Vinyl POSS (polyhedral oligomeric silsesquioxane) modified organic silicon resin, and preparation method and application thereof

A vinyl silicone oil and vinyl technology, which is applied in coatings, electrical components, circuits, etc., can solve the problems that the performance cannot meet the use requirements well, achieve excellent thermodynamics, overcome the decline in material strength, and have a simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

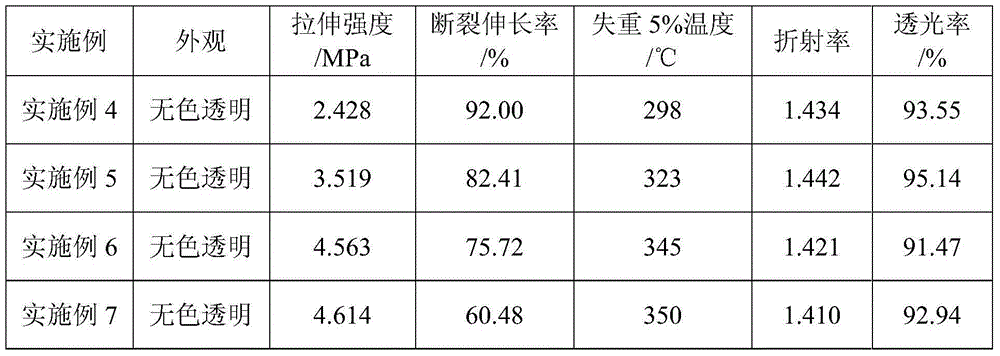

Examples

Embodiment 1

[0031] Embodiment 1: Preparation of vinyl POSS modified silicone resin encapsulation glue

[0032] (1) In a three-necked reaction flask equipped with a reflux condenser, a mechanical stirrer, and a constant pressure dropping funnel, add 0.5 parts by weight of octavinyl POSS (Aladdin reagent), 100 parts by weight of hydrogen-containing silicone oil (hydrogen content 0.5 %) (Guangzhou Xinhou CY202), 100 parts by weight of toluene, stir evenly, under the protection of nitrogen, add 0.0002 parts by weight of Karl's catalyst (1,3-divinyl-1,1,3,3-tetramethyl disiloxane platinum (0)), then heated to reflux for 1h, and rotary steamed to obtain POSS grafted modified polysiloxane polymer.

[0033] (2) Preparation of encapsulant: Mix 100 parts by weight of POSS grafted modified polysiloxane polymer and 20 parts by weight of vinyl silicone oil (Dongguan Hongyi HY205J), and add 0.0002 parts by weight of Karl's catalyst (1, 3-divinyl-1,1,3,3-tetramethyldisiloxane (platinum (0)), stir evenl...

Embodiment 2

[0034] Embodiment 2: Preparation of vinyl POSS modified silicone resin encapsulation glue

[0035] (1) In a three-necked reaction flask equipped with a reflux condenser, a mechanical stirrer, and a constant pressure dropping funnel, add 5 parts by weight of vinyl POSS, 100 parts by weight of hydrogen-containing silicone oil (0.5% hydrogen content), 300 parts by weight of Toluene, stirred evenly, under the protection of nitrogen, 0.0008 parts by weight of Karl Fischer catalyst was added, then heated to reflux for 5 hours, and then rotary steamed to obtain POSS grafted modified polysiloxane polymer.

[0036] (2) Preparation of encapsulant: Mix 100 parts by weight of POSS grafted modified polysiloxane polymer and 40 parts by weight of vinyl silicone oil evenly, add 0.0008 parts by weight of Karl Fischer catalyst, stir well and pour into preheated In the mold, remove the air bubbles and place it for 18 hours, then solidify according to the curing process of 80°C for 1.5h and 150°C...

Embodiment 3

[0037] Embodiment 3: Preparation of vinyl POSS modified silicone resin encapsulation glue

[0038] (1) In a three-necked reaction flask equipped with a reflux condenser, a mechanical stirrer, and a constant pressure dropping funnel, add 10 parts by weight of vinyl POSS, 100 parts by weight of hydrogen-containing silicone oil (0.5% hydrogen content), 500 parts by weight of Toluene, stirred evenly, under the protection of nitrogen, 0.0005 parts by weight of Karl Fischer catalyst was added, then heated to reflux for 10 hours, and rotary steamed to obtain POSS grafted modified polysiloxane polymer.

[0039] (2) Preparation of encapsulant: Mix 100 parts by weight of POSS grafted modified polysiloxane polymer and 80 parts by weight of vinyl silicone oil evenly, add 0.005 parts by weight of Karl Fischer catalyst, stir well and pour into preheated In the mold, remove air bubbles, place it for 24 hours, and then perform curing according to the curing process of 80°C for 2h and 150°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com