Novel capillary gas chromatographic column based on MOFs and preparation method thereof

A gas chromatographic column and capillary technology, applied in the field of chromatographic applications, can solve the problems of limited separation efficiency, time-consuming and laborious, etc., achieve novel topology, overcome cumbersome preparation, and adjust the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

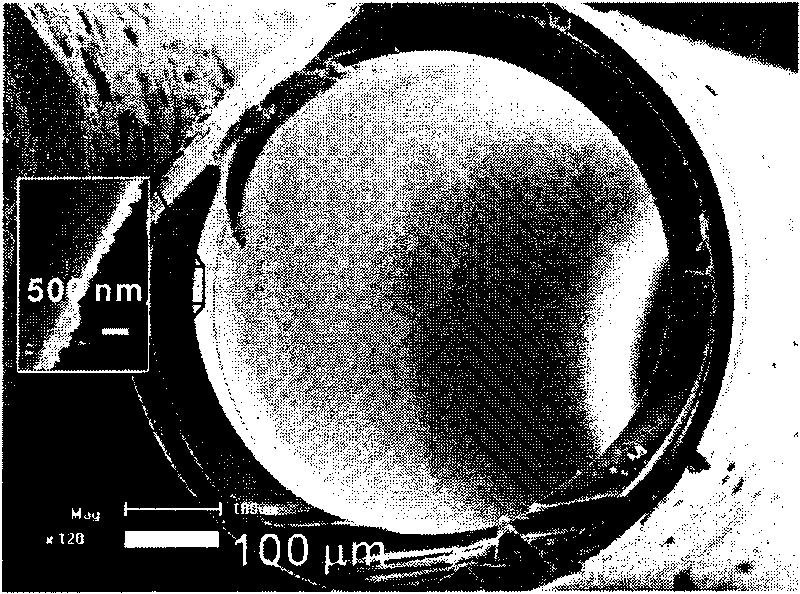

[0035] In the present invention, in order to prepare the novel capillary gas chromatography column based on MOFs, the present invention also provides a preparation method of the novel capillary gas chromatography column based on MOFs. The method uses MOFs material as the stationary phase of gas chromatography, and adopts the method of dynamic coating to prepare capillary gas chromatography, which specifically includes the following steps:

[0036] The first step, synthesizing solid particles of MOFs materials, and preparing a suspension of the synthesized MOFs materials;

[0037] In the present invention, the self-assembly reaction of metal and organic ligands is firstly used to generate MOFs materials with super large specific surface area. Then, the solvent and residual reactants in the pores of the MOFs material are washed away by an organic solvent, and the MOFs material is activated at a predetermined temperature. Finally, the powder of the MOFs material is taken to form...

