Electro-optic diode devices

A technology of diodes and devices, applied in the field of high-efficiency electro-optic diode devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

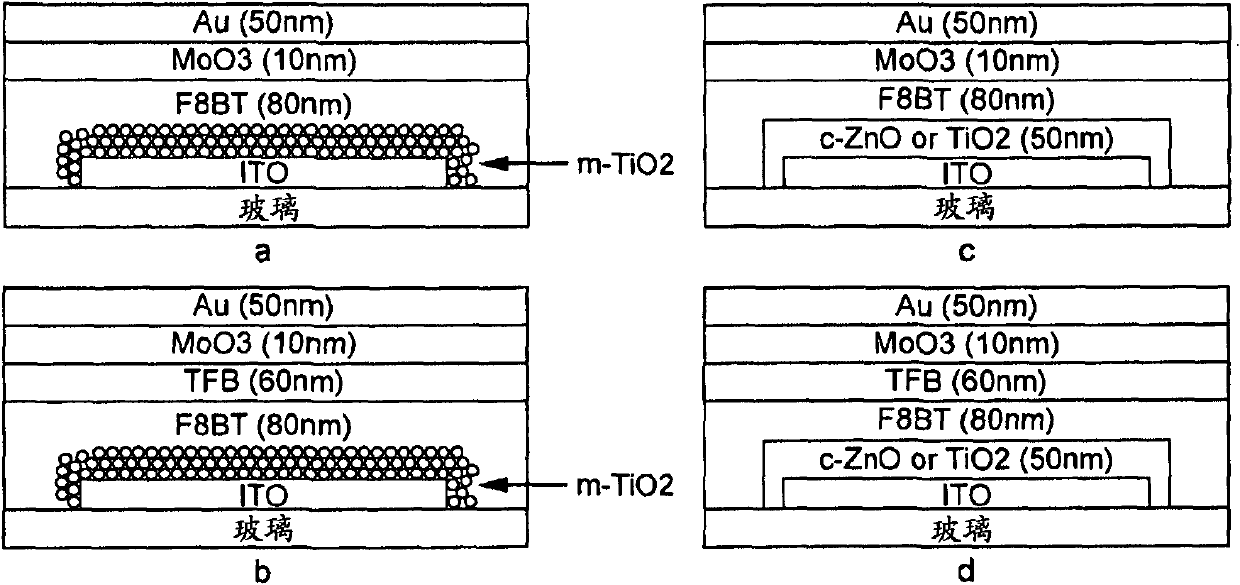

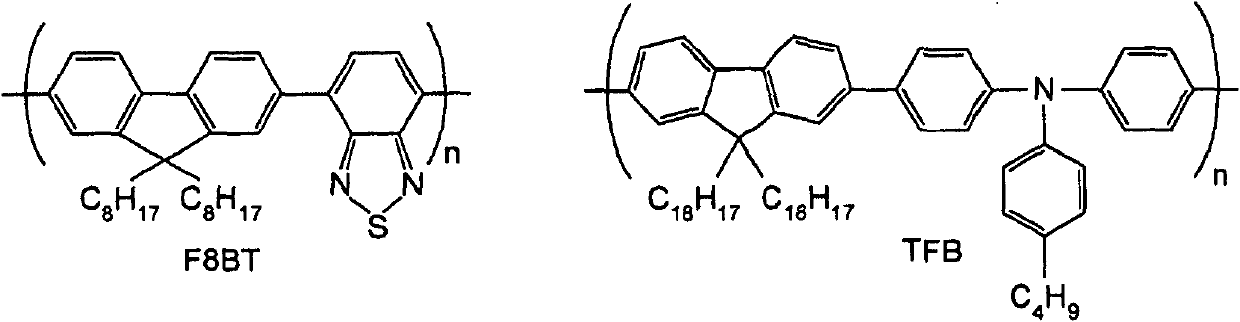

[0033] Light emitting devices to be described below use various metal oxides in mesoporous and compact forms for electron injection. It has been found that this results in high brightness COPLEDs. In one device form that has been found to be particularly effective, ZnO is used as the electron transport and injection material and MoO 3 Used as a hole injection material. In addition, the structure leaves room for the choice of component thickness and materials to enhance photonic effects.

[0034] Device structure

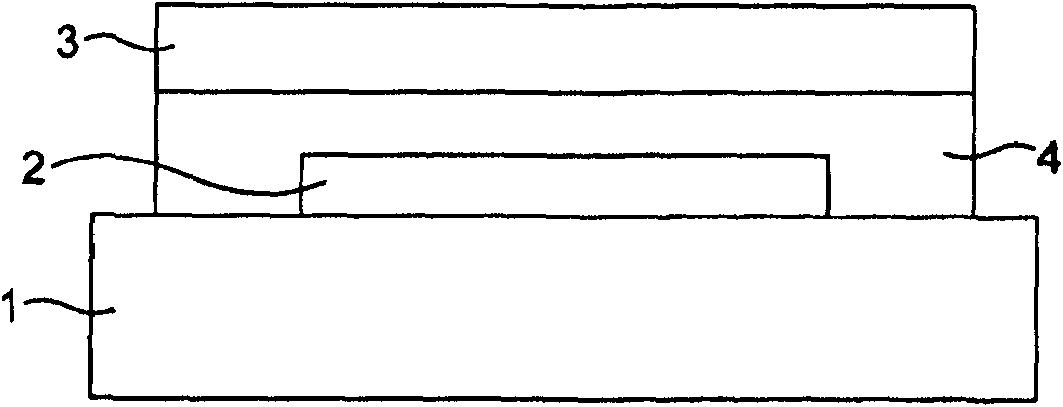

[0035] A schematic basic form of the device described herein is shown in figure 1 middle. The device comprises a substrate 1 (eg glass) on which is deposited a cathode structure 2 for electron transport and injection, and an anode structure 3 for hole transport and injection. The light emitting structure 4 is sandwiched between the cathode and the anode. In the devices that have been studied, the cathode, anode and light-emitting structures take the form of lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com