Preparation method of trivalent ytterbium ion doped lutetium aluminum garnet transparent ceramic optical fiber

A technology of lutetium aluminum garnet and transparent ceramics, which is applied in the direction of inorganic raw materials such as artificial filaments, can solve the problems of low solid content of green body and residual pores of ceramics, and achieve the effects of low energy consumption, low cost and low optical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

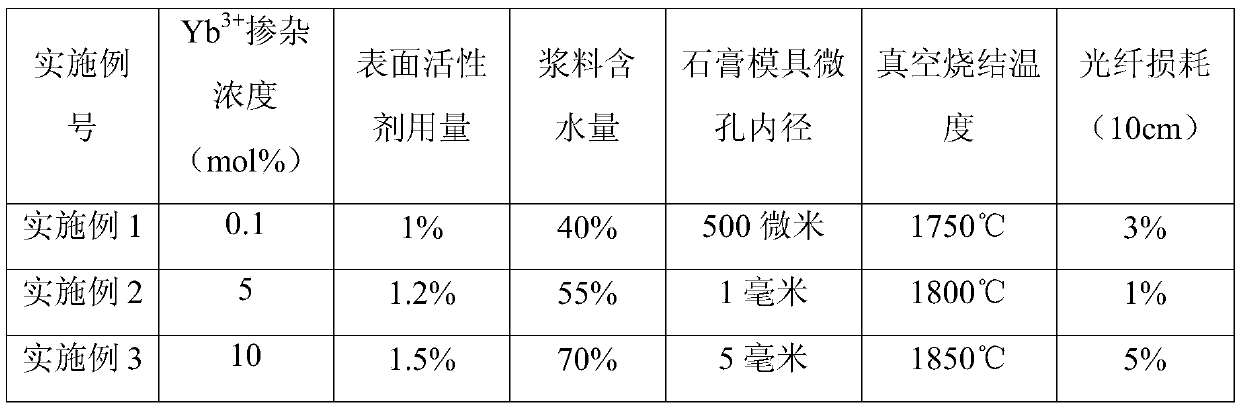

Examples

Embodiment 1

[0025] (1) Weigh 10g of 0.1mol% Yb-doped yttrium aluminum garnet nanopowder, 0.1g of ammonium polyacrylate and 4g of triple distilled water respectively; measure 31.7 μL of tetraethyl orthosilicate; then Ball milling in the ball mill tank for 3 hours, the ball milling speed is 200rpm, and the ball milling medium is high-purity alumina balls;

[0026] (2) according to the step in the claims 1 2. making inner diameter is the gypsum microporous mold that 500 microns, long are 10 centimeters

[0027] (3) Slowly inject the water-based slurry obtained in step (1) into the above-mentioned plaster mold, demould after standing for 24 hours, and place the molded green body in an oven at 50° C. for 12 hours;

[0028] (4) Put the above-mentioned slip-casting and dried green body into a muffle furnace, and calcined at 800° C. for 3 hours;

[0029] (5) Place the calcined blank in a vacuum tungsten wire furnace, raise the temperature to 1000°C at 5°C / min, then raise the temperature to 1750°...

Embodiment 2

[0032] (1) Weigh 10 g of 5mol% (mole percent) Yb-doped yttrium aluminum garnet nanopowder, 0.15 g of ammonium polyacrylate and 4 g of triple distilled water; measure 31.7 μL of tetraethyl orthosilicate; Then ball milled for 3 hours in a polyurethane ball mill tank, the ball milling speed was 200rpm, and the ball milling medium was high-purity alumina balls;

[0033] (2) according to the step in the claims 1 2. making inner diameter is the gypsum microporous mold that 500 microns, long are 10 centimeters

[0034] (3) Slowly inject the water-based slurry obtained in step (1) into the above-mentioned plaster mold, demould after standing for 24 hours, and place the molded green body in an oven at 50° C. for 12 hours;

[0035] (4) Put the above-mentioned slip-casting and dried green body into a muffle furnace, and calcined at 800° C. for 3 hours;

[0036] (5) Place the calcined green body in a vacuum tungsten wire furnace, raise the temperature to 1000°C at 5°C / min, then raise the...

Embodiment 3

[0039] (1) Weigh 10g of 10mol% (mole percent) Yb-doped yttrium aluminum garnet nanopowder, 0.1g of ammonium polyacrylate and 7g of triple distilled water; measure 31.7 μL of tetraethyl orthosilicate; Then ball milled for 3 hours in a polyurethane ball mill tank, the ball milling speed was 200rpm, and the ball milling medium was high-purity alumina balls;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com