Device and method being capable of achieving light beam shaping dodging and speckle eliminating at the same time

A technology of beam shaping and dispersing speckle, which is applied in the direction of optics, optical components, instruments, etc., can solve the problems of unfavorable system miniaturization or miniaturization, high system cost and power consumption, and increased light energy loss, so as to achieve easy promotion and application, Simple structure and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

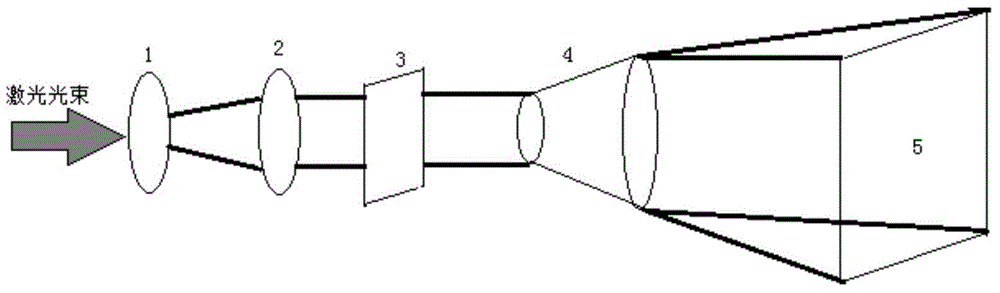

[0034] Such as Figure 1-3 shown.

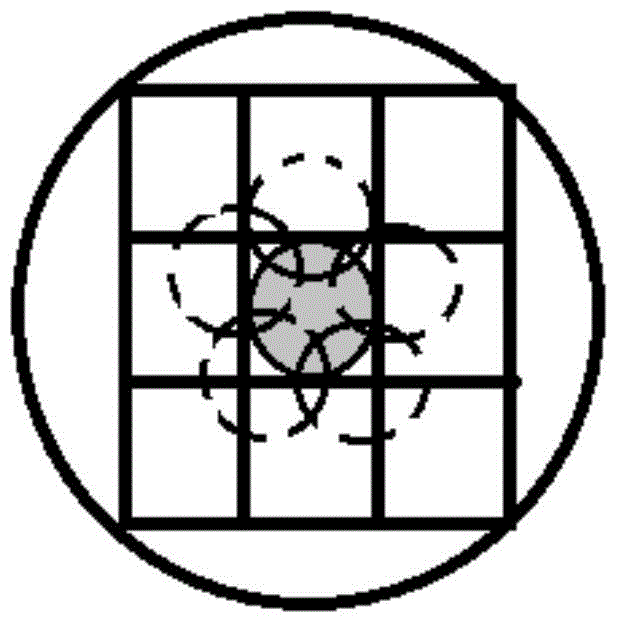

[0035] A device that can realize beam shaping and homogenization and speckle dissipation at the same time, including a drive motor and a phase plate 1; the phase plate 1 is a phase-type diffraction / scattering microstructure, and the phase plate 1 includes 60 rectangular sub-regions. The phase values corresponding to each sub-area mentioned above are randomly arranged; the phase plate 1 is driven by a drive motor to rotate or vibrate in its plane. Each sub-area is provided with a random microstructure, so that the phase values of each sub-area are randomly distributed and statistically irrelevant to each other, and the microstructure on each sub-area can realize shaping and uniform light.

Embodiment 2

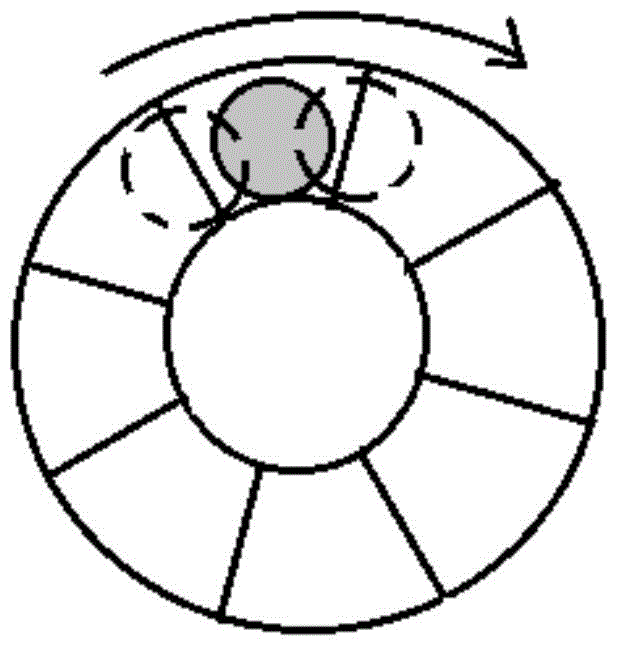

[0037] The device that can realize beam shaping and homogenization and speckle elimination at the same time as described in Embodiment 1 is different in that the phase sheet 1 includes 90 fan-shaped sub-regions.

Embodiment 3

[0039] A method capable of simultaneously realizing beam shaping and homogenization and dispersing speckles, comprising the following steps:

[0040] 1) Using the existing optical micromachining technology to process the transparent flat substrate into a phase-type diffraction / scattering microstructure to form a phase sheet 1; the processed transparent flat substrate is an optical diffraction device, which can play a role in shaping the laser beam.

[0041] 2) Laser beam expansion and collimation;

[0042] 3) start the driving device, drive the phase plate 1 to vibrate or rotate along the plane, so that the beam expanded and collimated laser beam is vertically incident on the surface of the phase plate 1, wherein the frequency of the plane vibration and The frequency of plane rotation is greater than 1000 Hz; during the plane vibration or plane rotation of the phase-type diffractive / scattering microstructure, the laser beam passes through different sub-regions in turn, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com