Multilayer printed wiring plate, and method for fabricating the same

A multi-layer printing, circuit board technology, applied in the direction of printed circuit manufacturing, multi-layer circuit manufacturing, printed circuit, etc., can solve the problems of signal delay, unstable electrical characteristics of conductor circuit, unstable signal transmission of signal wiring, etc., to reduce The effect of signal delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0224] (1) Prepare the substrate

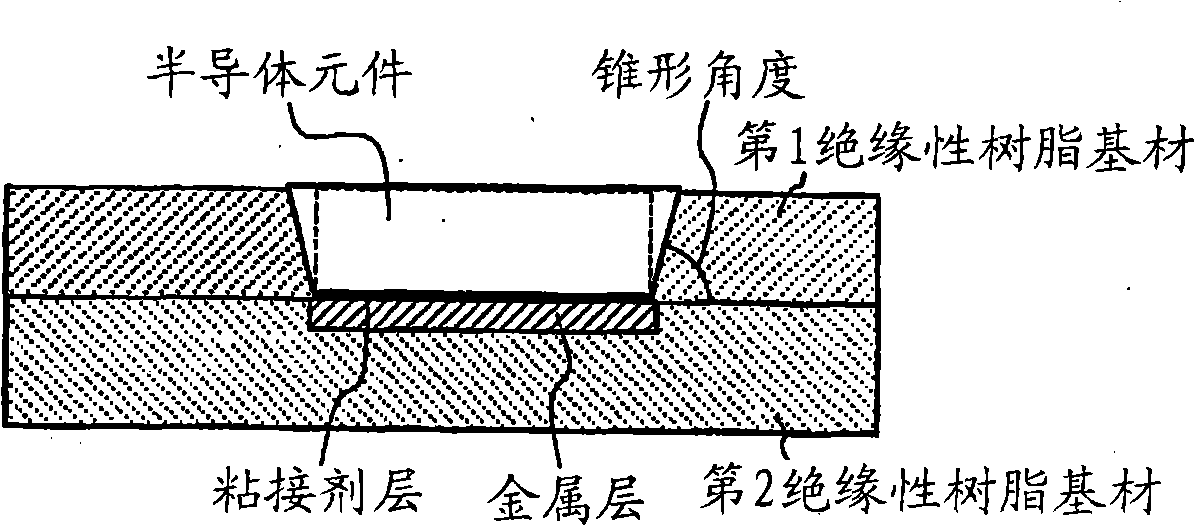

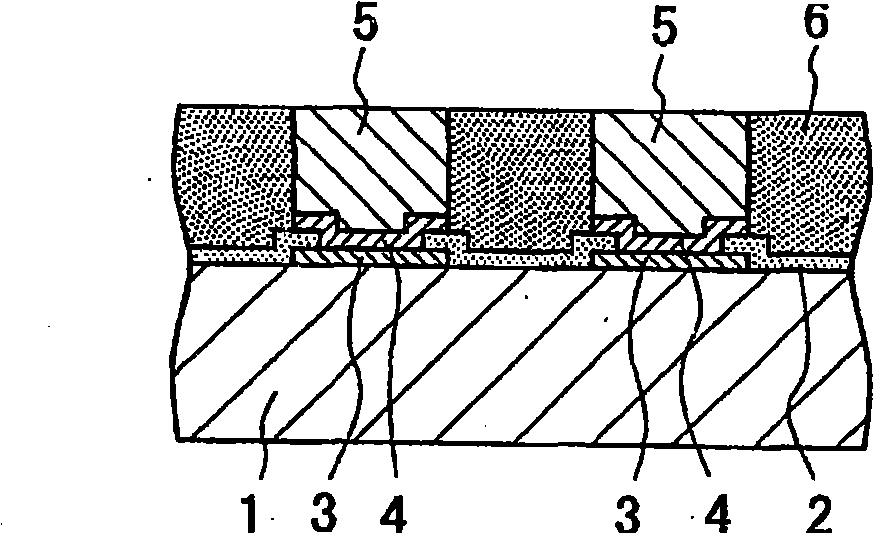

[0225] First, a printed circuit board constituting a substrate for accommodating a semiconductor element is fabricated. This printed circuit board is formed by the 1st insulating base material 30 and the 2nd insulating base material 40, and these base materials are laminated|stacked to form this printed circuit board. As an example of the material of the printed circuit board, a double-sided copper-clad laminate obtained by laminating prepreg cloth and copper foil and heating and pressing is used as a starting material. Cloth is made by impregnating epoxy resin into glass cloth to make B-stage.

[0226] As the first insulating base material 30, a double-sided copper-clad laminate in which copper foil 34 with a thickness of 15 μm is attached to both surfaces of a resin insulating layer 32 with a thickness of 60 μm was used. . The copper foil 32 of this laminated board can use the copper foil thicker than 15 μ m, through etching process, the...

