Method and its device for connection electric continuous electrolytic corrosion between metal belts

A technology of electrolytic corrosion and metal strip, applied in the direction of electrolysis process, electrolysis components, etc., can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0088] The metal strip before electrolytic corrosion is cold rolled to the final plate thickness under the following conditions. After decarburization annealing, an annealing separator made of MgO is coated and dried on both sides of the surface, and further finishing annealing is performed. In the two surfaces, forsterite (Mg 2 SiO 4 ) film, coated with a tension-imparting film (phosphoric acid-based insulating film), it becomes a sintered grain-oriented silicon steel sheet, and becomes a grain-oriented silicon steel sheet with an etching pattern formed on the surface of one side. After removing the forsterite film and the tension-imparting film, the corrosion pattern of ferrite is exposed. In addition, since this tension-imparting film is an electrically insulating film, it can be used as an etching mask.

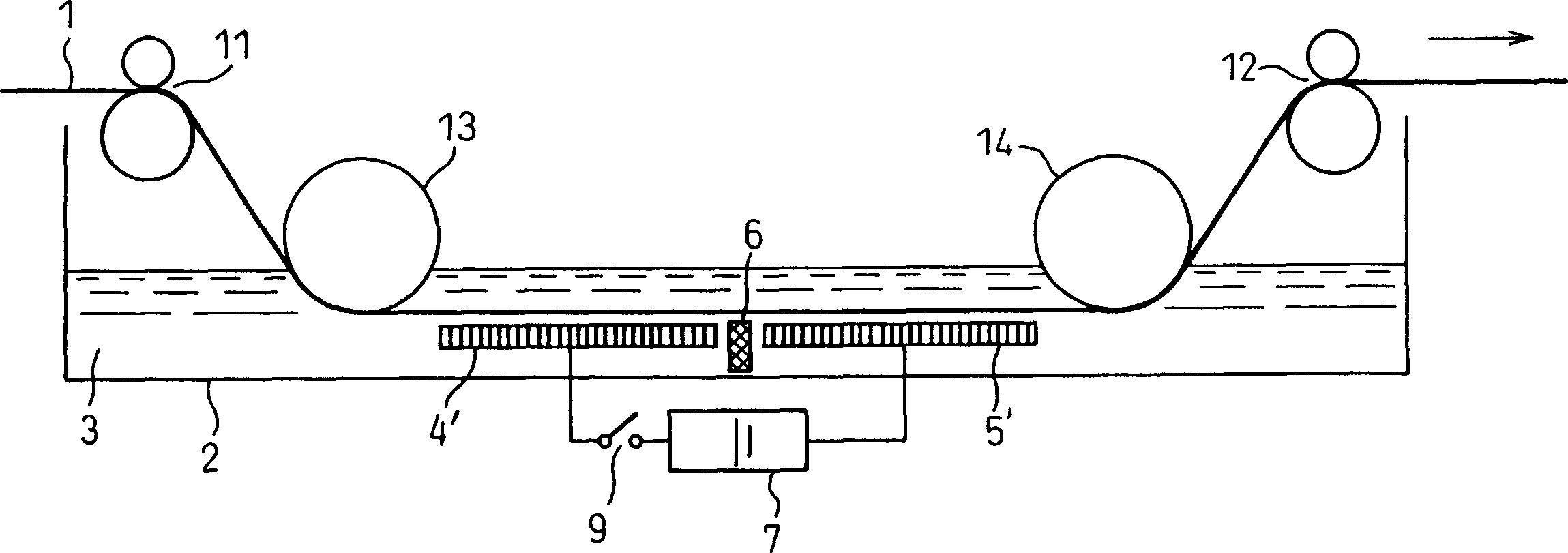

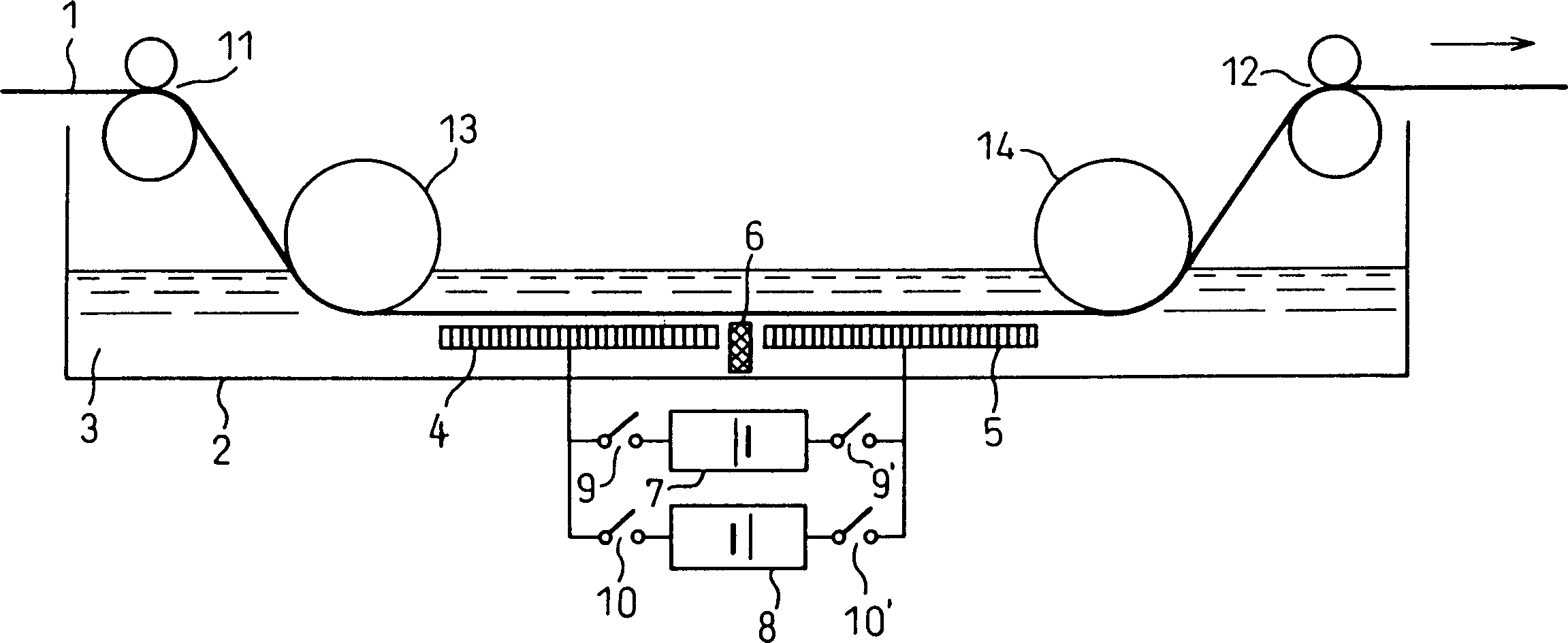

[0089] In the grain-oriented silicon steel sheet subjected to the above pretreatment, use figure 1 or image 3 The shown indirect energization type continuous electr...

Embodiment 6

[0104] Finished by cold rolling to a thickness of 0.23 mm, and subjected to finish annealing as a unidirectional electrical steel sheet, 0.3 mm wide corrosion patterns were formed on the steel sheet coated with an insulating film at intervals of 6 mm by laser irradiation, and then combined with ferrite The steel plate surface of the