Solar light condensed heat collector and method for designing solar light condensed heat collector

A technology of solar concentrating and design method, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc. Problems such as large temperature gradient on the pipe wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is described in detail below in conjunction with the accompanying drawings:

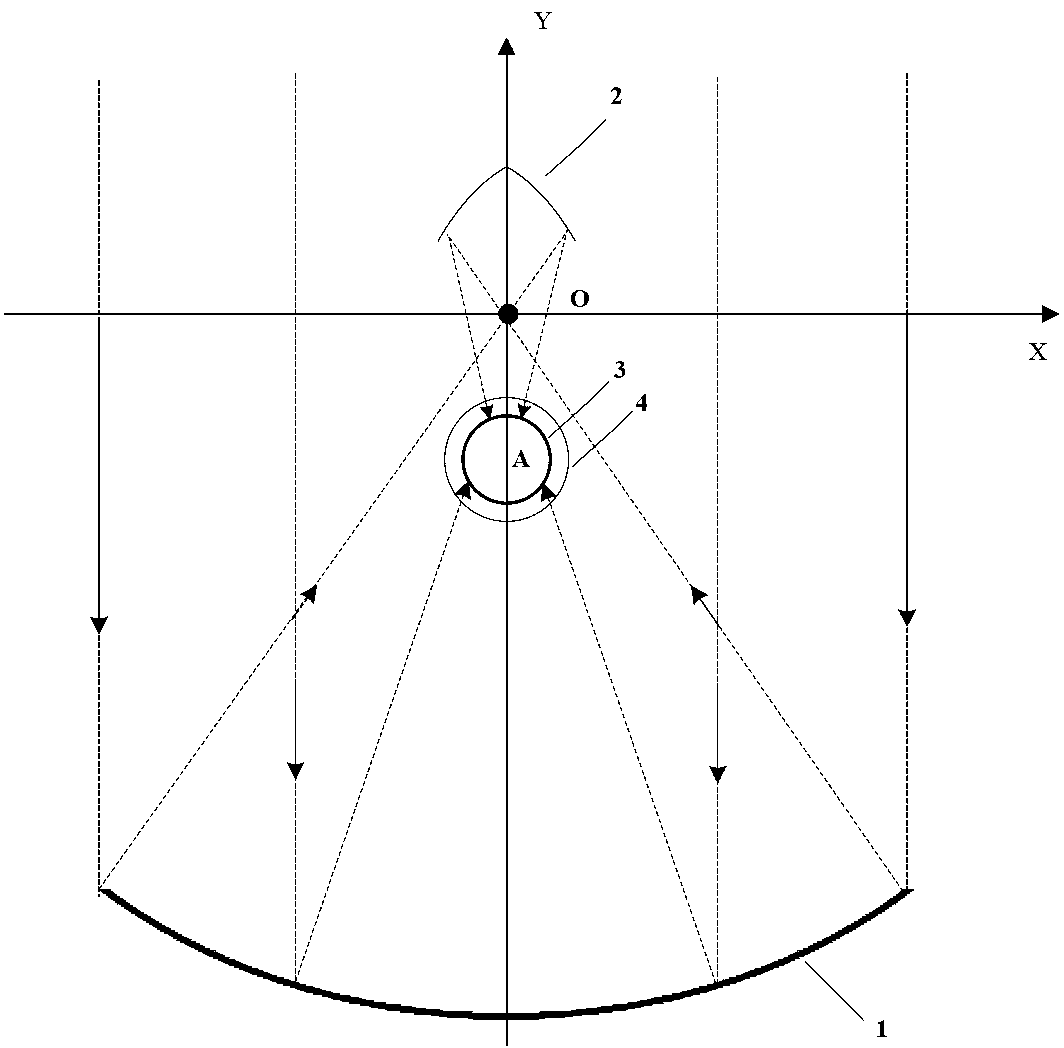

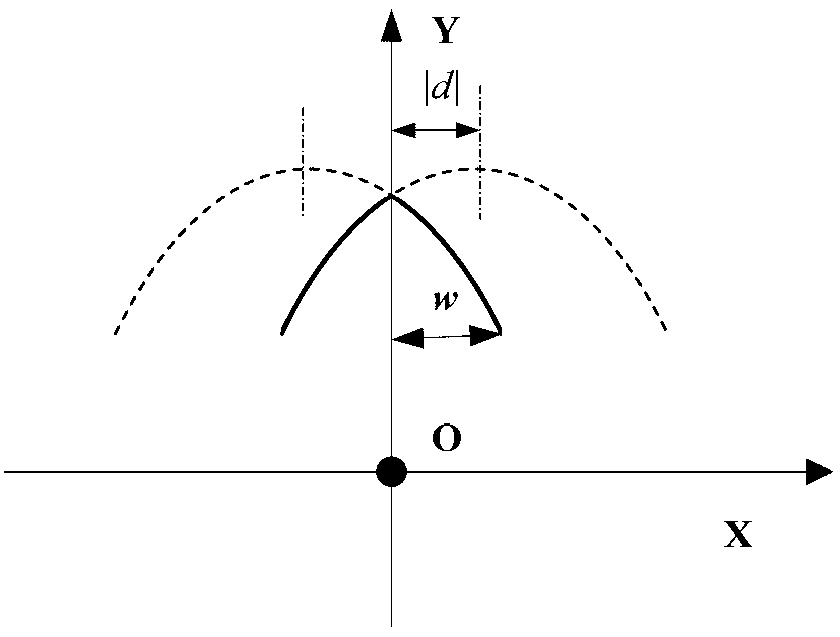

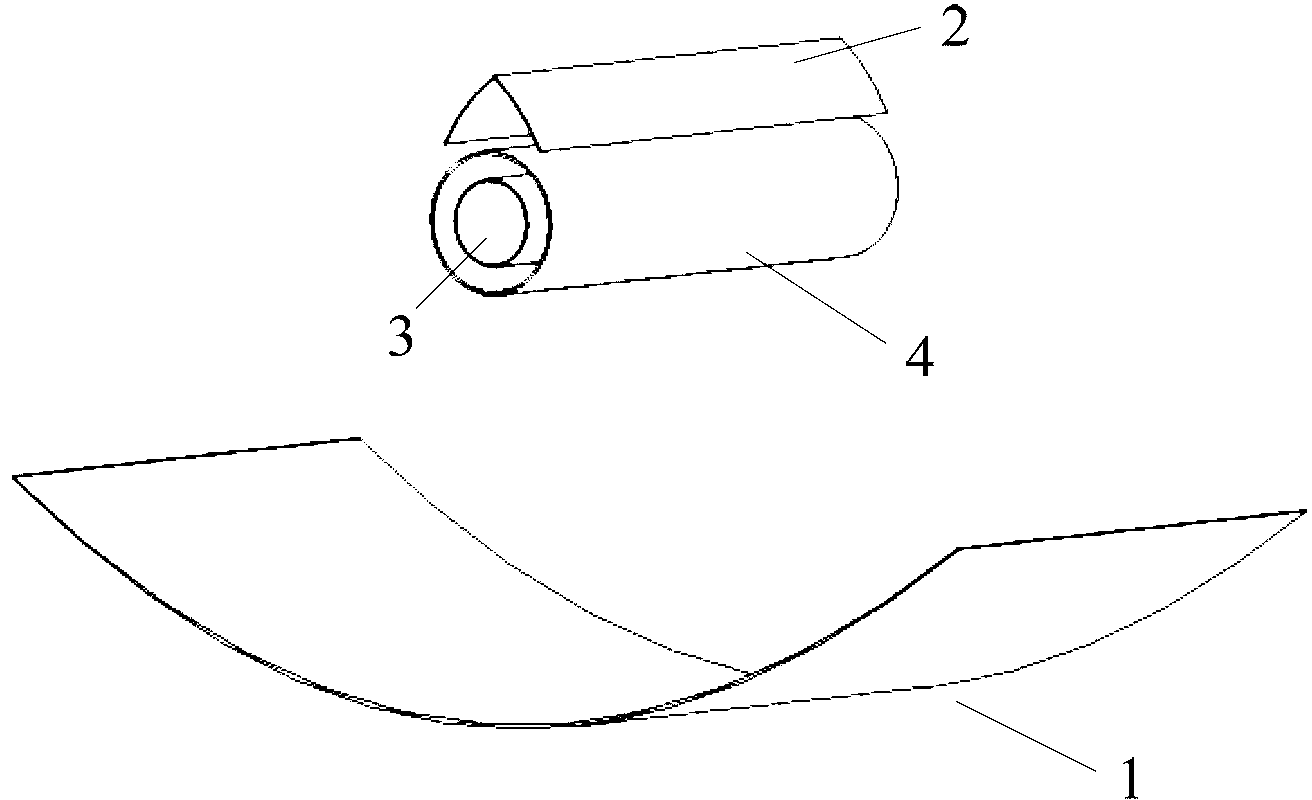

[0056] see Picture 1-1 , Figure 1-2 and Figure 1-3 , the solar concentrating heat collector of the present invention comprises a parabolic main reflector 1, a vacuum heat collecting tube and a homogenizing reflector 2, wherein the vacuum heat collecting tube is composed of a heat absorbing tube 3 and a glass sleeve 4 placed outside the heat absorbing tube 3 , the uniform light reflector 2 is composed of two symmetrical parabolic reflectors, and is fixed by the connecting bracket and the parabolic main reflector 1; the opening of the parabolic main reflector 1 and the homogeneous reflector 2 is arranged oppositely; as figure 2 As shown, the vacuum heat collection tube is arranged inside the focal line of the parabolic main reflector 1, so that a part of the light is directly reflected to the bottom of the heat-absorbing tube 3 after passing through the parabolic main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com