Preparation method of yttrium aluminum garnet (YAG)-based transparent ceramics in system taking Ca as auxiliary agent

A technology of transparent ceramics and sintering aids, applied in the field of preparation of Ca additive system YAG-based transparent ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

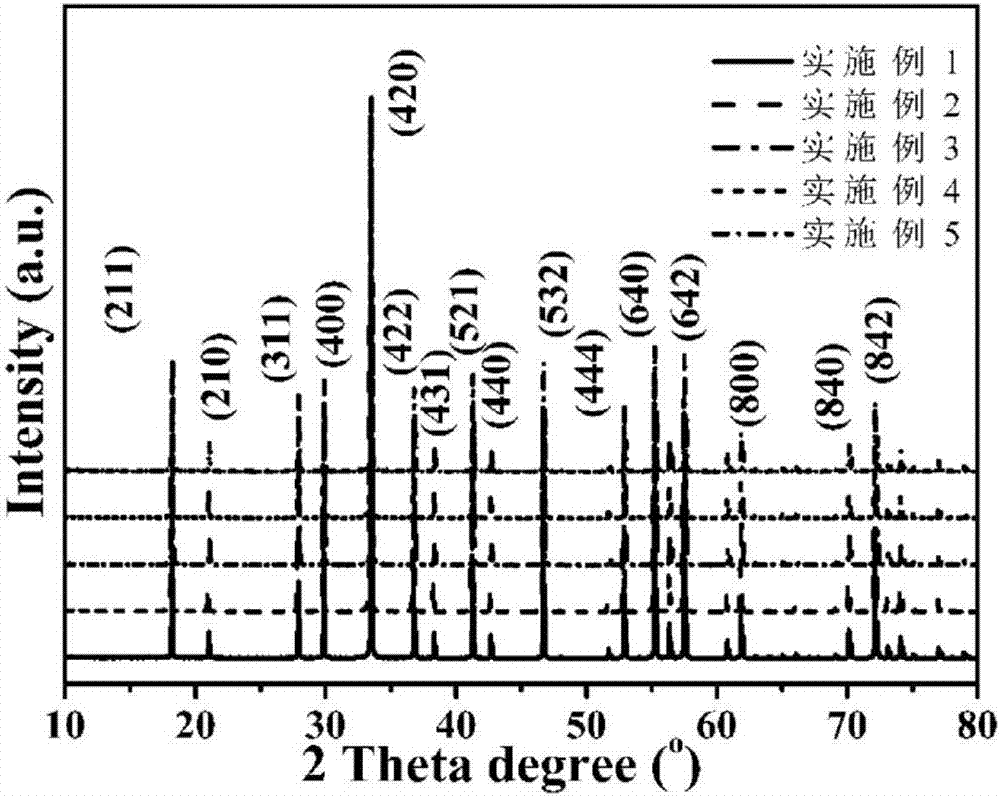

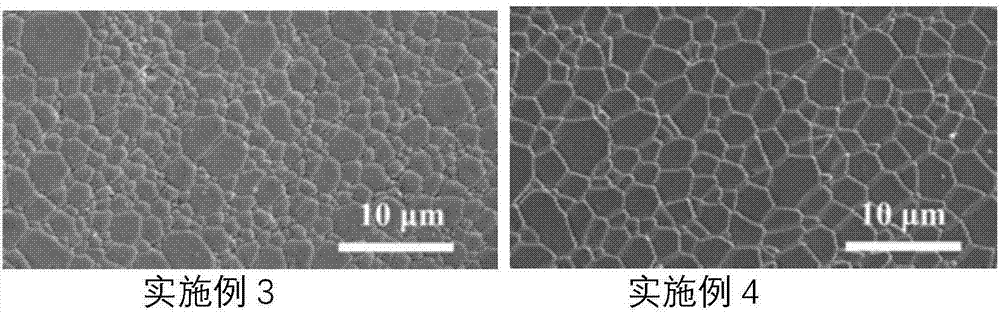

[0026] The present invention provides a non-annealing mechanism based on vacuum sintering of a small amount of Ca single sintering aid system to prepare yttrium aluminum garnet (Y 3 al 5 o 12 , YAG)-based transparent ceramics, using a small amount of Ca as a single sintering aid, using a single-step vacuum sintering method, without post-annealing, to prepare YAG transparent ceramics with good optical quality and fine grain size . Prepared transparent ceramic component should satisfy following (1) formula or (2) formula:

[0027] (Re x Y 1-x ) 3 al 5 o 12 (1)

[0028] Y 3 (Cr y al 1-y ) 5 o 12 (2)

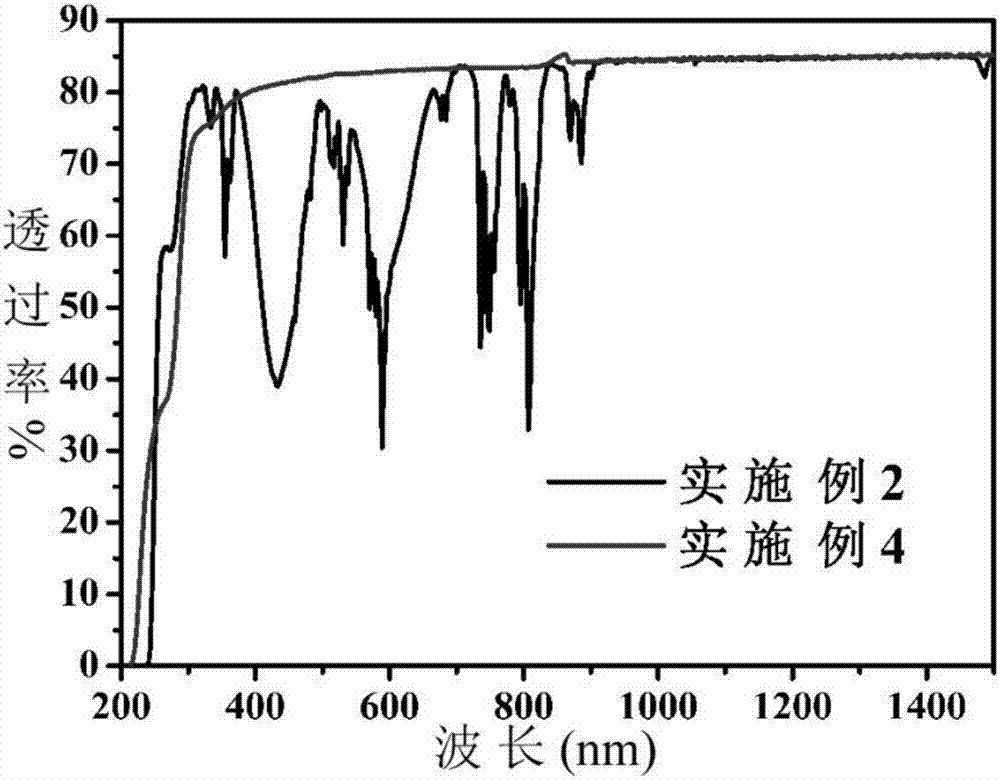

[0029] In the formula, the value range of x is 0≤x≤0.5, the range of y is 0≤y≤0.05, Re is one of Ce, Nd, Yb, Er, Ho, Dy, Pr, Tm, Sm, Eu or Tb . The amount of Ca added is 0.005-0.8wt.% of the total mass of Y, Al, Cr or Y, Al, Re raw material powder. The line transmittance at 1064nm of the finally prepared YAG transparent ceramic is higher than 84.0%-84.5% (thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com