exposed part of the body faces each other, and the plate is passed through an electrolytic cell in which two electrodes of positive and negative electrodes are alternately arranged. Wherein, the electrolytic solution uses a sodium chloride aqueous solution with a concentration of 5%, and uses sodium hydroxide and hydrochloric acid to adjust the pH. Etching was performed by varying the pH, passing the plates in the pH 1 to pH 12 range.

[0105] The above-mentioned sample according to the present invention was taken out, the shape of the groove was confirmed, and grooves with an average depth of about 20 micrometers were formed. Table 2 shows the re...

Embodiment 7

[0109] It was finished by cold rolling to a thickness of 0.27mm, and was subjected to finishing annealing as a unidirectional electrical steel sheet. On the steel sheet coated with an insulating film, 0.3mm-wide corrosion patterns were formed by laser irradiation at intervals of 4mm. Facing the surface of the steel sheet having the ferrite exposed portion, the sheet is passed through an electrolytic cell in which two electrodes, negative and positive, are alternately arranged. Wherein, the electrolytic solution uses a sodium chloride aqueous solution with a concentration of 3%, and uses sodium hydroxide and hydrochloric acid to adjust the pH. Etching was performed by varying the pH, passing the plates in the pH 1 to pH 12 range.

[0110] When the groove shape was confirmed for the above sample, grooves with an average depth of about 15 micrometers were formed.

[0111] Table 3 shows the results of investigating the amount of iron deposited during the treatment in the electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com