Variable line selection stable resonant cavity suitable for air flow chemical laser

A technology of lasers and resonators, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as the inability to guarantee the stability of lasers, and achieve the effects of reducing optical loss, stabilizing laser output, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

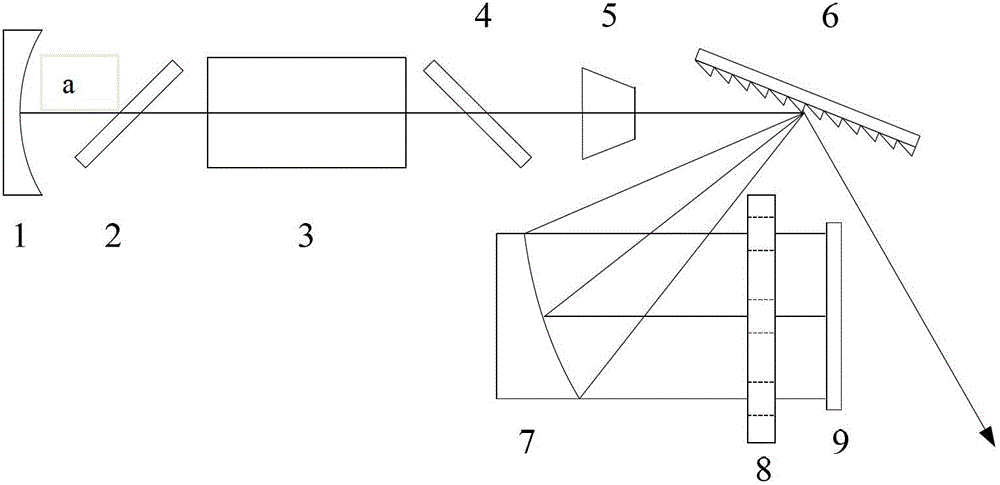

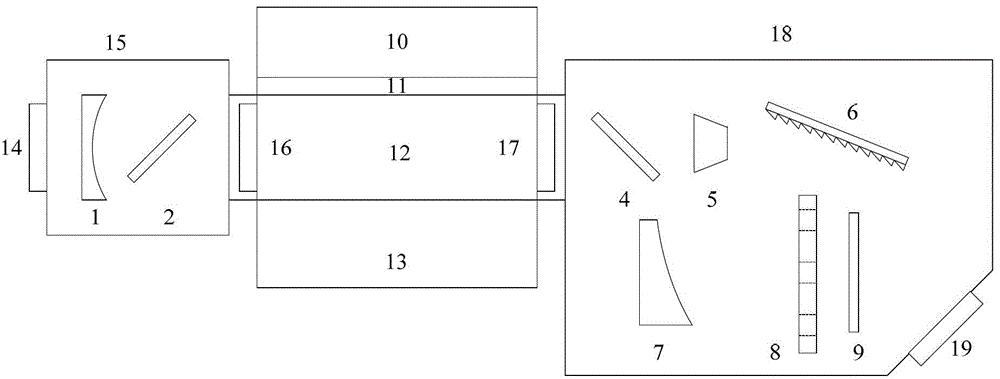

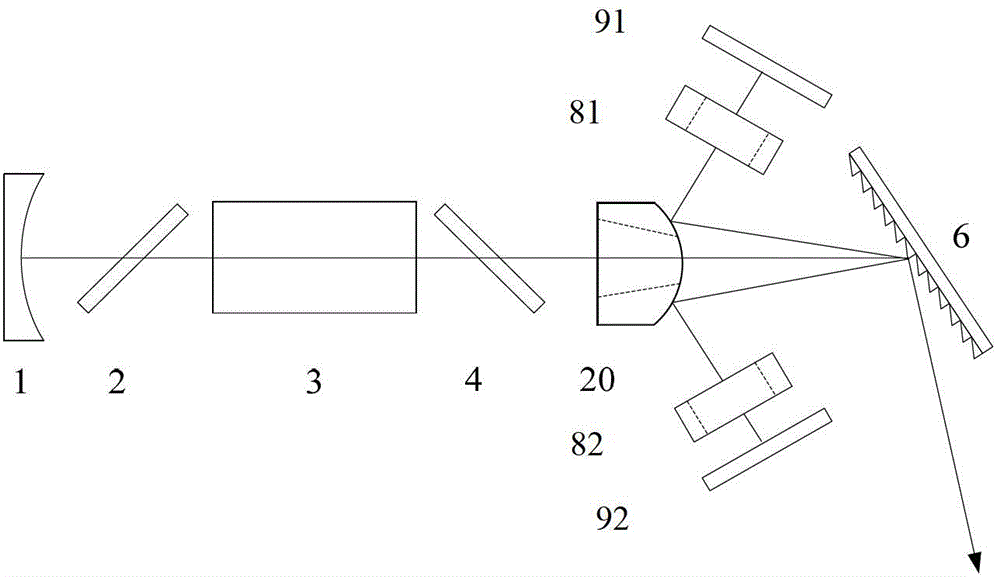

[0025] as attached figure 1 As shown, the optical structure of the optional line-stabilized resonator applicable to gas flow chemical lasers of the present invention includes: comprising a plano-concave reflector 1 and a plane reflector 9, and the plano-concave reflector 1 and planar reflector 9 form a resonator , a gain medium area 3 and an intracavity optical element are arranged in the resonant cavity; the intracavity optical element consists of Brewster plate I2, Brewster plate II4, diaphragm 5, and plane diffraction grating 6; off-axis Composed of a parabolic mirror 7 and a shutter system 8; the Brewster plate I2 is arranged between the plano-concave mirror 1 and the gain medium area 3; the other side adjacent to the gain medium area is sequentially set with a Brewster plate II4, aperture 5, plane diffraction grating 6; on the first-order diffraction optical path of the plane diffraction grating 6, an off-axis parabolic reflector 7, a shutter system 8 and a plane reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com