Embodiment 1-2

[0356] Except for embedding the semiconductor element 55 having an intermediate layer produced by the following steps (a) to (c) into the concave portion 42 of the substrate for accommodating the semiconductor element, the same process as in Example 1-1 was carried out to manufacture a multilayer printed circuit. plate.

[0357] (a) Continuously form a two-layer film of a chromium thin film and a copper thin film layer on the chromium thin film in a vacuum chamber by sputtering on the entire surface of the semiconductor element, and the semiconductor element is formed with a protective film on the connection pad and the wiring pattern. film, the thickness of the chromium thin film is 0.1 μm, and the thickness of the copper thin film layer is 0.5 μm.

[0358] (b) Next, a plating resist layer using a dry film is formed on the thin film layer. A mask on which a portion for forming an intermediate layer was drawn was mounted on the plating resist layer, and exposed and developed ...

Embodiment 1-3

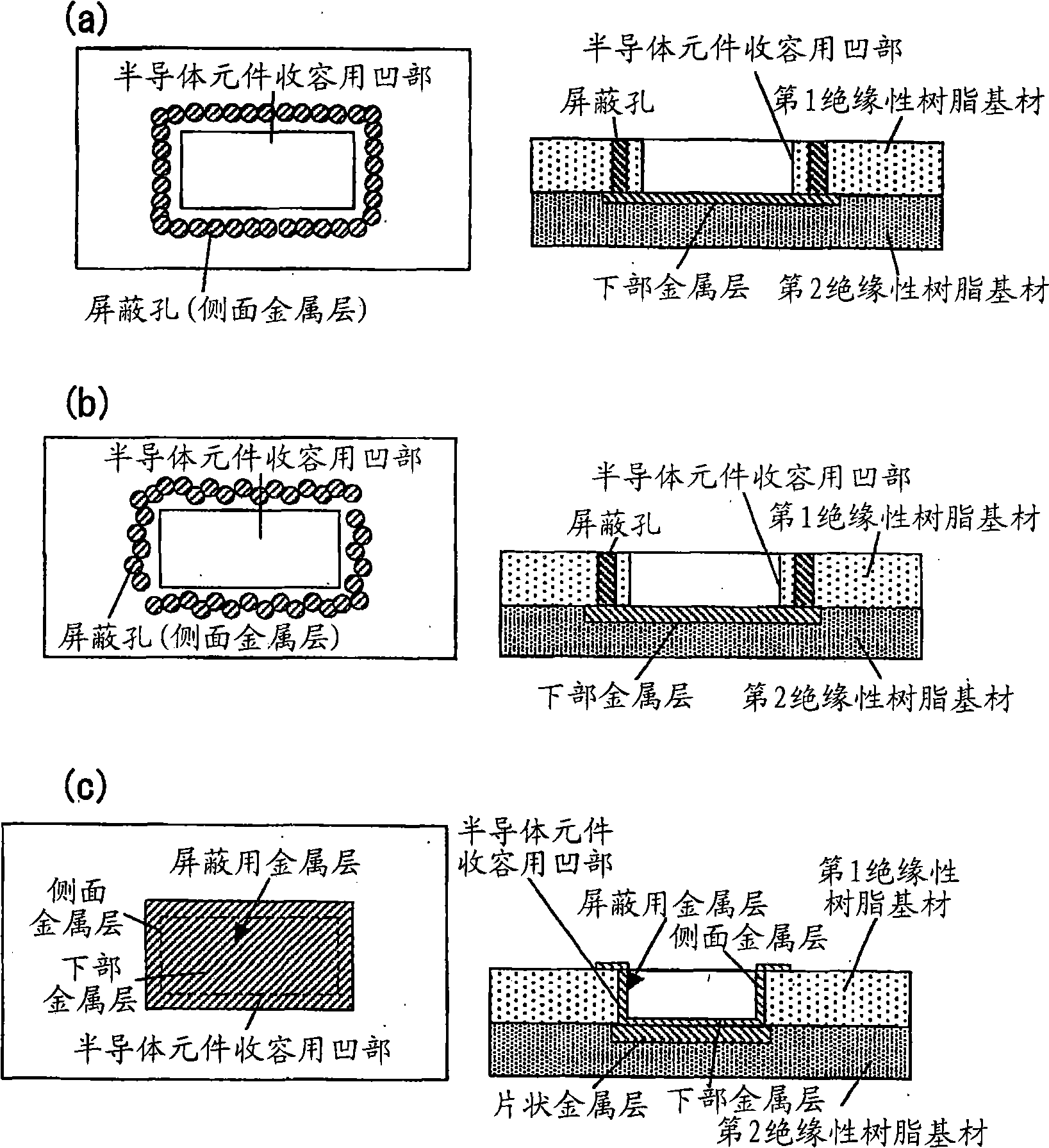

[0362] In addition to forming the shielding hole as figure 1 Except for the zigzag arrangement (staggered arrangement) as shown in (c), the same process as in Example 1-1 was performed to manufacture a multilayer printed wiring board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Interval | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com