Embodiment 1

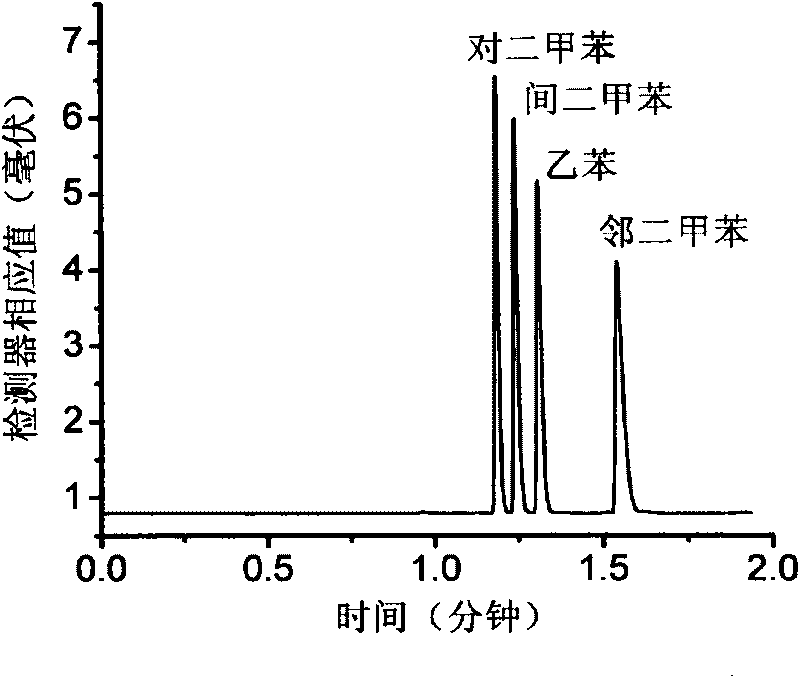

[0054] In the reactor, add 20 mL of water, 2 mmol of chromium nitrate, and 1 to 3 mmol of terephthalic acid, and seal it. Heat the reactor at 220 ° C for 12 hours. After filtering, green particles are obtained, and sequentially use toluene, N, N-di Soak in methylformamide and dichloromethane for 1 hour, then filter again, and dry the obtained solid in vacuum at 150°C for 24 hours. Take 20 mg of the solid powder and disperse it in 10 mL of acetone to obtain a uniform suspension; pour the above uniform suspension into In the pretreated capillary, ensure that the length of the liquid column is 3-5m. Under the pressure of 10-50kPa, make the liquid column in the capillary at a rate of 10cm min -1 Moving at a constant speed until all the liquid flows out of the capillary. In order to ensure that the liquid column at the end of the capillary can still move at this speed, it is necessary to connect a 5m-long empty capillary; after coating, continue to pass nitrogen for 2 hours to dry ...

Embodiment 2

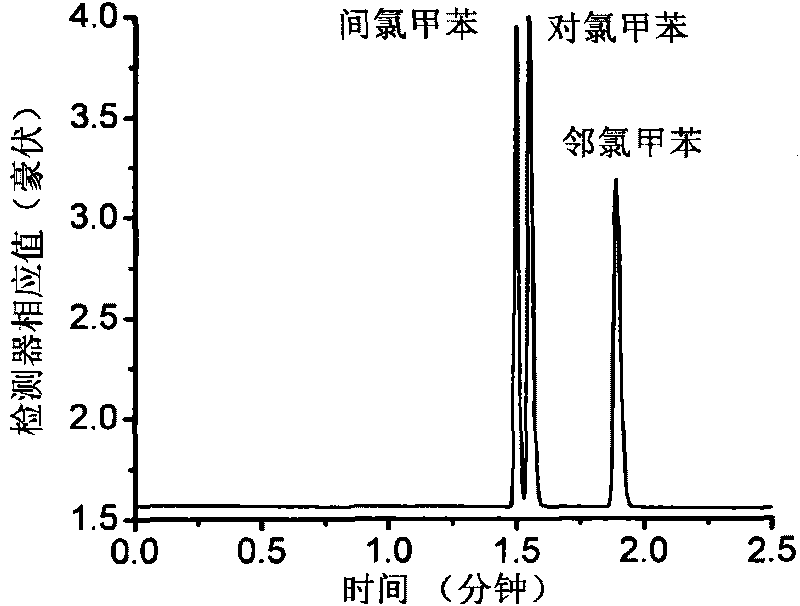

[0057] In the reaction kettle, add 20mL N,N-dimethylformamide, 2mmol zinc nitrate, 1mmol terephthalic acid, and seal it. The autoclave was heated at 120°C for 24 hours. After filtration, colorless particles were obtained, which were soaked in N,N-dimethylformamide and dichloromethane for 1 hour in sequence, and then filtered again, and the obtained solid was vacuum-dried at 150° C. for 24 hours. Take 20 mg of the solid powder and disperse it in 10 mL of acetone to obtain a uniform suspension; pour the above uniform suspension into a pretreated capillary to ensure that the length of the liquid column is 3 to 5 m. Under the pressure condition of 10 ~ 50kPa, make the liquid column in the capillary at 10cm min -1 Moving at a constant speed until all the liquid flows out of the capillary. In order to ensure that the liquid column at the end of the capillary can still move at this speed, it is necessary to connect a 5m-long empty capillary; after coating, continue to pass nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com