil

[0042] The soil is compacted by rollers.

[0043] Sprinkle the wheat seeds on the surface of the cultivated land in strips, press them into the soil with rolling sowing whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com